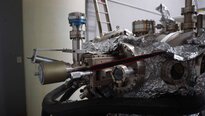

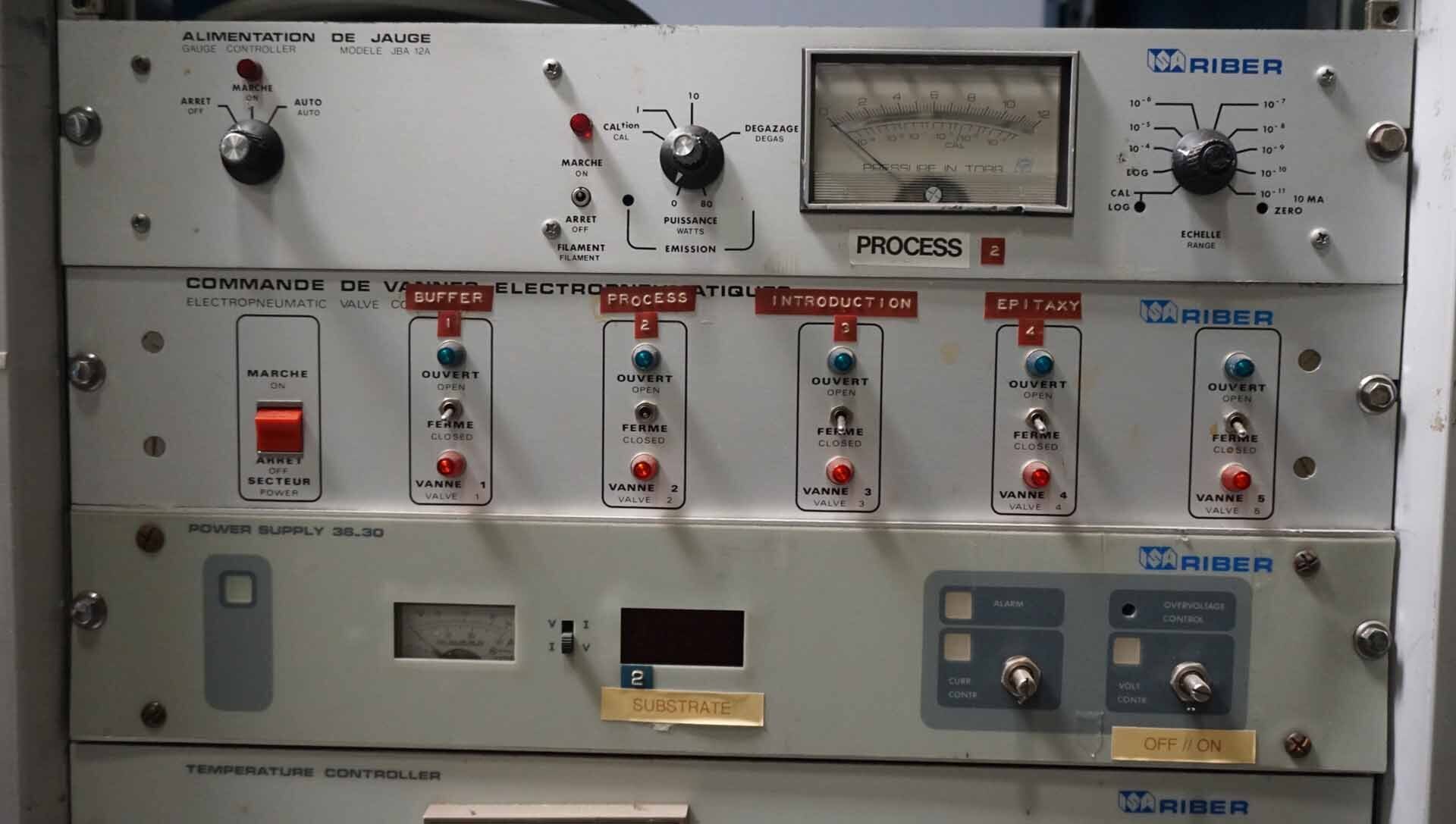

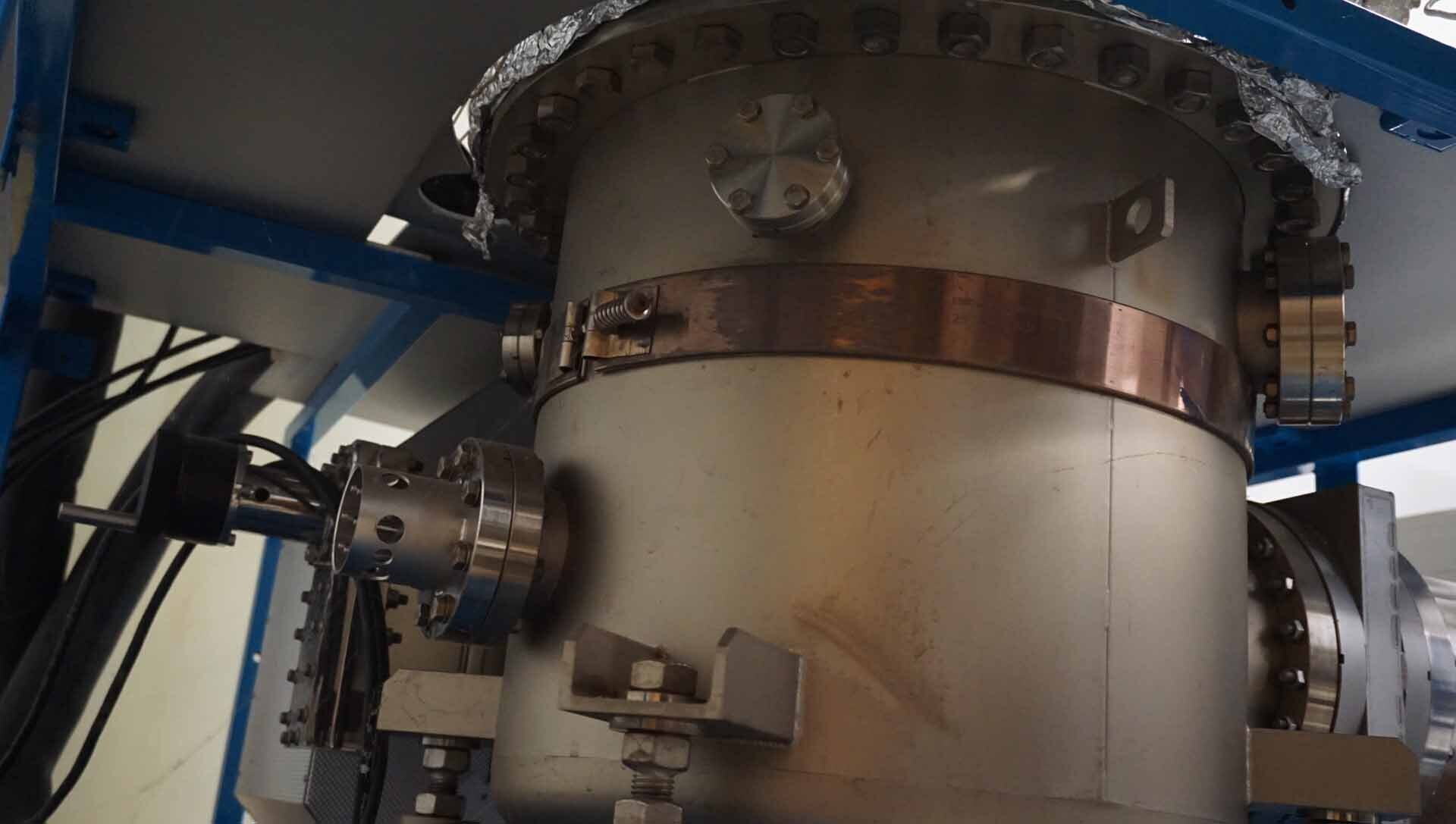

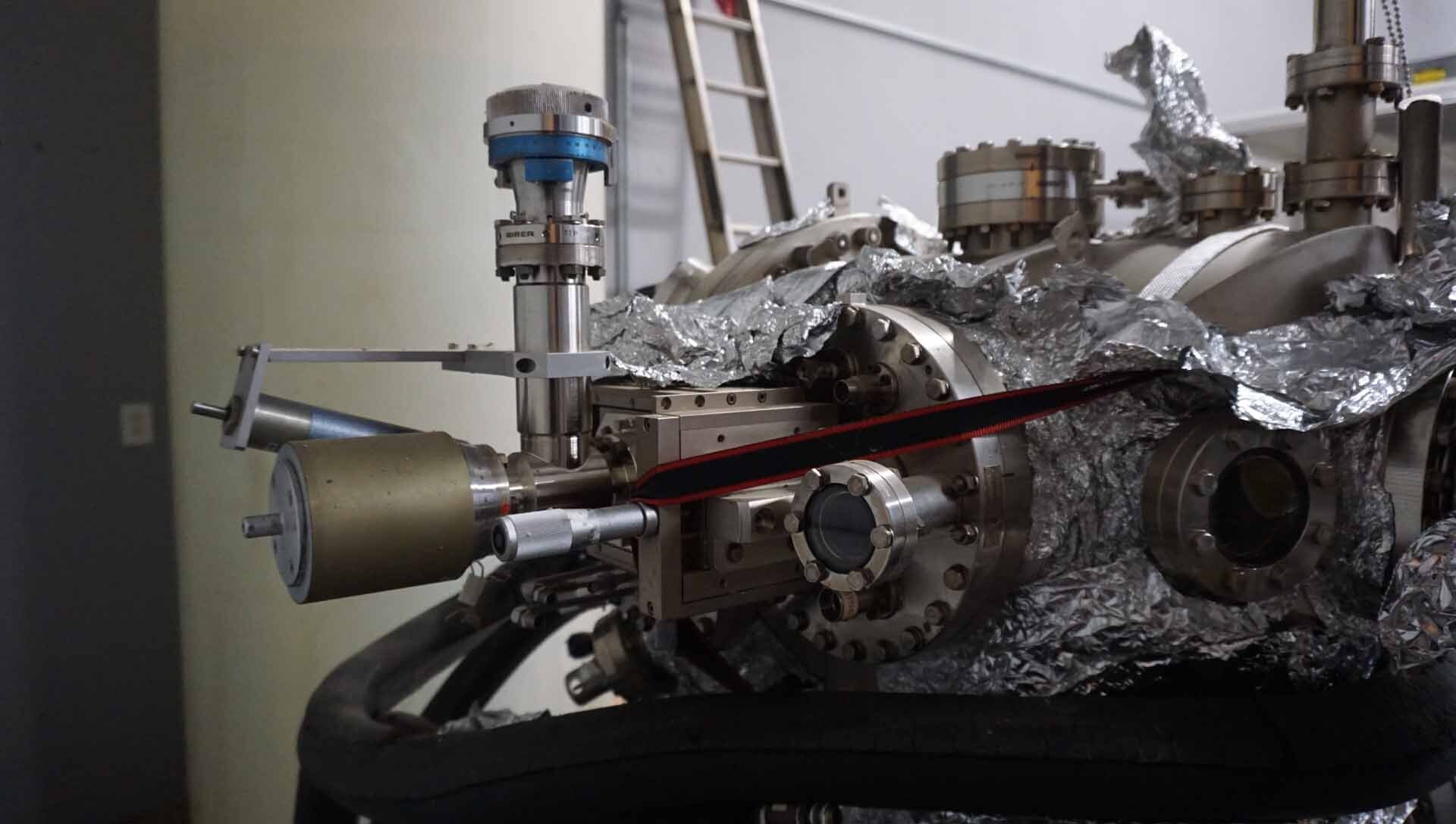

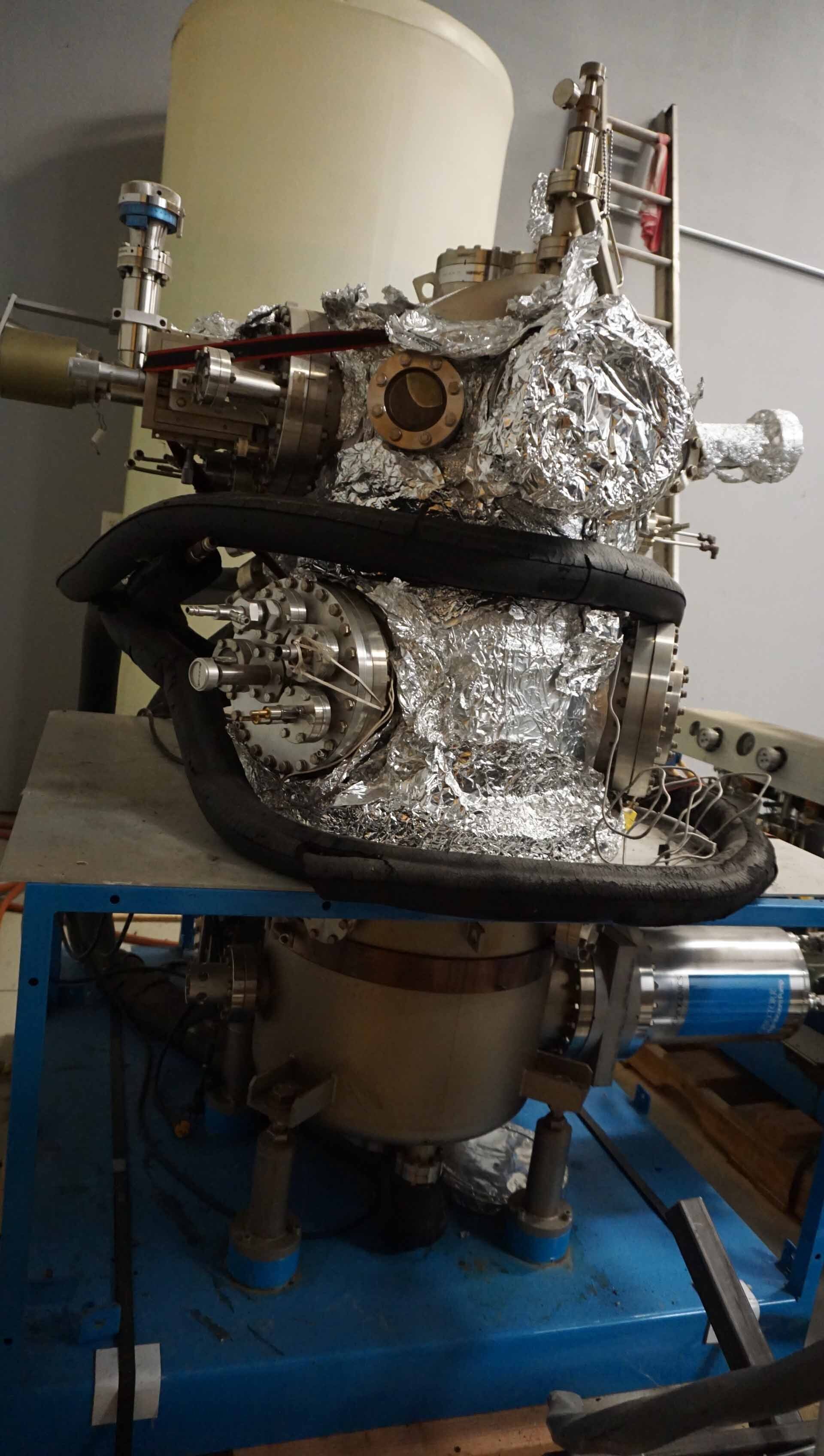

Used RIBER 32P #293628041 for sale

URL successfully copied!

Tap to zoom

ID: 293628041

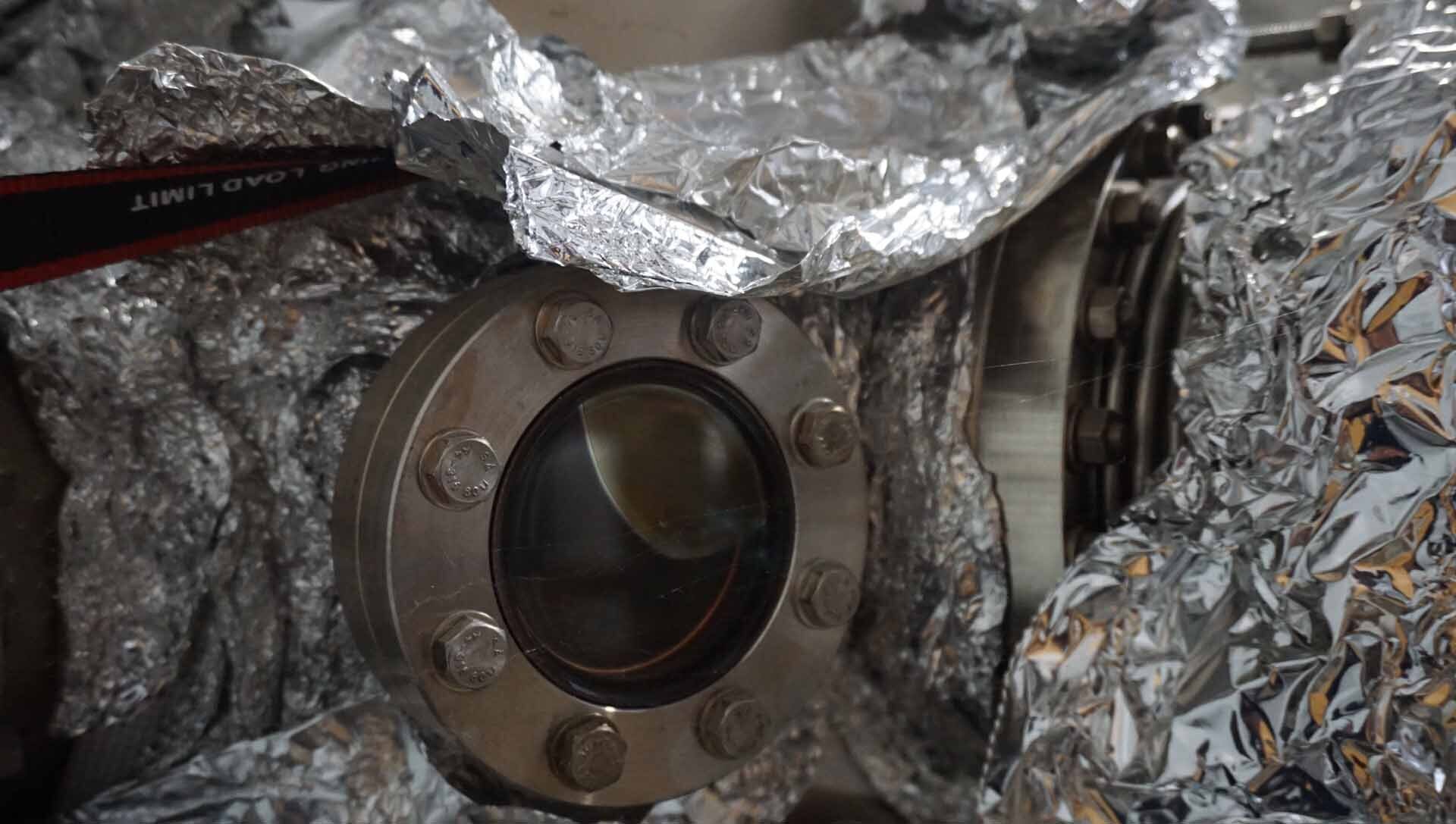

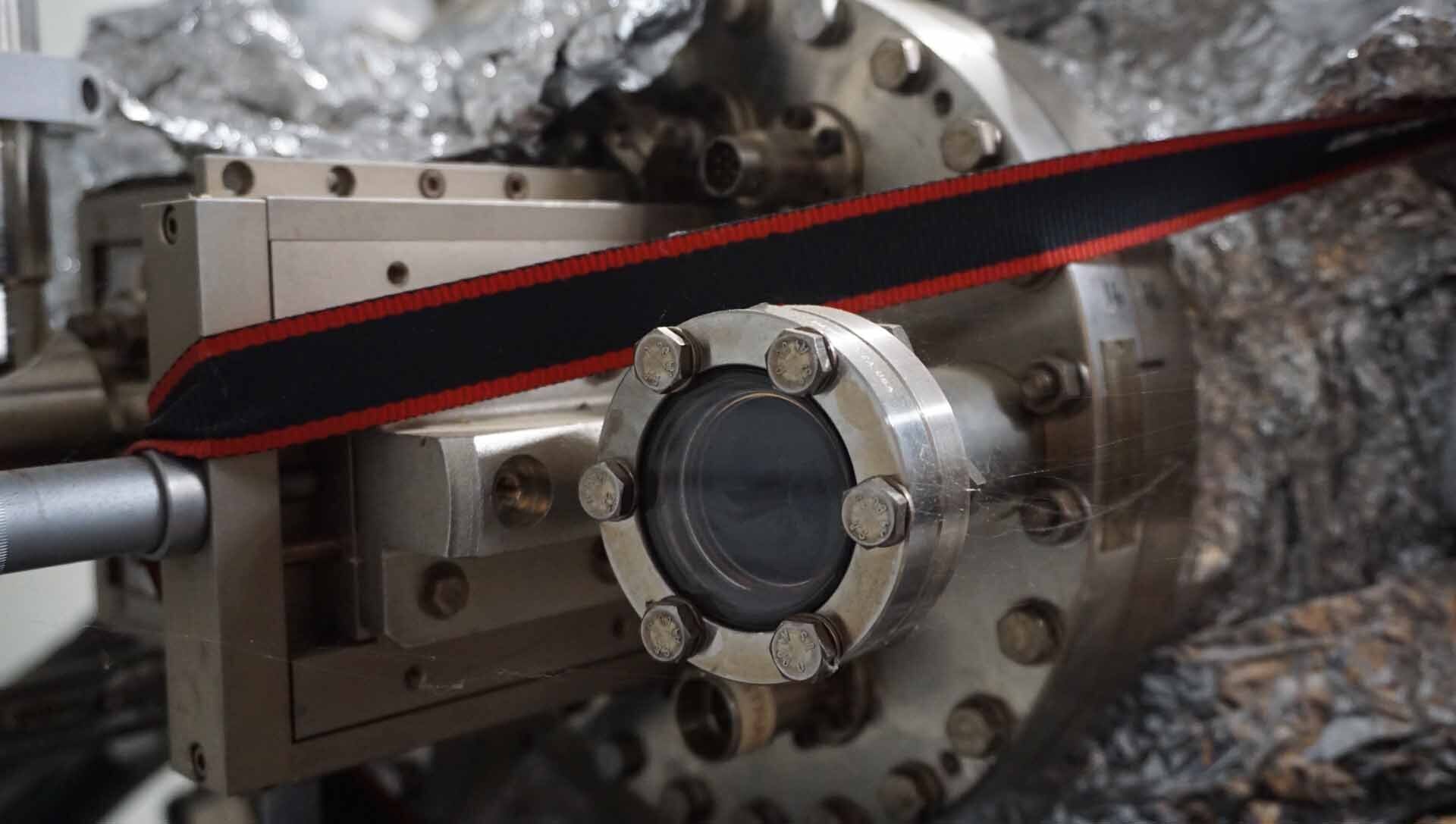

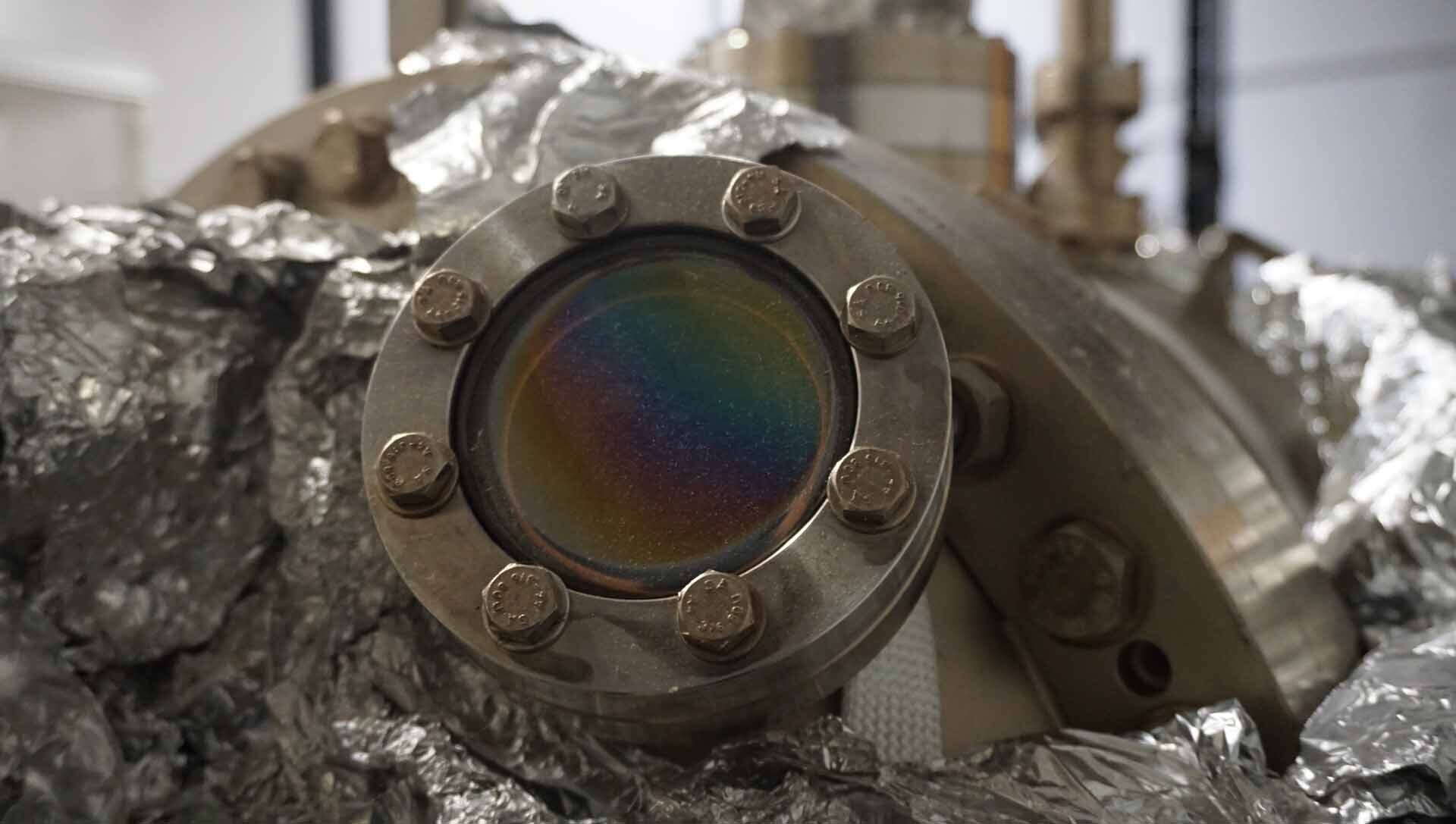

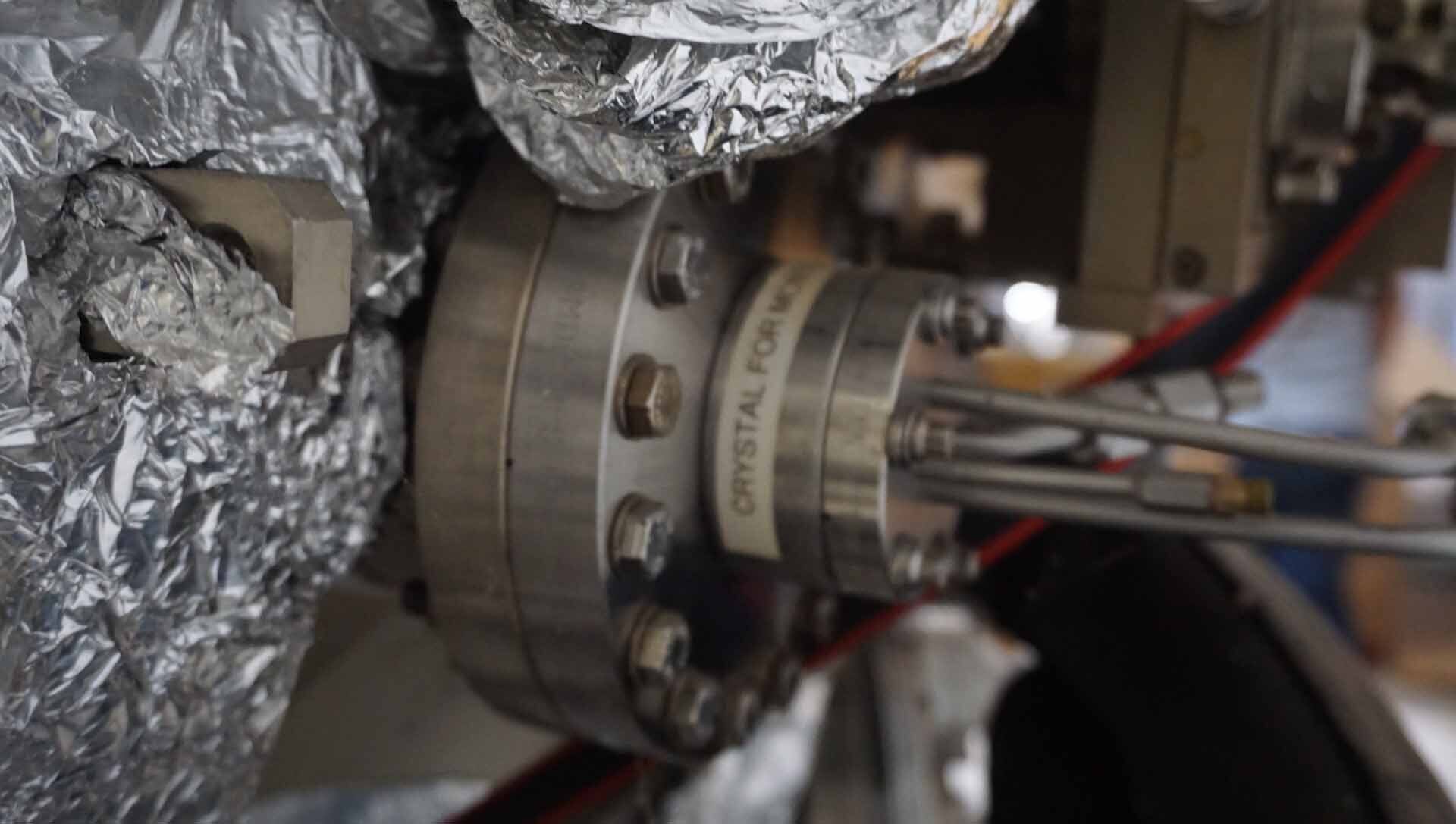

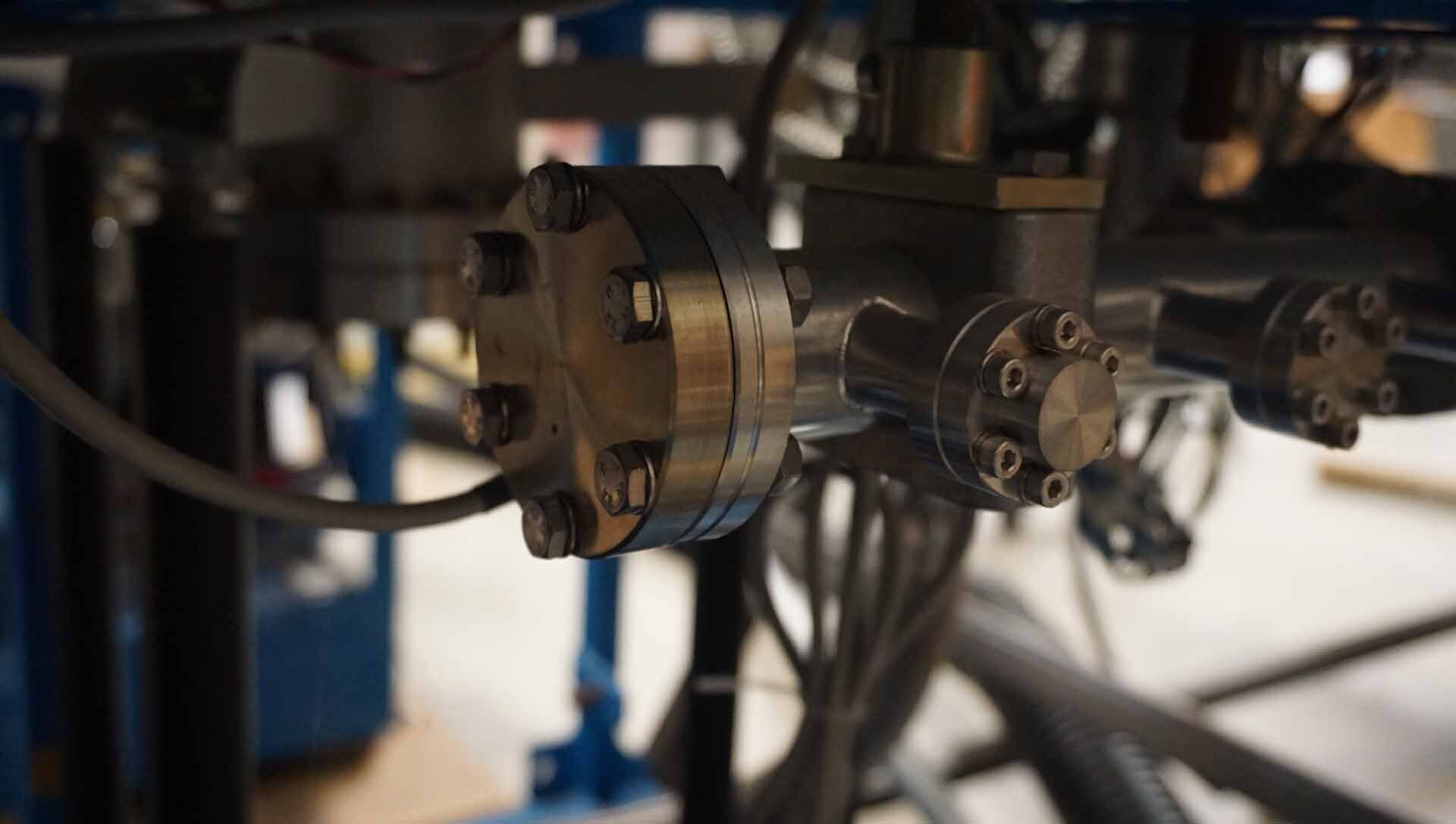

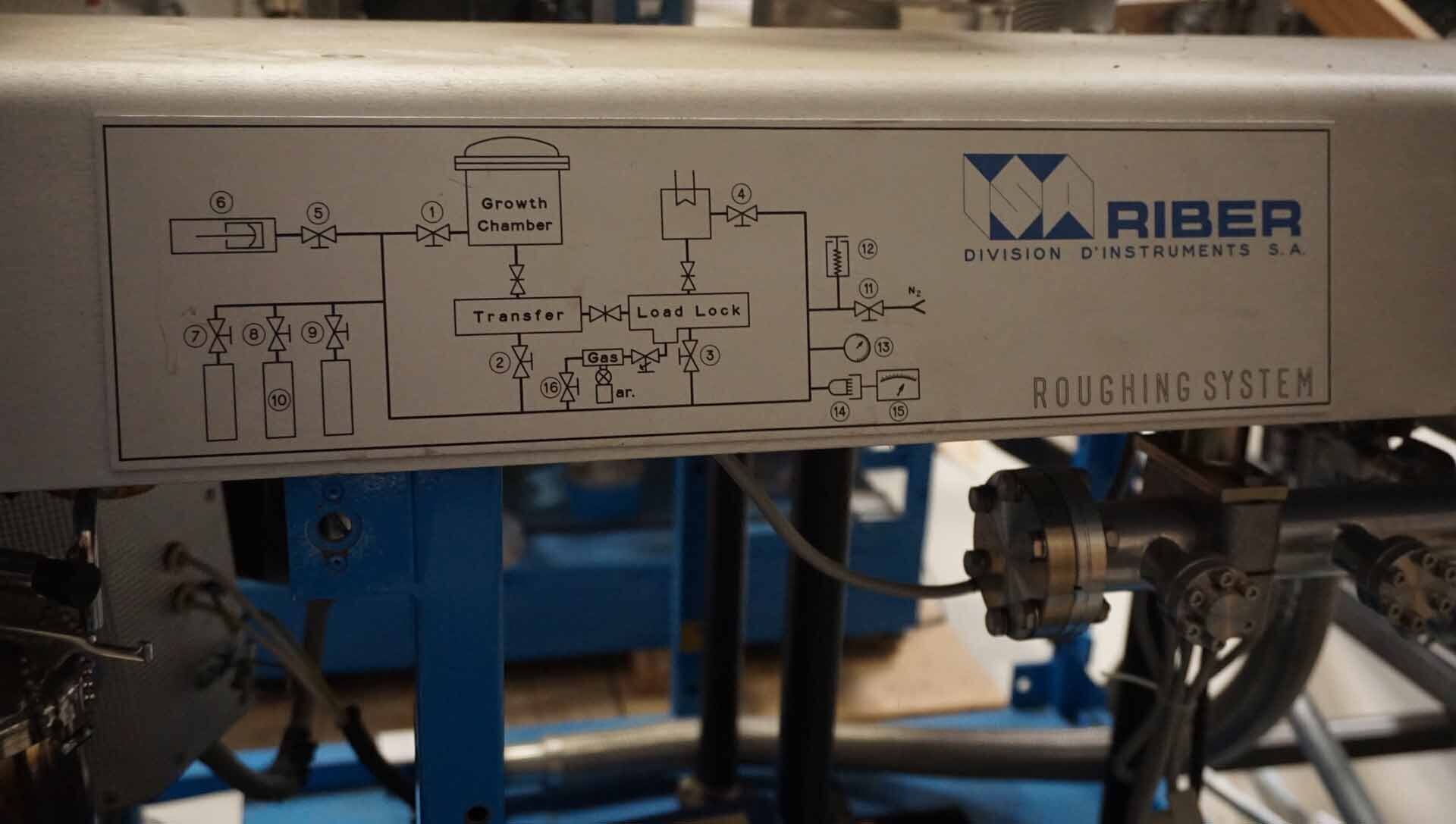

Molecular Beam Epitaxy (MBE) System

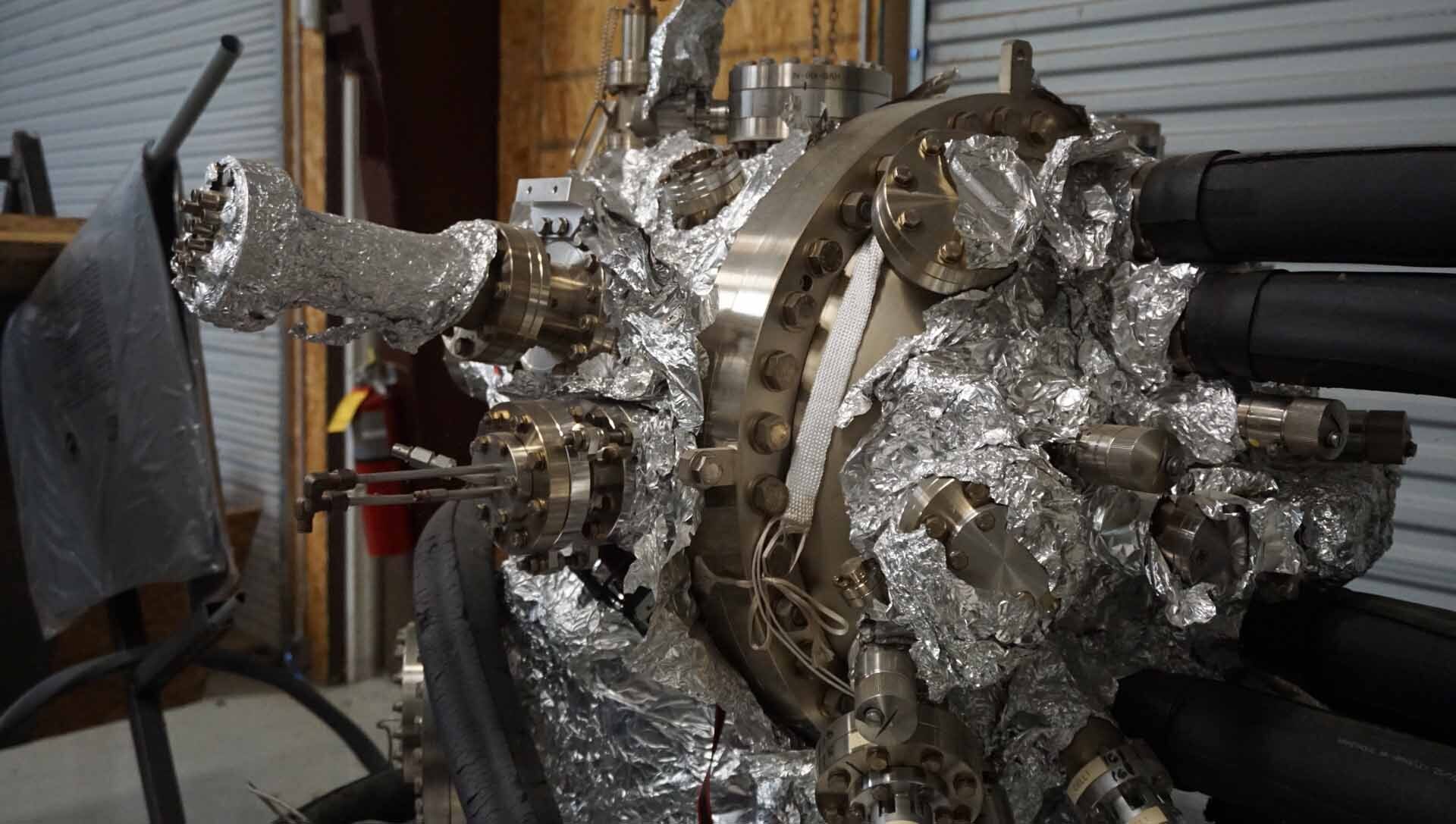

II-VI Growth system with load lock

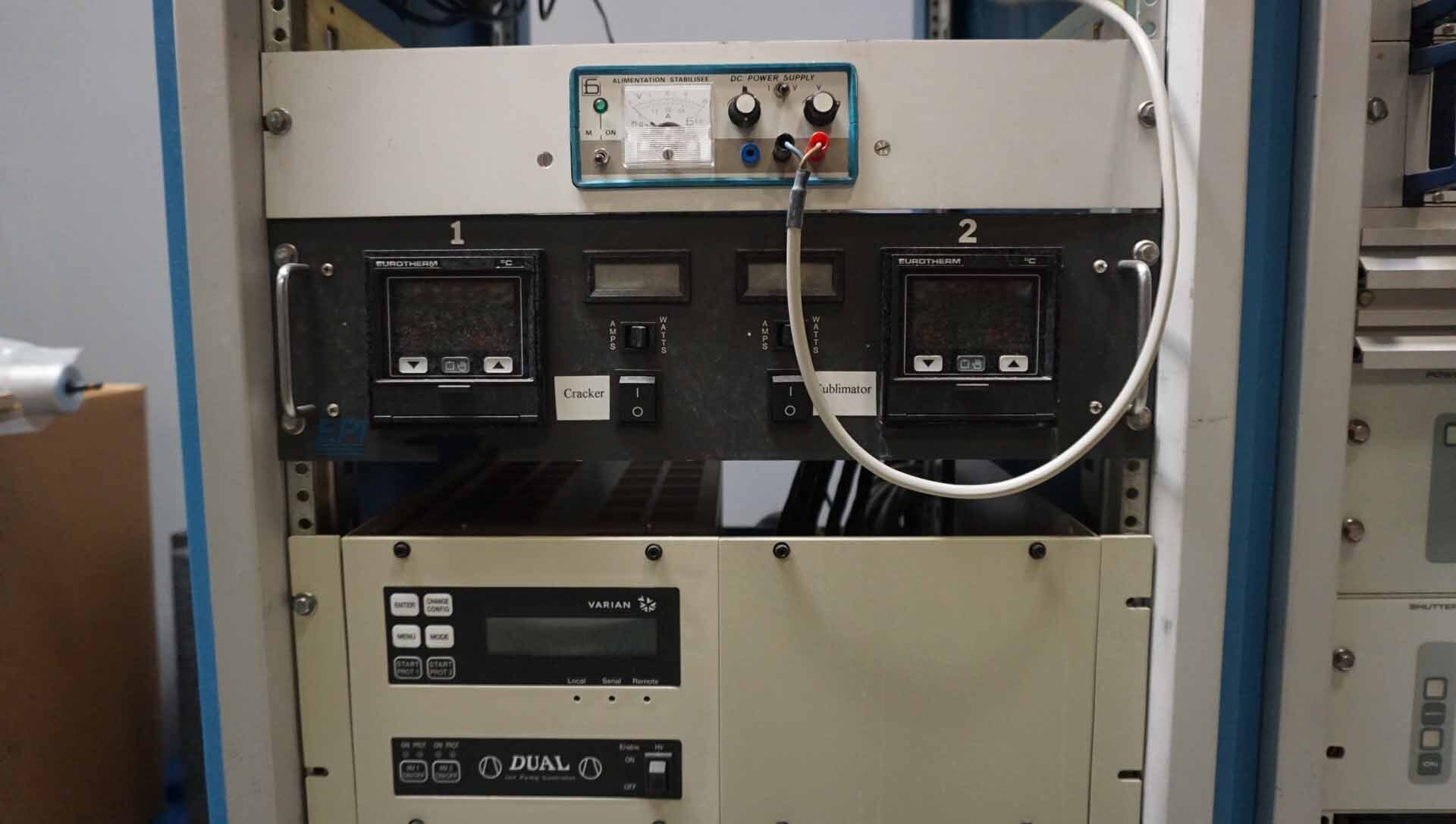

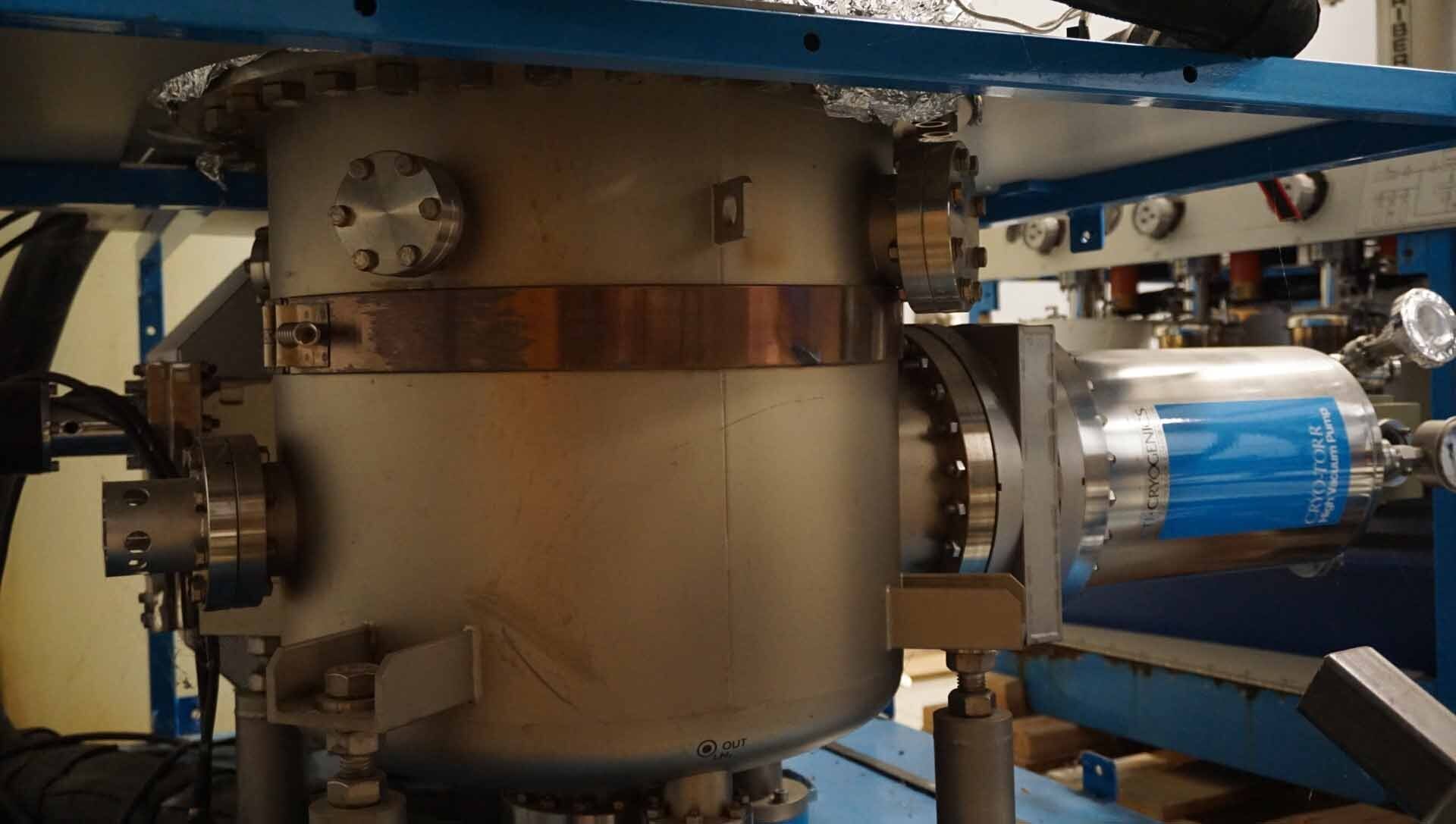

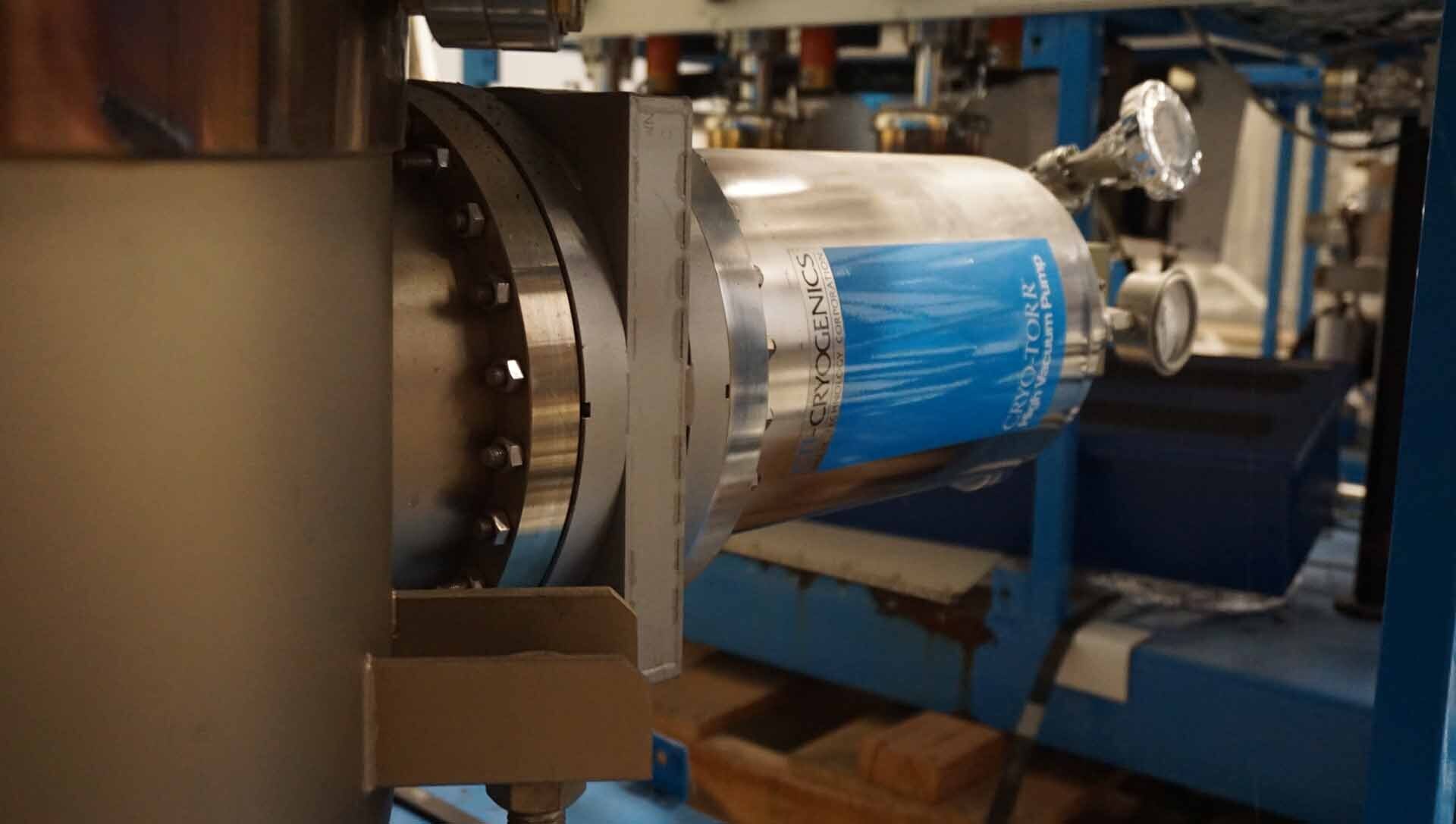

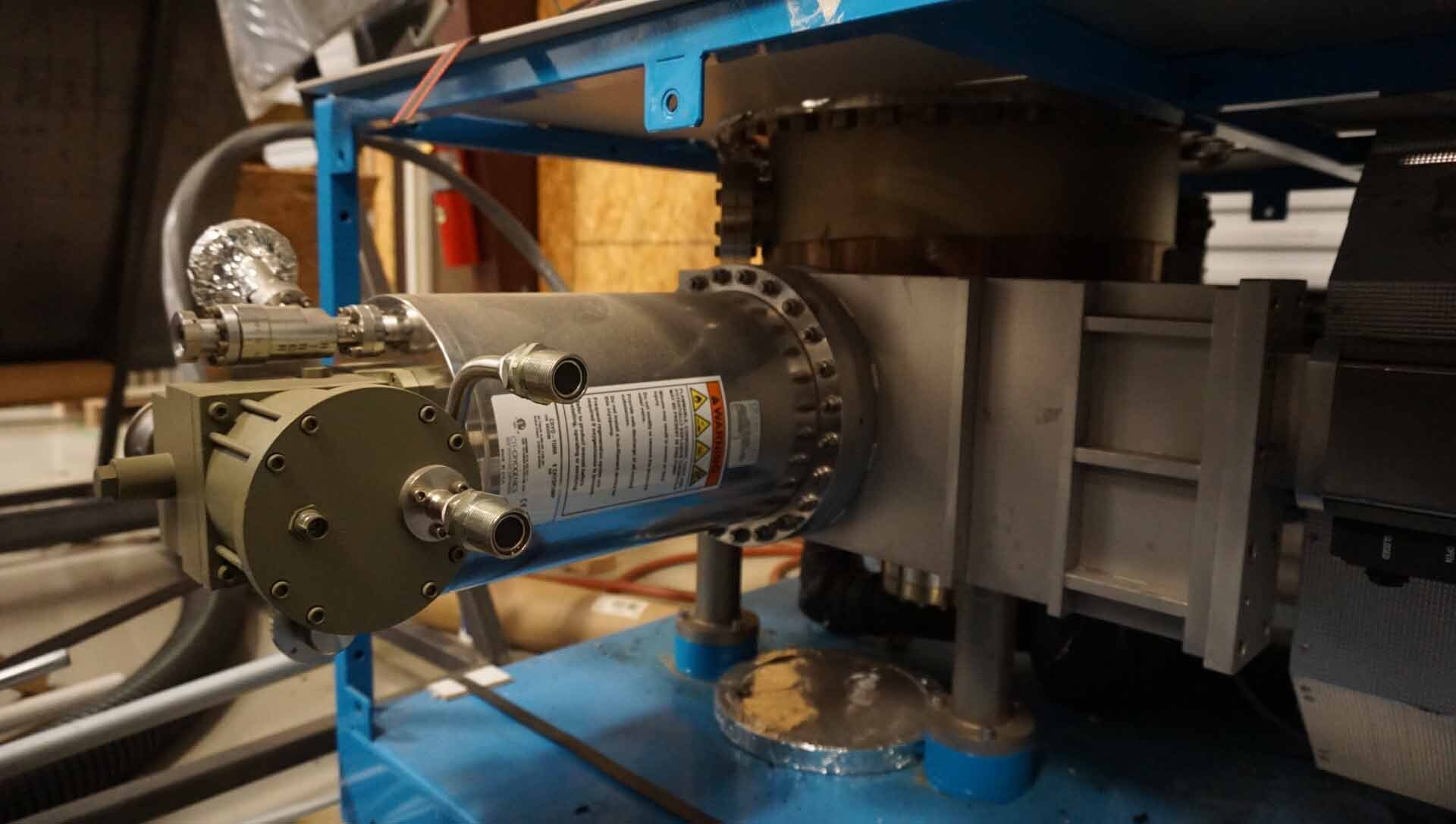

Cryo pump

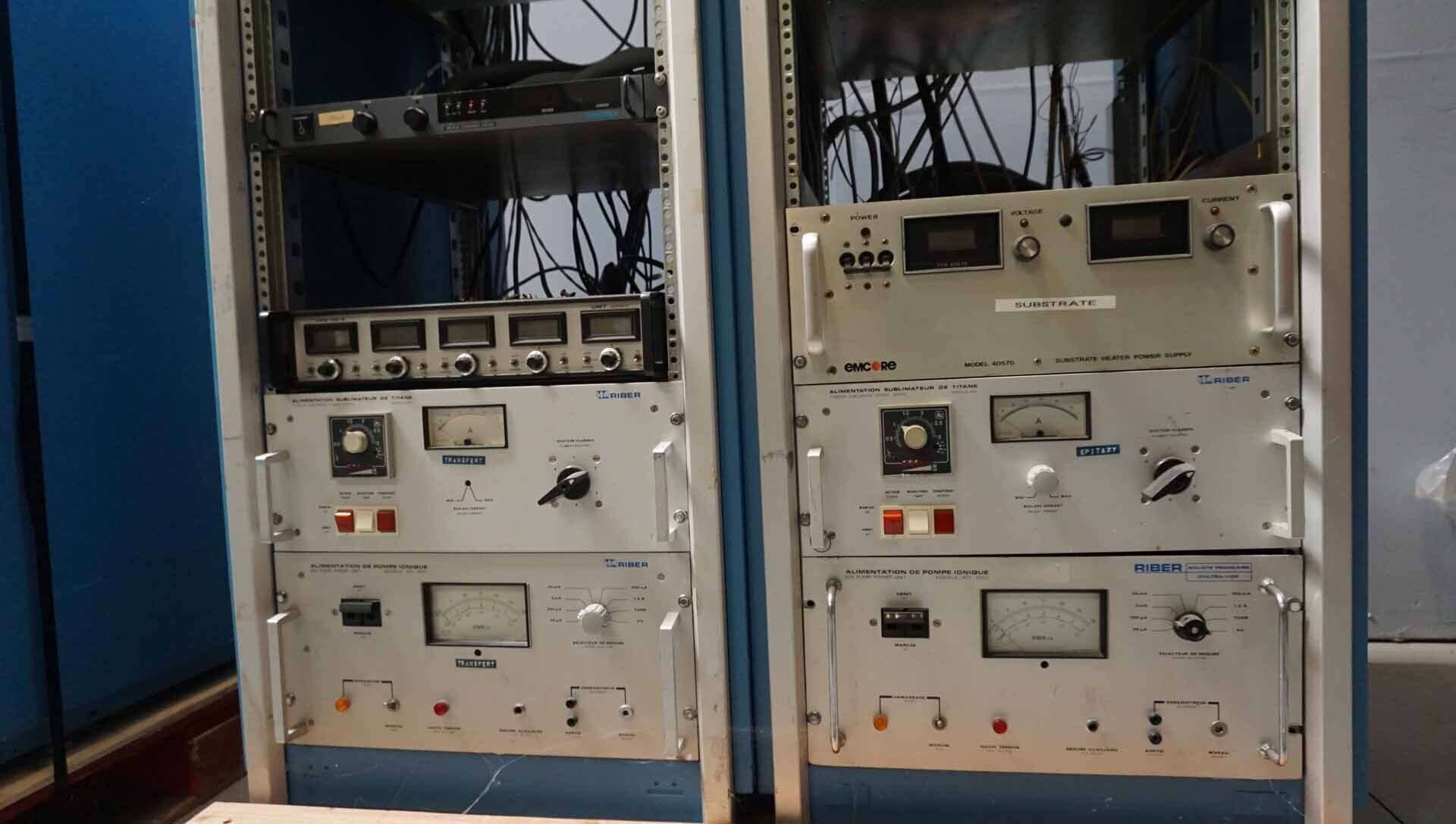

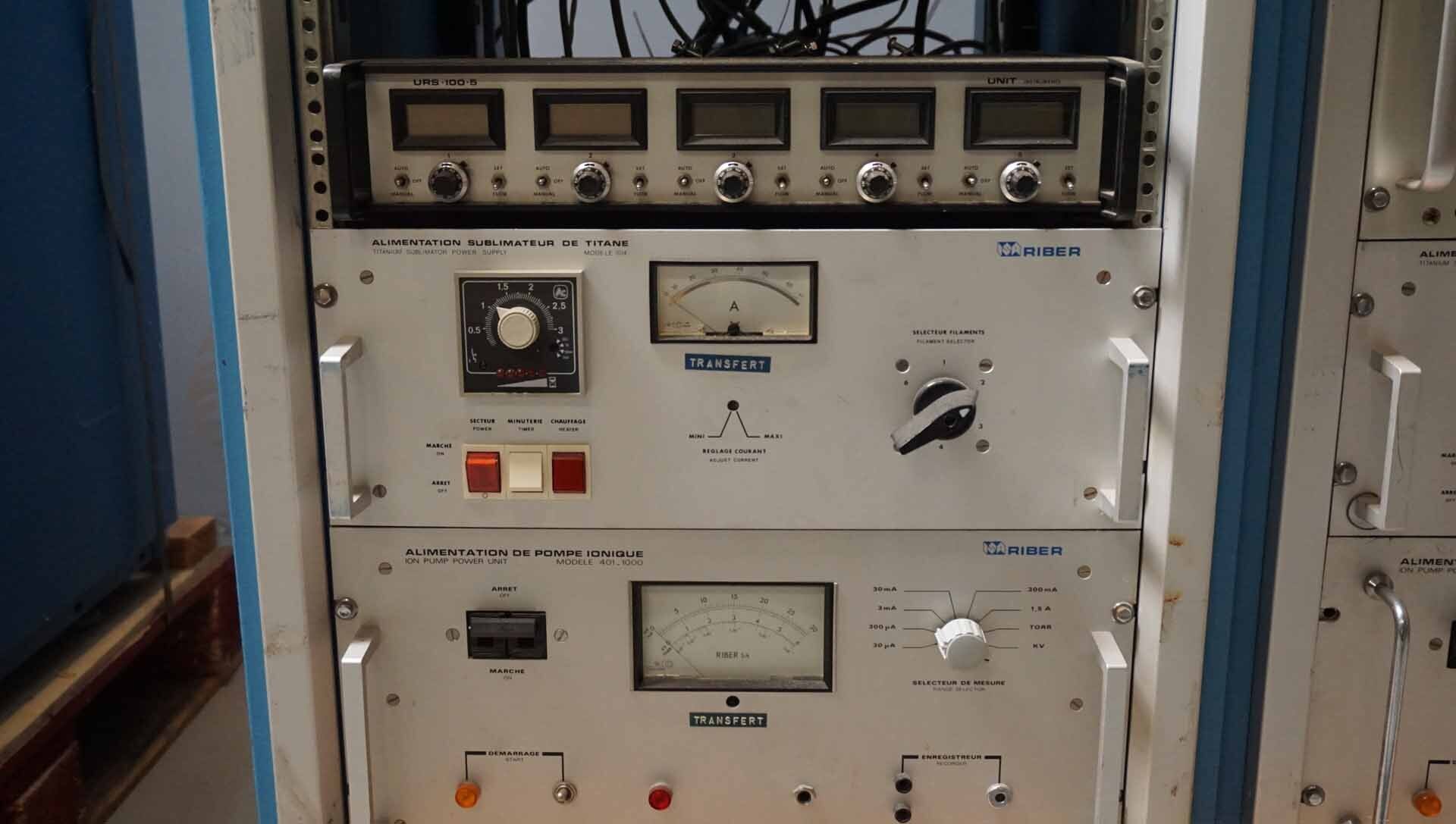

Ion pump

Titanium sublimation pump

(3) Sorption pumps

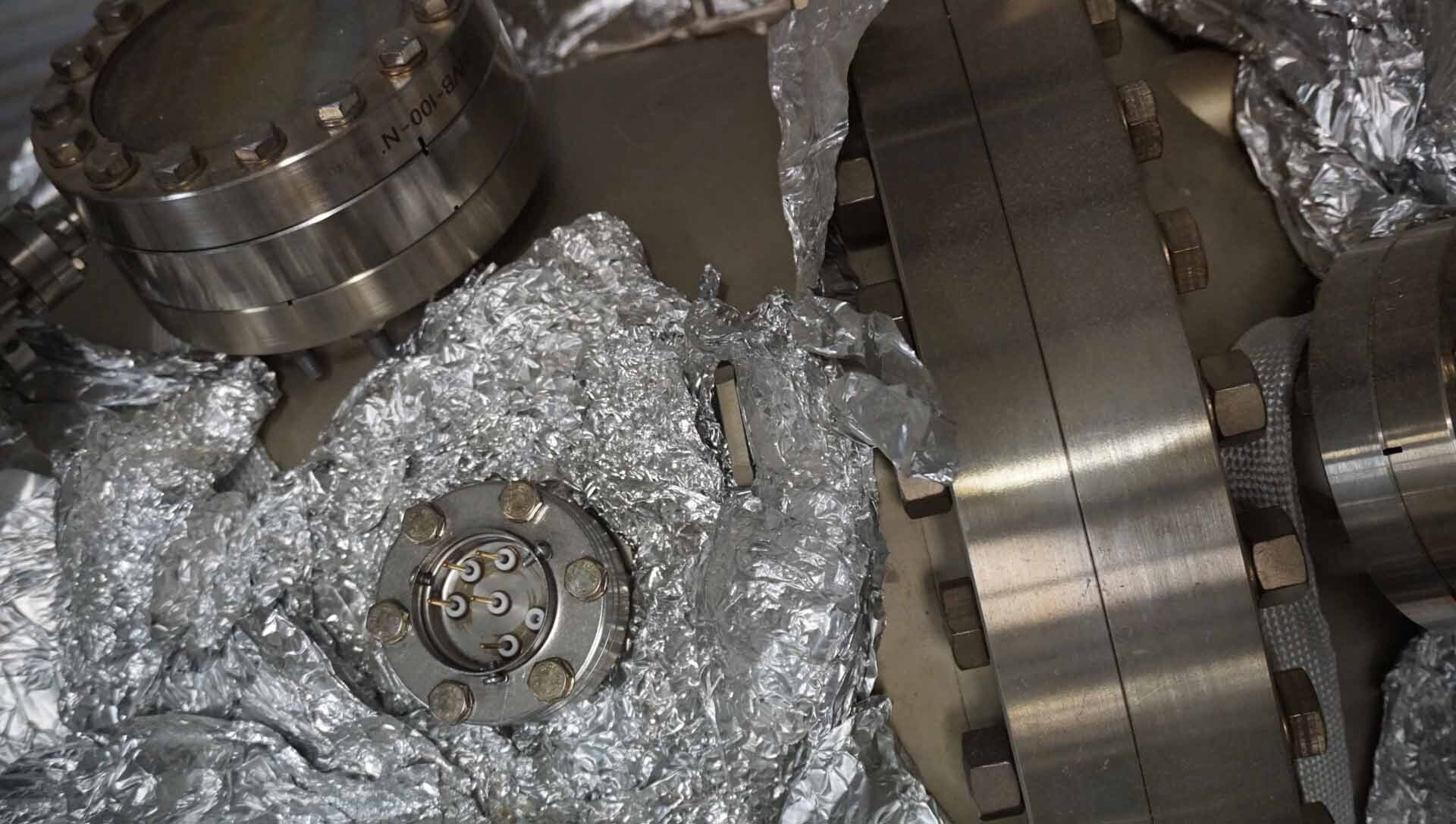

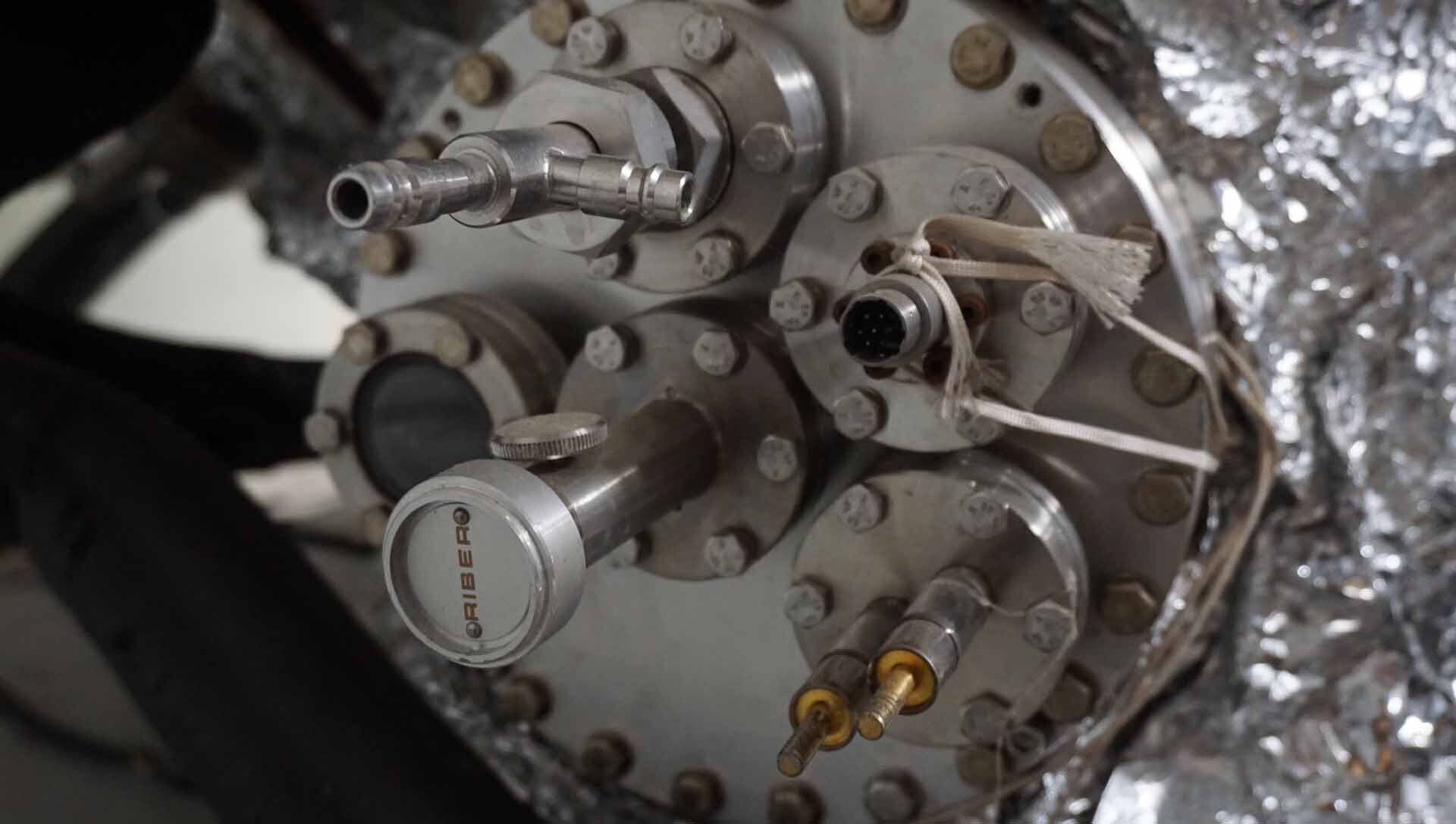

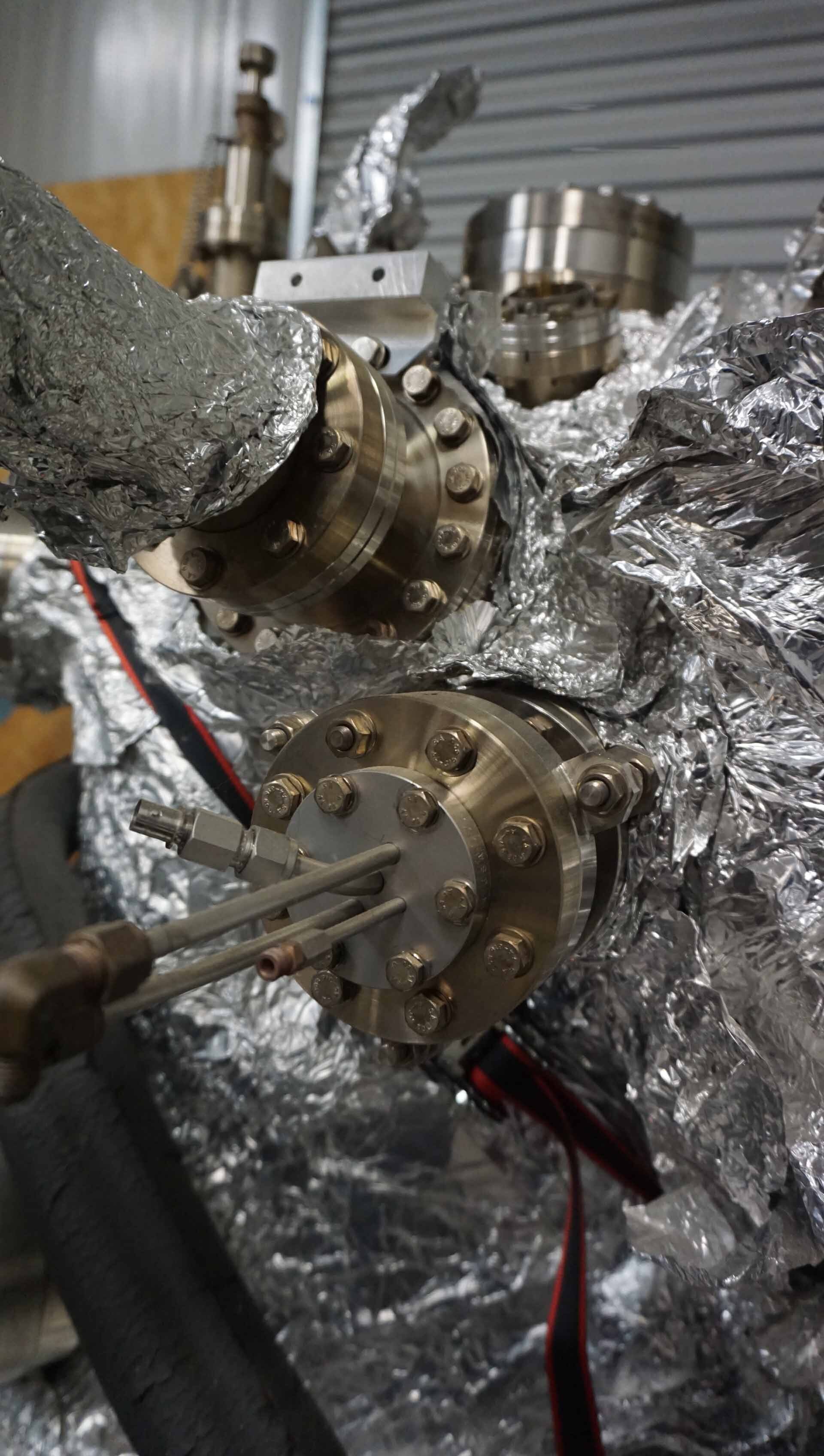

(9) Effusion cell ports

Flux monitor

Ion gauge controller

RIBER Microcontroller

Enhanced power substrate heater power supply

Cell power supply

Includes:

MBE Spares

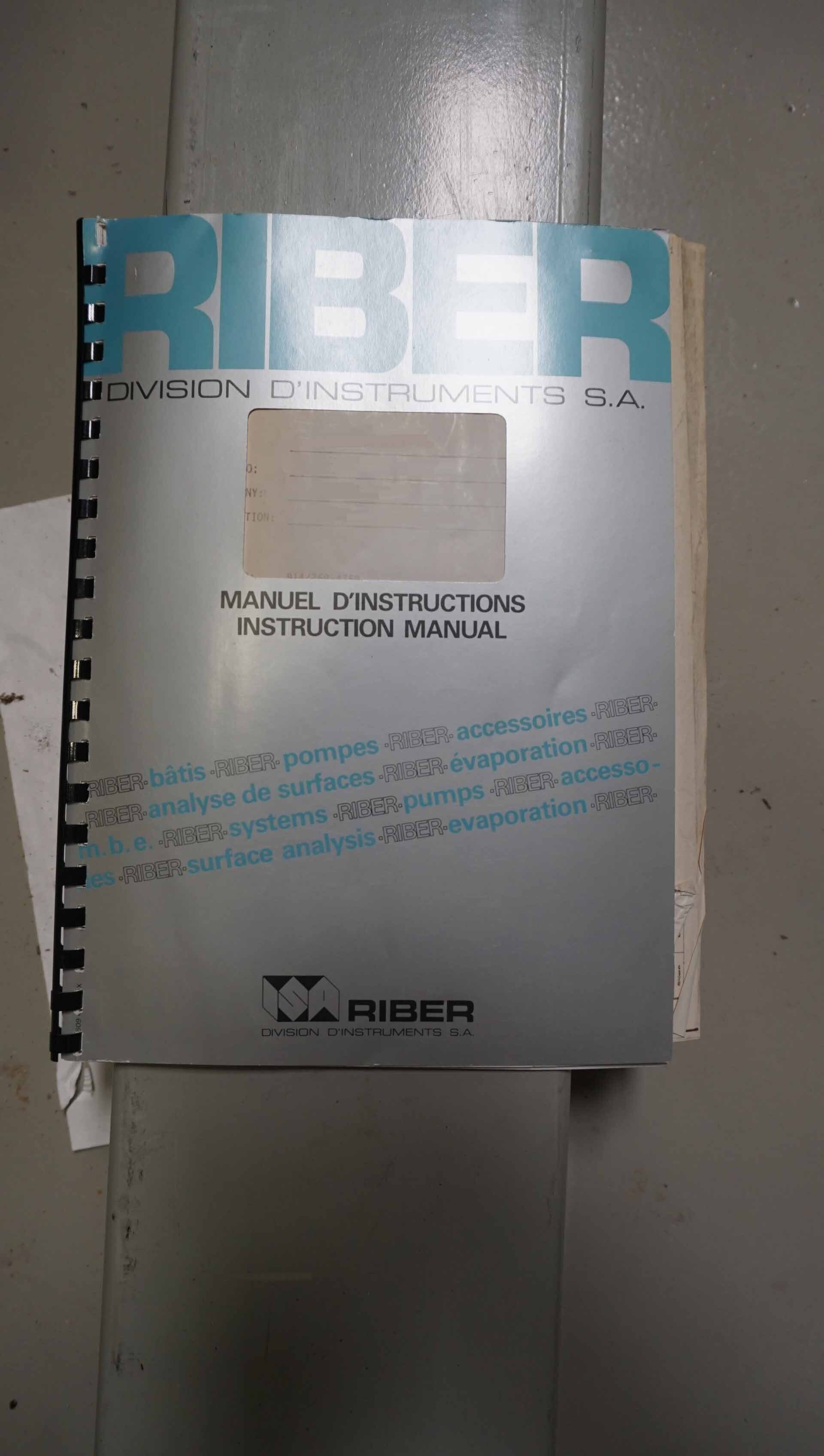

Manuals

Missing parts:

Compressor

Lines for cryo pump.

RIBER 32P is a Molecular Beam Epitaxy (MBE) equipment designed for thin-film deposition. MBE is based on the concept of depositing monolayers of materials onto a substrate surface in a vacuum environment. This process promotes self-assembly of atoms, molecules and nanostructures, allowing the production of high-quality thin film materials with superior properties. 32P MBE system is a high vacuum unit, capable of reaching pressures of 10E-9millibar, and sends beams of atoms through apertures to allow precise control over the deposition rate, beam energy, and area of deposition. This enables a wide range of thin films to be deposited, including high-temperature superconductors, optically active materials, semiconductors, and transparent conductors. RIBER 32P contains six source effusion cells, capable of dispensing atoms at temperatures between 300 and 1000°K, resulting in an optimal recipe to deposit stoichiometric (targeted combination of different elements) materials. The furnace section of 32P allows thermal control of the substrate, allowing samples of different sizes, from 25mmsquare to 5inchesquare, to be heated and/or cooled according to the desired temperature range. This enables the deposition of multiple layers of material onto the substrate, with a high degree of control and accuracy. RIBER 32P also contains an optical monitoring and diagnostics set-up, allowing for real-time analysis of the deposition process. This includes a quartz-crystal microbalance coupled to a residual gas analyzer, allowing for gas and film thickness measurements, as well as a quadrapole mass spectrometer and optical emission spectroscopy, which allows for real-time observation of the chemical environment within the MBE machine. The output of these systems can be then fed into an MBE-control tool, allowing for full computerized control of the process. Overall, 32P is a comprehensive MBE-asset, capable of producing high-quality thin films with superior properties. The high vacuum environment, coupled with sophisticated monitoring systems, allows for tight control over the deposition process and fine-tuning of the material used. This ensure high-accuracy deposits, with reliable reproducibility over repeated runs.

There are no reviews yet