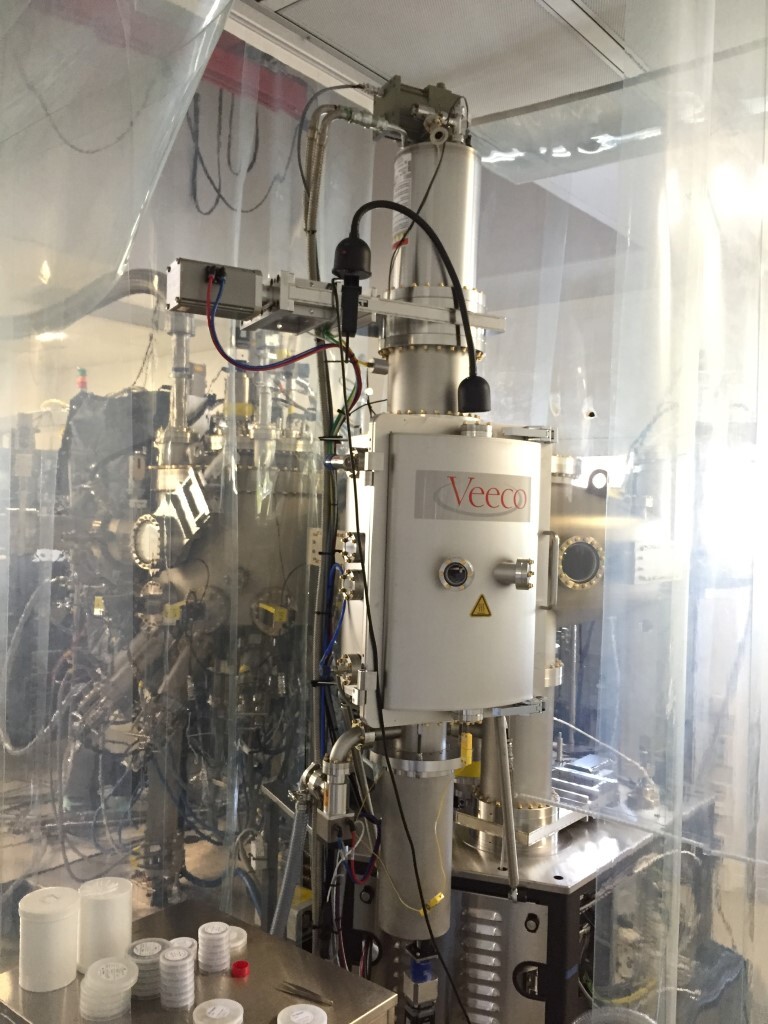

Used VARIAN / VEECO GEN 200 #9093517 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9093517

Wafer Size: 2" - 4"

MBE growth system, 2" - 4"

Cluster tool

Growth chamber

Loadlock

Prep / degas module

Storage module

Advanced cryo panel (~50% reduced liquid nitrogen consumption)

Spare cryo panel

Solid State Sources Layout:

(3) Gallium SUMO

(3) Aluminum (2 SUMO + 1 Conical)

(1) Nitrogen plasma source with turbo pump

(1) Arsenic valved cracker, MARK V

(1) Phosphorus valved cracker

(1) Indium SUMO

(1) Silicon

+ CBr 4-gas line

Growth chamber:

UHV ultra high vacuum chamber

Accepts up to 4x4”, 7x3”, 13x2” substrates

Advanced cryo panel (~50% reduced liquid nitrogen consumption)

Water cooled split-panel (ports area)

Pyrometer

Flux meter

RHEED 30kV

Quadruple mass spectrometer

Growth Chamber Pump System:

Ion pump (800 l/s)

Turbo Pump (830l/s)

Cryo Pump CT-10

Scroll-Pump

Titanium sublimation pump

Cluster Tool:

Cryo Pump

Quadruple mass spectrometer

Loadlock:

(8) Platens

Cryo Pump

Lamp Heating up to 120°C

Platens: 7 x 3", 14 x 2"

Does not require LN2 phase separator

Documentation available

Gas delivery line: Port 7

Gas dopant: CBr4

Materials (MBE grade):

Aluminium

Gallium

Indium

Silicon

CBr4

Arsenic

Phosphorous

Nitrogen

Substrates: GaAs.

VARIAN / VEECO GEN 200 is a molecular beam epitaxy (MBE) equipment used for the fabrication of semiconductor device structures. It is a modular, multi-zone, low-temperature system that offers an atmosphere-controlled ultra-high vacuum environment for precise deposition of highly controlled epitaxial films. The unit manipulates and transports atomic or molecular beams of heat-evaporated precursors and dopant sources to a substrate wafer, which can be heated or cooled depending on the deposition material. This enables high-quality deposition of materials down to the atomic or molecular level with very low unintended incorporation of impurities. The major components of VEECO GEN 200 machine are the molecular beam epitaxy chamber, which provides the ultra-high vacuum, and the chemical source and effusion day. The vacuum chamber utilizes two separate chambers; one for wafer handling and one for wafer deposition. The source and effusion day contains thermal sources for ternary, quaternary, and pentenry deposition and are equipped with shutters for accurate and precise deposition control. A multi-level rotating shutter tool for each source ensures the desired deposition conditions. An integrated electronic heater asset along with an automated wafer cooling model allow the substrates to be heated or cooled depending on the material being deposited. VARIAN GEN 200 equipment features a robust automation software with manual/automatic operation modes for wafer handling. It provides precise control over each MBE process, including parameter setting, recording, and logging. The software engineering allows for personalized recipes, more efficient processing, and better data analysis. It can also be interfaced with an external controller for additional features such as wafer loading, thermal source, cooling, shutter control, and automatic feedback and control of the deposition rate. GEN 200 system provides reliable, accurate deposition and device fabrication processes. Its ultra-high vacuum atmosphere ensures highly controlled deposition of epitaxial films with precise control over temperature, maximum deposition rate, uniformity and profile of the deposited material, and minimal unintentional incorporation of impurities. This unit simplifies molecular beam epitaxy processes making it one of the most efficient and reliable systems for device fabrication.

There are no reviews yet