Used VARIAN / VEECO GEN II #9232278 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

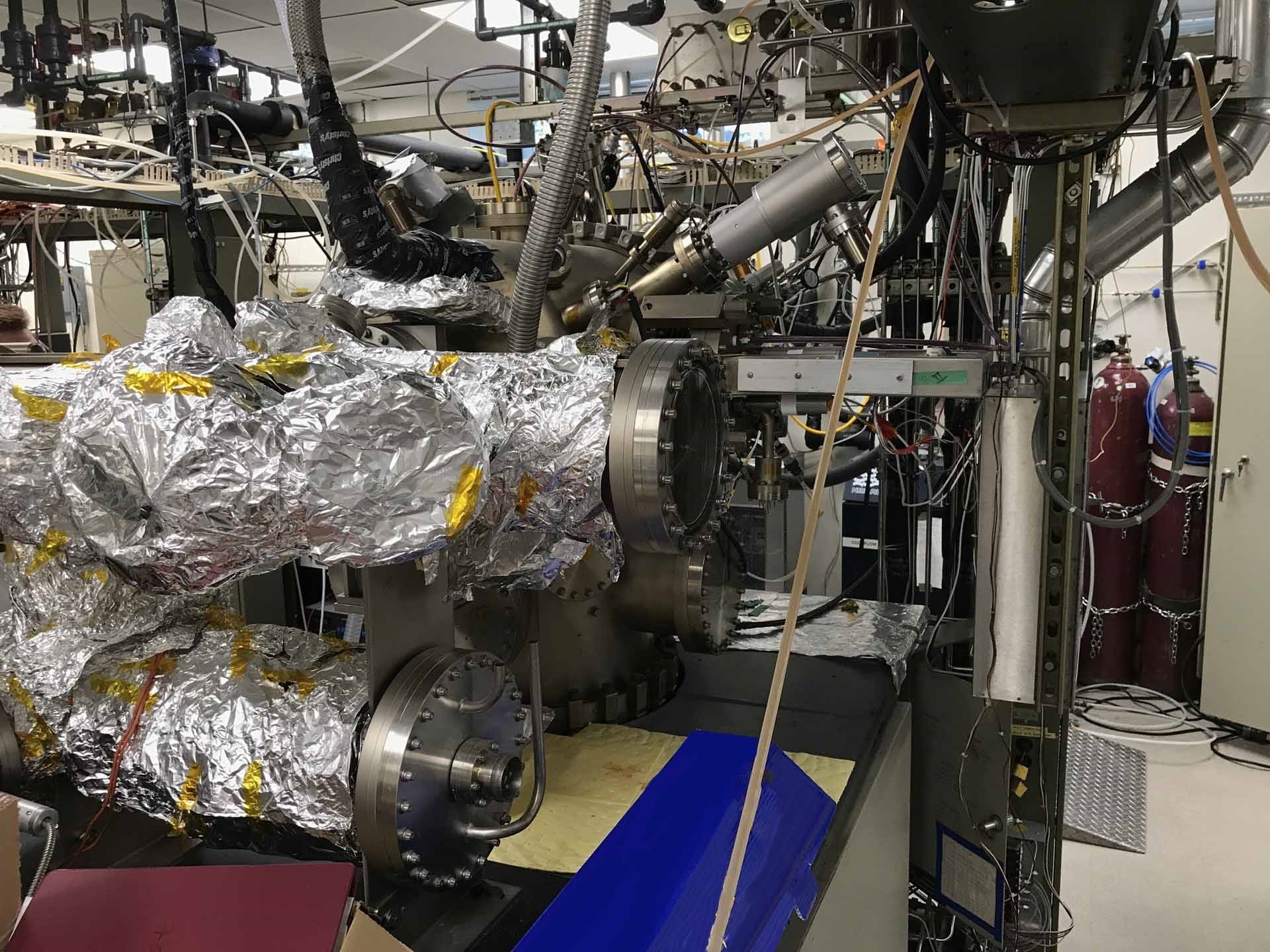

VARIAN / VEECO GEN II is an advanced molecular beam epitaxy (MBE) equipment consisting of a growth chamber, evaporator, gas delivery system, and unit control unit. The growth chamber is made from stainless steel, and it has a base pressure of 10-10 Torr. This chamber is large enough for up to 8 substrates and for the flow of in-machine gases, like oxygen and hydrogen. The evaporator has multiple independent sources and is temperature monitored. The sources can be heated up to 1200°C, and each are controlled by their own temperature controllers. The gas delivery tool is designed to handle up to thirteen gases and provides automatic manual control over the partial pressures of gas through a proportional controller. The gas delivery asset is designed to provide uniform gas distribution. Lastly, the model experimental control unit can control the growth rate, the nitrogen doping, linearity & uniformity of deposition, homogeneity of the layer, and can monitor all parameters such as growth rate and p-doped species. VEECO GEN II is designed for high-quality, reproducible semiconductor growth on up to 8 substrates using MBE technology. It is used for a wide range of applications, from the development of special materials to the manufacture of the most demanding quantum devices. It is ideal for depositing III-V materials, such as gallium arsenide (GaAs) and indium phosphide (InP), for high-quality layer deposition. It is also used for doping layers and epitaxial patterning. Its gas delivery equipment is designed to have fast switchability between 8 gases, allowing for improved process flexibility, as well as low-temperature growth processes. Overall, VARIAN GEN II is a professional grade MBE system designed to be efficient, reliable, and versatile. It provides the features and specifications necessary for advanced MBE processes. Its wide range of deposition parameters, superior control abilities, and flexibility makes it an ideal choice for advanced MBE research and development of semiconductor applications.

There are no reviews yet