Used VARIAN / VEECO GEN II #9257205 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9257205

MBE System

Main chamber

Loadlock

Wafer transfer module

Cryo pump lg

Cryo pump compressor

Wafer trolley

Rod, main chamber, trolley wafer load / Unload

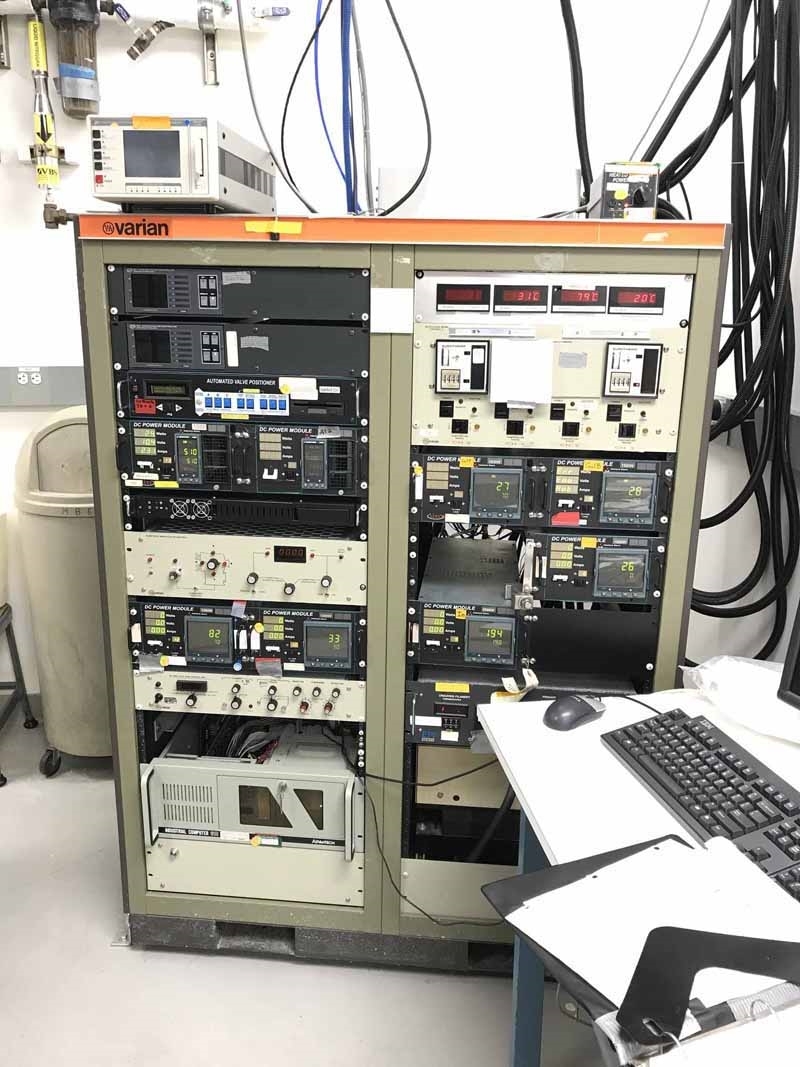

Control rack

Cryo pump SM load lock

Ion source gun

Rod, loadlock, trolley wafer load / Unload

(2) Loadlock cryo pump stands

Variable power supply

Main chamber gate valve poppet assy

Controller, Ion vacuum gauge

Spool piece for trolley

Cables and chamber end mount

(5) Cable tray assemblies

(2) Tracks and trolleys

Misc items:

Bellows

Trolley

Wafer grippers.

VARIAN / VEECO GEN II is a type of Molecular Beam Epitaxy (MBE) equipment and is used for the fabrication of semiconductor devices. This system uses a high-vacuum environment to create a beam of particles that can be manipulated to produce extremely thin layers of semiconductor material. The unit can be used to create small, precise layers that are used in the construction of devices such as transistors and solar cells. VEECO GEN II consists of, a mainframe structure that houses two large deposition sources— also known as effusion cells. These cells are used to create the molecular beams that are used to deposit a layer of material onto a substrate surface (the object being coated). The deposition sources can be heated to very high temperatures in order to create beams of high temperature molecules. VARIAN GEN II has a pumping machine that runs a turbo molecular pump so that the vacuum inside the mainframe is maintained at a very low level (less than 10-6 mbar). This is an important feature to ensure good homogeneity of the depositing material. The tool also consists of several other components such as a beam steering mechanism, a shutter, a controller, and a gun vane; all which are used to help manipulate the beam of molecules and direct it towards the desired substrate. The gun vane enables the asset to reach the directed angles required. The shutter controls the speed of the beam and can be adjusted in order to alter the speed of deposition. The model is also equipped with a computerized monitoring and control station. This station is used to monitor the conditions inside the mainframe such as the vacuum level and the temperature of the deposition sources. This station also has the ability to control the equipment parameters such as the flow of the beam, the heating levels of the deposition sources, and the shutter speed of the beam. GEN II is the perfect system for the fabrication of delicate, small, and precise layers of semiconductor materials. The flexibility of the unit and its fast deposition rate enable it to create layers that are few nanometers thick. The precision and quality of these layers is the key to the successful construction of the modern semiconductor devices used today.

There are no reviews yet