Used VARIAN / VEECO UHV #9081064 for sale

URL successfully copied!

Tap to zoom

ID: 9081064

System

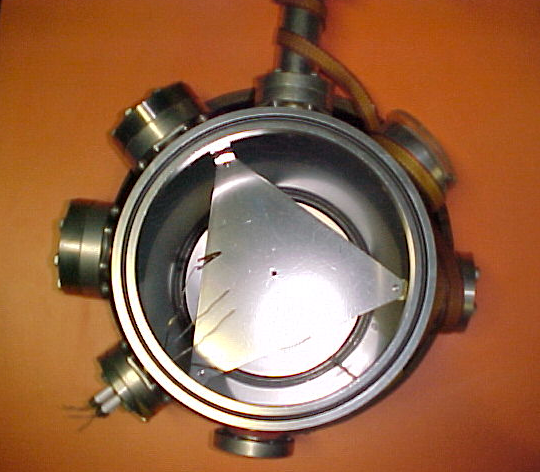

SS Chamber:

O-ring sealed cover & has a 1 ½" viewport

(2) sets of Curvac ports around the circumference

Upper set of ports include four 2 ¾" and three 3-3/8" Curvac flanges

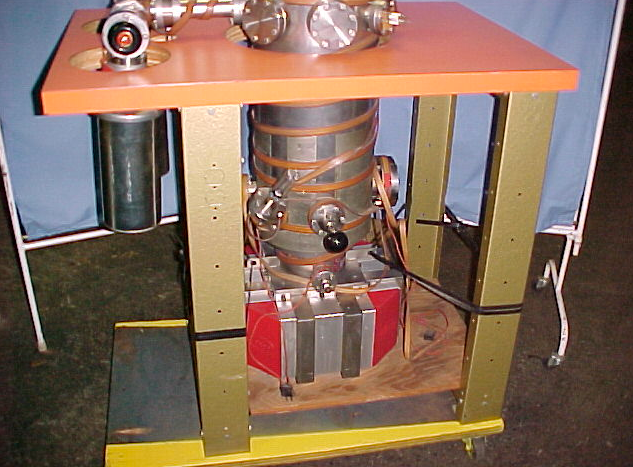

Pumping system:

(2) Ultek sorption roughing pumps including manifold & manual valving

Veeco MI300 Mag Ion pump rated at 300 l/s complete w/ Model CU510 power supply

Mounted on a compact table.

Molecular beam epitaxy (MBE) is a tool used for the fabrication of crystalline materials on the nanoscale. VARIAN / VEECO UHV MBE equipment is designed for the deposition of complex thin-film materials on a variety of substrates, allowing for complex heterostructures to be created via molecular growth. By combining the components of a conventional molecular beam source, such as effusion cells and electron-beam guns, with those of a high-temperature, high-vacuum system, high deposition rates and uniformity are achieved. At the heart of VEECO UHV MBE unit is the ultra-high vacuum (VARIAN UHV) chamber. Inside is an environment with a base pressure of less than 10-7 Torr, a temperature range of up to 1200°C, and the ability to accommodate substrates with dimensions up to 6" in diameter. Such conditions are essential for working with molecular beam deposition. In addition to UHV chamber, VEECO MBE machine also features a suite of molecular beam sources, including a dual-gun electron-beam gun, evaporation cells, and sputter sources. The dual-gun electron-beam gun is designed for low-temperature deposition while evaporation cells are used for high-temperature precision. The sputter sources offer a more diverse range of depositional capabilities. By controlling the parameters of the sources, VARIAN / VEECO UHV MBE tool is able to create a nearly limitless variety of thin-film and/or heterostructures. A separate power supply asset, which provides DC and RF input, powers the sources. This helps to ensure accurate and precise deposition of the material. Further supporting the process is a selection of automation components, such as positioners, automated sample-rotation systems, and mass-flow controllers. These components enable the user to accurately select the desired substrates and maintain precise control over the parameters of the growth process. Finally, VEECO UHV MBE model is housed in a rugged, ergonomic enclosure, designed for user comfort and safety. The equipment also features a variety of advanced system monitoring and safety systems, making it an ideal choice for any laboratory undertaking molecular beam epitaxy projects.

There are no reviews yet