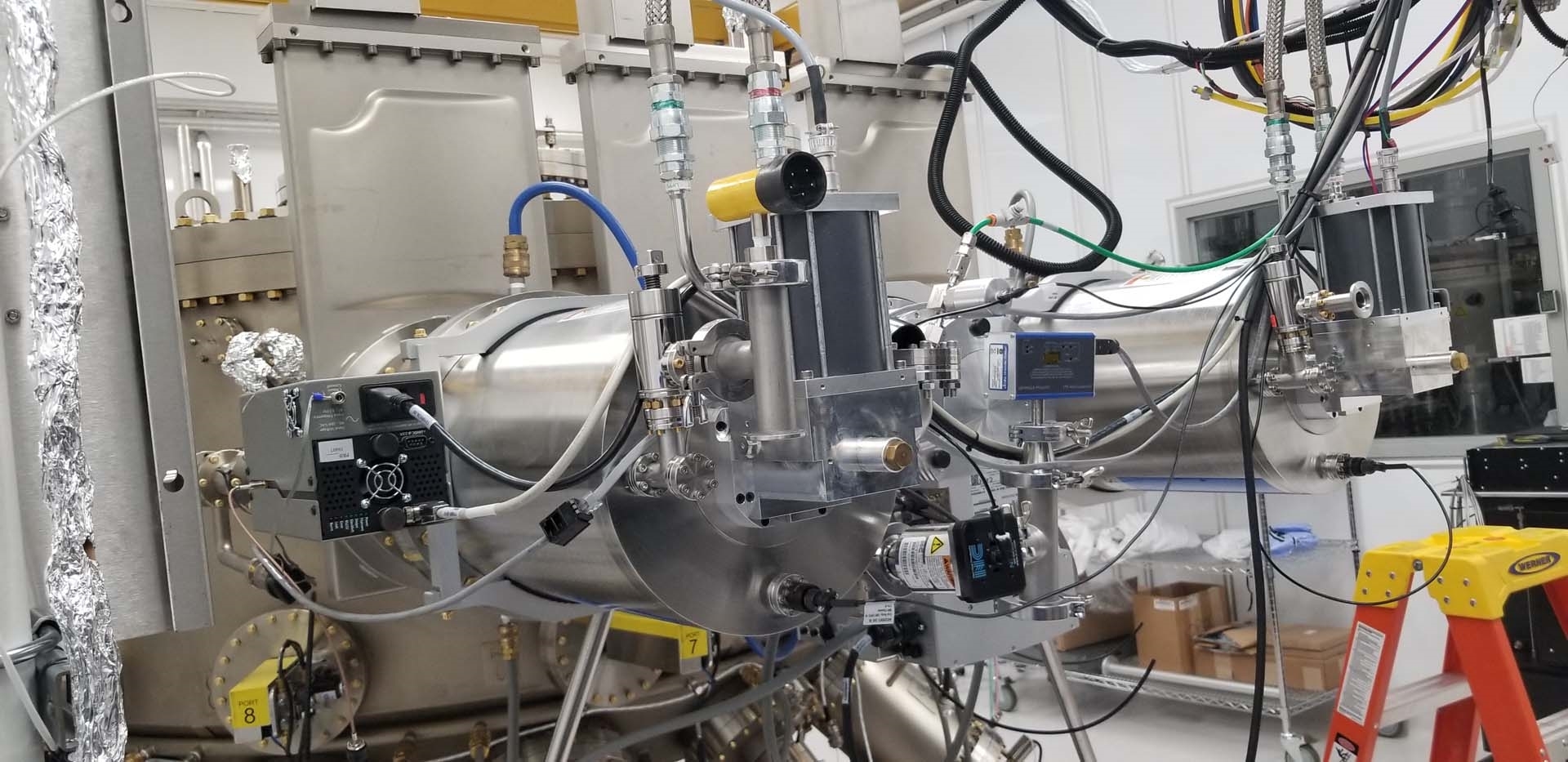

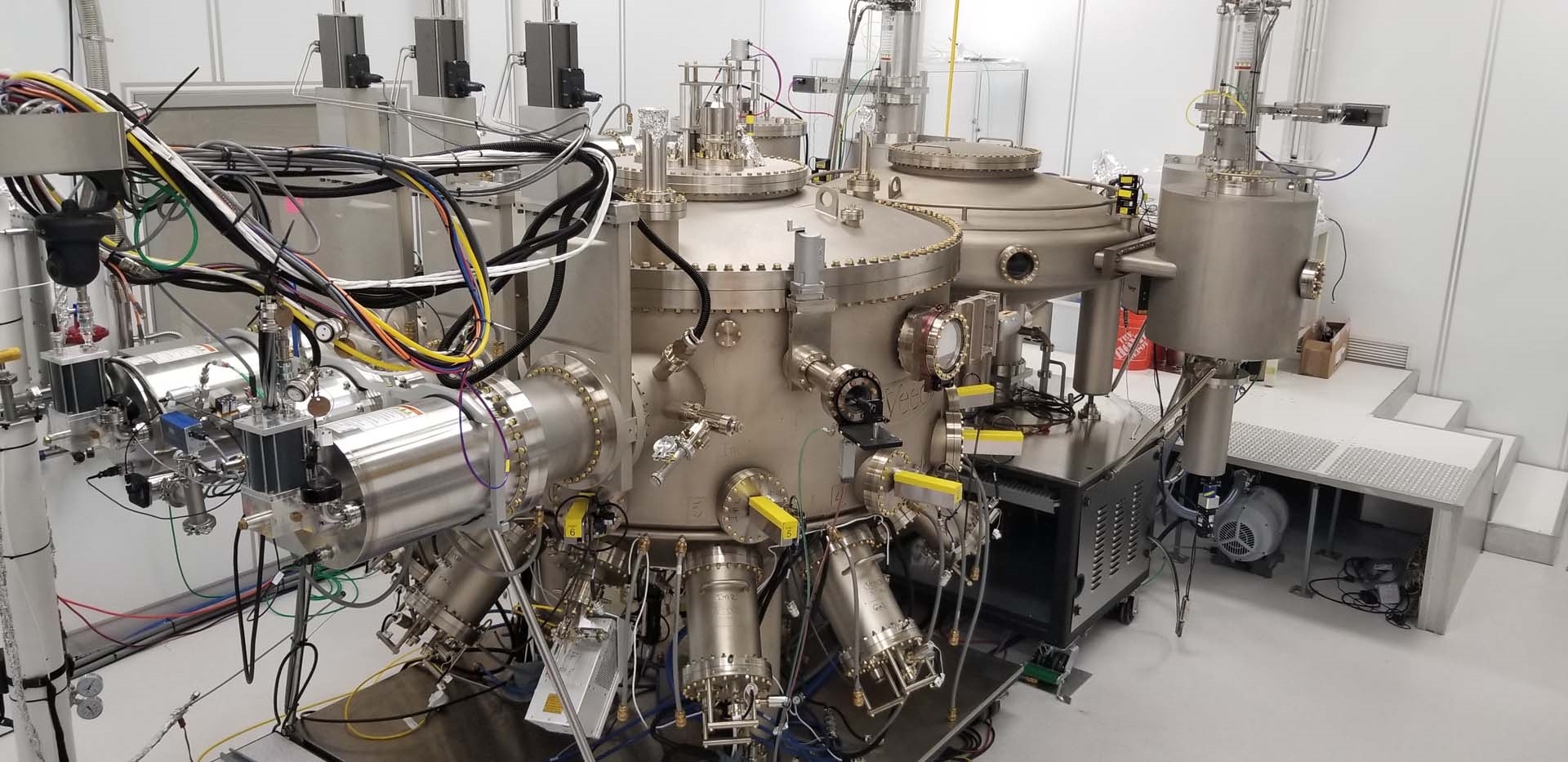

Used VEECO GEN 2000 #9281809 for sale

URL successfully copied!

Tap to zoom

ID: 9281809

MBE System

Process: GaAs

Chamber: AlGaIn AsSb, Be, Si, CBr4, plasma source

RHEED

K-Space cameras.

A VEECO GEN 2000 is a molecular beam epitaxy (MBE) equipment, mainly used for growing thin films of semiconductor materials. The system consists of several components such as a chamber, deposition sources, shutter, power supplies, vacuum pumps and a computer controller. The chamber is made of stainless steel material with a rough vacuum pressure between 10-5 and 10-7 Torr and a working pressure of 10-8 to 5x10-10 Torr. It has been designed to ensure a high quality films and homogeneous layers depositions. The unit comes with three types of deposition sources, namely heat evaporation, electron beam evaporation and molecular beam epitaxy. Heat evaporation is the simplest form of deposition which involves heating a metal material that subsequently leads to the release of atoms to form a thin layer on the substrate. On the other hand, electron beam evaporation utilizes an electron beam to dissociate a molecular material, inducing the release of atoms which end up deposited on the preferred surface. The main advantage of electron beam evaporation is the ability to reach higher temperatures. Lastly, molecular beam epitaxy is considered to be one of the most advanced deposition techniques. In this technique, the release of atoms is induced by activating a molecular beam with an energy flux. This is the most accurate and uniform depositing method of the three and is ideal for obtaining quality thin layers that are needed in semiconductor device fabrication. GEN 2000 also includes a shutter that can be used for controlling the deposition rate and an automated power supply that is used for controlling the deposition sources. The shutter can be opened and closed using a solenoid in order to regulate the amount of material that is deposited onto the substrate. Additionally, the power supply can be used to adjust the energy levels of the deposition sources in order to optimize the layer deposition rate. VEECO GEN 2000 also includes a computer controller that can be used for controlling each of the components in the machine. The controller is equipped with an interface for entering user parameters such as the deposition source, layer thickness, substrate temperature and pressure. Additionally, the controller monitors each of the processes on the tool to ensure the highest quality is achieved during deposition. In conclusion, GEN 2000 is an advanced molecular beam epitaxy asset that provides a reliable, high quality and homogeneous layer deposition. By using its three different deposition sources, this model can generate a variety of thin layers for semiconductor device fabrication with ease. Additionally, the user friendly computer controller ensures that all processes are under control and that the highest quality is achieved.

There are no reviews yet