Used VEECO Gen II #9073487 for sale

URL successfully copied!

Tap to zoom

ID: 9073487

Wafer Size: 3"

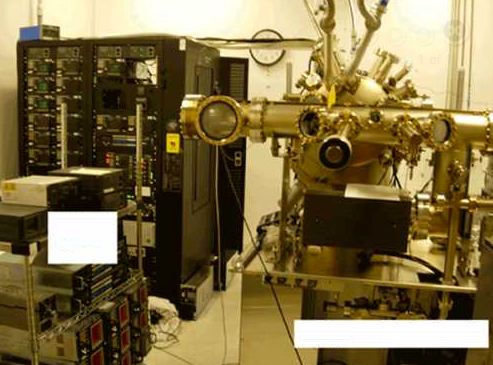

MBE Growth system, 3"

(10) ports for dopants

Process: Growth of arsenides and phosphides

Liquid nitrogen

Phase separator

AlGaAs Laser

Room temperature: 6°C - 10°C

Vacuum:

Growth chamber (GC)

Triode ion pump: 400 l/sec

Buffer chamber (BC)

Triode ion pump: 200 l/sec

(2) TSP Controllers

Loadlock chamber (LC)

(100) CTI Cryotor cryopumps

(2) Vacshorption pumps

Ventury pump

In situ and calibration tools:

RHEED System: 0-10 keV

RHEED Oscillation growth rate calibration system

Cells:

EPI

Valved cracker with valved controller

Cable

Riber three zone

P Valved cracker with valve controller

Power supply

(4) 400g Sumo cells Ga, In, Al

(2) Dopont cells

Dual electronic equipment rack, 19"

(12) Solenson DC power supplies

Riber P valved cracker

2704 Dual channel

Eurotherm controller

Substrate and heated station

(2) DC Power supplies

Substrate heater

Heated station

Other tools:

Ircon optical pyrometer

Growth chamber and beam flux

(2) GP Ion gauge controllers

Buffer and loadlock chamber

RHEED Power supply

RGA Power supply unit

TEK Scope

Riber P cracker power supply

Pyrometer port heated viewport

Substrate manipulator controller

Loadlock chamber

Lamp power and controller

AGILENT / HP / HEWLETT-PACKARD / KEYSIGHT Chart record mounted

RHEED Oscillation recording

Trolley for substrate handling.

VARIAN / VEECO GEN II is a molecular beam epitaxy (MBE) equipment used for producing thin films and layers of materials for use in a wide range of applications. The system consists of several components, including a main chamber, a growth chamber, an effusion cell, pumps, and a computer-controlled monitor. The main chamber houses the effusion cell, which contains the sources of the material to be evaporated. The main chamber is vacuum sealed and the thin film growth takes place inside the growth chamber. The effusion cell can be heated to temperatures of up to 1000°C, which enables the evaporation of the material. The chamber walls are heated to ensure uniform temperatures throughout the MBE growth chamber. VEECO GEN II is capable of producing thin films and layers with thicknesses in the range of 3-200nm. The unit is equipped with three effusion cells, and all of the cells are connected to a turbomolecular turbomolecular pump. This enables the machine to achieve a pressure of 1.0x10-10 Torr in the main chamber, which is ideal for thin film growth. The cells can also be fitted with an external baffle to reduce the flux of neutrals during film deposition. In addition to its ability to produce thin films and layers, the tool also includes a computer-controlled monitor. This monitor is used to control the temperature and pressure inside the chamber and to monitor the growth process. The asset also includes a variety of safety features such as vacuum seals and thermocouples for monitoring the chamber temperature. VARIAN GEN II is an ideal model for producing thin films and layers for a wide range of applications. The equipment includes features needed for large-scale thin film growth, and the system's computer-controlled monitor allows for precise control over the thin film growth process. The unit is also designed to be modular, allowing users to expand or reduce the number of effusion cells as needed. With its robust design and advanced features, GEN II is an excellent choice for thin film researchers and developers.

There are no reviews yet