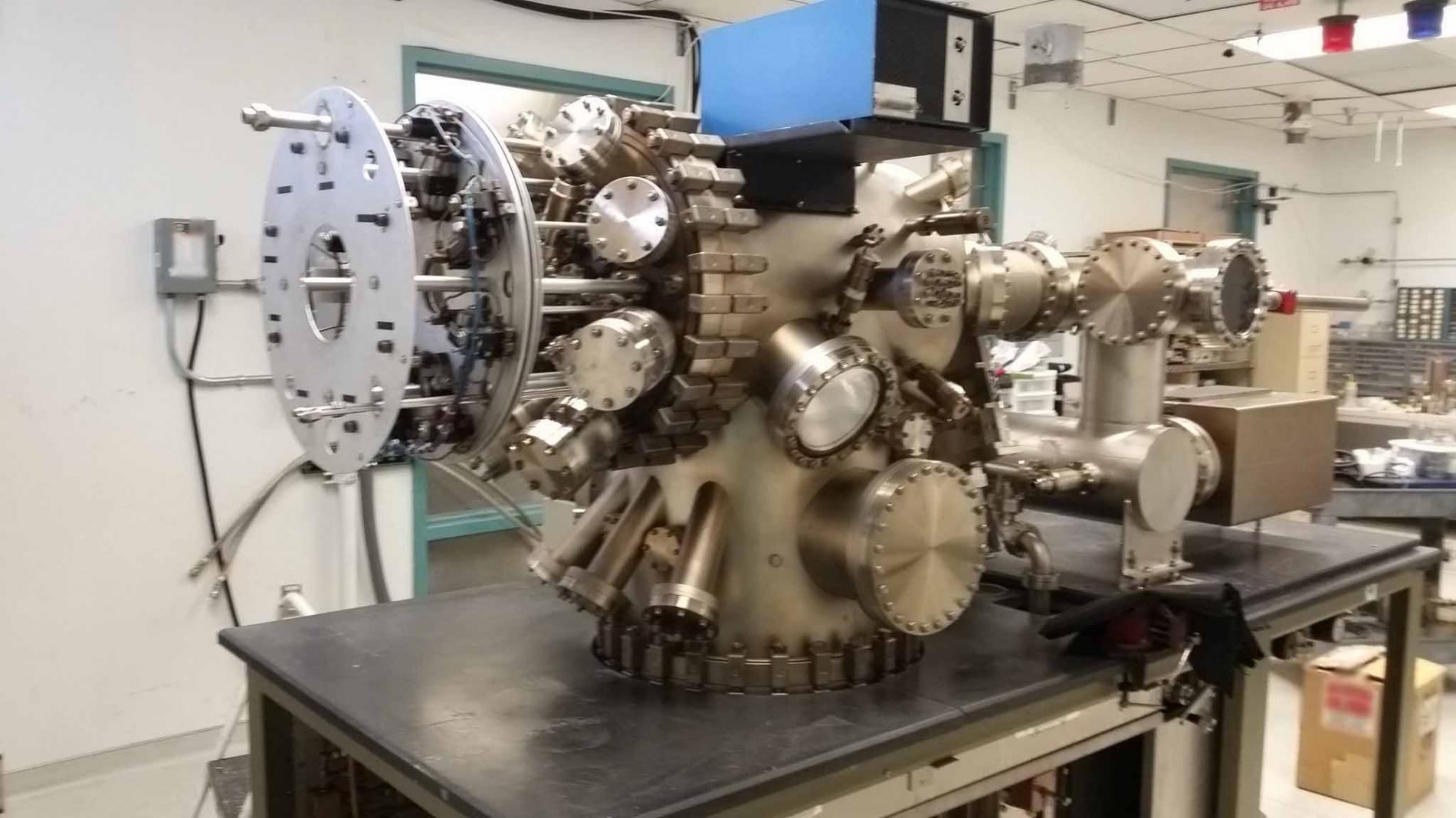

Used VEECO Gen II #9173265 for sale

URL successfully copied!

Tap to zoom

ID: 9173265

MBE Growth system

Chamber with (8) source flange size 4.5”

Sources: Al, Ga, In, Be, Si, GaTe, As, Sb

(2) Ion pumps:

Main chamber (600 l/m)

Preparation chamber (400 l/m) with (2) power supplies

CTI8 Cryo pump for main chamber

6” Turbo pump with dry pump for load lock

(2) Ti-Sublimation pumps

With power supplies in base of main chamber

Sample manipulator with servo motors for rotation, 2" or 3"

Position setting

Control unit

Beam flux monitor

Controller

Sample manipulator heater with power supply

Temperature controller and display

(3) Ion gauges:

With (3) power supplies and controllers

Main chamber

Preparation chamber

Load lock

Load lock for 4-10 wafers

With heater for pre-bake out at 150°C, power supply included

Temperature controller

Preparation chamber

With heater for bake out at 400°C, power supply included

Temperature controller

Electrical distribution panel

Bake out panels with electrical connections

(8) Shutters with their control units

Utility distribution box for water, air, N2

QMS and RHEED with power supplies

Operating system and computer (Latest version of Moly, or AMBER, or EPIMAX)

4-6 Sample holders

Silver coated copper gaskets

Pyrometer

RHEED Camera and analysis software

Turn key project

Effusion cell:

Flange, 4.5"

Dual or single heater up to 1350 C

85-155 CC PBN crucible

Power supply

Temperature controller.

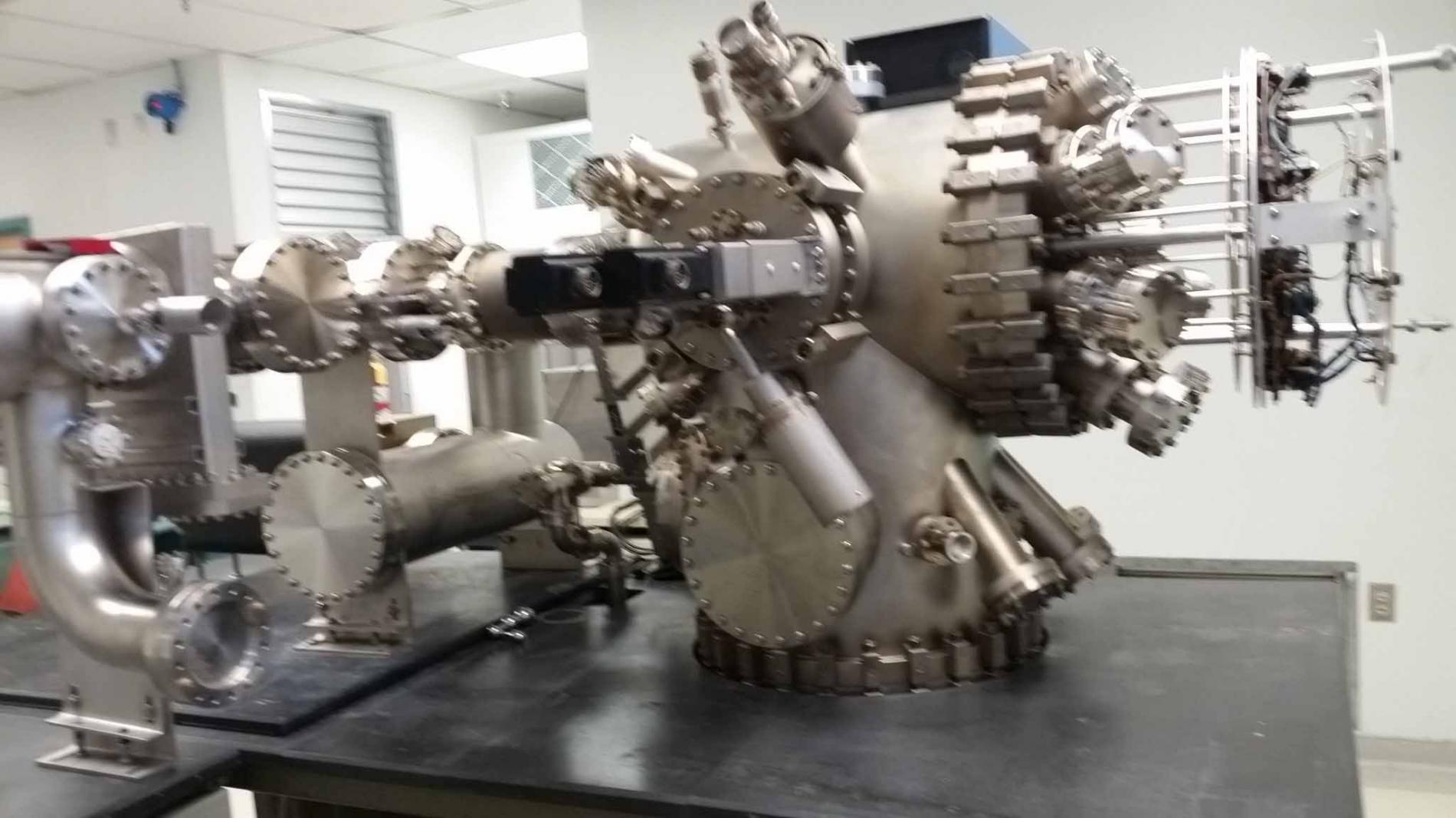

VARIAN / VEECO GEN II is a Molecular Beam Epitaxy (MBE) equipment available for the growth of a wide range of materials including III-V polytype, oxides, nitrides, graphene, and rare-earth elements. The system consists of two major components, including a two chamber MBE unit and a full compliment of tooling and instrumentation. The two chamber MBE machine consists of an evaporation chamber and a growth chamber. The evaporation chamber is home to six Knudsen cell sources, allowing for variation in material types. The growth chamber is a highly customisable bath tube based chamber designed to maximise epitaxial growth. The tool is equipped with a plethora of subsystems, all aimed at optimising material quality, including temperature control, substrate heating, and six-axis in situ monitoring. The control asset allows for automated growth processes, as well as remote control. In addition, the model is equipped with a range of optional parameters including customization of source geometry, slit blades and grid, sample throughput and chamber pressure control, as well as pre-alignment and post-alignment capabilities for improved material quality and accuracy. Finally, the equipment is equipped with a number of different support systems, including a degassing cluster, a remote electron gun, a laser system, and a controller combination that allows the user to plot out potentials to further optimize material quality and growth speed. All in all, VEECO GEN II is a powerful unit capable of growing a wide range of materials. Its numerous auxiliary systems and parameters, as well as automated control, allow for precise manipulation of material growth to produce consistent high quality materials that can then be used in a variety of applications.

There are no reviews yet