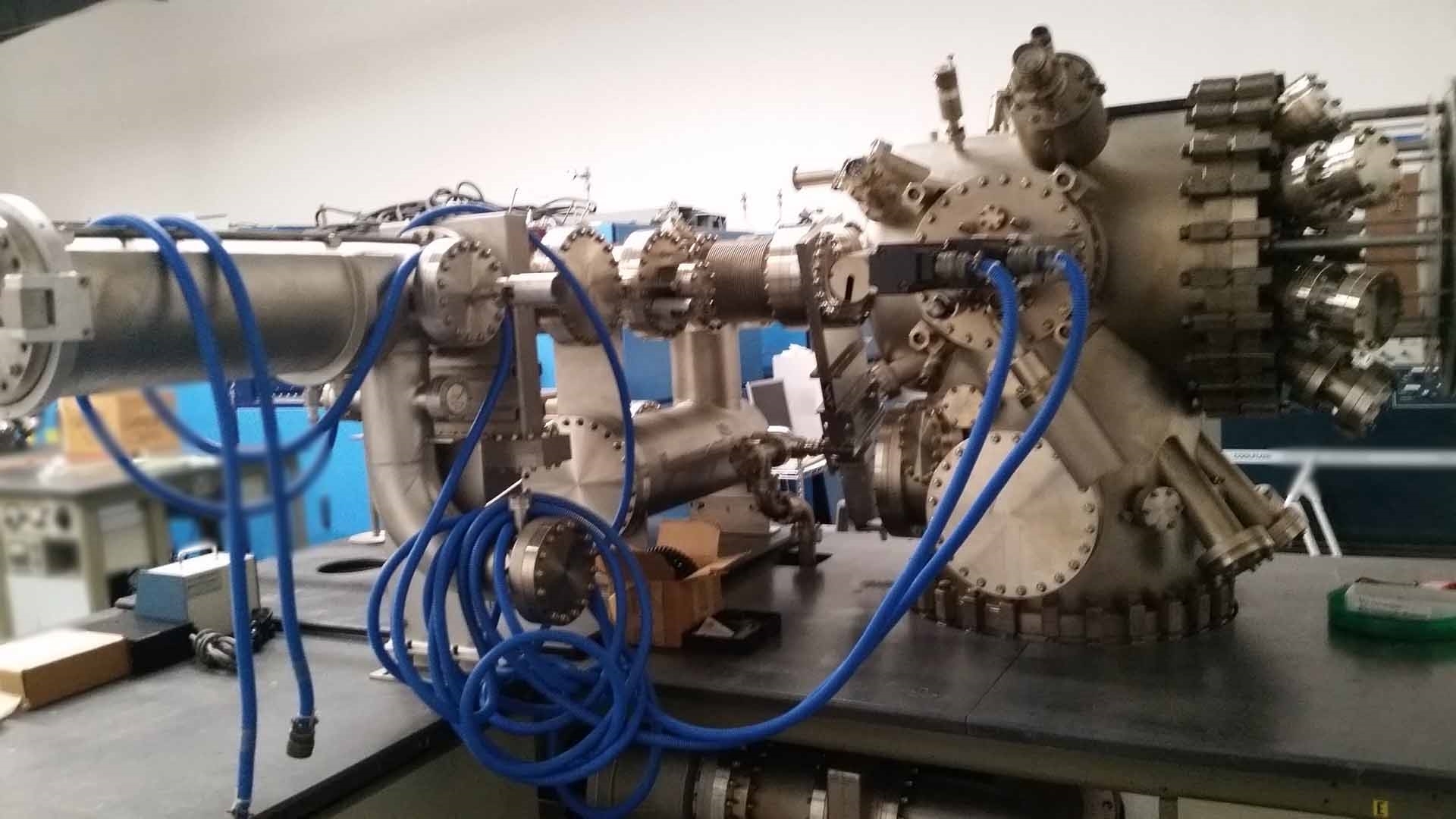

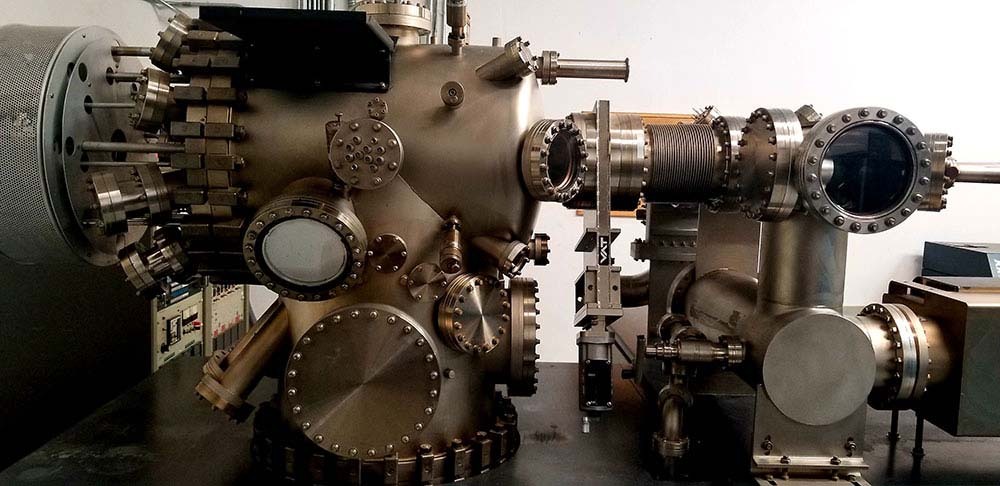

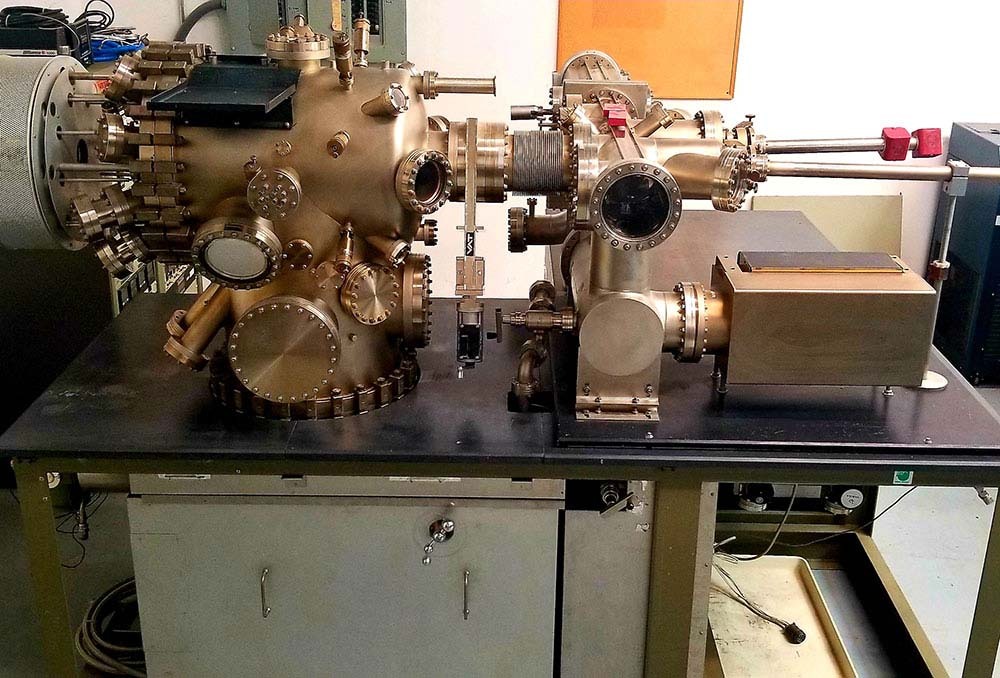

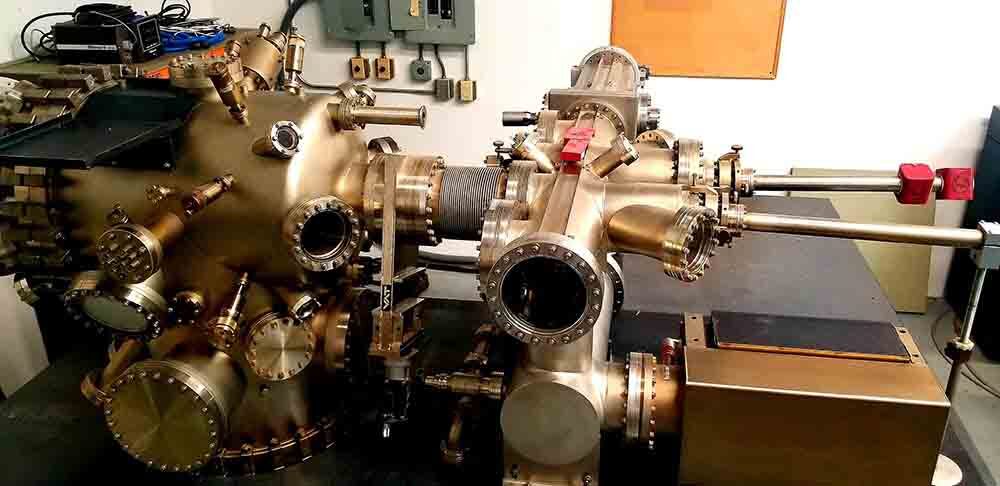

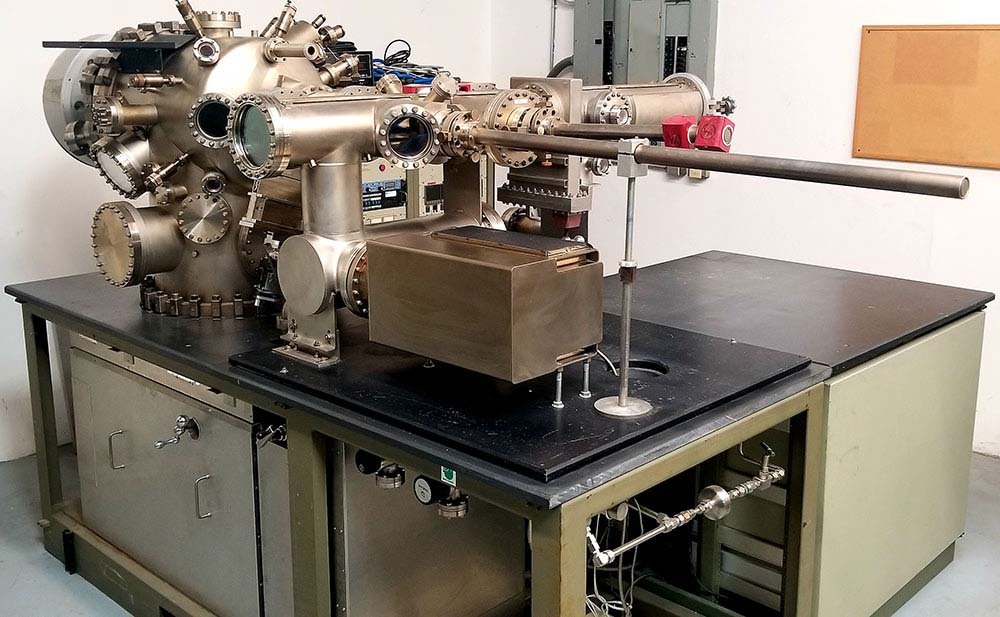

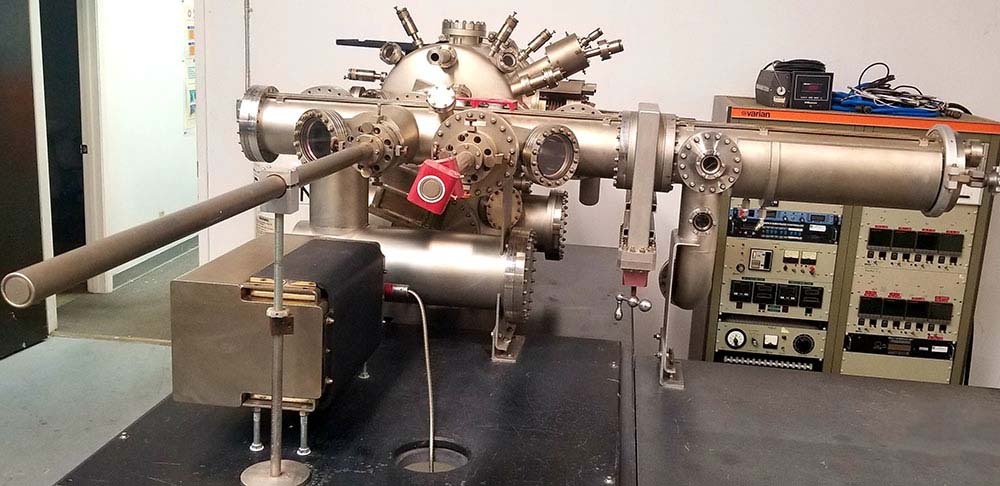

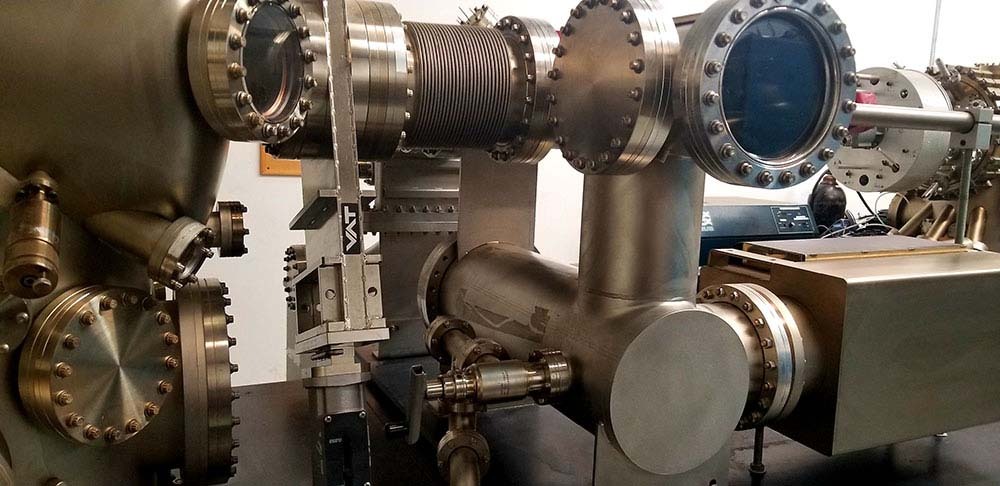

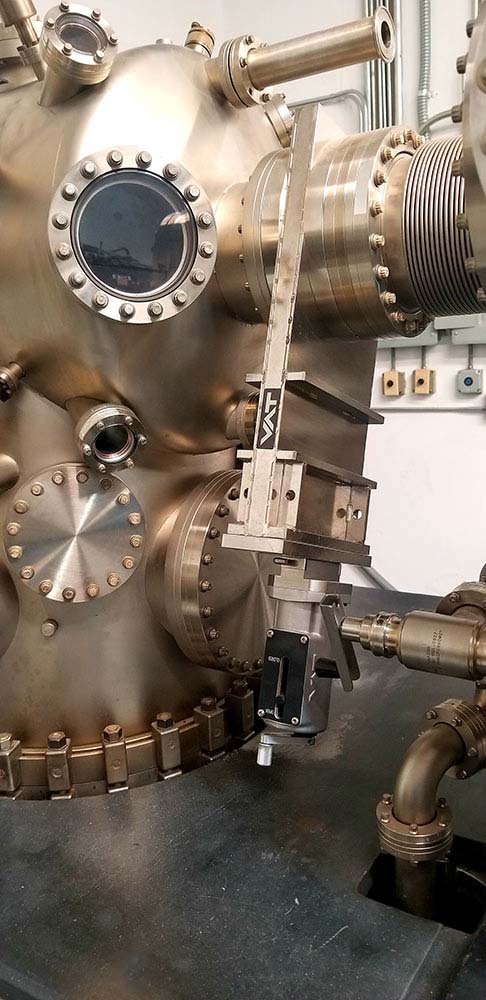

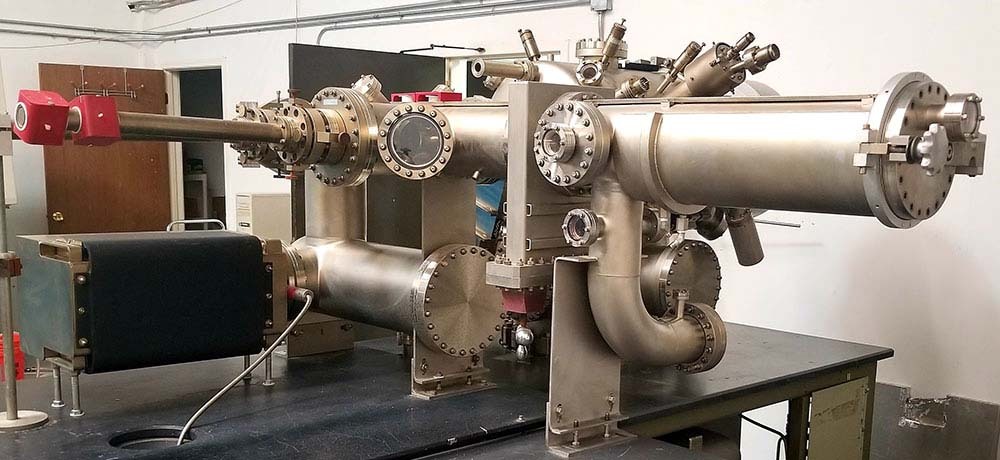

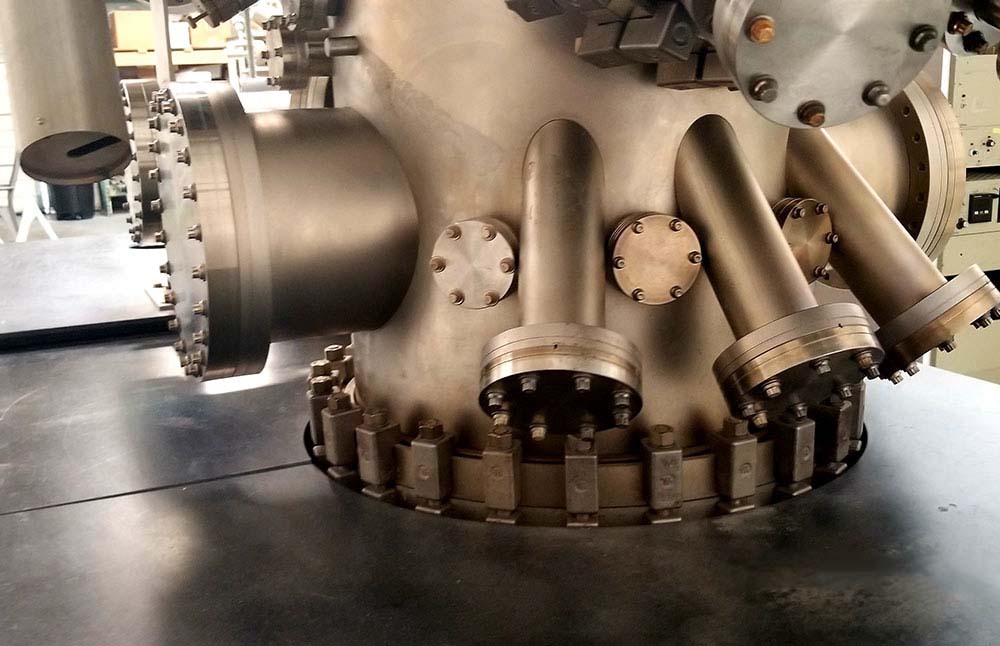

Used VEECO Gen II #9207238 for sale

URL successfully copied!

Tap to zoom

ID: 9207238

Wafer Size: 3"

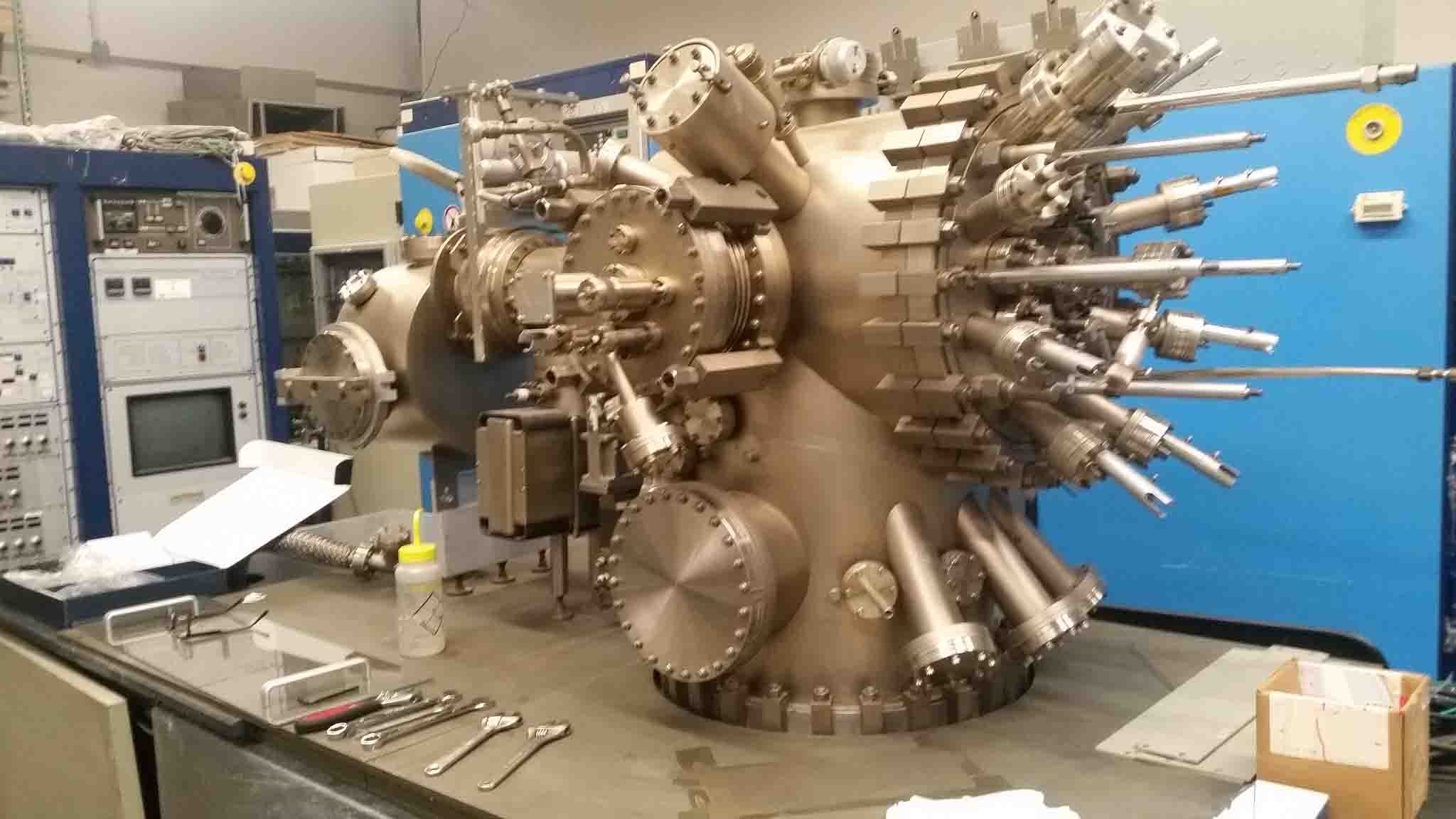

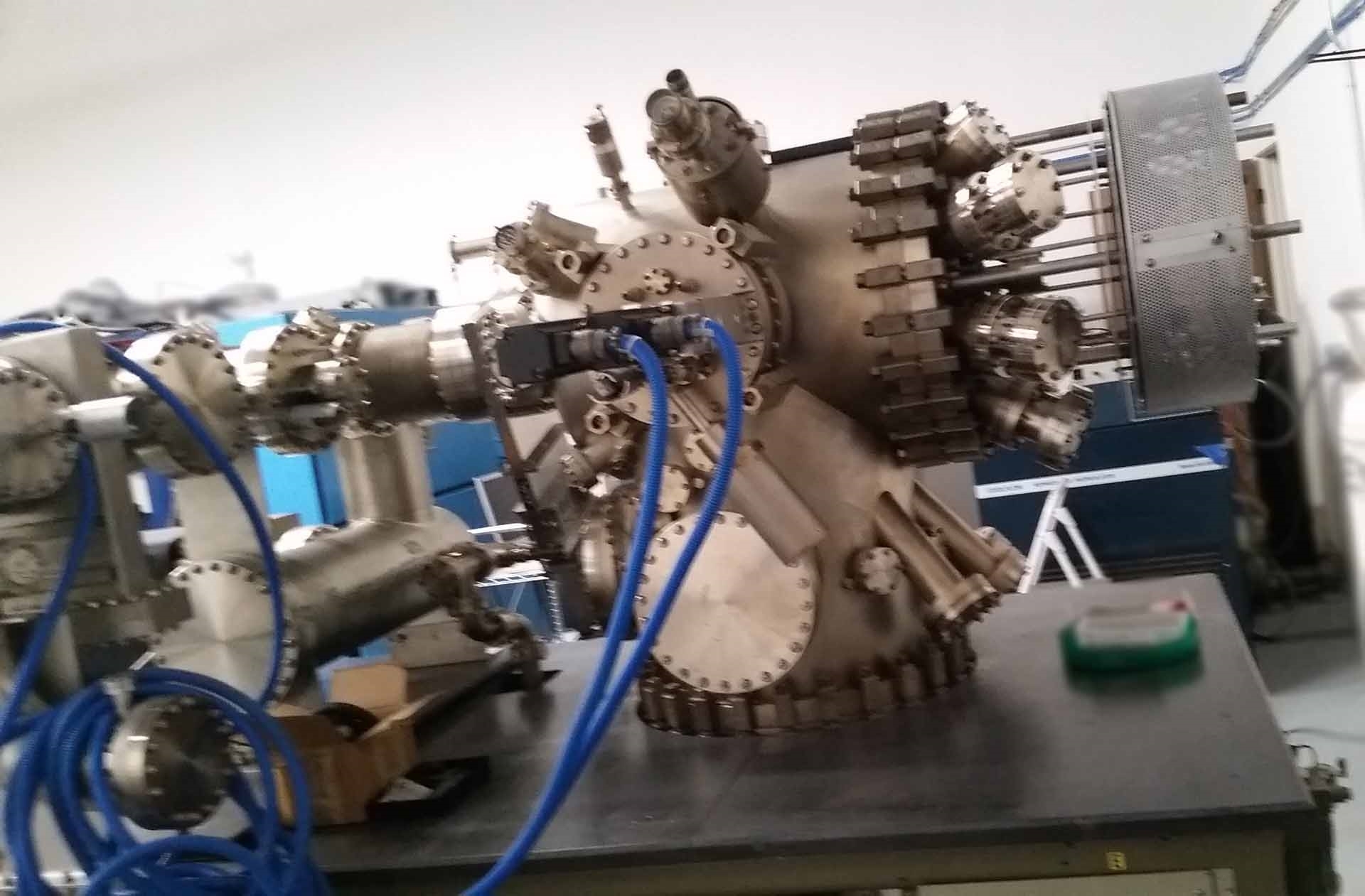

MBE System, 3"

For III / V growth

Sources: Flange, 4.5"

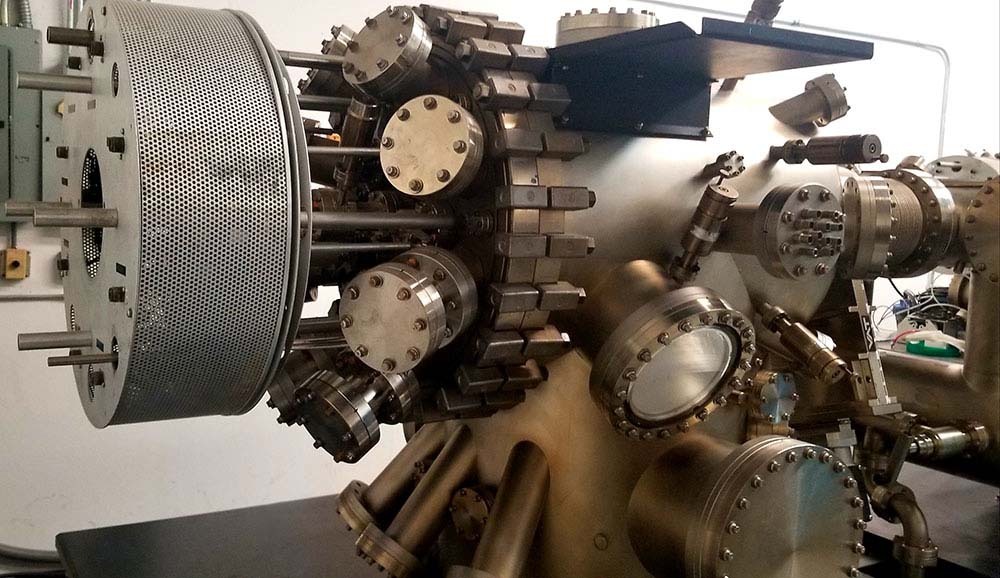

(8) Sources:

(2) Ga

(2) In

Al

Si

Be

Valved as cracker

RHEED / QMS

(2) Ion pumps

Growth chamber: 400 Liters

Prep chamber: 220 Liters

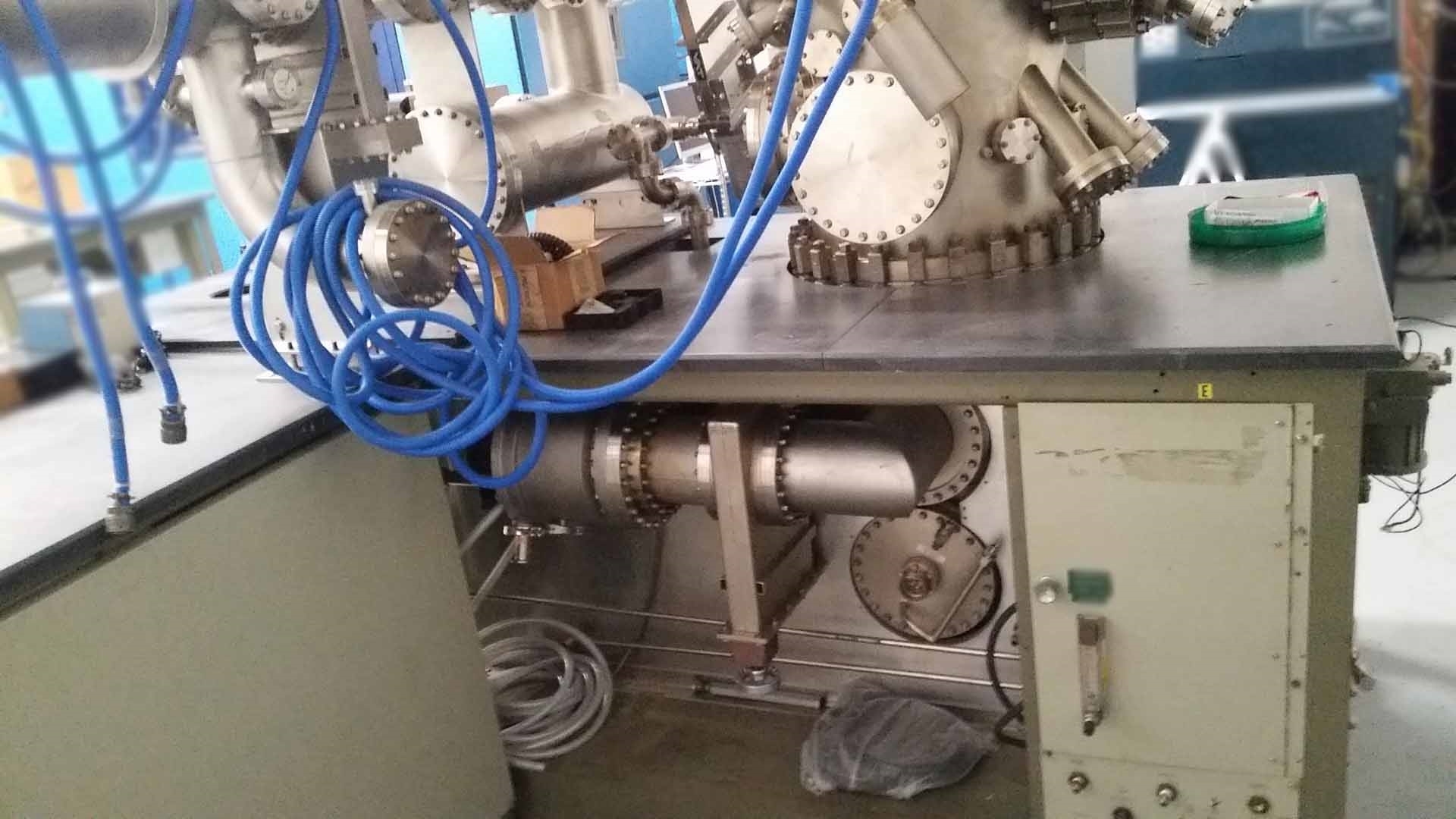

Cryo pump for growth chamber

Turbo pump and mechanical pump for load lock

Bake out panels

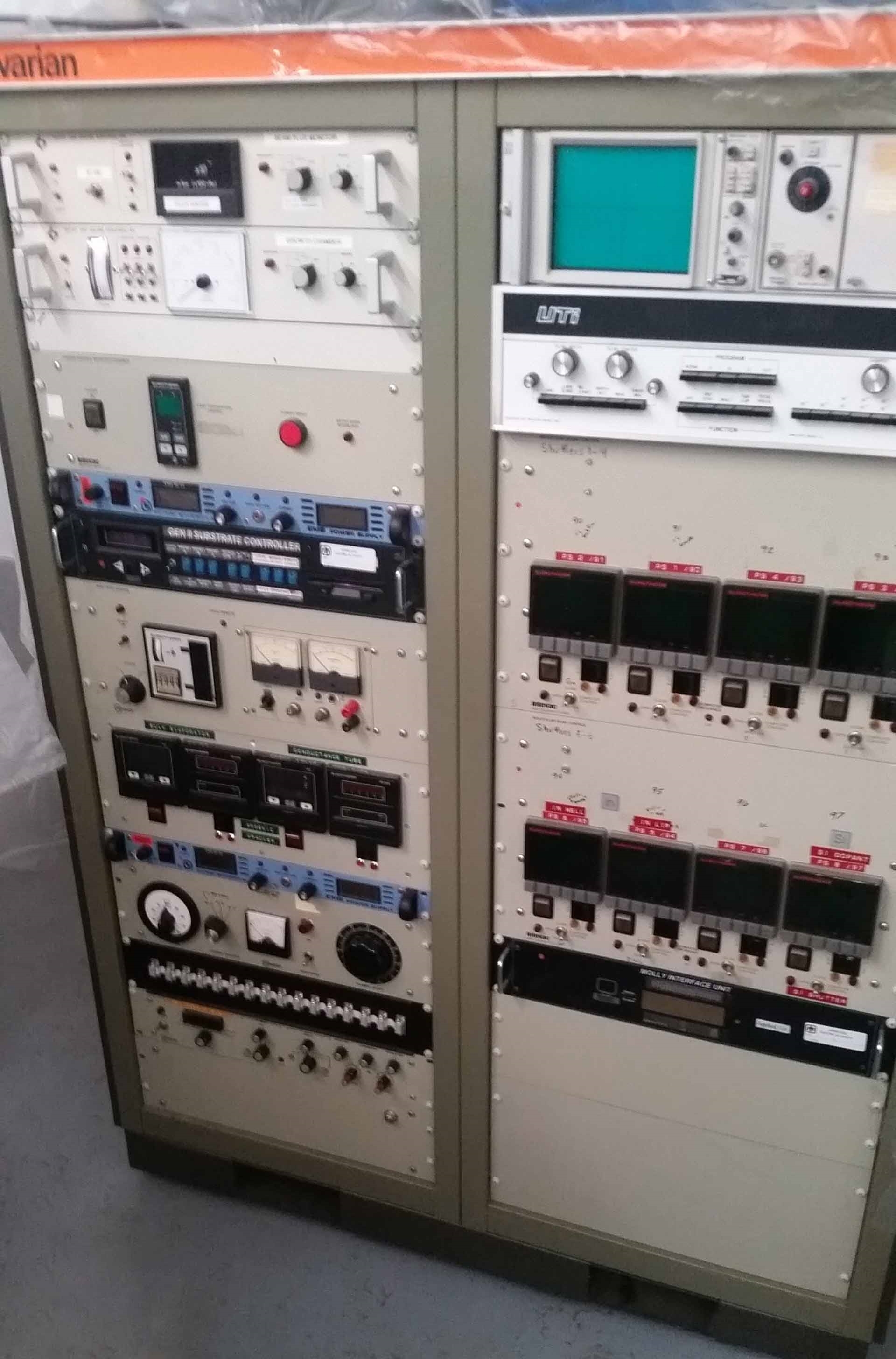

AMBER

Nitrogen / Oxygen RF plasma source

Power supplies

Temperature controller

Servo motor control

Sample manipulator with control system, 3"

Sample holders

Clean chamber

Crucible size: 30 to 60 cc

CTI8 Cryo pump

Turbo pump size: 140 Liter per second

Substrate heater: 1000°C

(3) Ion gauges

Pyrometer

PC

(5) Sample holders.

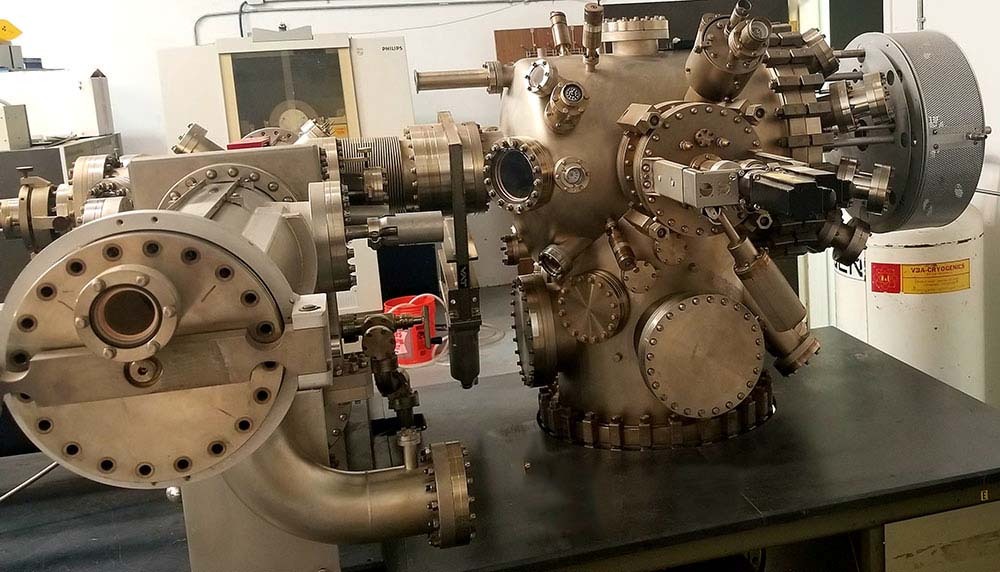

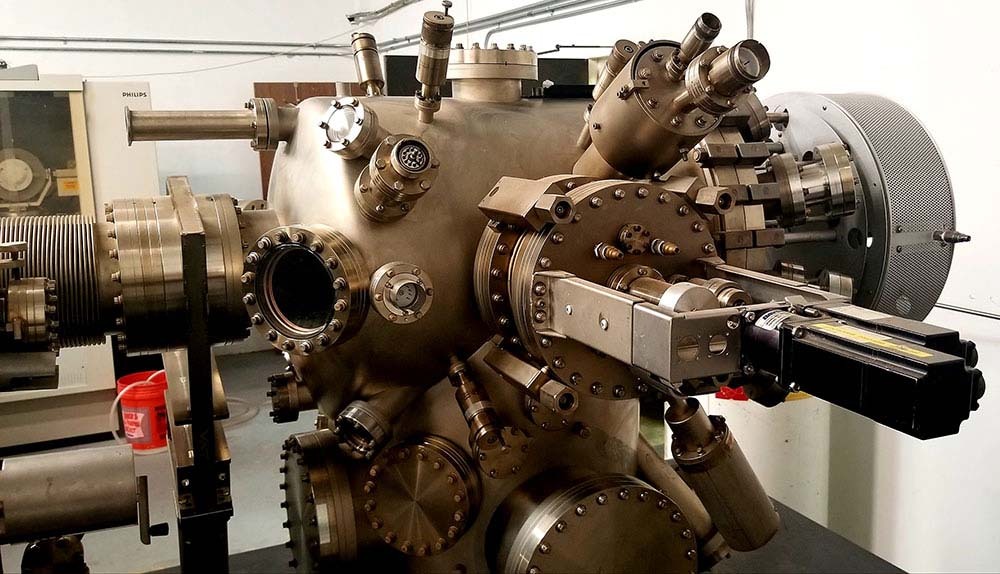

A VARIAN / VEECO GEN II is a sophisticated form of Molecular Beam Epitaxy (MBE) equipment designed for advanced research and development in the field of semiconductor material sciences. This machine provides precise control in the growth of nanometer-scale layers of material from single atoms to complex molecules. The system is capable of performing multi-atomic layer-by-layer growth processes with ultimate uniformity and controllability. At the heart of the unit is the MBE cell, which is divided into two separate chambers. The first chamber is the sample holder, or substrate holder, which is designed to securely accommodate a wide variety of basic substrate types, including wafers, substrates, epitaxial layers and other materials. The sample holder is then heated to the desired temperature and is monitored by a thermocouple. Inside the MBE cell, the substrate is positioned in an ultra-high vacuum chamber and is managed by several knobs and switches which are used to adjust parameters such as pressure, temperature and flow rate. The second chamber contains several gas sources which are used to create the various materials needed for the epitaxy process. These sources can include elemental sources, such as arsenic and phosphorus, and molecular sources of more complex molecules such as hydrogen selenide. The gases are then transported to the sample holder chamber, usually via an effusion heater, where they are exposed to a substrate and can be used to generate compound layers. The machine also contains several MBE control subsystems which manage these processes, such as the thermal and pressure control systems, the RF scanning stage and the Automatic Tuning and Calibration (ATC) tool. The ATC provides comprehensive feedback information about the growth processes and ensures that the proper conditions are established for each layer of deposition. Overall, VEECO GEN II asset provides a comprehensive and precise tool for the advanced research and development of semiconductor material systems. The model offers superior control of a variety of parameters, allowing for controlled growth of complex materials to nano-scale levels. With the advanced features of this equipment, researchers are able to create custom and precise nanostructures which can be used in a variety of applications and research areas.

There are no reviews yet