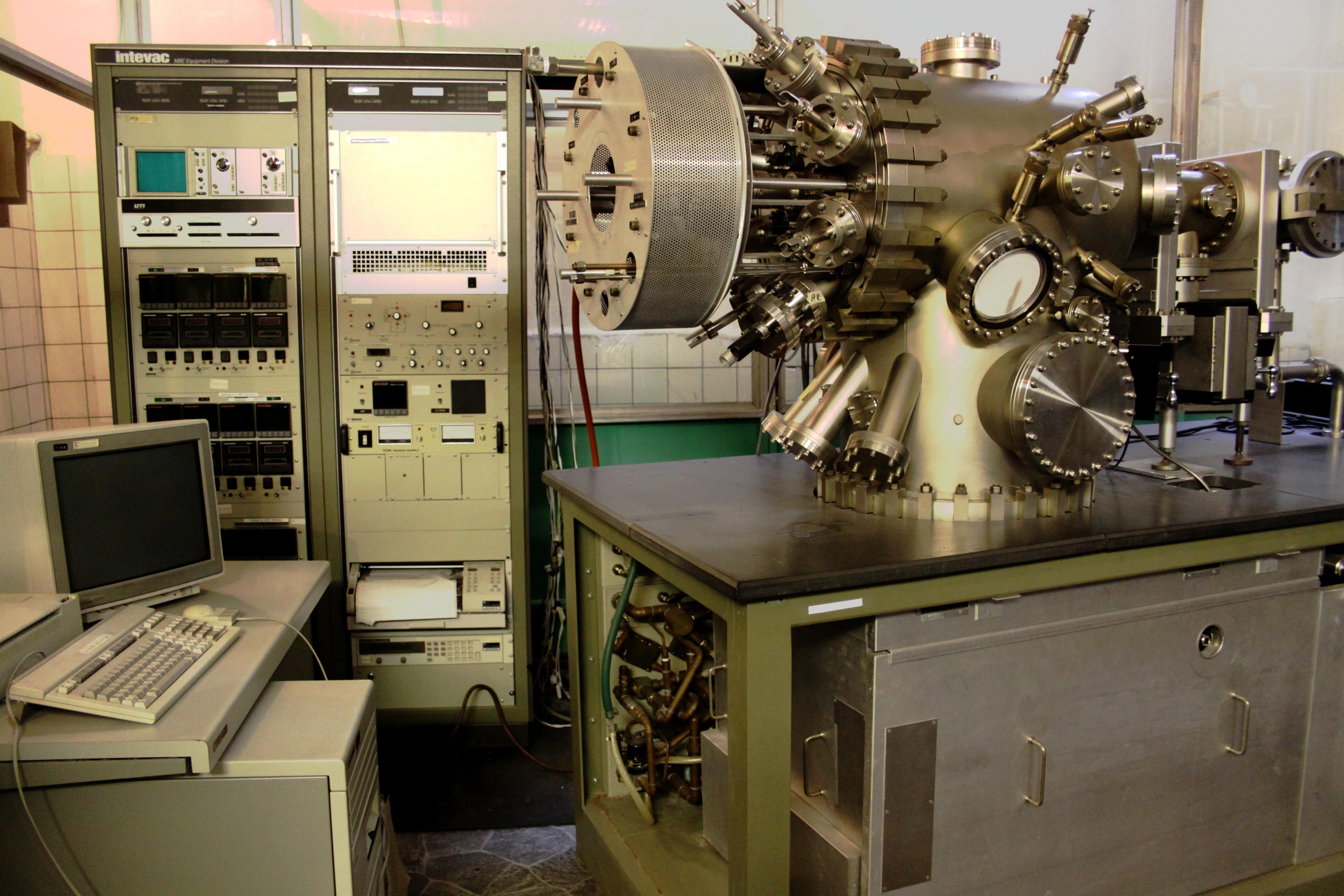

Used VEECO Gen II #9214855 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9214855

Vintage: 1982

MBE System

MBE Switching unit

Low vacuum gauges

Low vacuum and loading chamber vacuum measuring unit

Loading chamber

Magnetic-discharge pump

Technological chamber with (8) molecular sources

With diffractometer screen

Units for residual gases control

Backside equipment with idle cryo-pump

Molecular sources control unit (Left)

Manual cover sheet

1982 vintage.

VARIAN / VEECO GEN II Molecular Beam Epitaxy (MBE) equipment is a highly advanced, state-of-the-art thin-film deposition system used for creating bespoke, nanostructured materials. MBE is an ultra-high vacuum, molecular-level deposition technique for thin-film deposition and hetero-structuring with the capability to fabricate material structures down to atomic-level layer thickness with superior uniformity and crystallinity. VEECO GEN II MBE unit is a particularly powerful machine, offering industry-leading functionality with extraordinary levels of precision and reproducibility. The machine comprised of an ultra-high vacuum chamber, a six crucible effusion cell evaporation tool, two electron beam evaporators, two ion guns and an automated temperature controller. It includes advanced in-situ temperature measurement systems, a view-port, a quadrupole mass spectrometer, plus a deposition control asset for simple, user friendly control and process tracking. VARIAN GEN II model is capable of fabricating multiple material systems based on a variety of materials, including group III-V semiconductors, oxides, metals and alloys. GEN II equipment is used for thin-film deposition of epitaxial layers, as well as for fabrication of nanostructures for optoelectronic and energy storage applications. During the process, high-precision rate controllers provide users with complete control of substrate temperature and layer thickness, as well as a comprehensive selection of source temperatures. The system's deposition controllers also allow users to monitor deposition rates in real-time, which allows control of material uniformity and layer thickness with increased accuracy. Users can also program in-situ cleaning cycles during deposition, minimizing contamination and providing superior crystallinity and total area coverage. VARIAN / VEECO GEN II MBE unit is an incredibly versatile and capable production machine for the fabrication of high-quality thin-film materials for numerous advanced applications. With its advanced ultra-high vacuum process, the tool enables the production of quality nanostructured materials with total area coverage, high-uniformity homo-epitaxial layers and high-mobility heterostructures. Combined with its advanced in-situ deposition monitoring capabilities and programmable temperature parameters, VEECO GEN II MBE asset offers unrivaled levels of precision and reproducibility.

There are no reviews yet