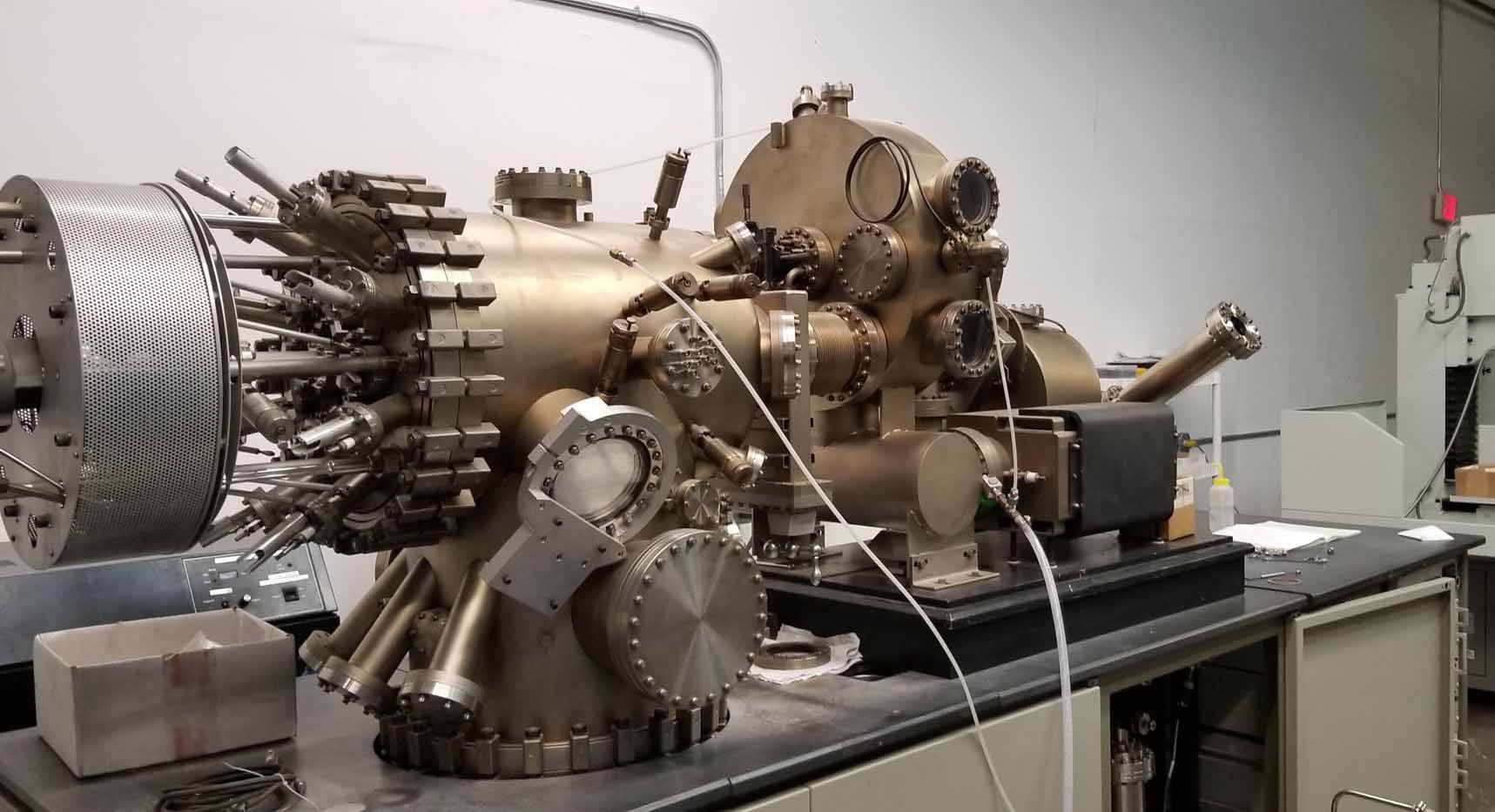

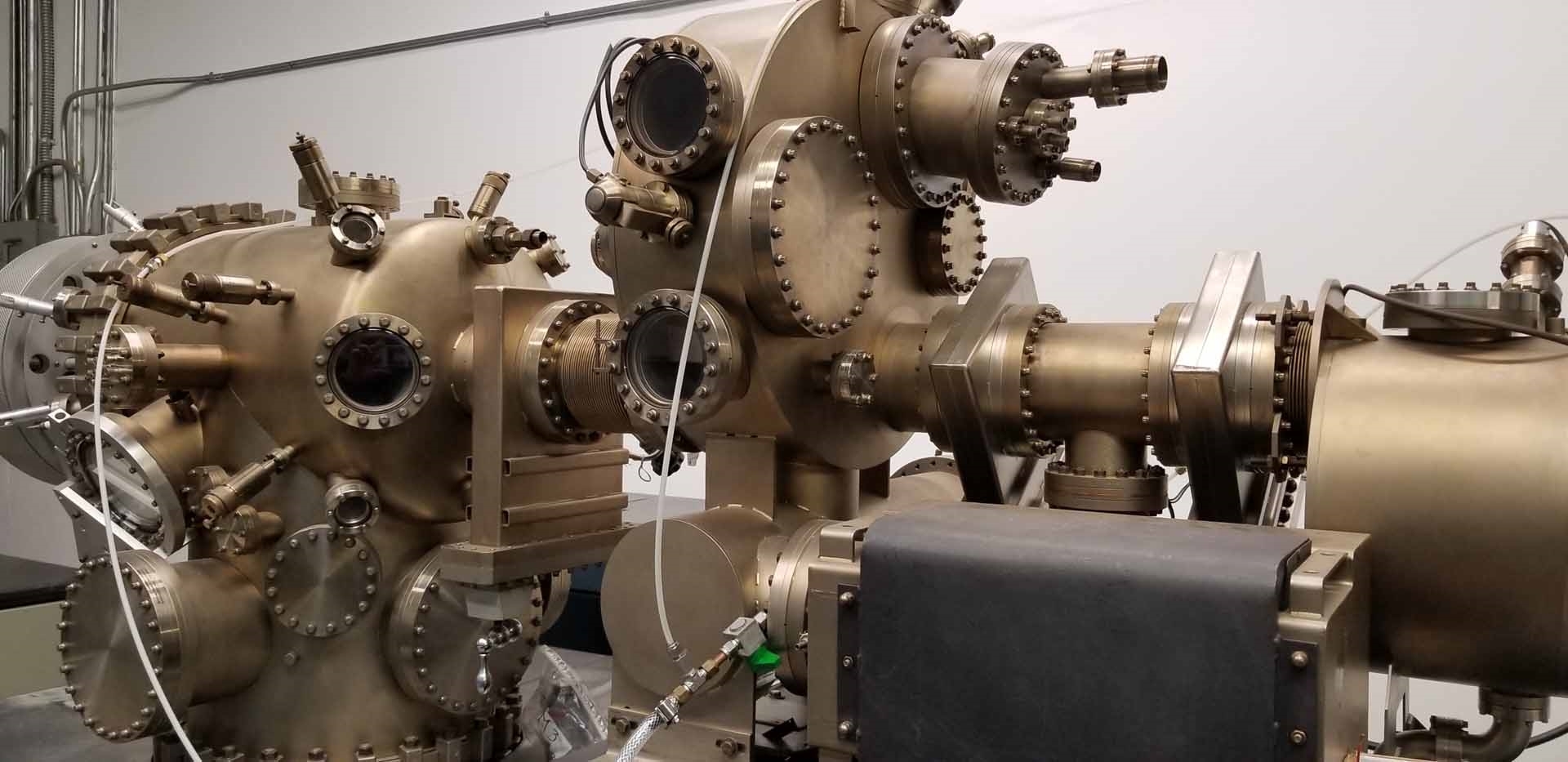

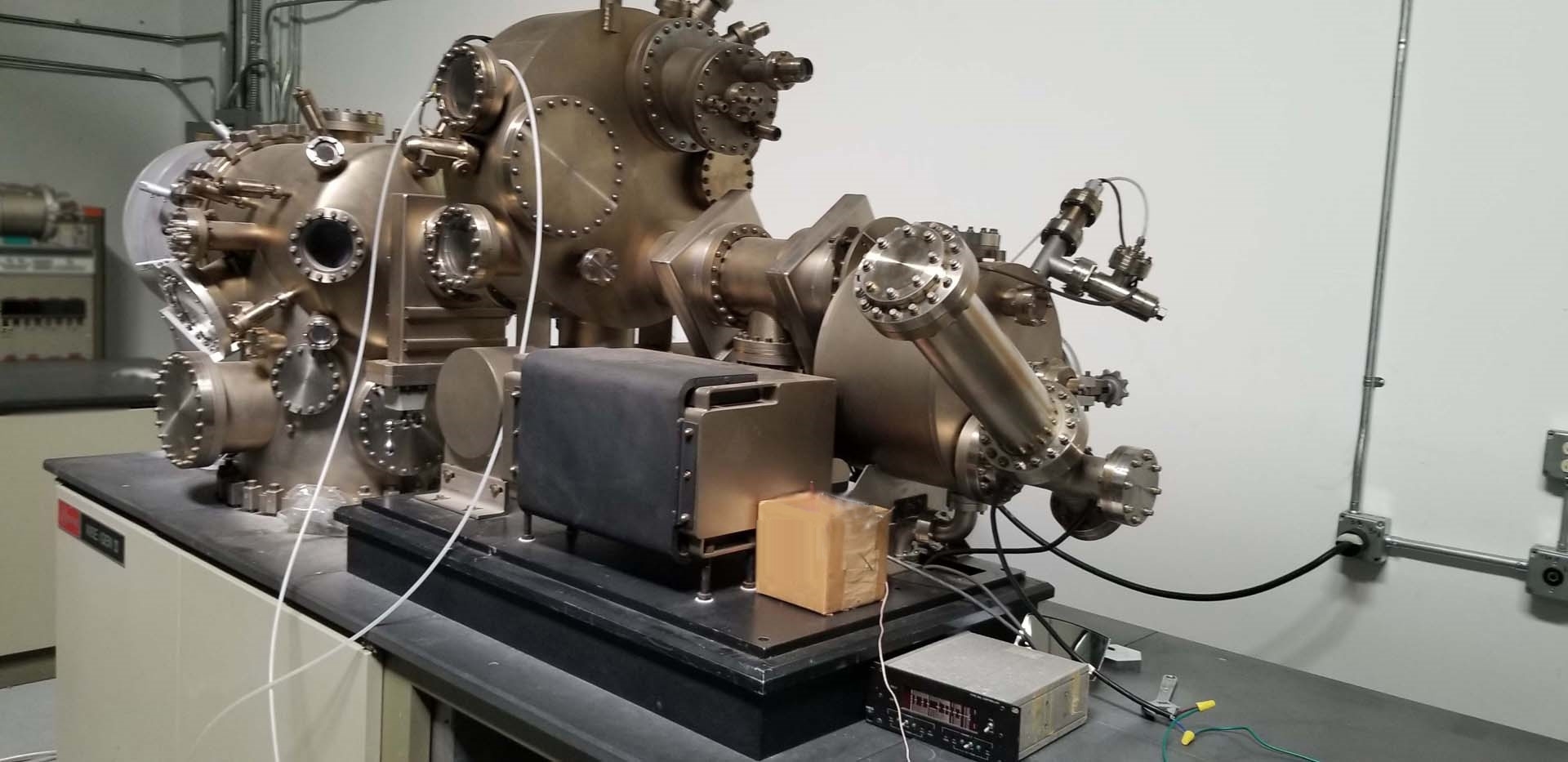

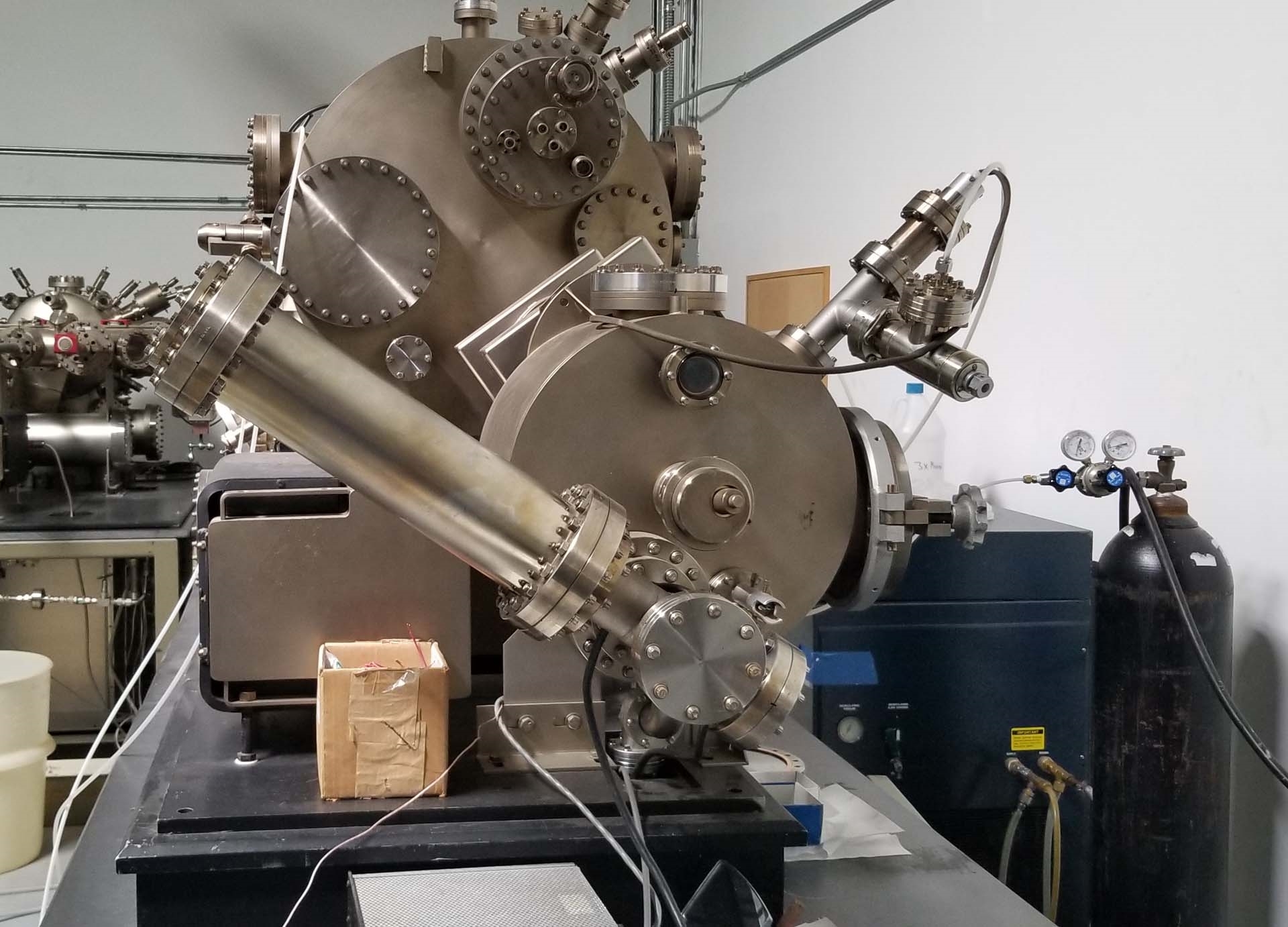

Used VEECO Gen II #9234453 for sale

URL successfully copied!

Tap to zoom

ID: 9234453

Wafer Size: 2"

Vintage: 1995

MBE System, 2"

Horizontal reactor

E-Beam

Single / Dual E-gun capability

Manual wafer transfer

Shutters included

Computer controlled

Process gases: GaAs, AlGaAs, InGaAs

Missing parts:

RHEED System

QMS System

Electronic rack

Sample manipulator

1995 vintage.

VARIAN / VEECO GEN II molecular beam epitaxy (MBE) equipment is a high-performance deposition system that is capable of creating high-quality epitaxial layers of materials on wafers. VEECO GEN II is capable of creating thin layers of semiconductor materials such as gallium arsenide (GaAs) on III/V compound semiconductor materials like indium phosphide (InP). The unit achieves this by using a combination of high-resolution evaporation sources and precise flux control, enabling the deposition of epitaxial layers with thickness down to less than one nanometer. VARIAN GEN II is equipped with two independent MBE cells, enabling simultaneous deposition of different layers for optoelectronic and other semiconductor device fabrication. Each MBE cell has three materials sources, with each one being configured independently to allow for the deposition of a single material to the wafer or a combination of up to three species simultaneously. These sources are independently heated to a temperature up to 1000°C, and the MBE cell allows precisely controlling the flux of these species until the desired layers are formed. GEN II is equipped with an RF plasma generator and an electron cyclotron resonance plasma source with external antennas. These plasma sources help to achieve better atomisation and higher deposition rates. This helps reduce the deposition time needed for MBE layers, saving time on fabrication and increasing production efficiency. VARIAN / VEECO GEN II also includes a highly accurate process monitoring and control machine. This tool allows simultaneous monitoring of several physical and chemical parameters during the growth process, ensuring that precise process control is maintained throughout. This asset allows MBE processes to be accurately conducted, resulting in the production of high-quality epitaxial layers. VEECO GEN II is equipped with a post-growth cleaning controller for removing residual material from the substrate surface. The model also includes a heating stage for pre- and post-growth treatments on up to 3-inch substrates, as well as a closed-loop automatic feedback control for monitoring and regulating the chamber pressure and other process parameters. VARIAN GEN II MBE equipment is an advanced, highly accurate epitaxial deposition system that enables the reliable production of high-quality epitaxial layers. The unit combines the power of high-resolution evaporation sources together with precise flux control, allowing for the growth of layers with thickness down to less than one nanometer. GEN II also includes a highly accurate process monitoring and control machine, allowing for highly precise conduct of MBE processes. The post-growth cleaning controller and heating stage effectively complete the growth process, helping to maintain high yields in the production of epitaxial layers.

There are no reviews yet