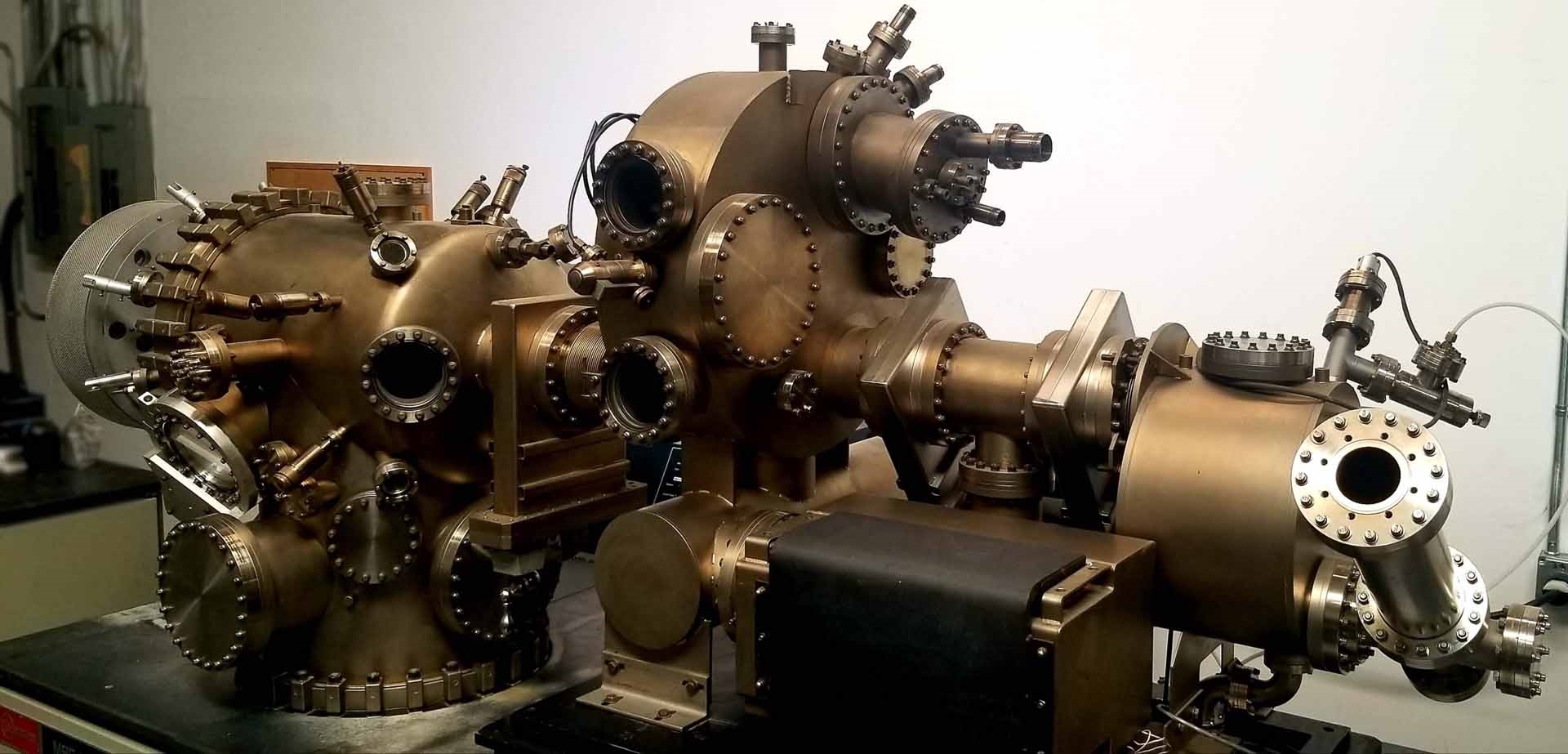

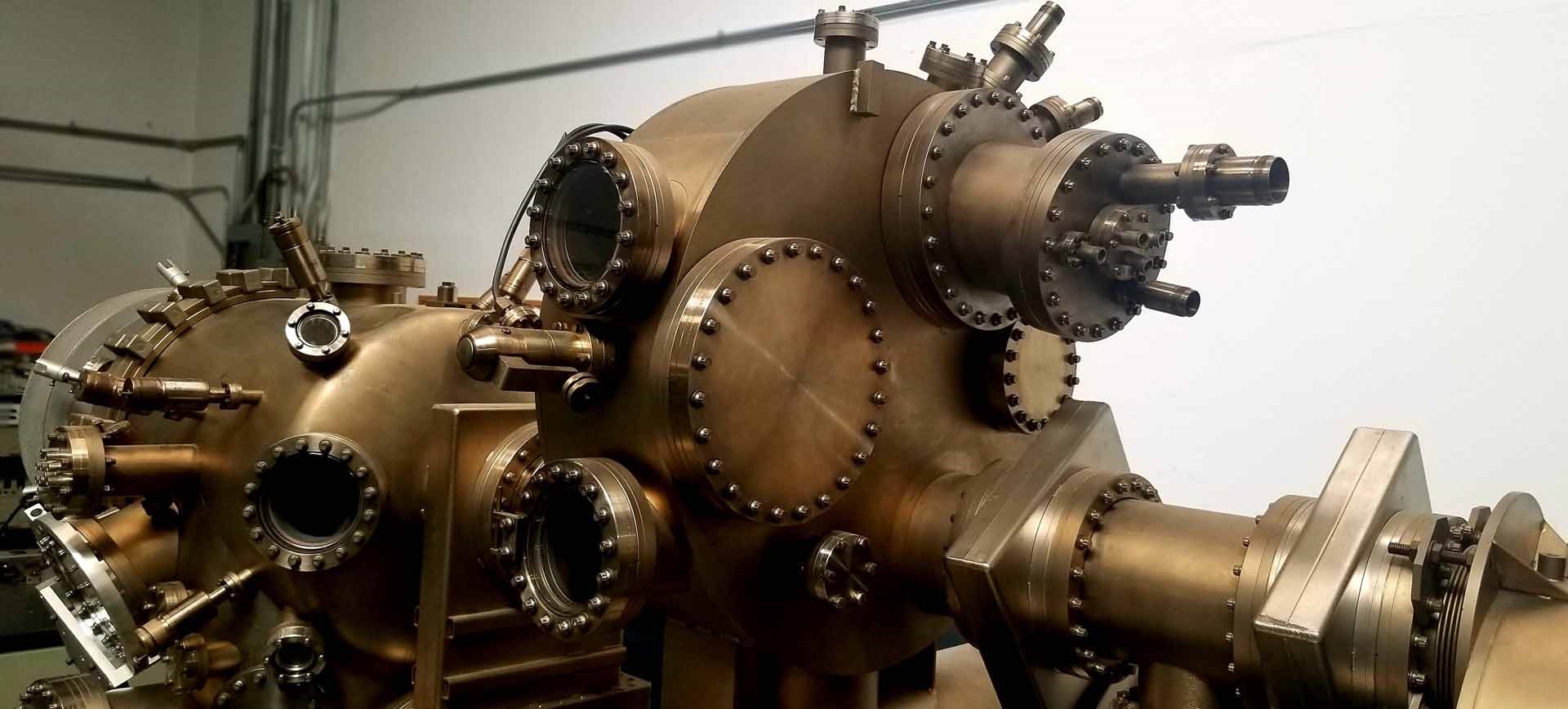

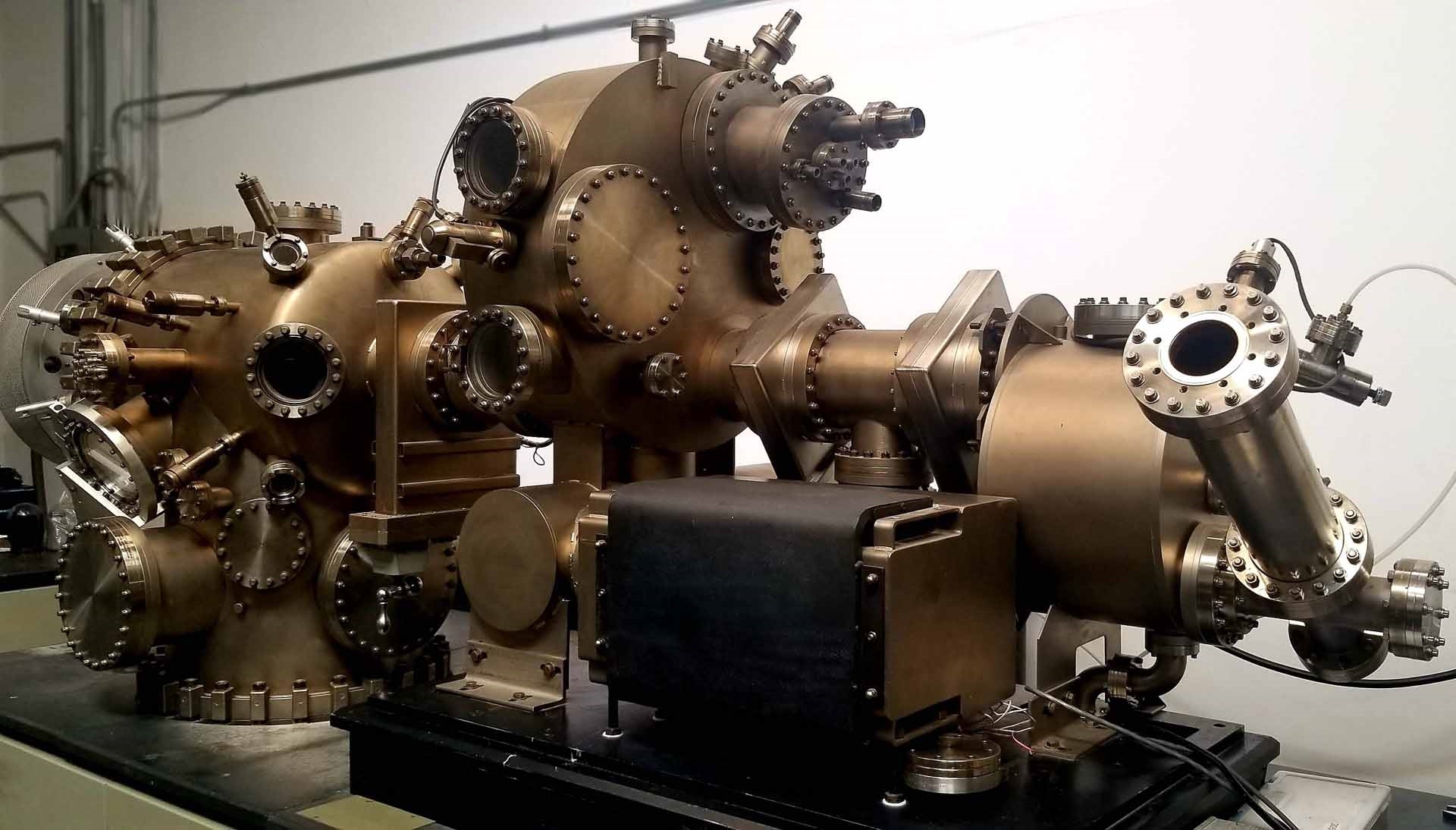

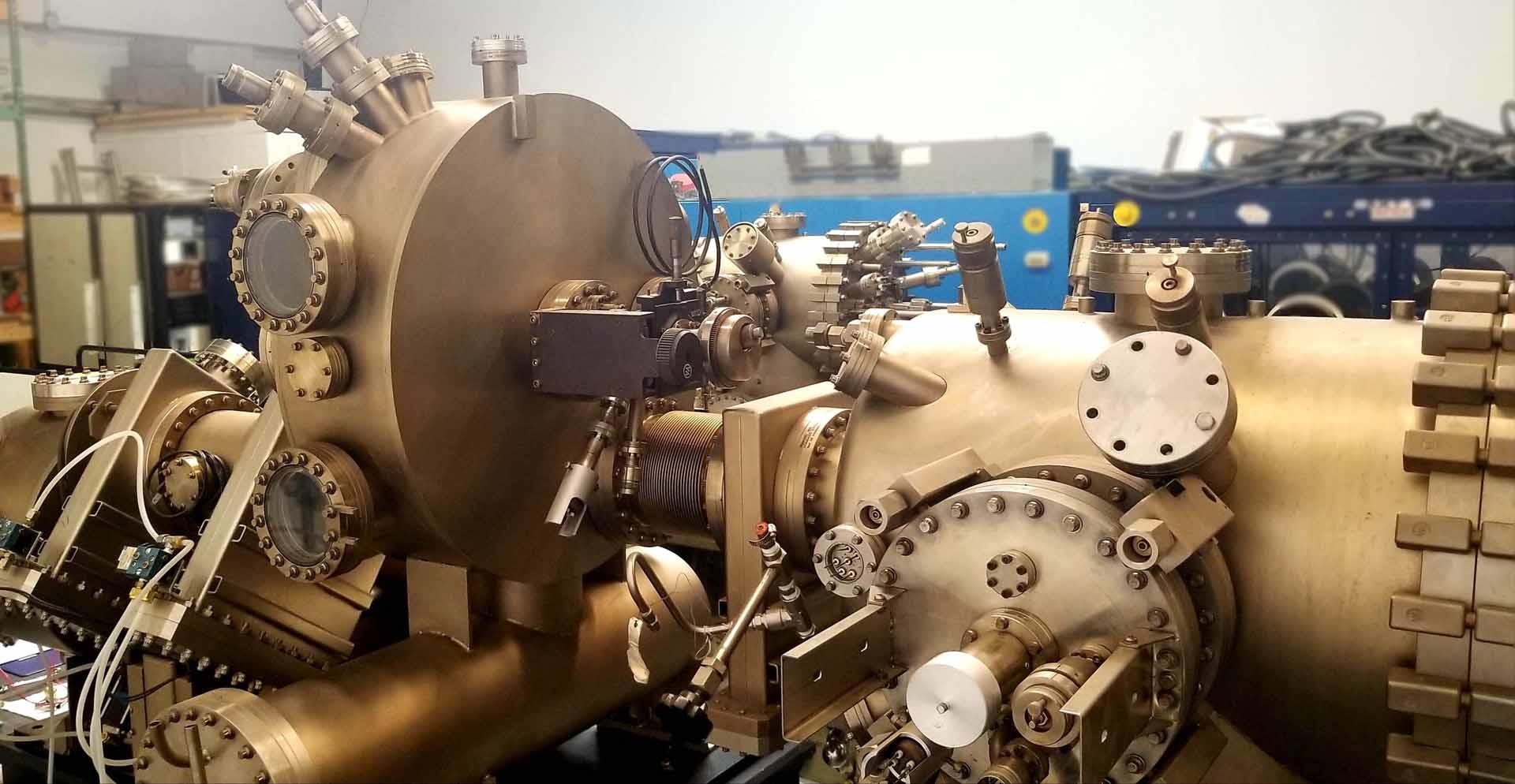

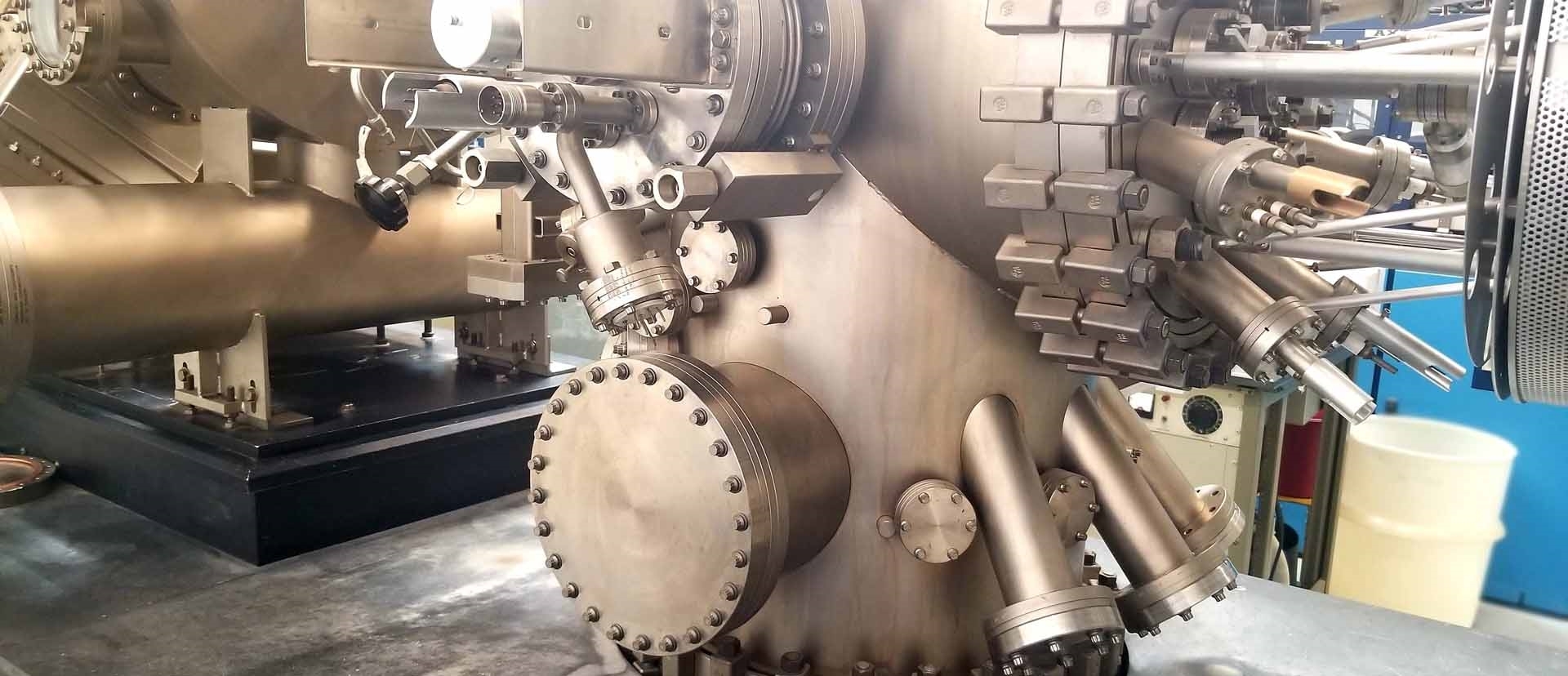

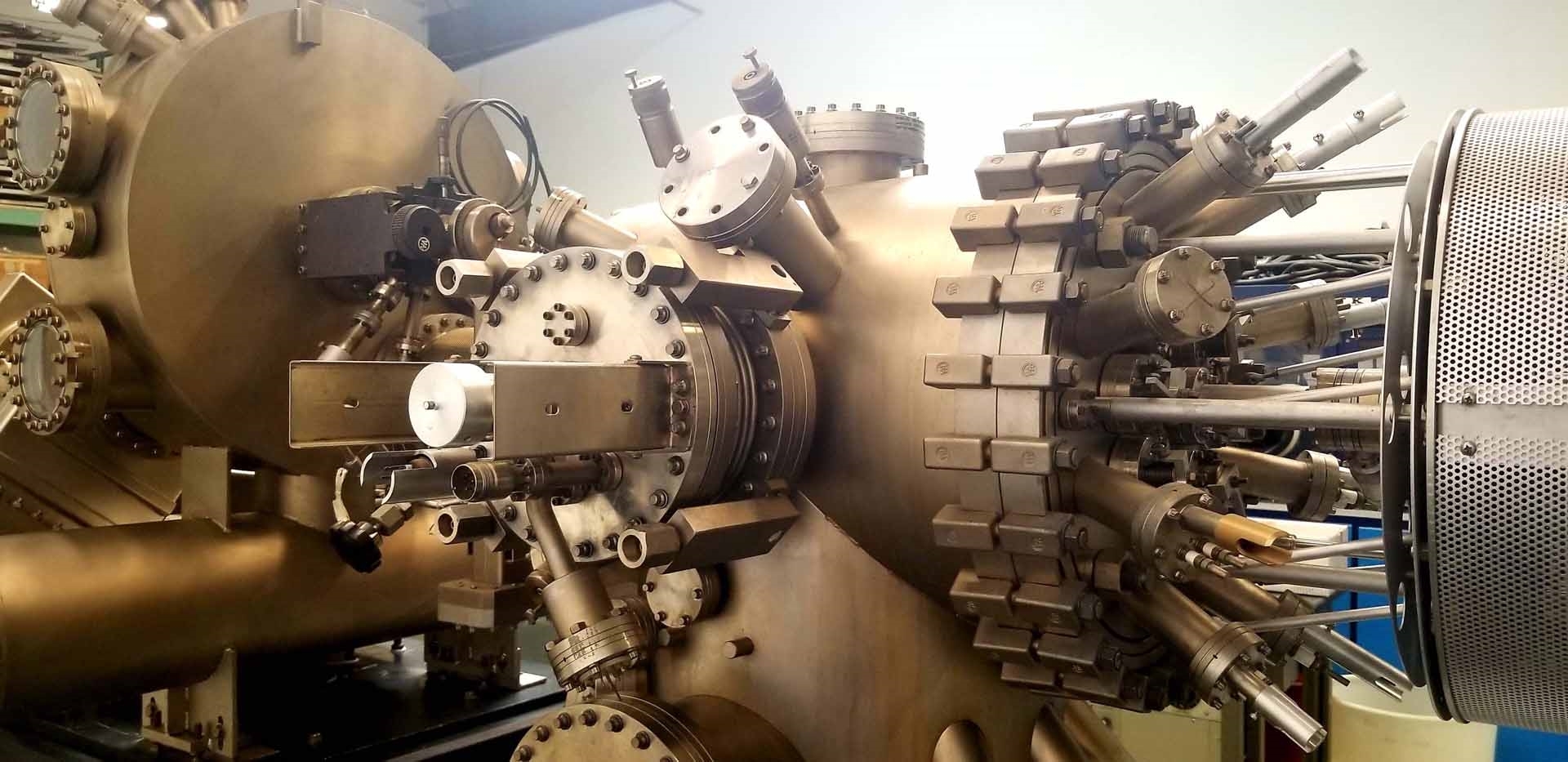

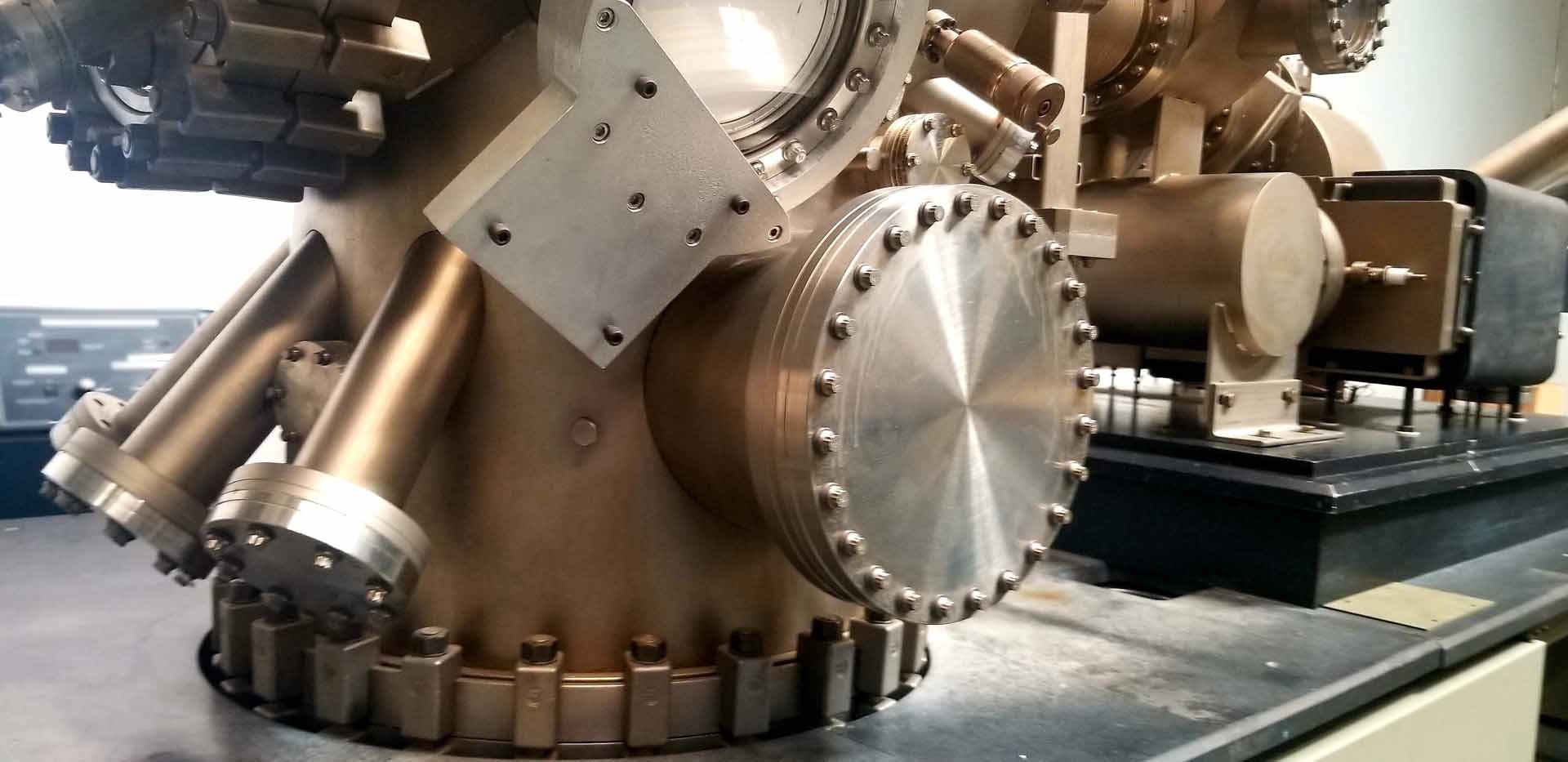

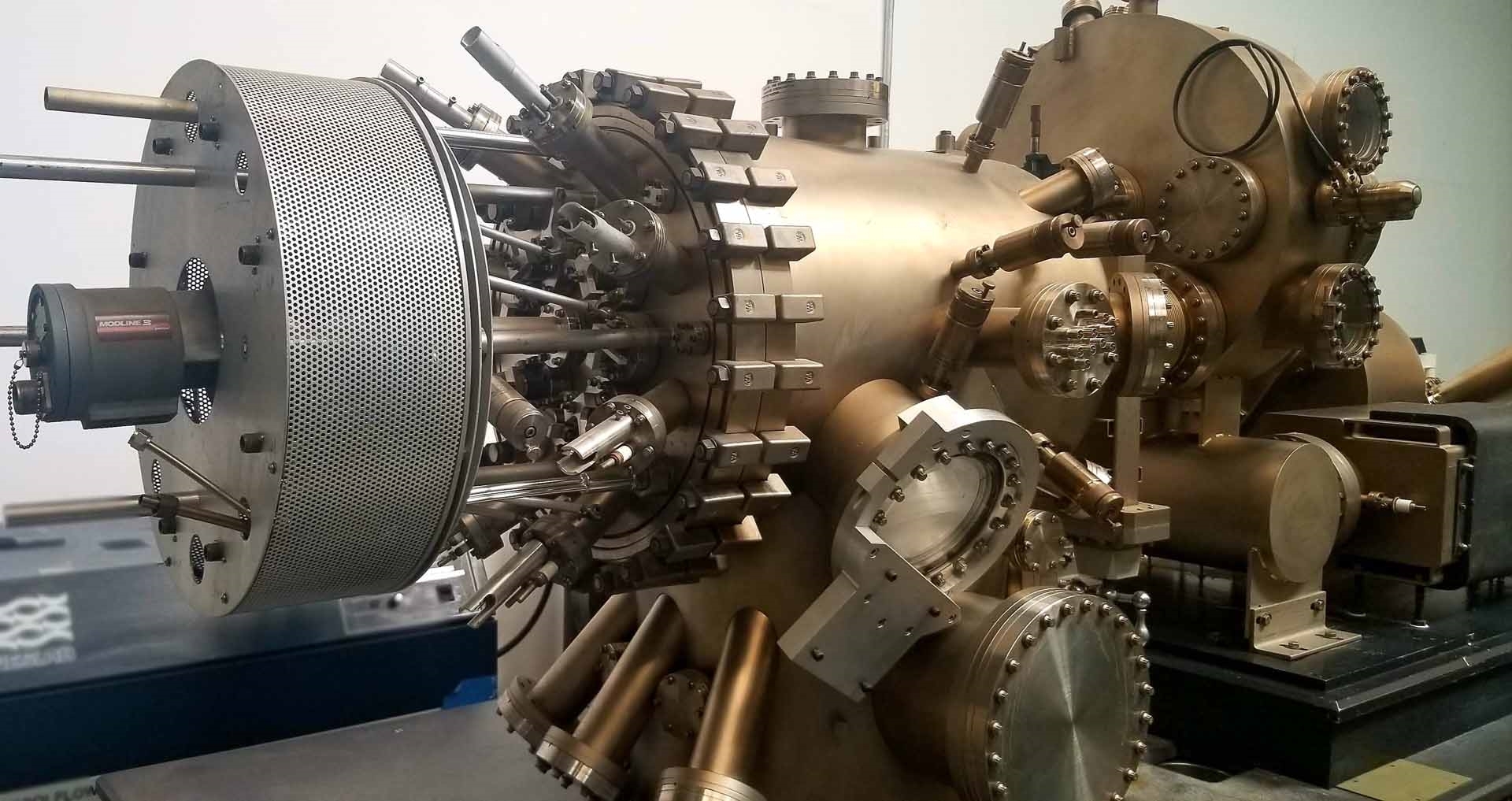

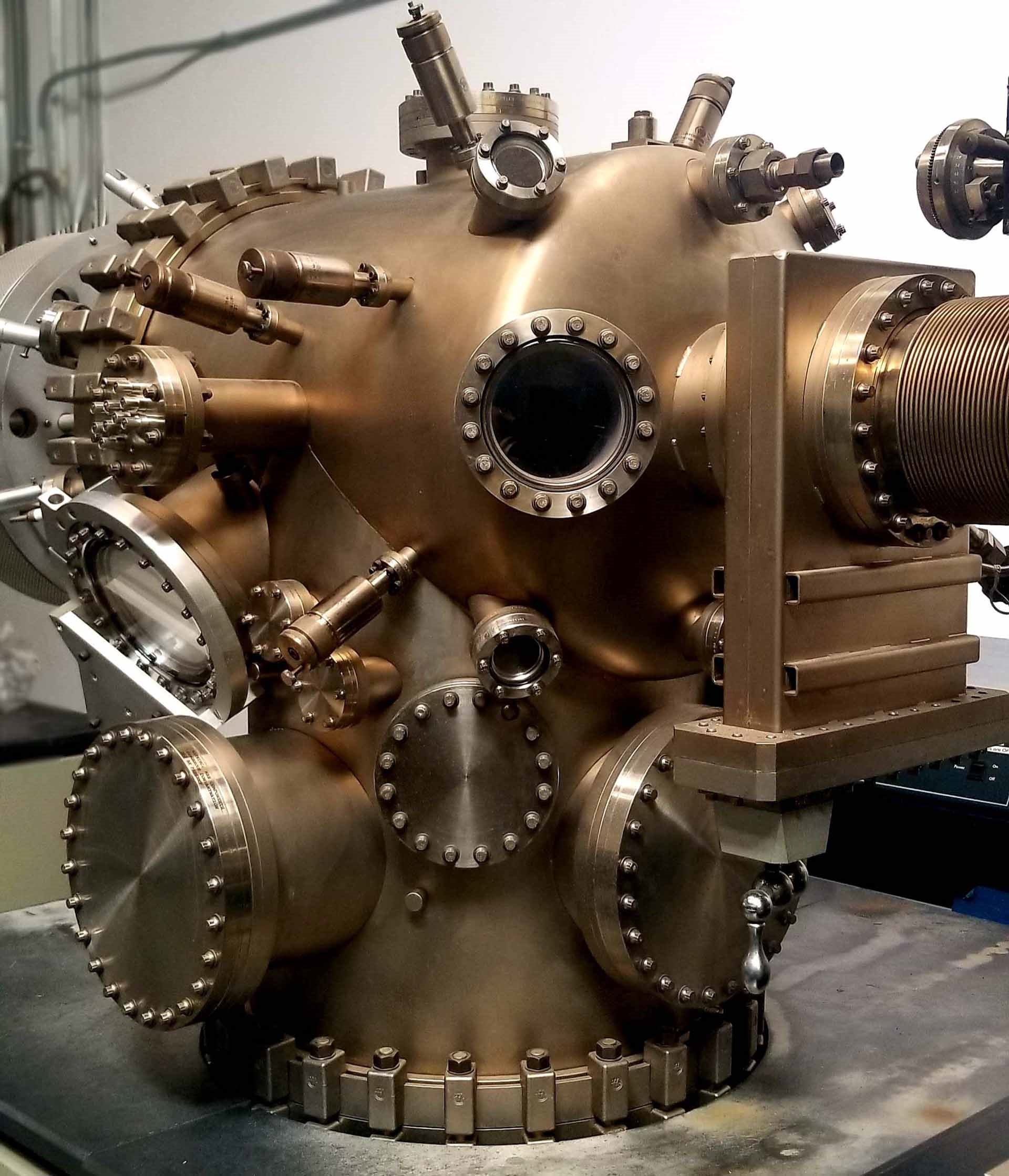

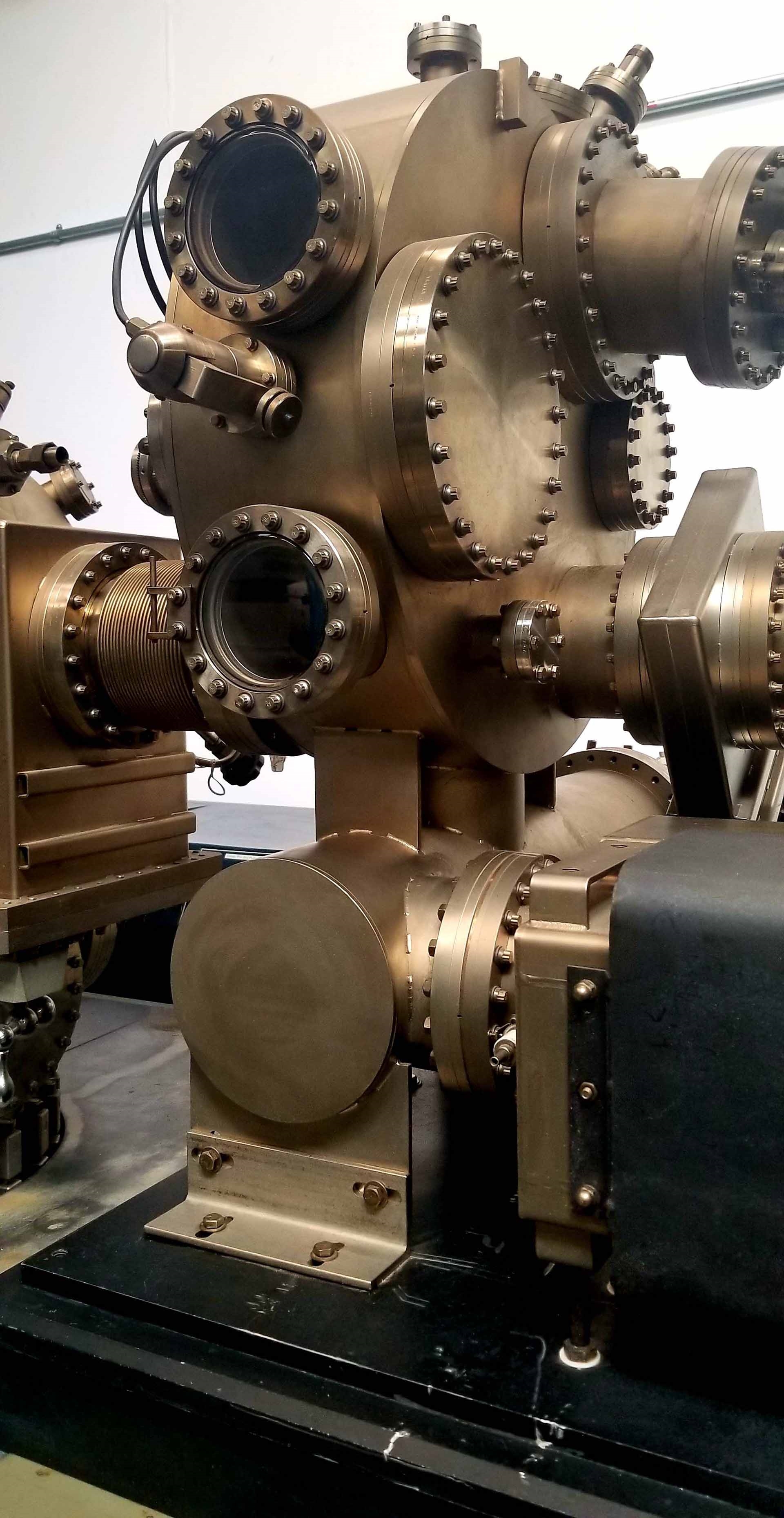

Used VEECO Gen II #9257149 for sale

URL successfully copied!

Tap to zoom

VARIAN / VEECO GEN II molecular beam epitaxy (MBE) equipment is a high-performance deposition and growth technology used in the semiconductor industry for the production of nanoscale structures and materials. It is capable of depositing and growing thin films of semiconductor, metallic, and other materials in a controlled, near-ideal environment. VEECO GEN II MBE system is designed around a modular hot-wall cavity with multiple sources for different elements, allowing for precise control of material growth. It has an ultra-high vacuum (UHV) unit, temperature-sensing thermocouple, and a closed-cycle cooling unit. The latter, in particular, helps ensure accurate temperature control and gas flow during the deposition process. The deposition process begins with a heated, high-purity source chamber, which is deposited onto a substrate that is held in place by a wafer-lift mechanism. To ensure a homogenous film, the parameters such as the substrate temperature and the flow of gases are precisely monitored and adjusted by an automated controller. An in-situ shutter and mass spectrometer are also used to monitor the accuracy and purity of the deposited material. VARIAN GEN II MBE machine also has the capability to produce multi-layer structures, with different materials on different levels inside the same substrate. This is achieved through a process called "graded multilayer deposition" and involves alternating the deposition of multiple layers of different materials, one layer on top of the other. This allows for the fabrication of multi-functional materials, such as transistors, LEDs, and photovoltaic cells. GEN II MBE tool is capable of producing high-quality, defect-free films with low levels of strain and stress. As a result, it has a wide range of applications in microelectronics, optoelectronics, and nanotechnology, making it a valuable tool in the semiconductor industry.

There are no reviews yet