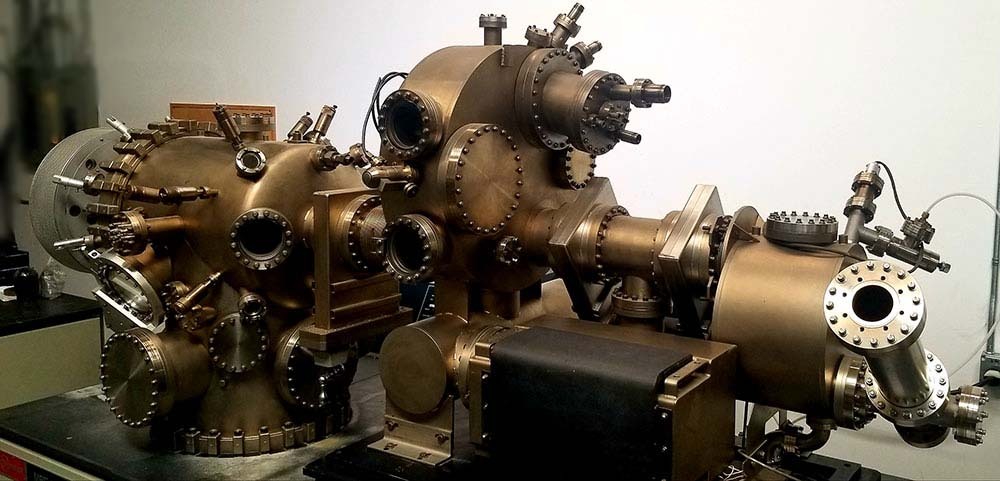

Used VEECO Gen II #9359602 for sale

URL successfully copied!

Tap to zoom

ID: 9359602

Wafer Size: 2"

MBE System, 2"

(8) Sources:

(7) 2.75" Flanges

4.5" Flange

Indium-free (6) sample holders with profiles

Substrate heater: Up to 900°C

Substrate manipulators:

Power supply

Temperature controller

Servo motor control unit

Clean chamber

Effusion cells

(2) Valve crackers

RF Plasma source: Nitrogen / Oxygen

Growth chamber pumps:

Ion pump: 400 l/m

Cryo pump, 10"

Prep chamber pumps: Ion pump

Load lock pumps: Sorption, mechanical, turbo pumps

(3) Ion gauges and controllers

RHEED and QMS Systems

Pyrometer

Computer

Panels.

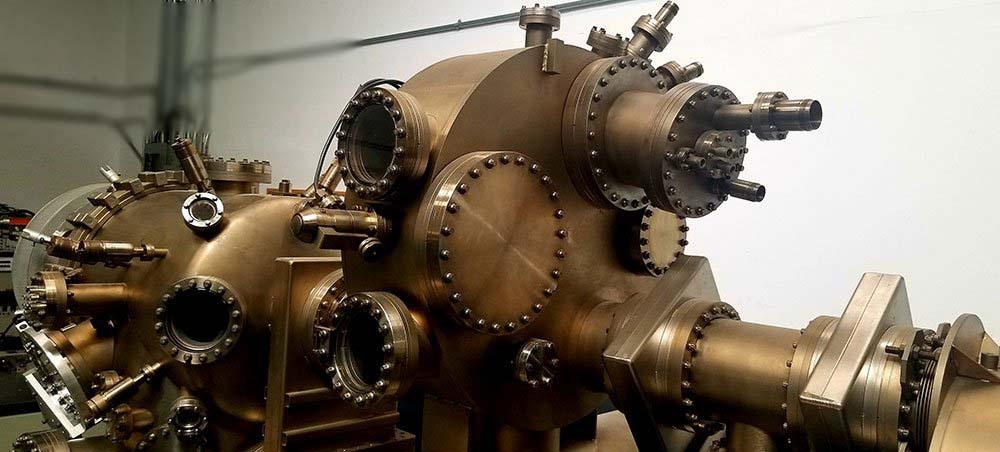

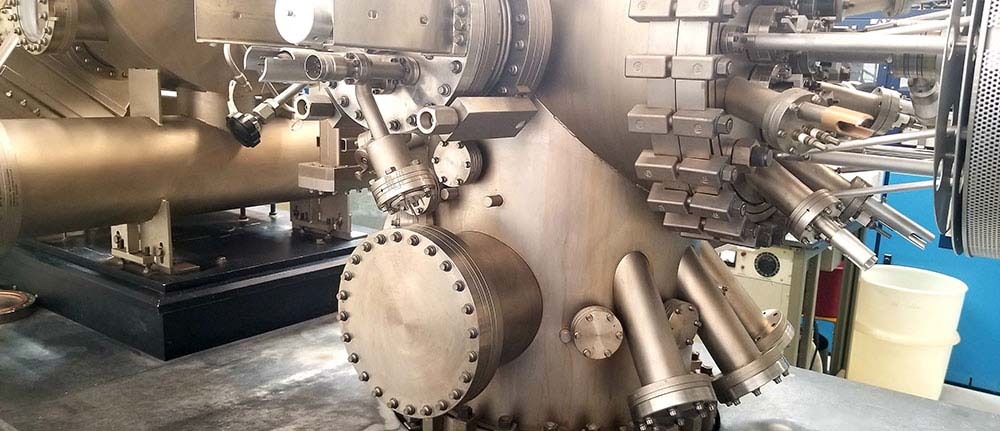

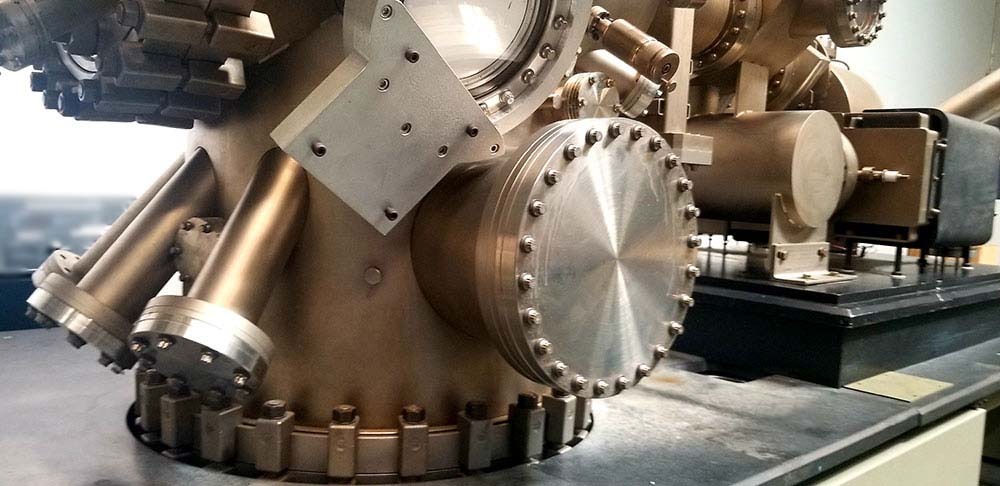

Molecular Beam Epitaxy (MBE) is a complex thin-film deposition process used to create atomically-precise layers of materials for a variety of microelectronic device applications. VARIAN / VEECO GEN II MBE equipment is a full-featured MBE machine designed for research and development laboratories and manufacturers from both the university and commercial sectors. By providing precise control over many environmental parameters and substrate position, this MBE system lets users manage an array of deposition processes from low-pressure to ultra-high vacuum. VEECO GEN II MBE is a four-source, tilt-source unit with two dedicated Group V and one dedicated Group III low-pressure sources (rhenium and arsenic, respectively). The fourth source is an ultrahigh vacuum source machine optimized for GaAs and related alloy growth. Mainframe gas-source valves enable quick and clean substrate transfer in and out of the MBE chamber, while a built-in safety interlock tool monitors asset conditions to ensure safe operation. Precise substrate positioning is provided by a linear manipulation stage, which can be integrated into various MBE loading and unloading sources, ensuring accuracy and repeatability. Additionally, VARIAN GEN II also includes both manual and closed-loop temperature control with thermocouple flexibility. Residual gas analysis is provided by a laser-augmented multi-pulse quadrupole mass spectrometer for improved accuracy and speed. GEN II MBE model features a variety of control and automation features designed to make the user's experience more efficient. This includes a user-friendly graphical user interface (GUI) allowing for setup and control. Additionally, this MBE equipment features multiple pre-programmed recipe protocols for optimized growth and reproducibility. Overall, VARIAN / VEECO GEN II MBE provides users with a high-performance and accurate system for creating atomically-precise layers of materials. It offers superior temperature control, precise substrate positioning, closed-loop operation, enhanced safety interlock unit and gas source valves, along with efficient GUI control and automation. With its wide array of features and its ability to meet cutting-edge technology requirements, VEECO GEN II MBE machine is sure to be a valuable tool for many research and manufacturing projects.

There are no reviews yet