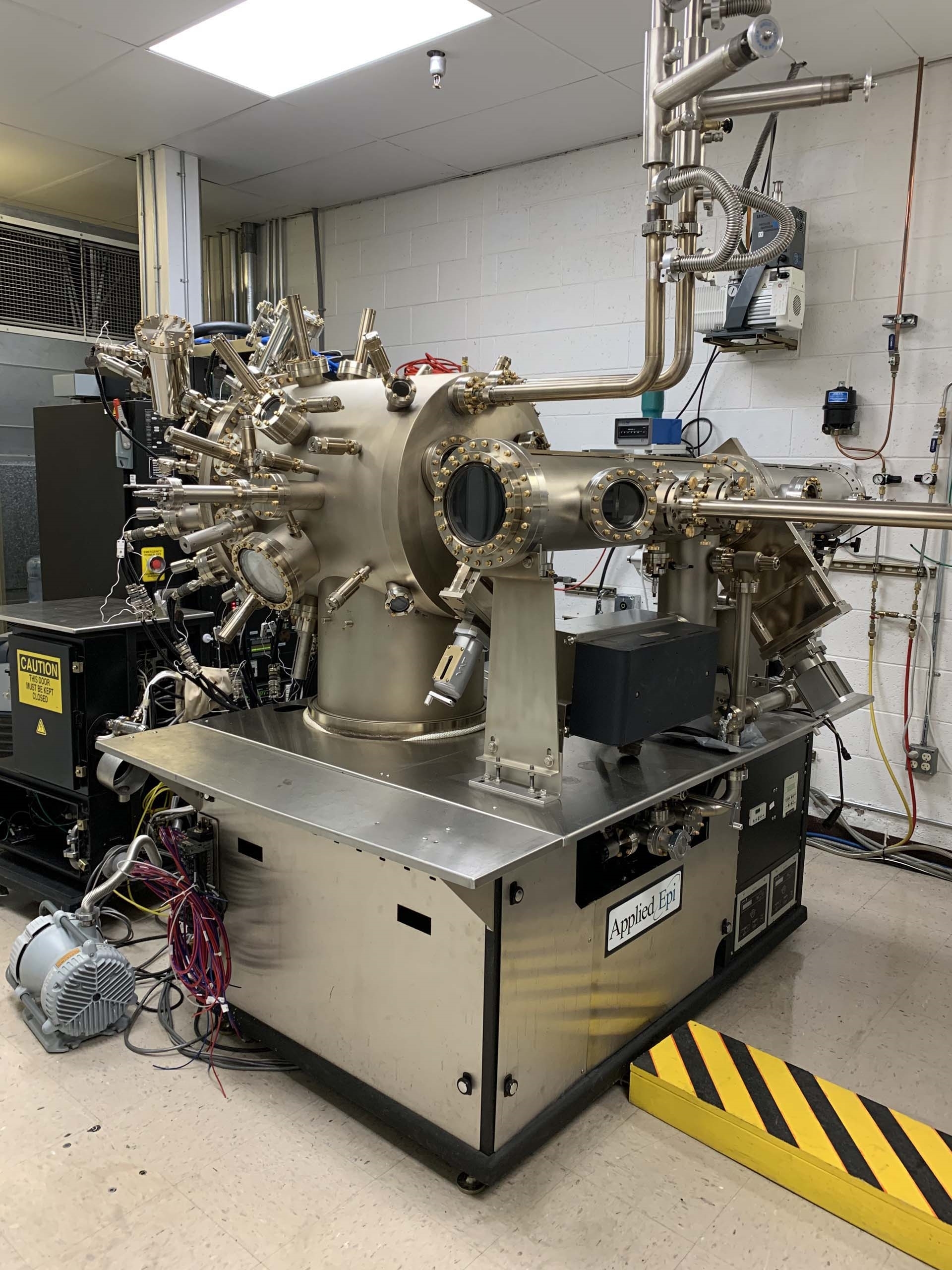

Used VEECO GEN III #9262111 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9262111

Vintage: 2001

MBE System

(3) Al Sources: 400g

(2) Ga Sources: 900g Sumo

In Source: 400g Sumo

CBr4 Carbon Source includes mech pump

Silicon source

(2) Arsenic crackers

RHEED System

Substrate pyrometer

STANFORD RESEARCH SYSTEMS Residual gas analyzer

Cryo and compressor

Ion pumps

Load lock turbo

CAR

Spare parts:

(2) Al Sources – 400g

(2) 400g Sumo

900g Sumo

Be Source

As cracker (Needs rebuild)

Phosphorous cracker

Phosphorous recovery system

Bakeout panels

Spare gate valve

Sump pump

Miscellaneous hardware in cabinet (Gaskets, bolts, crucibles, spare cables)

Includes:

Electronic racks

Computer and desk

Shutter hardware

Trolley

Substrate holders

LN2 Phase separator

Water chiller for source shroud

Water chiller for Arsenic crackers

UPS system for Ga and Al cells

Manuals

2001 vintage.

VARIAN / VEECO GEN III is a molecular beam epitaxy (MBE) growth equipment that is typically used for the deposition of thin films at the atomic level. The system is comprised of several major components, such as a high temperature growth image furnace, an ultra-high vacuum chamber, multiple effusion cells, a thermal proximity shutter, and several foreline pumping systems. The image furnace, which is capable of reaching temperatures up to 1000 degrees Celsius, is used to convert material from solid to gaseous form in order to deposit high quality, ultra-thin films. The ultra-high vacuum chamber is the area in which the deposition occurs, and it is typically pressurized down to a few tenths of a millibar. The multiple effusion cells contain the source materials, which need to be heated to a high temperature in order for them to evaporate their elements and pass into the chamber to form the thin film. The thermal proximity shutter is used to control the relative position of the effusion cells to the substrate upon which the film is deposited. The foreline pumping systems are required to maintain a high level of vacuum, which is essential for MBE as it requires a low partial pressure environment in order to prevent contamination of the film. The pumping unit is attached to the vacuum chamber and serves two functions: to regulate the pressure of the machine and to generate a high quality vacuum. The pumping tool may also employ additional components, such as cryo traps, vacuum gauges, manifold valves, and lapped valves, to optimize performance. Overall, VEECO GEN III MBE asset is a powerful growth tool that can provide a range of material properties under extremely precise conditions. It offers an unparalleled level of control over the deposition process and makes it possible to create complex and intricate thin films.

There are no reviews yet