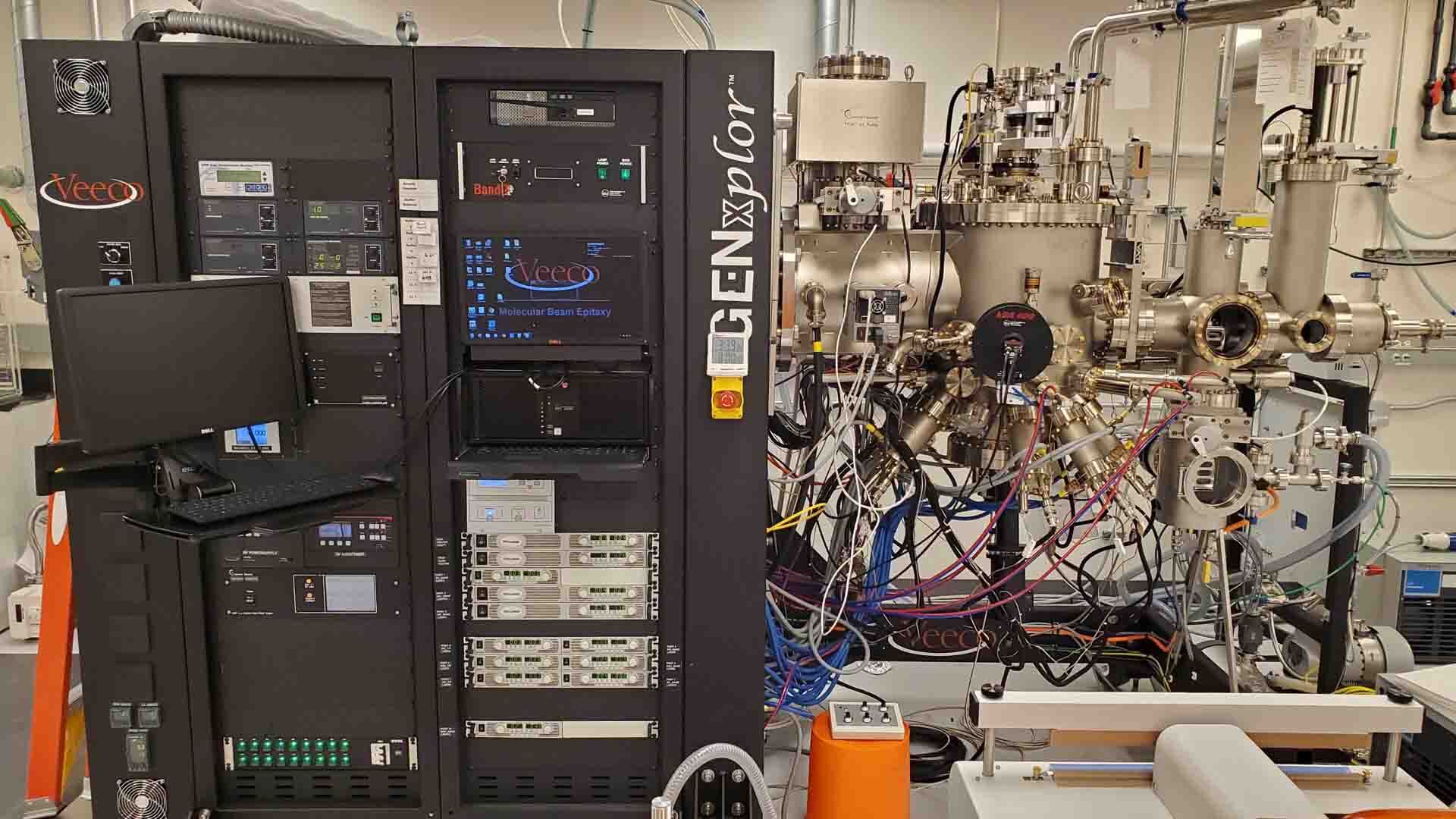

Used VEECO GENxplor #293648270 for sale

URL successfully copied!

Tap to zoom

Molecular beam epitaxy (MBE) is a type of vacuum deposition technique used in semiconductor device fabrication. MBE utilizes a vacuum chamber that is sealed, allowing for the deposition of thin film materials onto different substrates, in the form of atoms or molecules. VARIAN / VEECO GENxplor, specifically, is a high-vacuum, low-temperature atomic layer epitaxy (ALE) system that enables deposition of materials featuring enhanced performance and reproducibility. VEECO GENxplor is a two-zone system that is composed of an insert containing either two of VEECO patented high-purity, low-oxygen furnaces at either end, or a single, dual-zone furnace with two distinct temperature zones on the same substrate. The use of two-zone furnaces allows for the deposition of two thin film materials at different temperatures with precise temperature control. VARIAN GENxplor is also equipped with three molecular beam valves and two effusion cells to provide a greater array of metalorganic source chemicals. The molecular beam injects an extremely precise dose of metalorganic vapor into the growth chamber, which is said to be 130-600 times more accurate than traditional metal-organic vapor deposition processes. Additionally, GENxplor offers excellent wafer uniformity with its advanced wafer position module, which is precise to within 1 µm. This enables a greater level of control over the temperature of both the source and the substrate during deposition, allowing for the growth of high-quality thin film layers over the entire wafer. Finally, VARIAN / VEECO GENxplor is bundled with VARIAN GRIP patterned growth software, which offers a precise, repeatable process for the fabrication of state-of-the-art nanoscale memory devices and other high-performance devices. The software automates the deposition process by controlling the molecular beam valves and effusion cells, ensuring precise and reliable deposition. In conclusion, VEECO GENxplor is an advanced MBE system that delivers increased accuracy and performance compared to traditional MBE systems, making it a valuable tool for device manufacturers aiming for full precision and control for their thin-film deposition.

There are no reviews yet