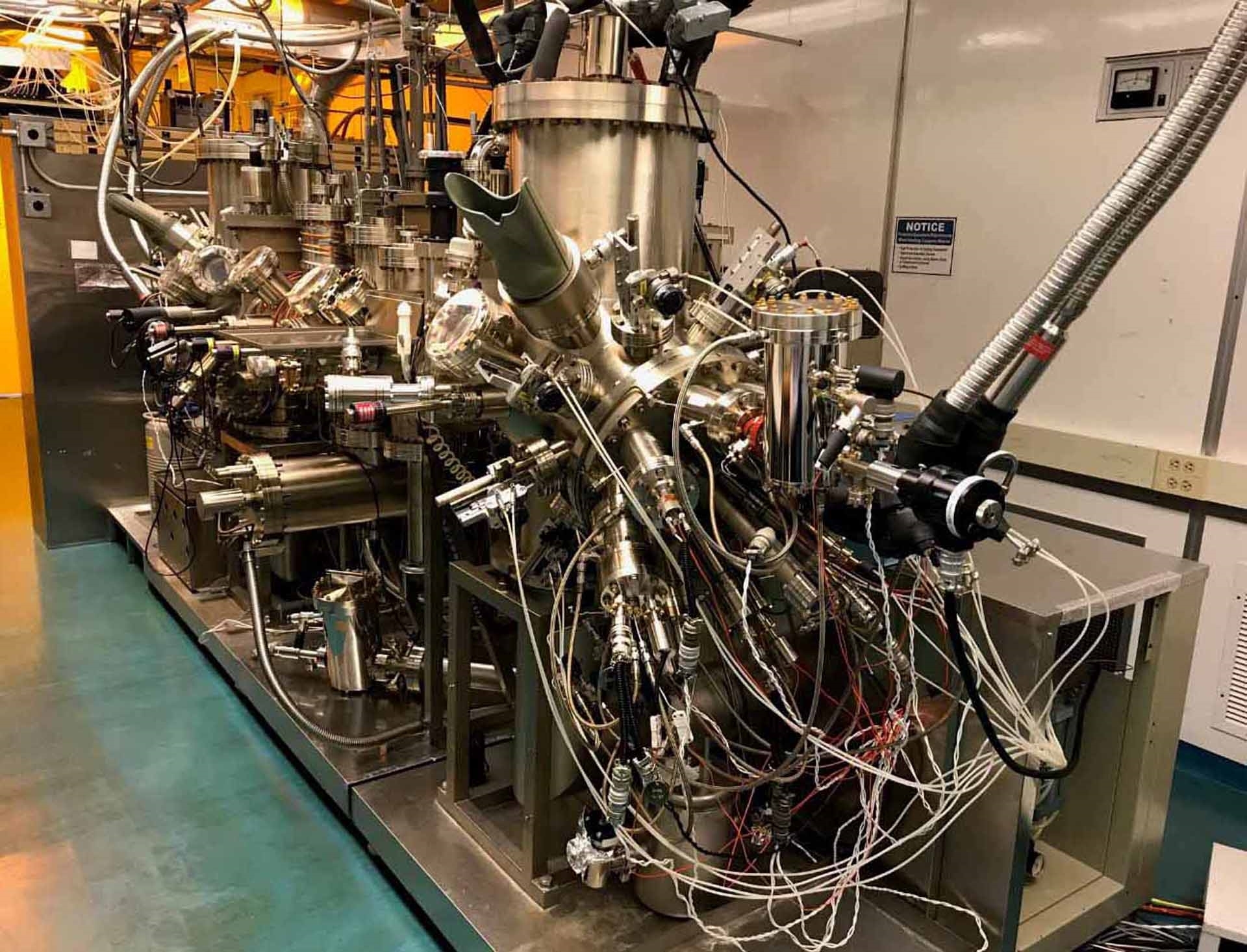

Used VG SEMICON / OXFORD V80 #9226450 for sale

URL successfully copied!

Tap to zoom

ID: 9226450

Wafer Size: 3"

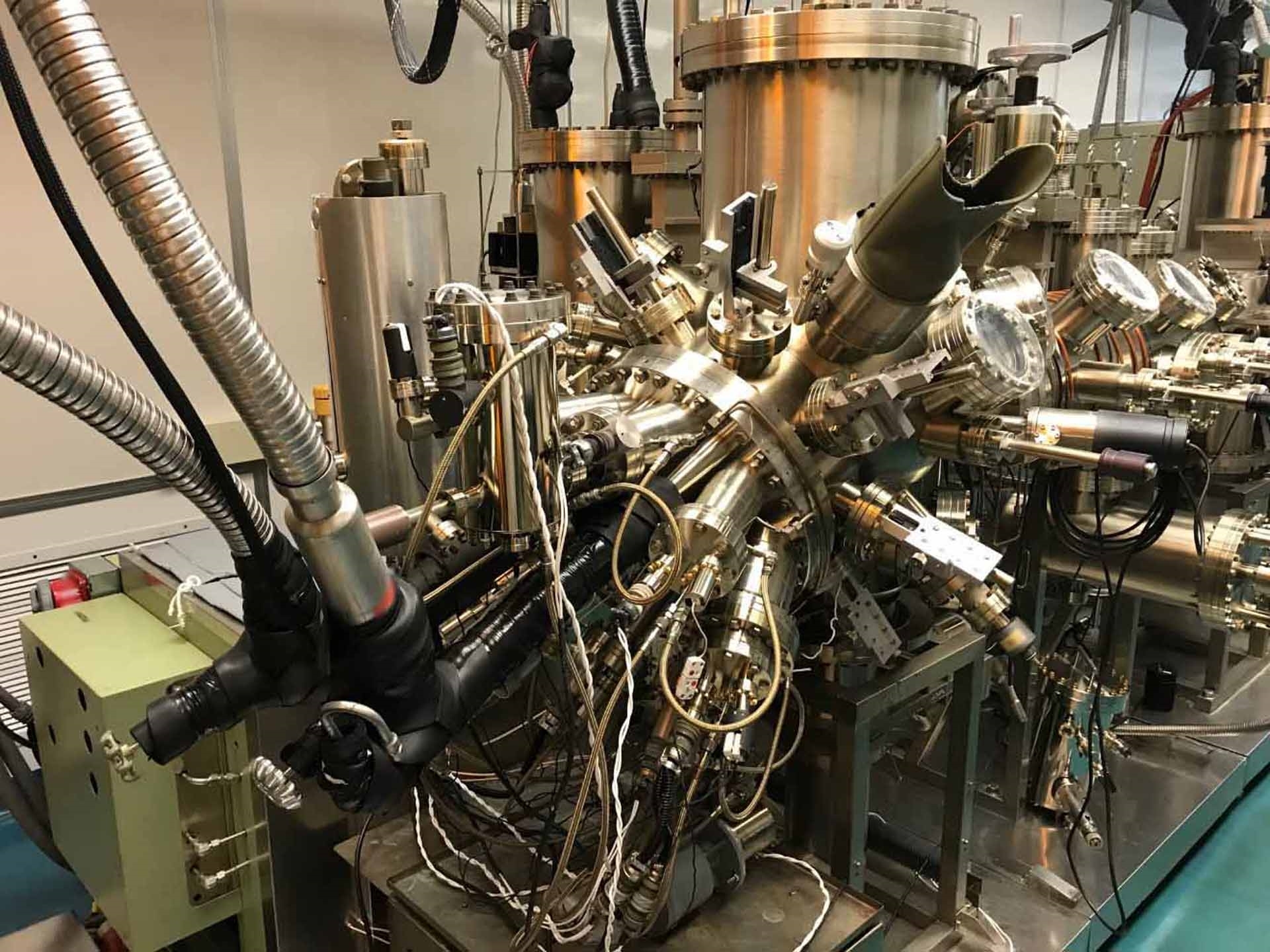

MBE System, 3"

Ion pump

Furnaces

(2) Chambers: GaAs Work

Arsenic cracker

Phosphorous cracker

Gallium

Aluminum

Indium & Silicon

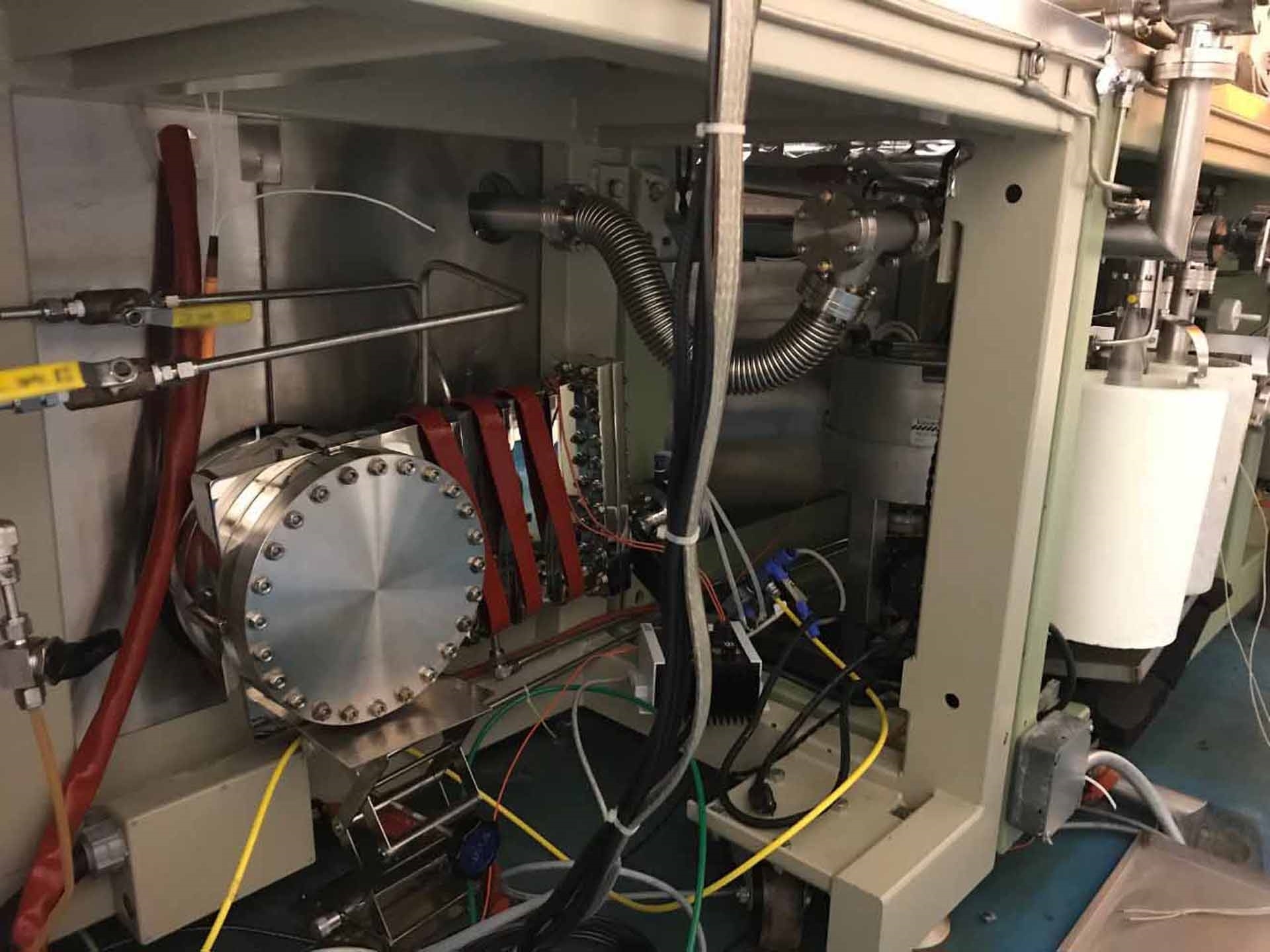

Bake-out panels & heaters

8-Port

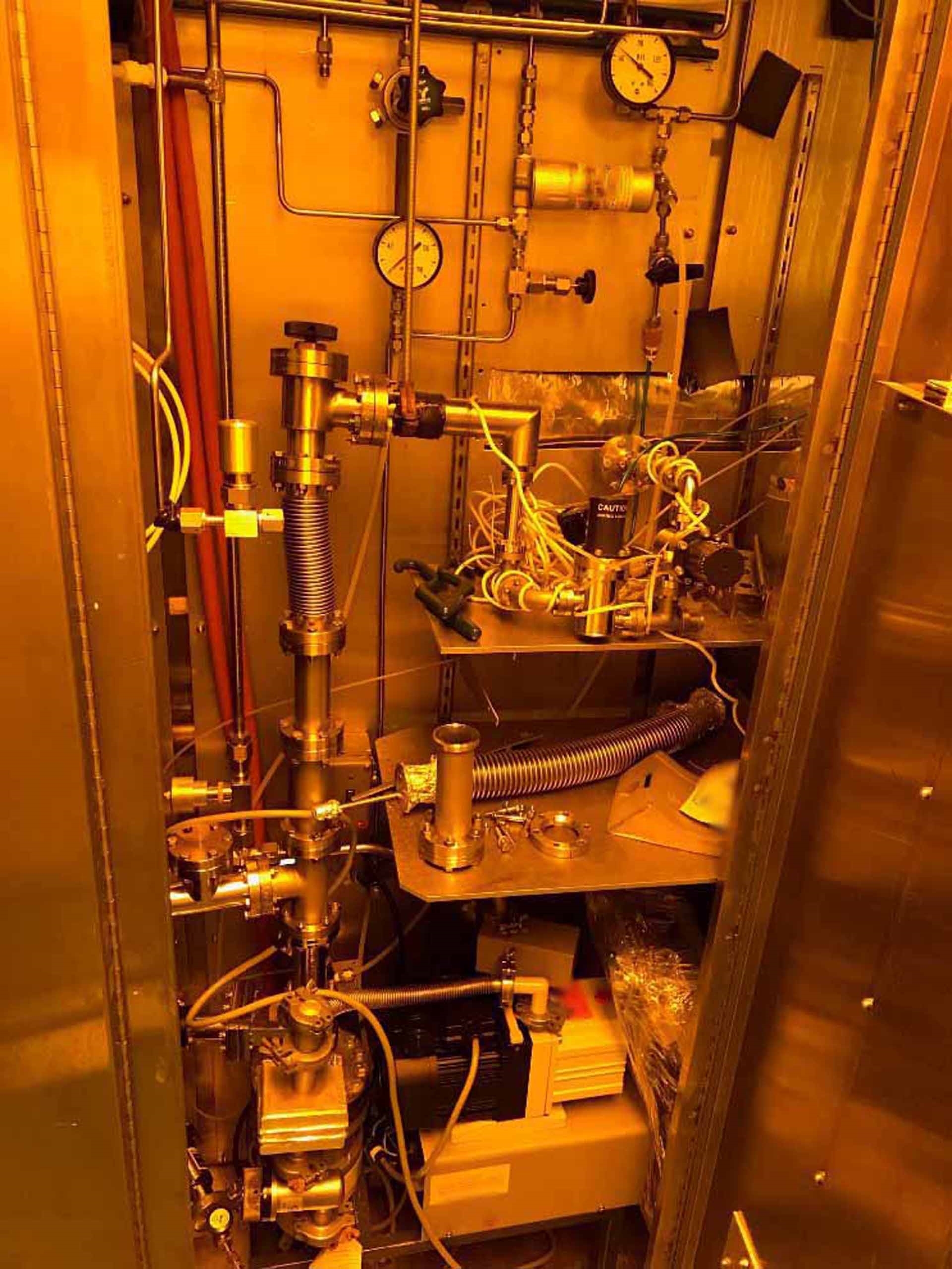

LN2 Piping

Does not include vacuum barrier phase separator

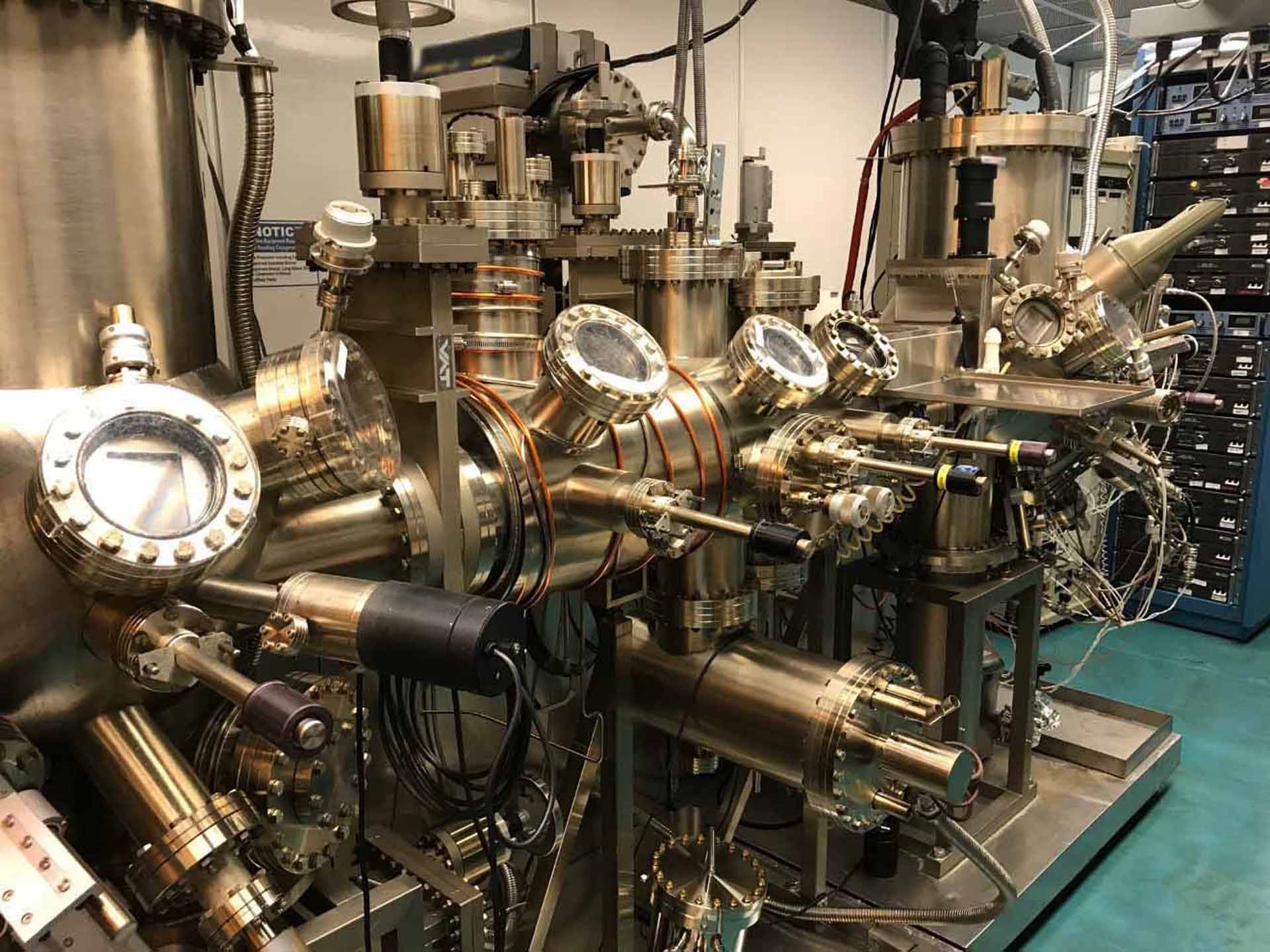

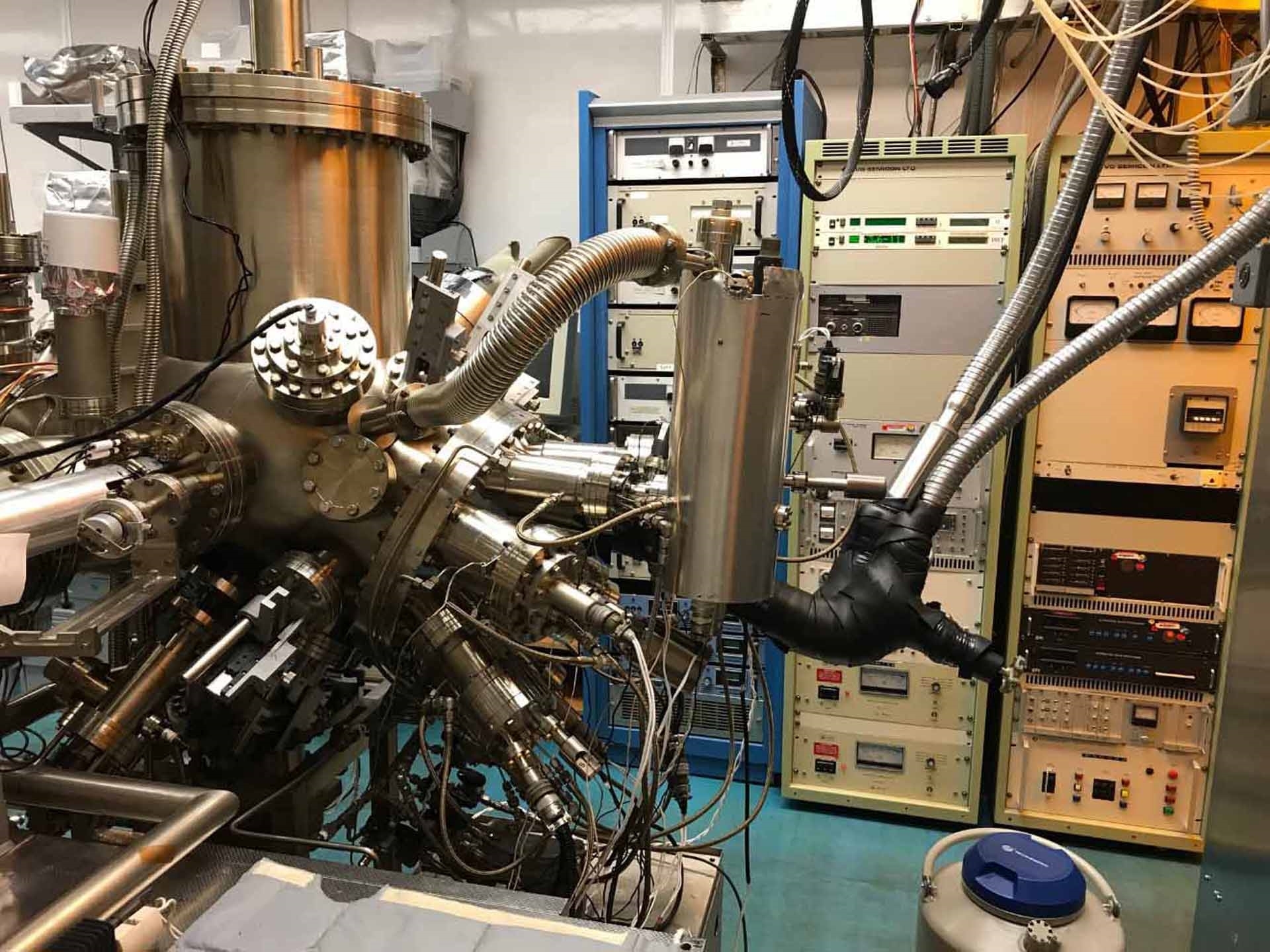

G Chamber:

Materials: As, P, Be, In, In, Al, Ga, Si

Ion pump

Diffusion pump

V Chamber:

Materials: Si, As, Cr, Ga, Al, In, Ga, Be

Ion pump

Prep chamber:

Vac-sorbs

Ion pump

RHEED Guns

GaAs Substrates

GaAs Wafers: 650°C (Max temperature)

GaAs Growth temperature: 500°C - 650°C

RHEED Gun power supply

Sumo cell, 300 CC

Bake out panels with heaters

Spare parts

Manuals.

VG SEMICON / OXFORD V80 is a molecular beam epitaxy (MBE) equipment designed for high quality, low-temperature research grade preparation of devices and electronic components. This MBE system offers a wide range of capabilities that enable researchers to get the most out of their research. It includes several features that set it apart from other MBE systems, such as an advanced multi-stage pressure control unit, a unique long-distance greater-than-unity net (GNET) view cell, a ceramic boat furnace, and a full set of high-performance quartz components. One of the unique capabilities of OXFORD V80 is its advanced multi-stage pressure control machine. This tool is capable of providing accurate control of both the pressure and the temperature of the MBE chamber. It provides a high degree of control over the process. Furthermore, the asset is designed for stability, ensuring that desired conditions stay consistent throughout the entirety of the deposition process. Another unique feature of VG SEMICON V80 is its unique long-distance greater-than-unity net (GNET) view cell. This cell uses an advanced imaging model to monitor the growth of the substrates within the chamber. It also allows for precise control of the deposition rate and composition. The cell has a greater than unity optical view for better resolution without distortion. V80 also includes a ceramic boat furnace. This furnace is capable of operating at temperatures up to 1000°C and provides uniform heating and consistent performance. It can be used to melt samples before and after MBE deposition and provide uniform heating across the chamber. This furnace also features a cooling cycle for sample recovery, allowing researchers to quickly reset the MBE chamber for another deposition. Finally, VG SEMICON / OXFORD V80 is equipped with a full set of high-performance quartz components. These components are housed within a stainless steel vacuum chamber and offer protection from contamination. This ensures that clean, uncontaminated samples are produced and helps to limit any risk of damage to the samples due to deposition. In summary, OXFORD V80 is an advanced, high quality MBE equipment offering a wide range of features and capabilities that make it the ideal choice for researchers wishing to achieve the highest quality and most precise deposition results. From its advanced multi-stage pressure and temperature control system, to its unique long-distance greater-than-unity net view cell, to its ceramic boat furnace and full set of high-performance quartz components, VG SEMICON V80 has all the bases covered to ensure the best possible results and maximum efficiency.

There are no reviews yet