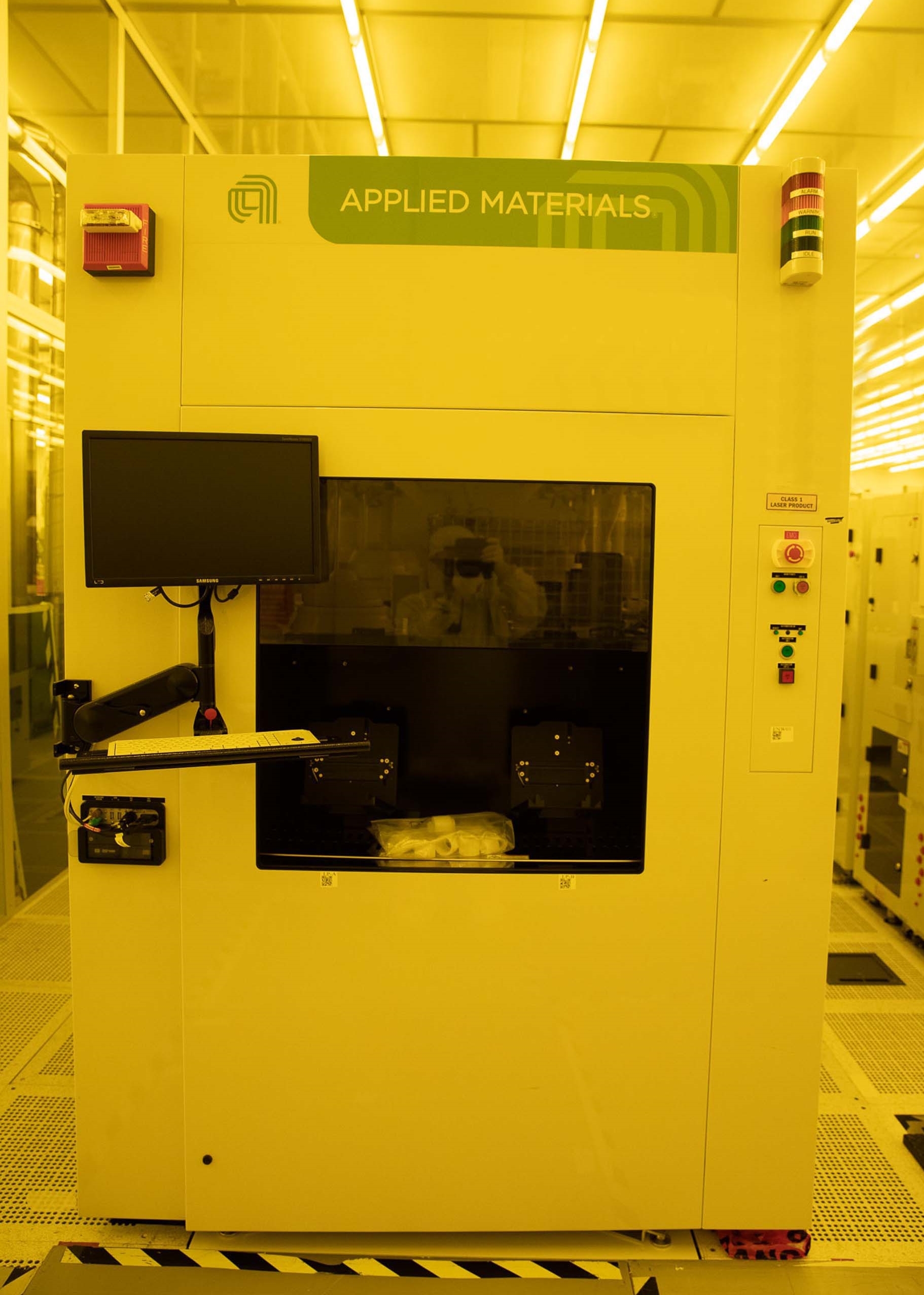

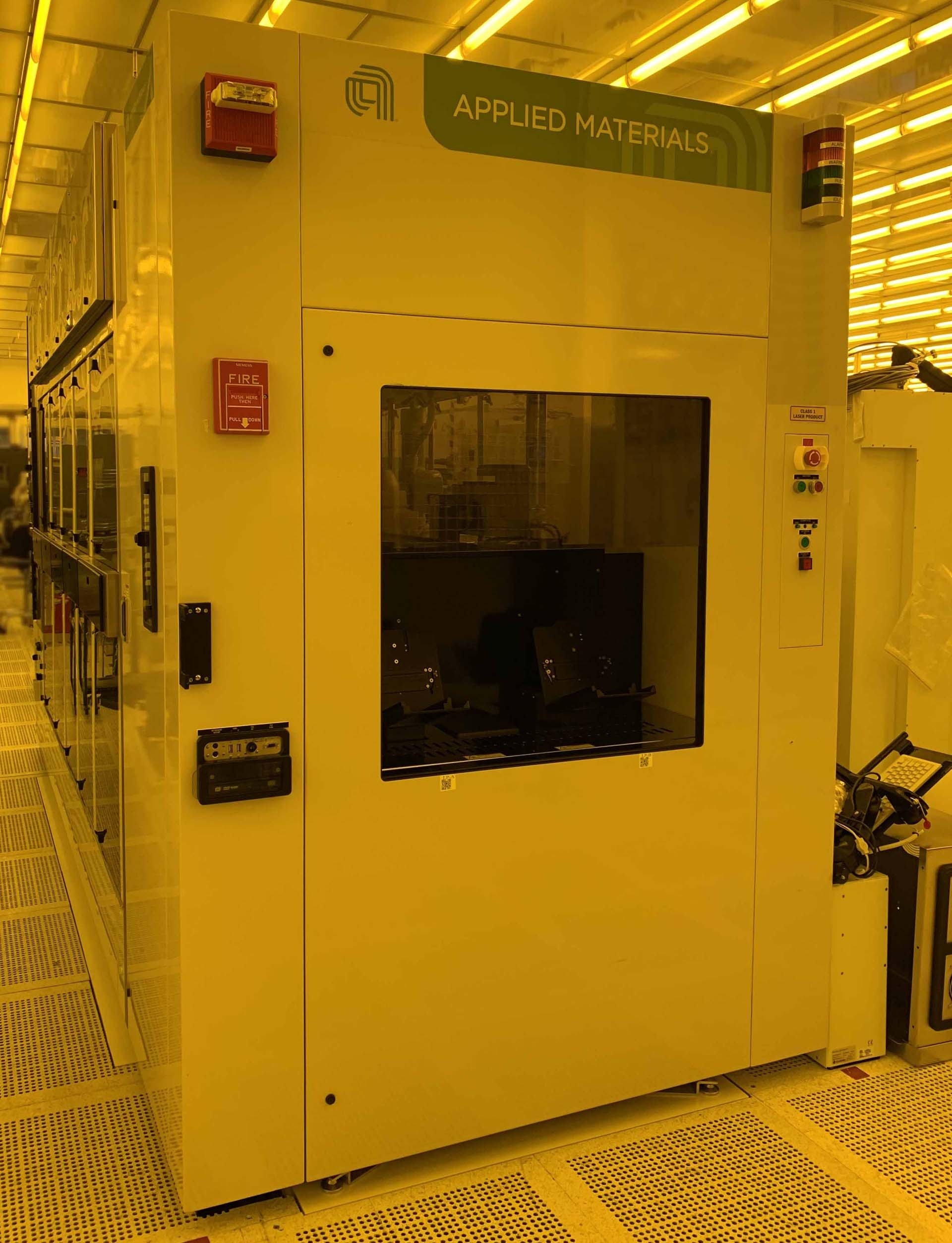

Used AMAT / APPLIED MATERIALS Raider #9260103 for sale

URL successfully copied!

Tap to zoom

ID: 9260103

Wafer Size: 6"

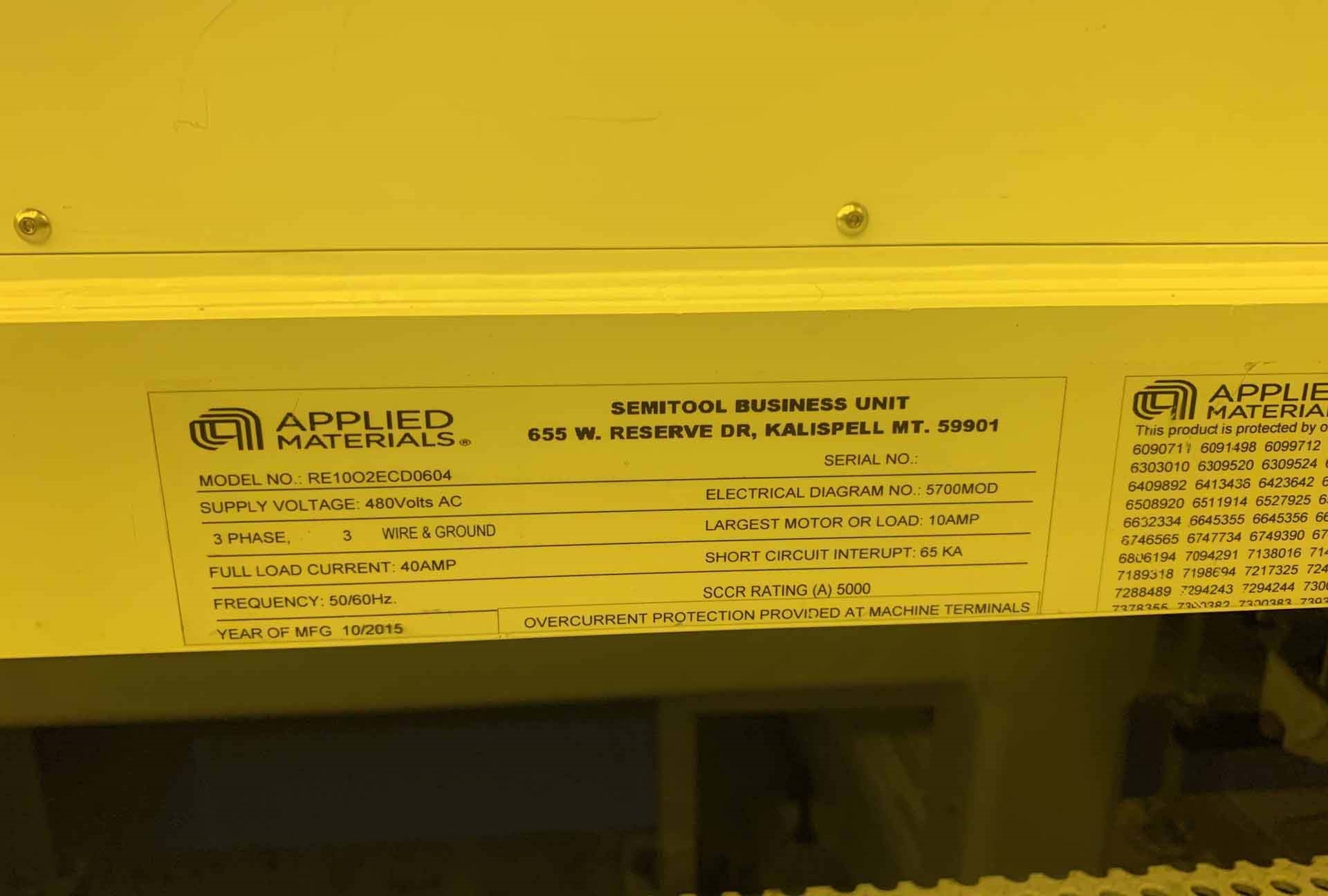

Vintage: 2016

System, 6"

Model no: RE10O2ECD0604

ECD for SiC wafers, 6" (Bridge, 8")

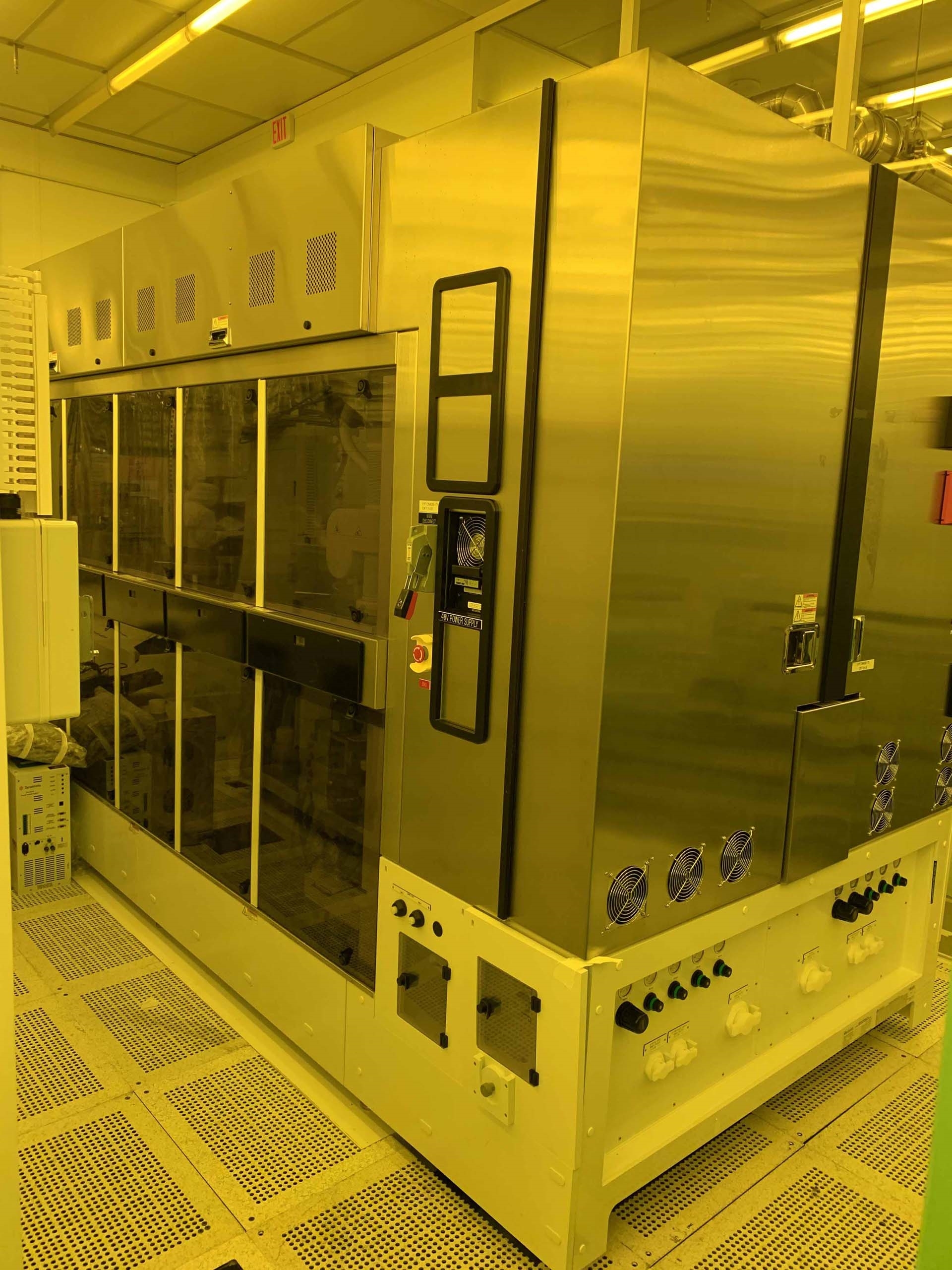

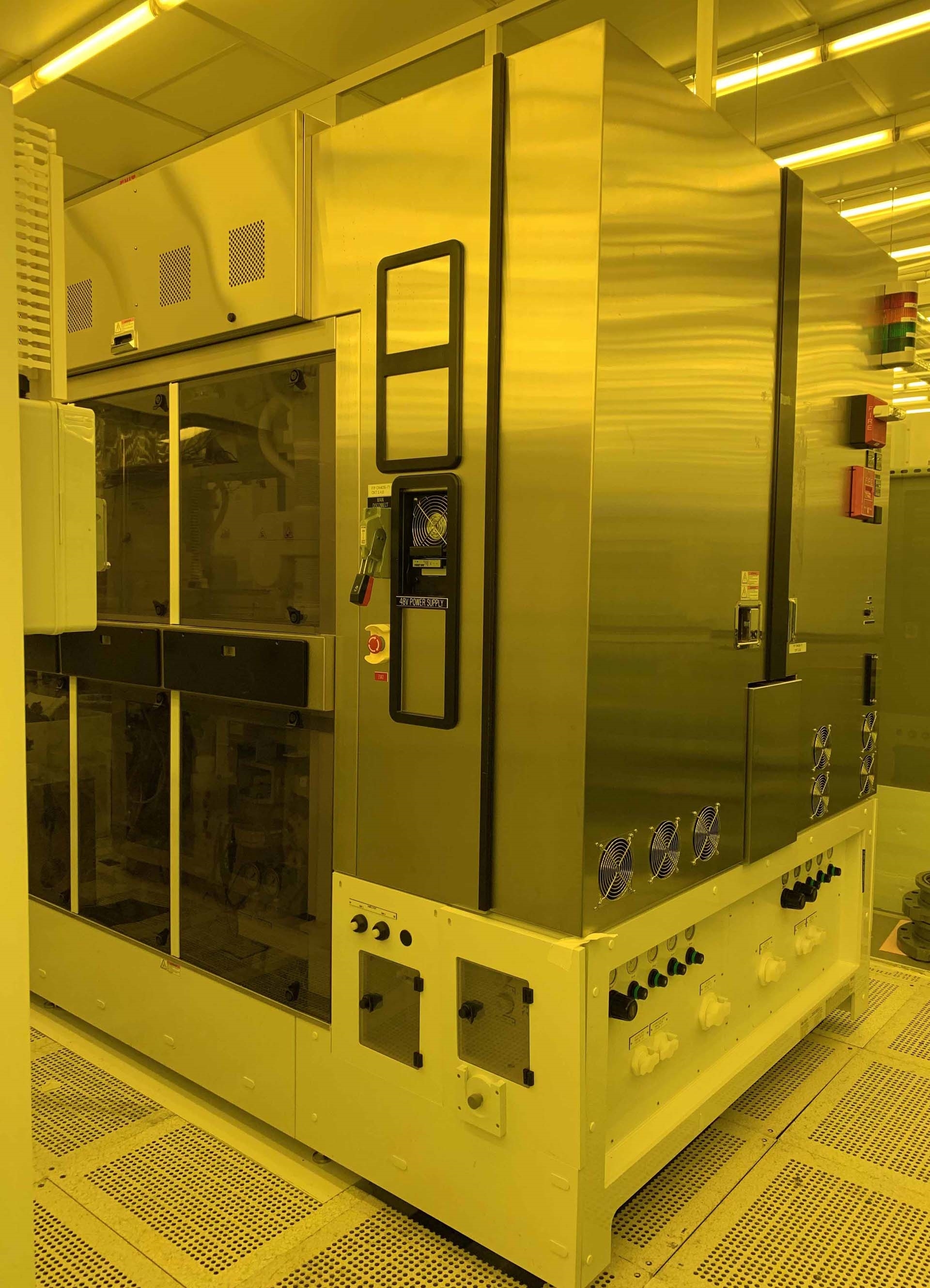

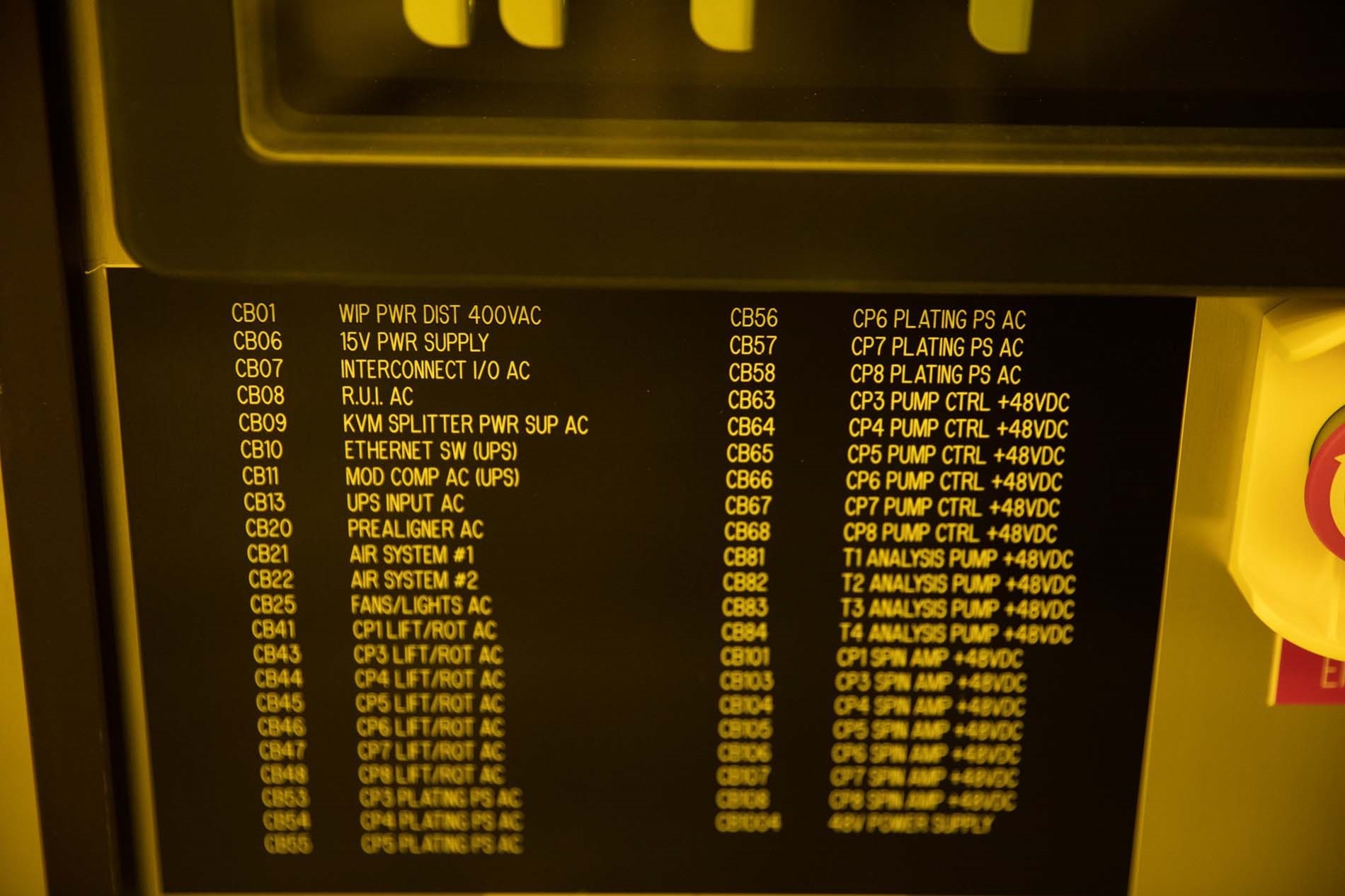

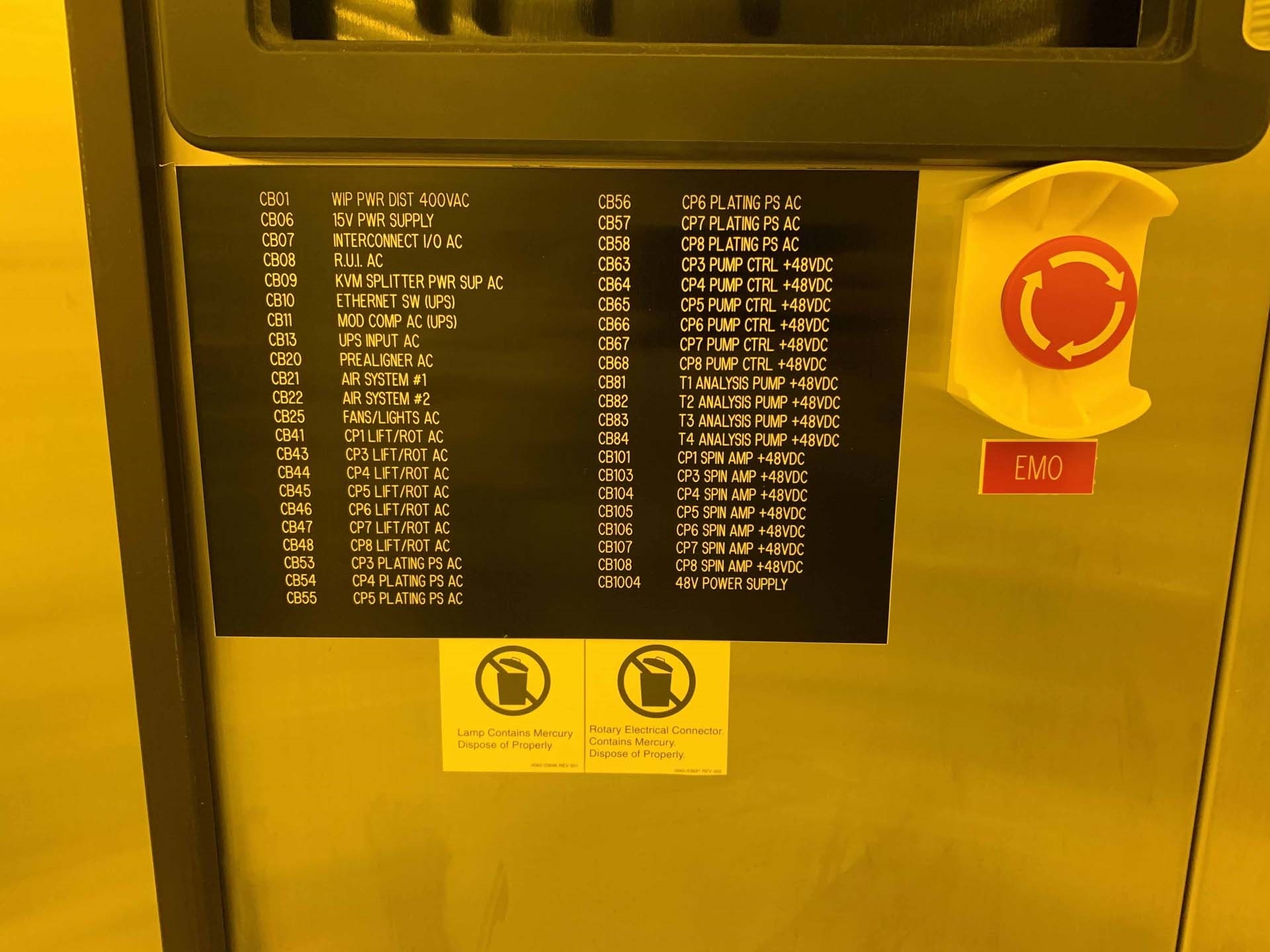

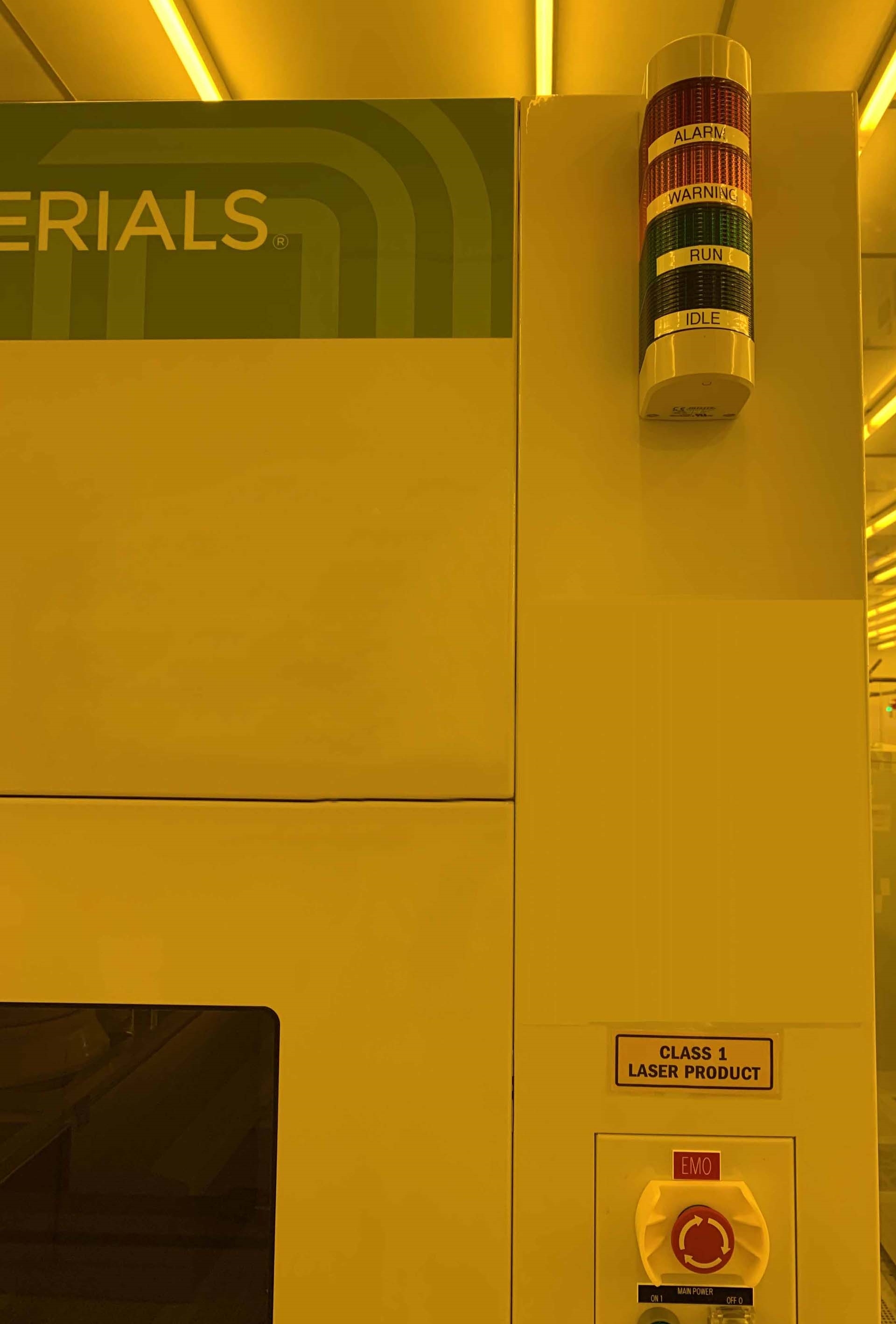

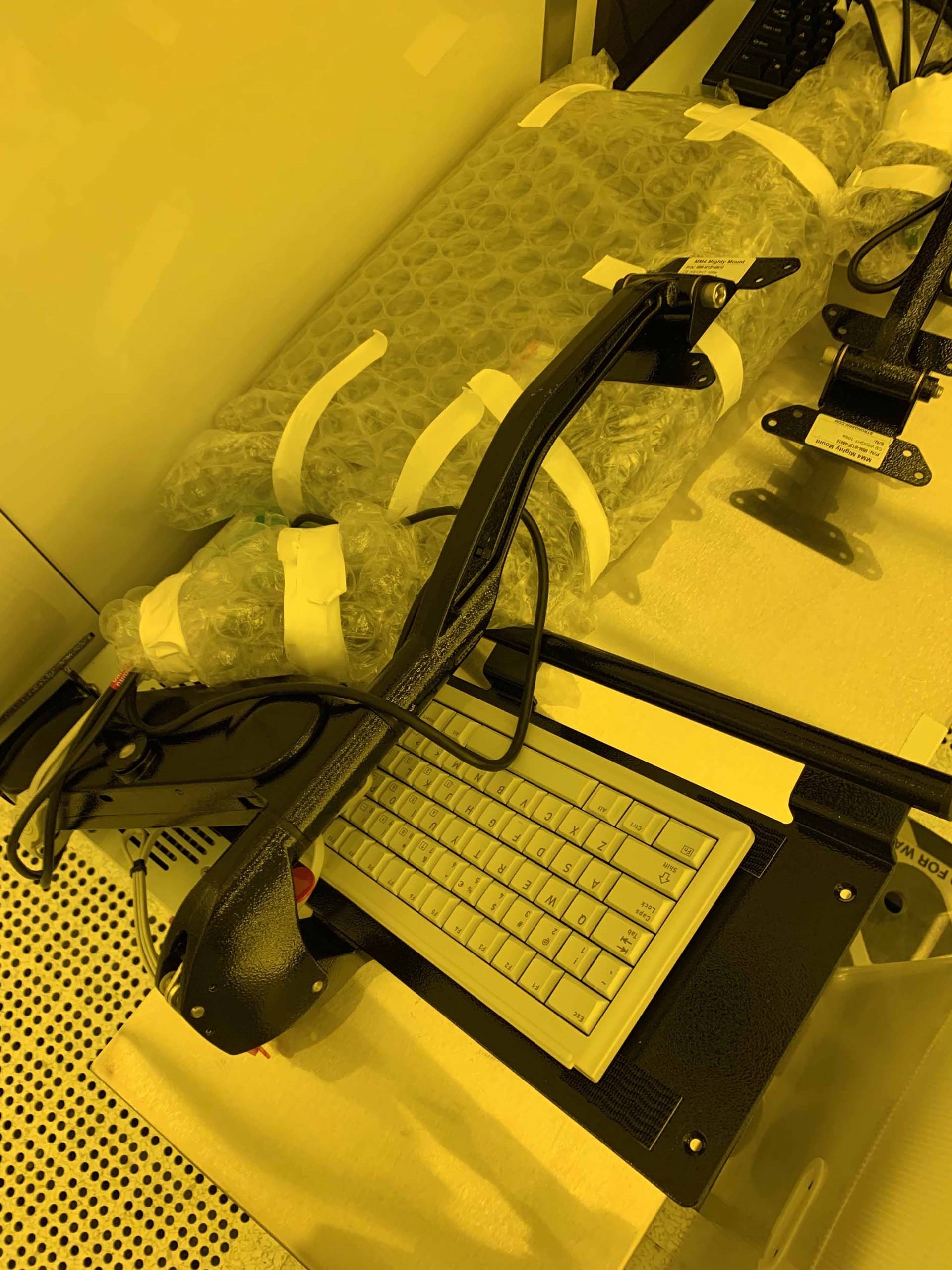

(10) Chamber raiders: Cabinet / Frame

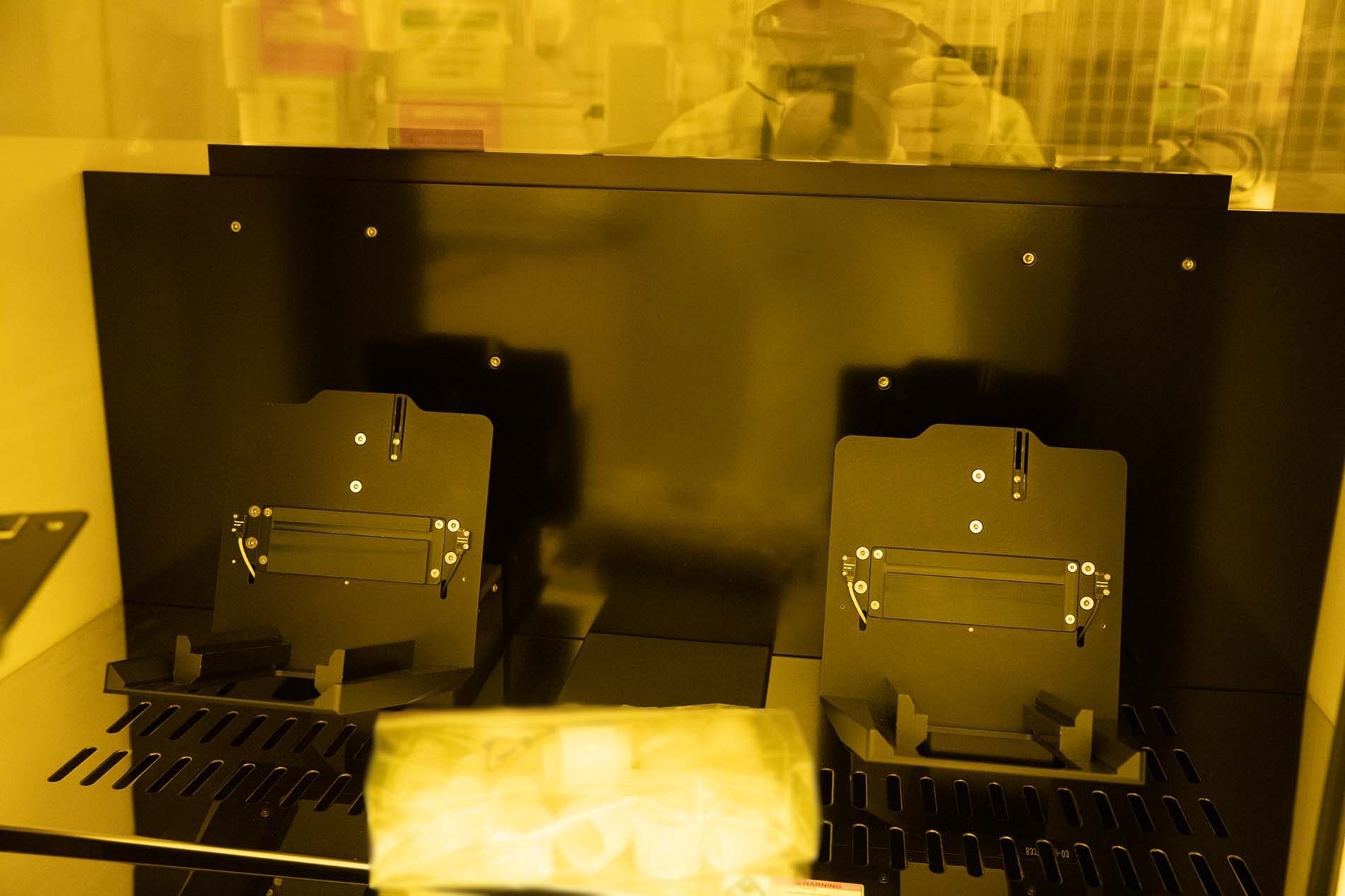

2-Position cassette: WIP

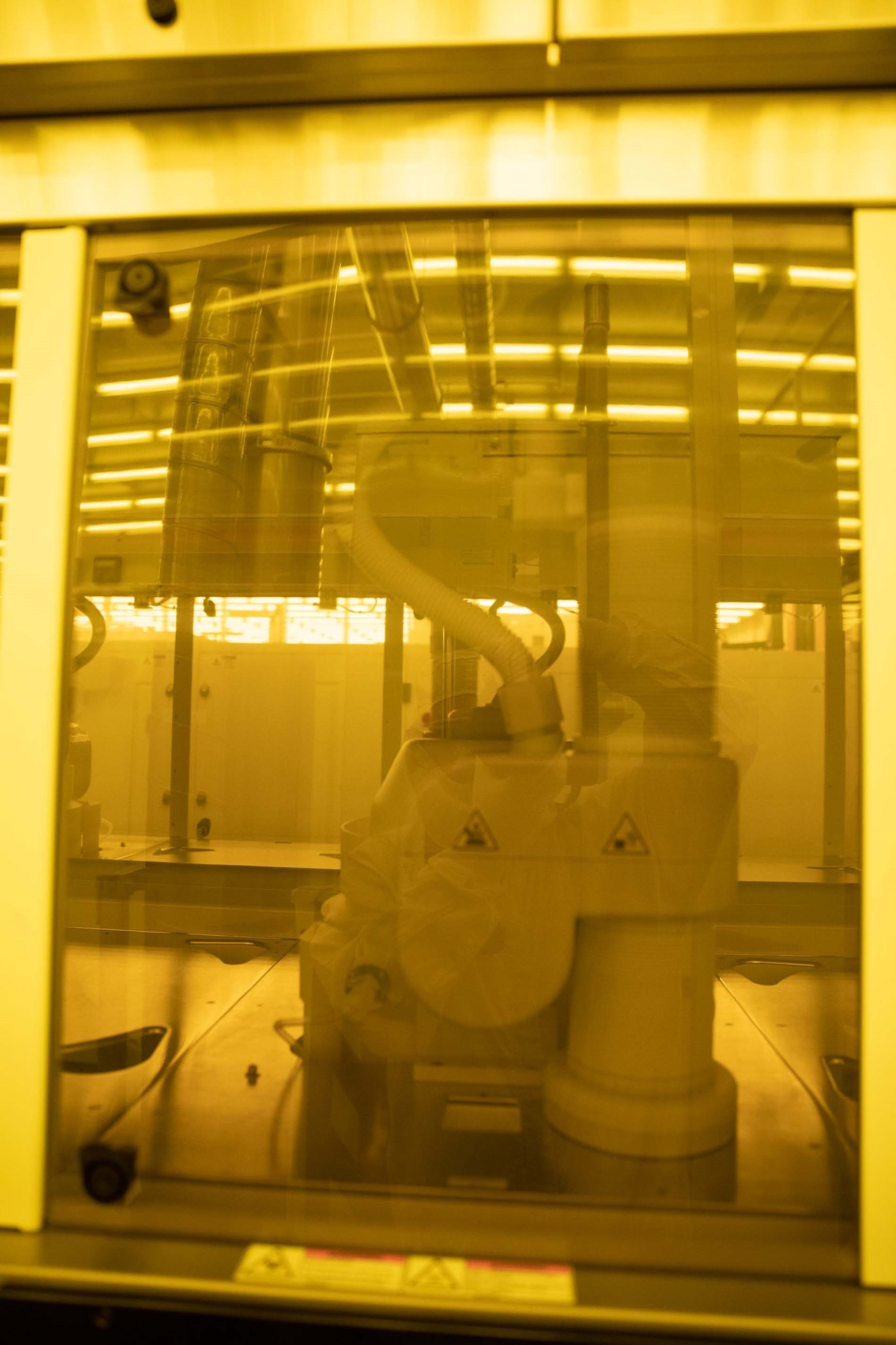

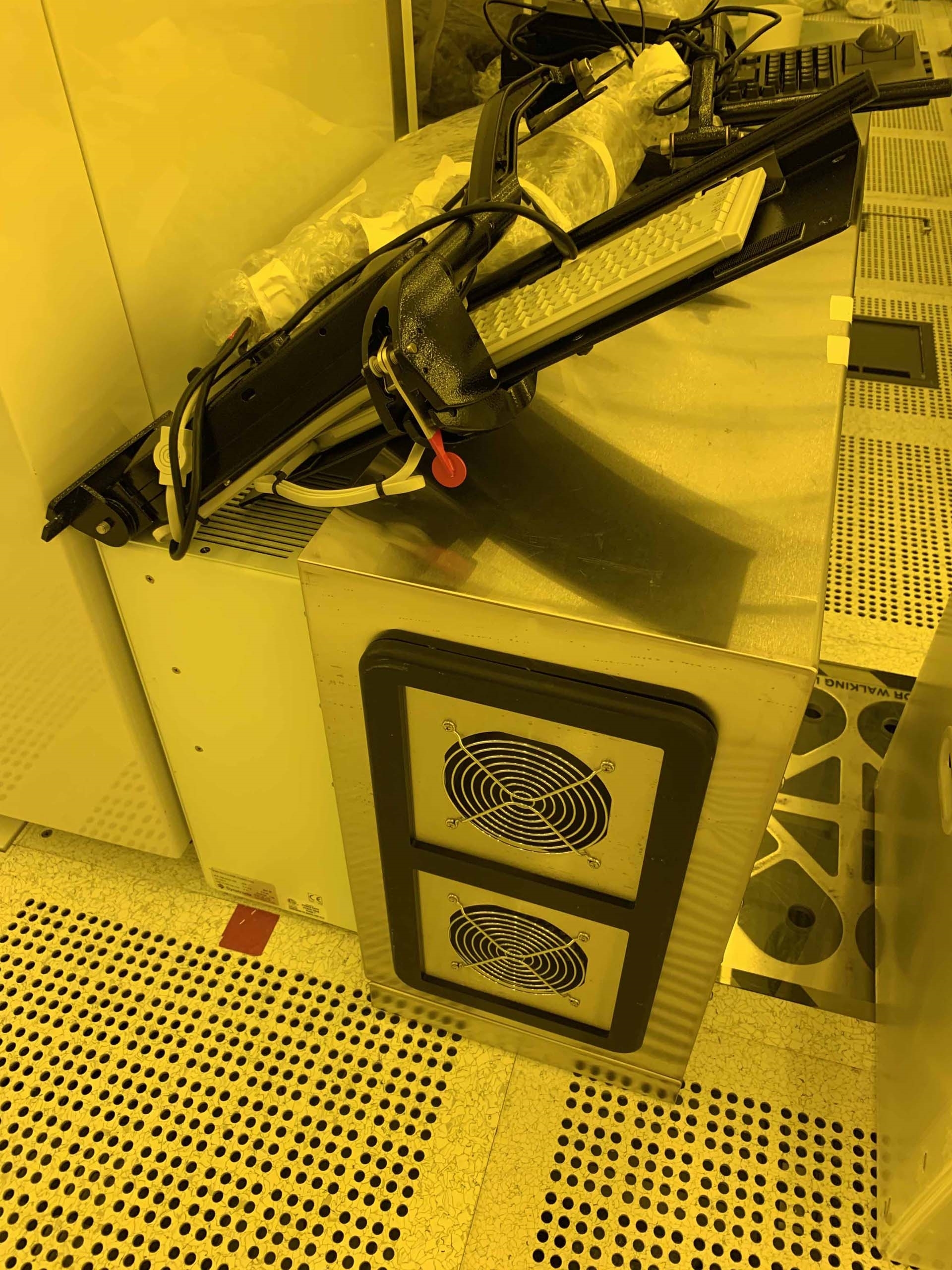

Raider automation and control system

Pre-aligner

Spin rinse dry chamber

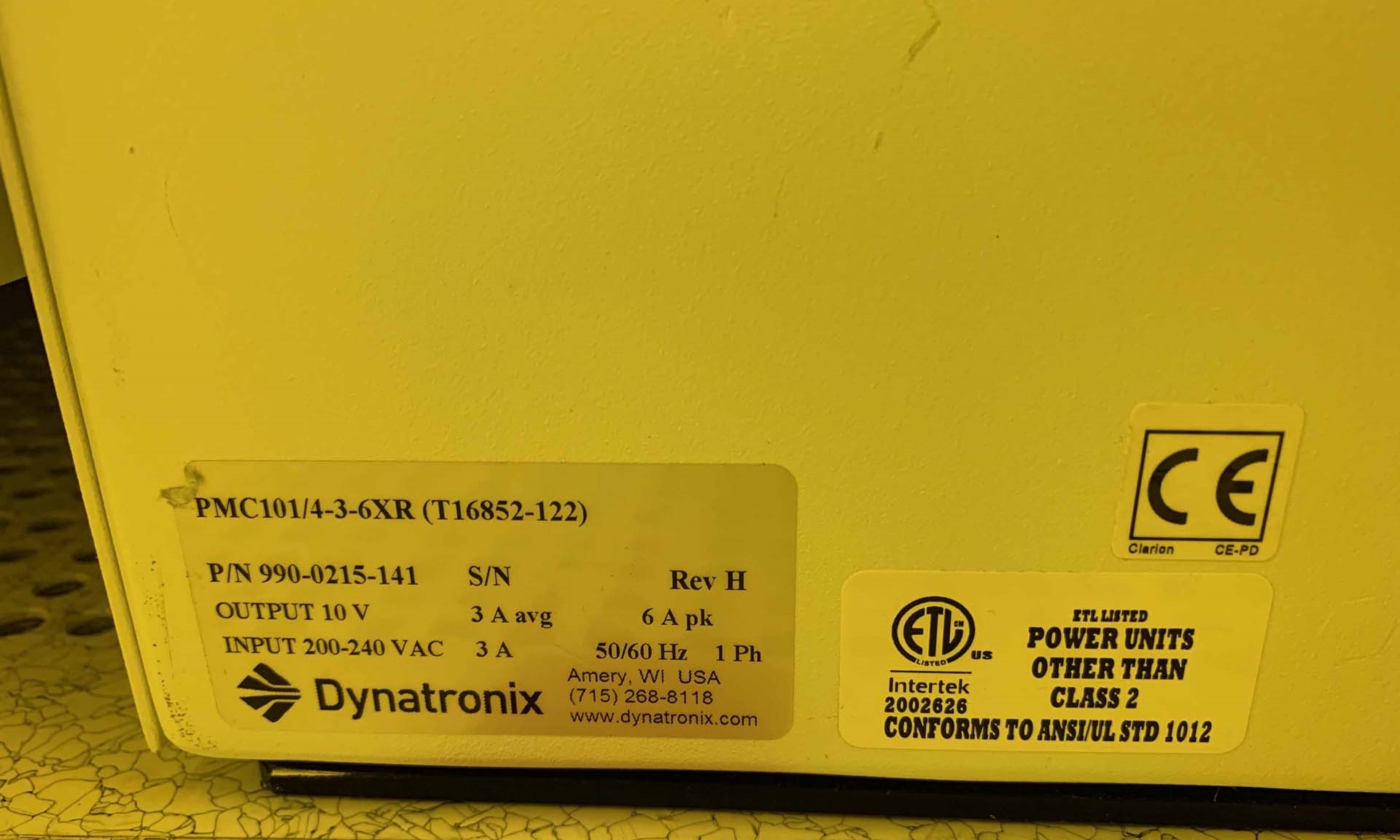

DYNATRONIX Power supply for plating chamber

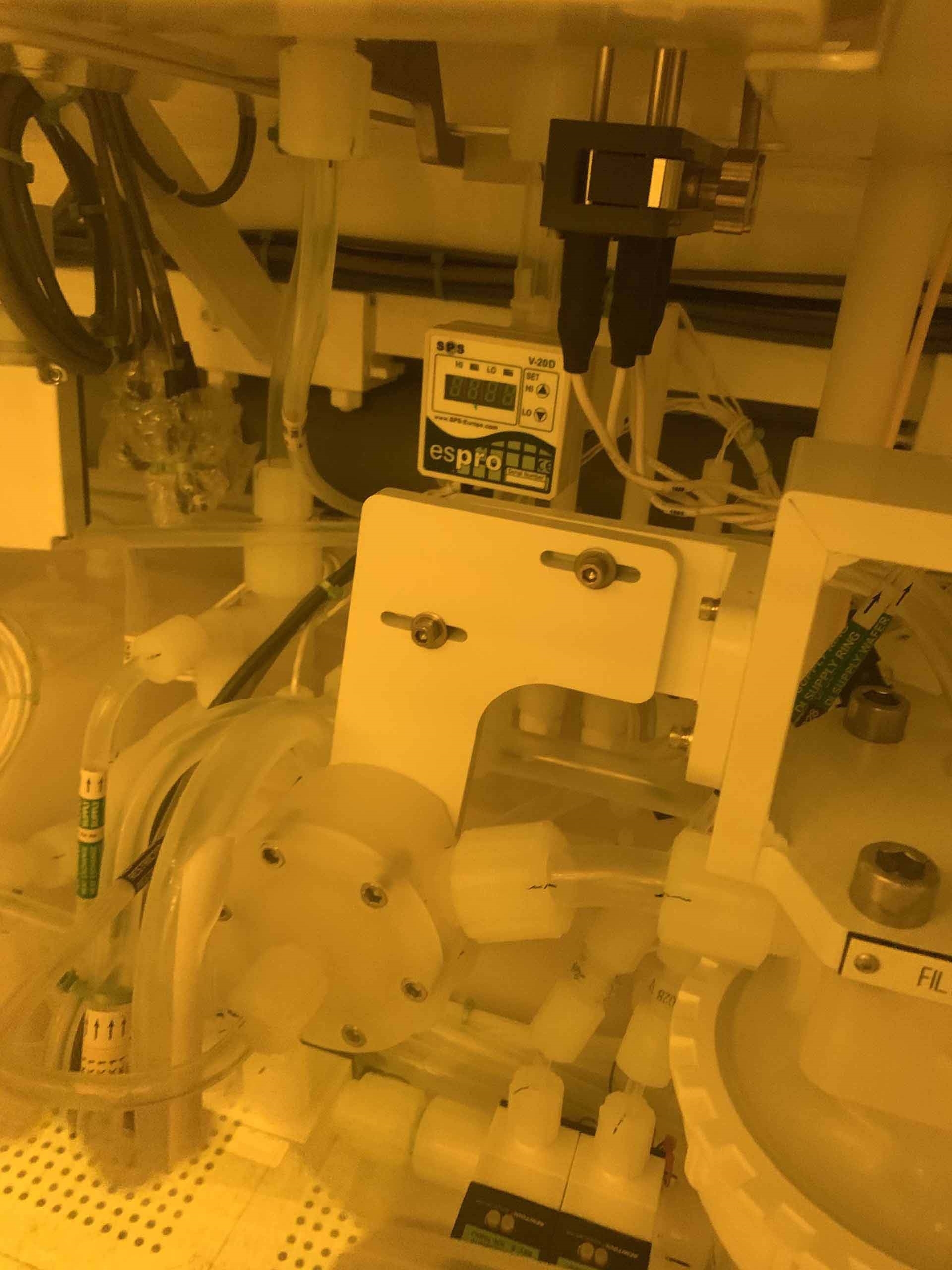

SMC Chillers

CFD3 Plating cells:

(2) XX Platings

(2) XX Strike platings

Process tanks:

(2) XX Baths

(2) XX Strike baths

No auxiliary equipment

2016 vintage.

AMAT / APPLIED MATERIALS Raider is a photoresist equipment designed to facilitate the production of repeatable and high-precision features on wafers. This system is specifically designed to enable feature development on a range of materials, such as oxides, nitrides, and high-k dielectrics. The unit offers the highest possible repeatability and repeatability accuracy, thanks to its feature size and placement accuracy. The machine also features an imaging repeatability of 0.5 μm and allows a feature development resolution of 0.18 μm. In addition, the tool's resolution and speed can be customized to suit the production needs of the user. AMAT Raider is comprised of two main components: an Aseptix Commander and a Matik Photoresist Asset. The Matik model is an advanced, modular photoresist equipment that is integrated into the Aseptix platform. This system enables feature development with a top-to-bottom mask approach and provides users with the ability to apply digital patterning technology. The unit also offers a variety of other features to make the production process easier. These features include an automatic planner for locating fiducial marks, an auto-tuning function for setting the optimal exposure conditions, and an auto-focus machine for improved imaging accuracy. In addition, the tool offers a closed-loop, automated process that eliminates the need for manual intervention. APPLIED MATERIALS Raider asset is ideal for a wide range of feature development requirements. Its features, such as its high resolution and accuracy, make it an ideal solution for the manufacture of high-performance microelectronic components. Additionally, its automated features reduce production time and costs, while also improving the repeatability of feature development. This makes Raider an essential tool for producing high-quality microelectronic devices.

There are no reviews yet