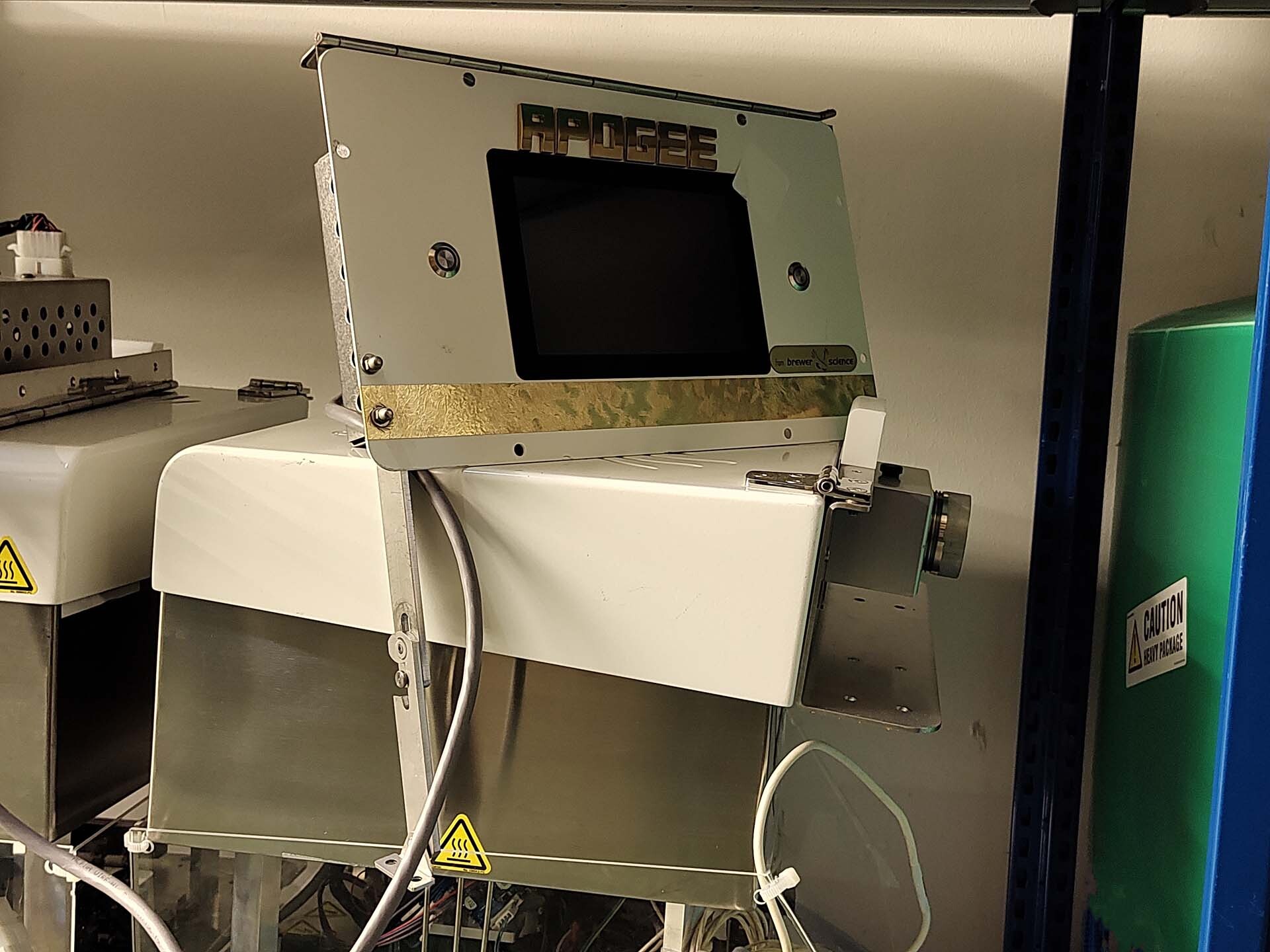

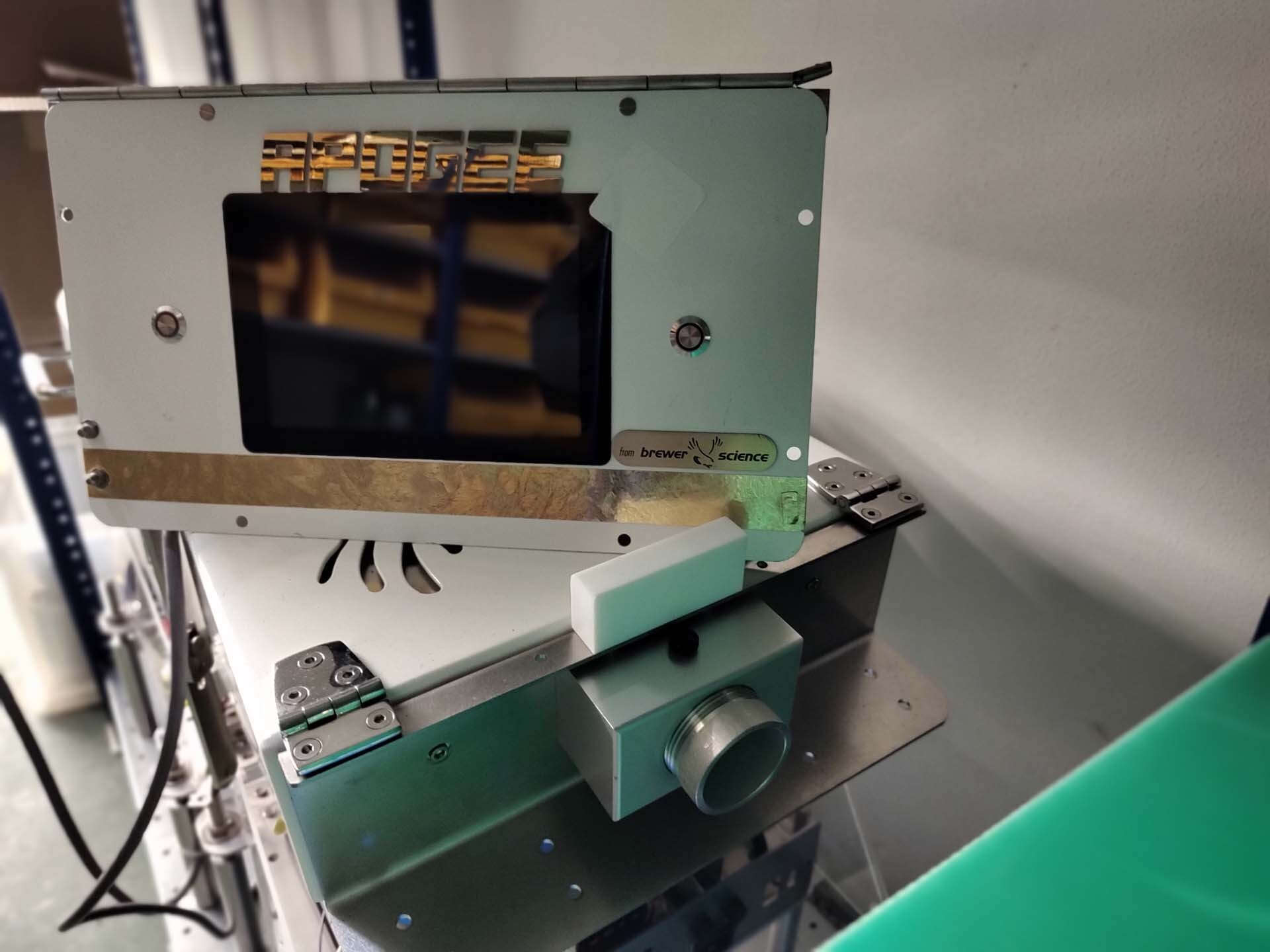

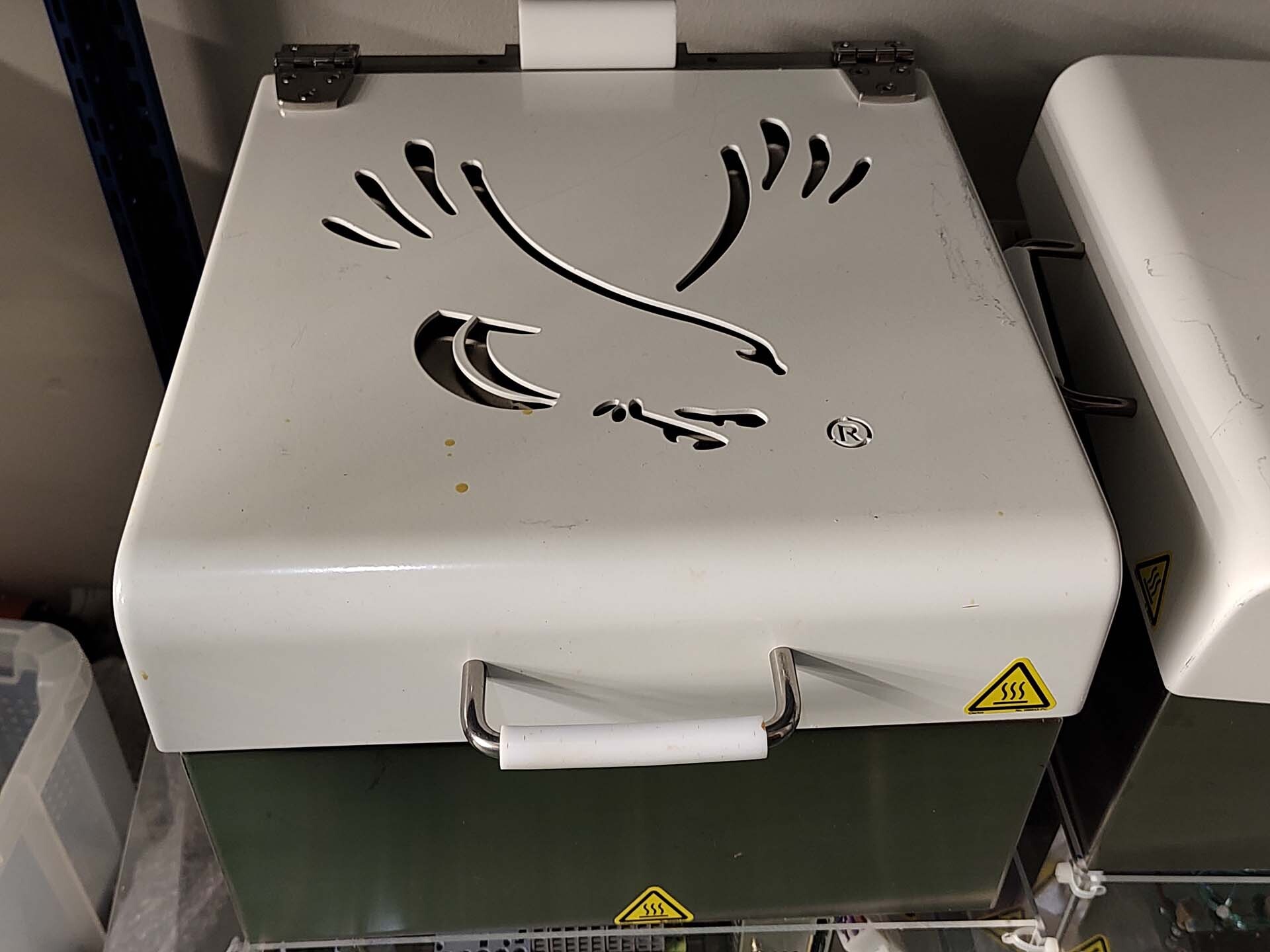

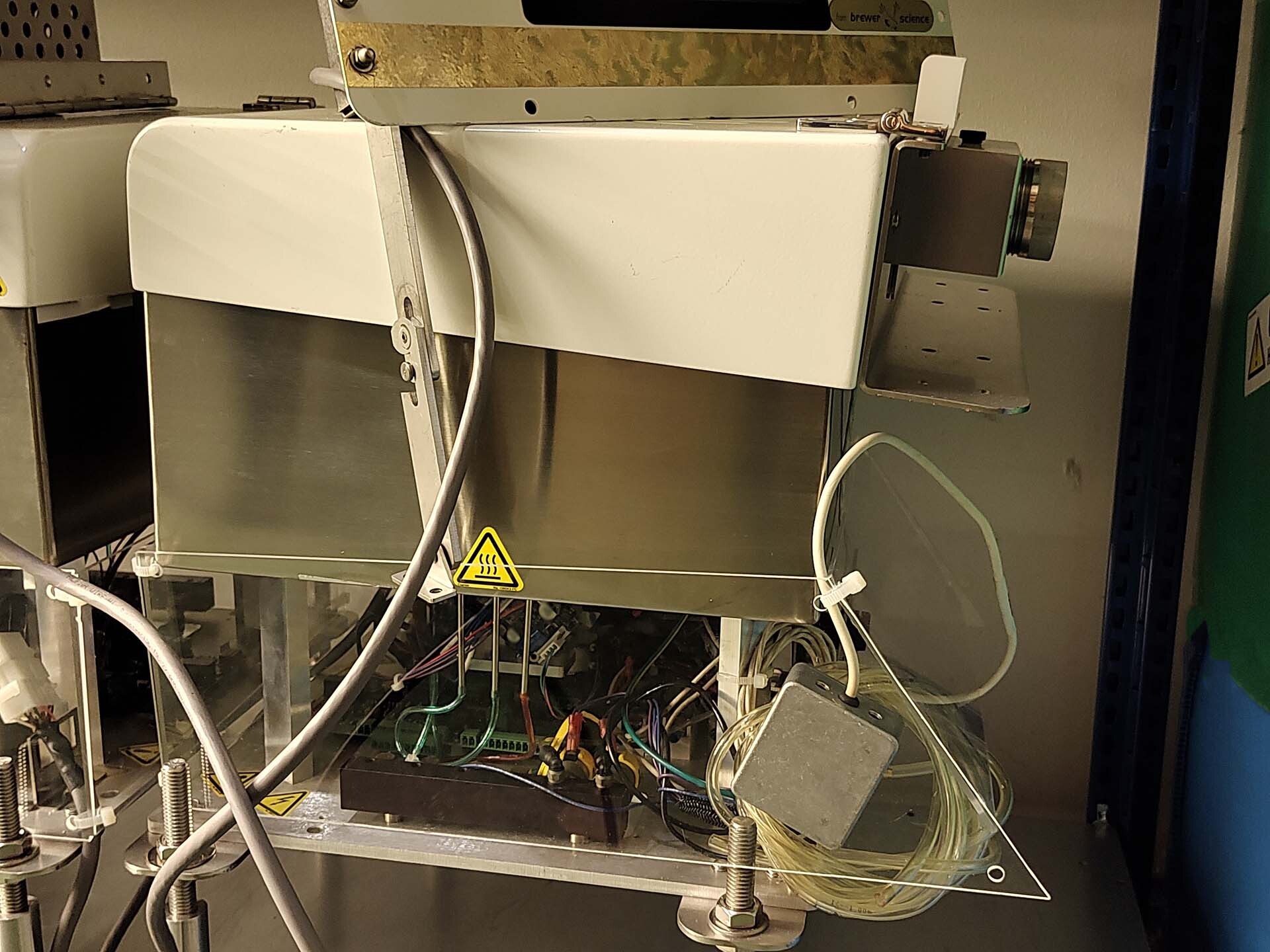

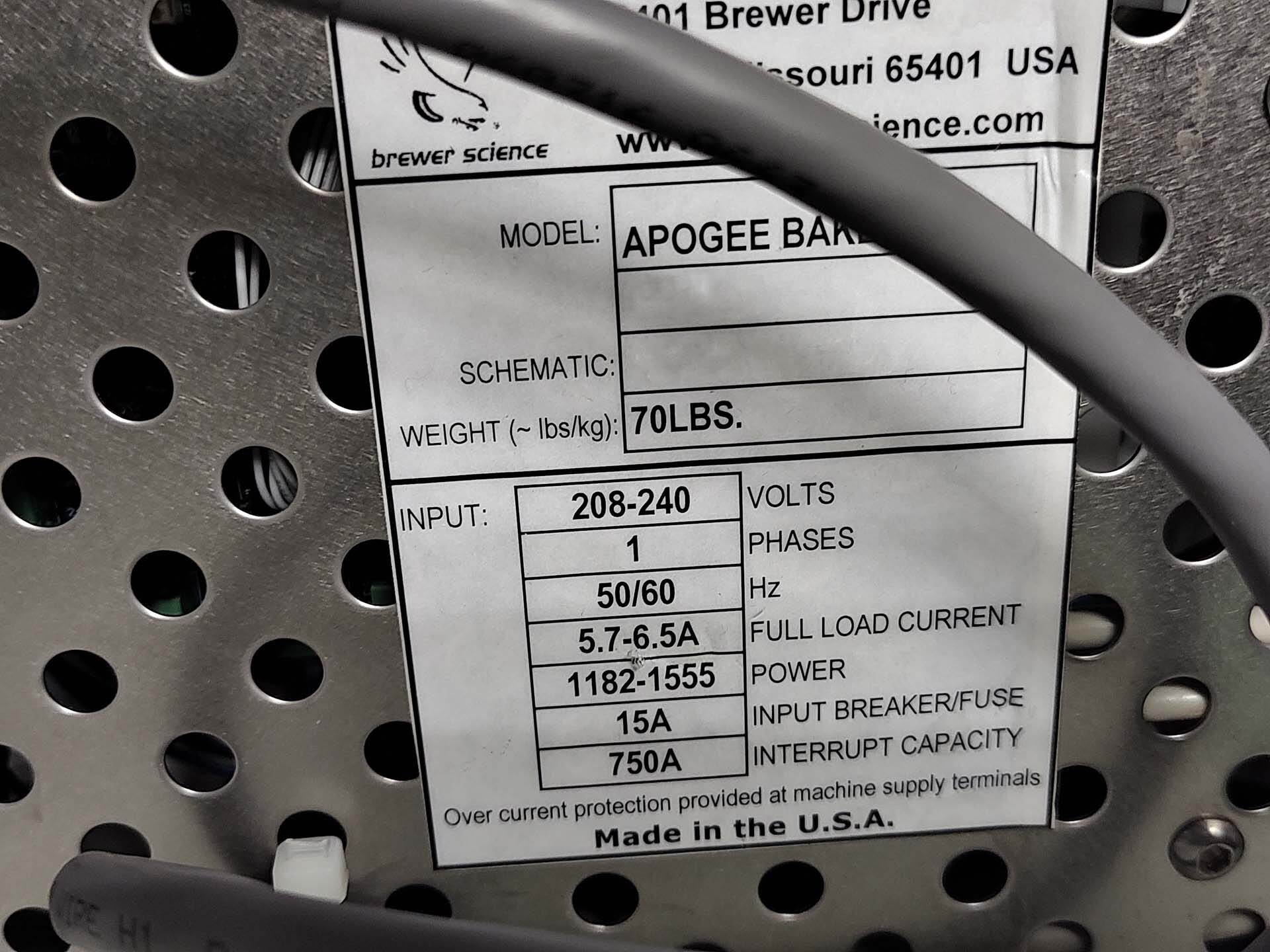

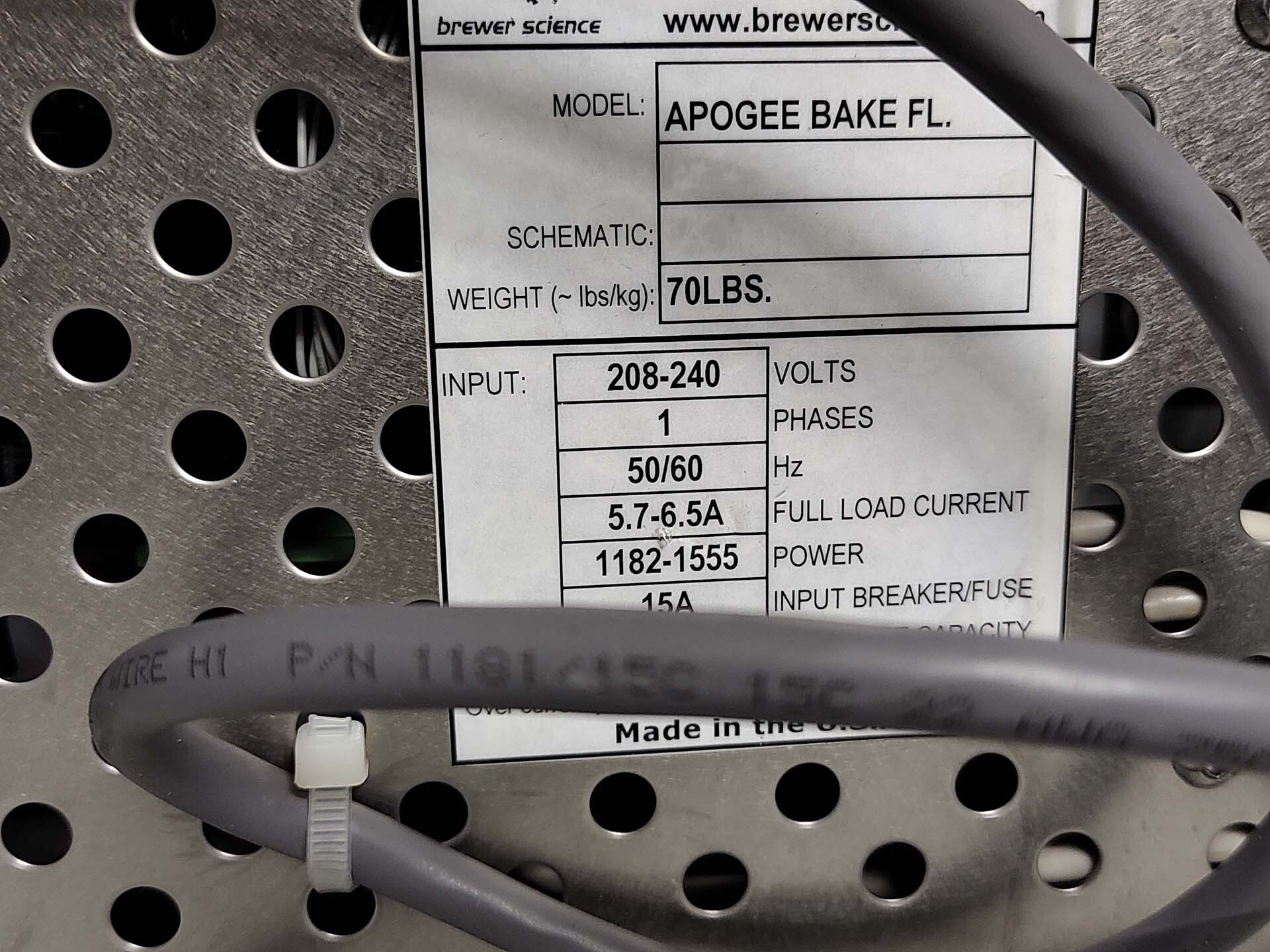

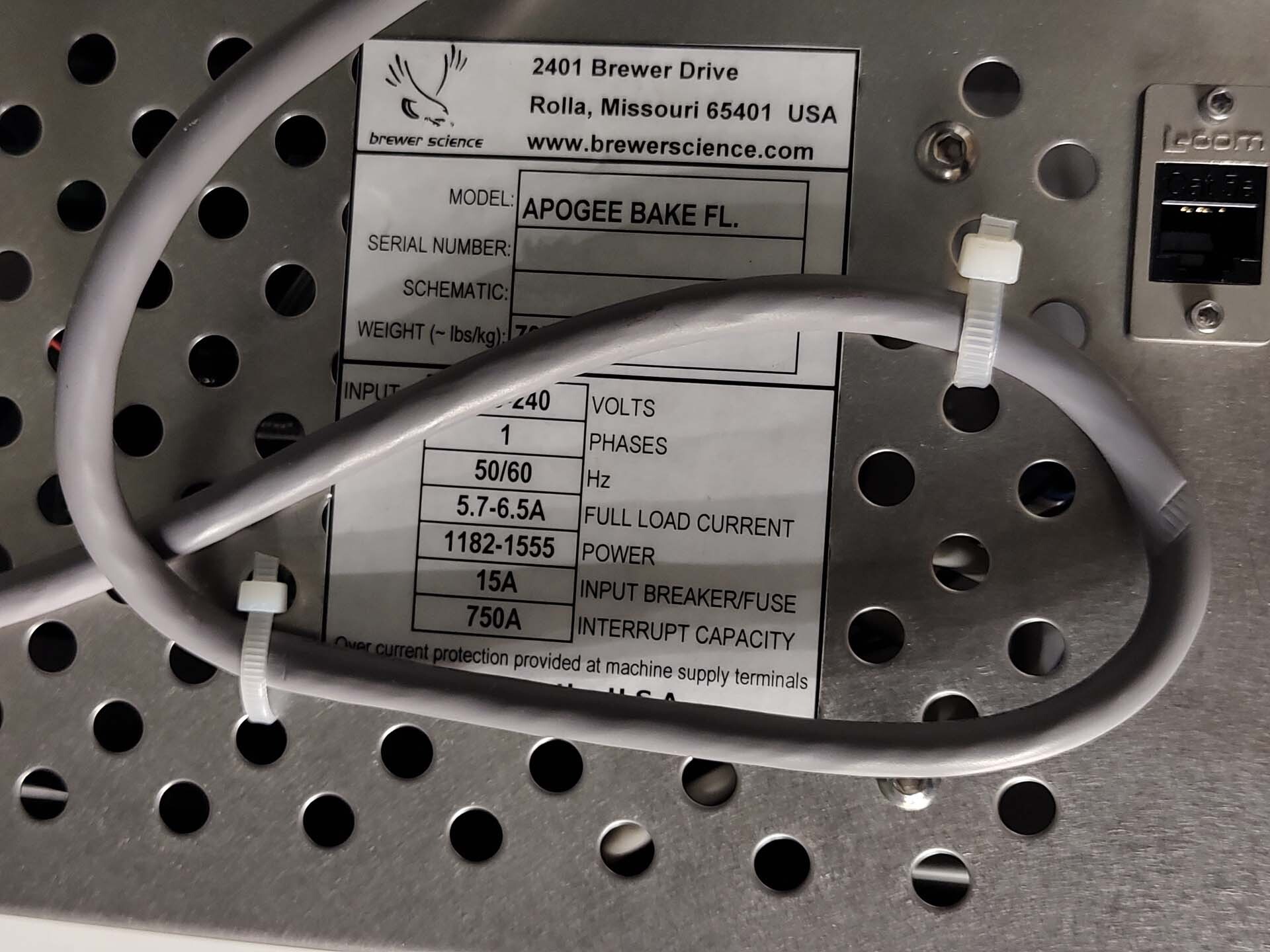

Used BREWER SCIENCE Apogee bake FL #293659674 for sale

URL successfully copied!

Tap to zoom

BREWER SCIENCE Apogee bake FL is a state-of-the-art photoresist equipment designed for the deployment of film resist systems. This system is suitable for high-volume lithography needs, allowing for fast, reliable, and repeatable processes. The unit works by controlling both the spin speed and the process time applied to the photoresist, and then baking the resist layer onto the wafer surface. The machine utilizes a unique "spin-and-bake" method to create an even and reliable coating layer. This method involves spinner-based coating, followed by high-accuracy baking in a closed environment. With this method, the resist is applied to the wafer at a constant flow rate and at a VOC-free environment. High-accuracy baking is achieved with the use of precision heating elements and sensors. The tool is able to accurately monitor temperature and time, ensuring uniform heat distribution. The dimensions of the baking chamber are optimized for uniform distribution of temperatures up to 230° C, allowing for the shortest possible bake time. Apogee bake FL also features advanced automated software, enabling users to create automated recipes, process files, and control parameters to fine tune the asset for specific requirements. Users will be able to program the subsystems to optimize their results, such as the speed and time of the shingle feeder, the dwell time of the spinner, the speed of the infiltration chamber, the temperature setpoint, and other parameters. Additionally, the model is equipped with an array of onboard processing recipes. In addition to process automation, the equipment offers a number of safety and environmental protection features, such as self-monitoring of temperatures, low chemical emissions, and efficient energy-saving technology. This ensures a safe and eco-friendly environment in the workplace. BREWER SCIENCE Apogee bake FL is an advanced and efficient photoresist system that is designed to meet the demands of high-volume lithography needs. It offers an even coating layer, precise temperature control, automated recipes, and a range of safety and environmental features. With the unit, users can achieve repeatable and reliable results, ensuring their success in a multitude of lithography applications.

There are no reviews yet