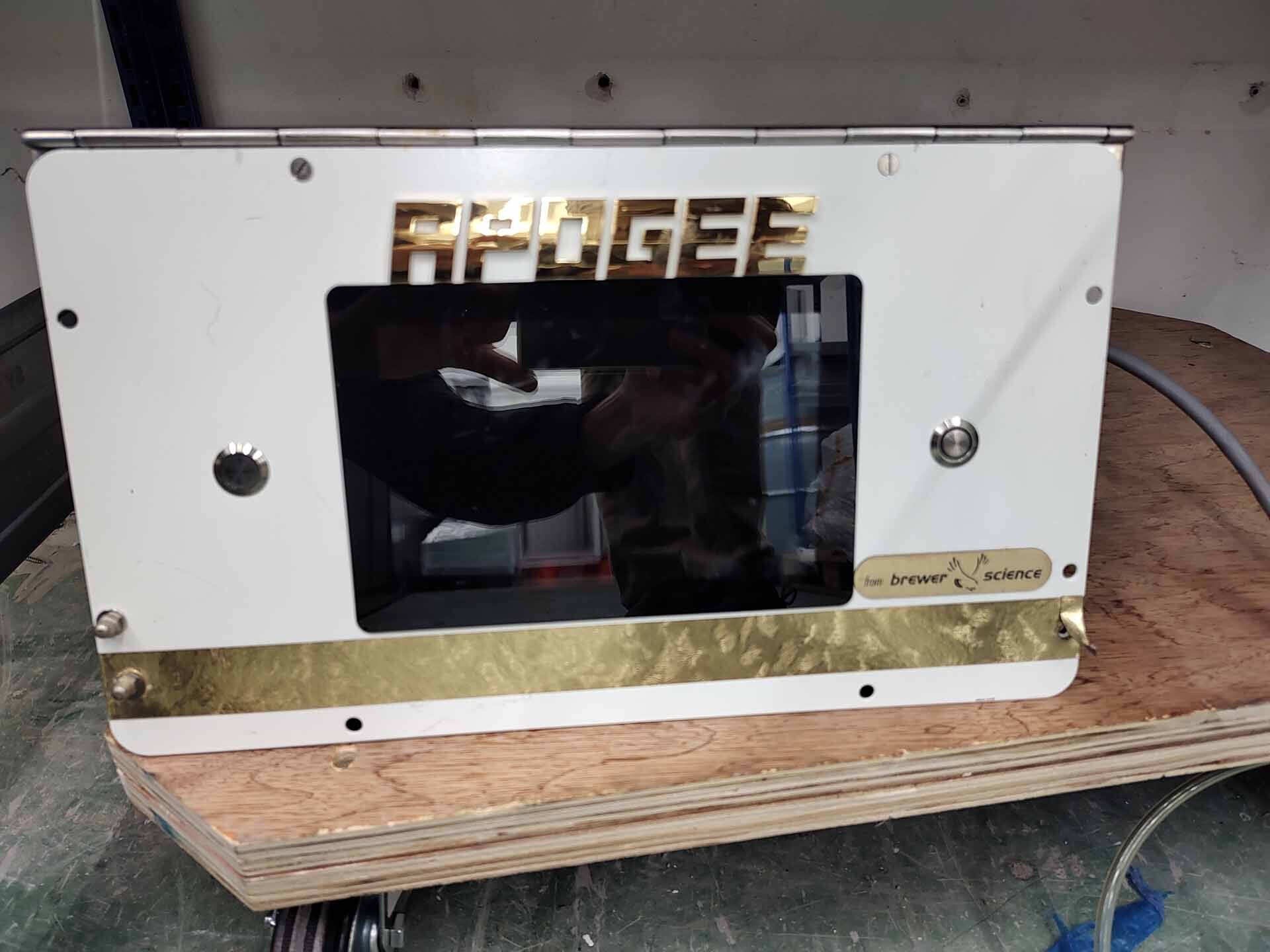

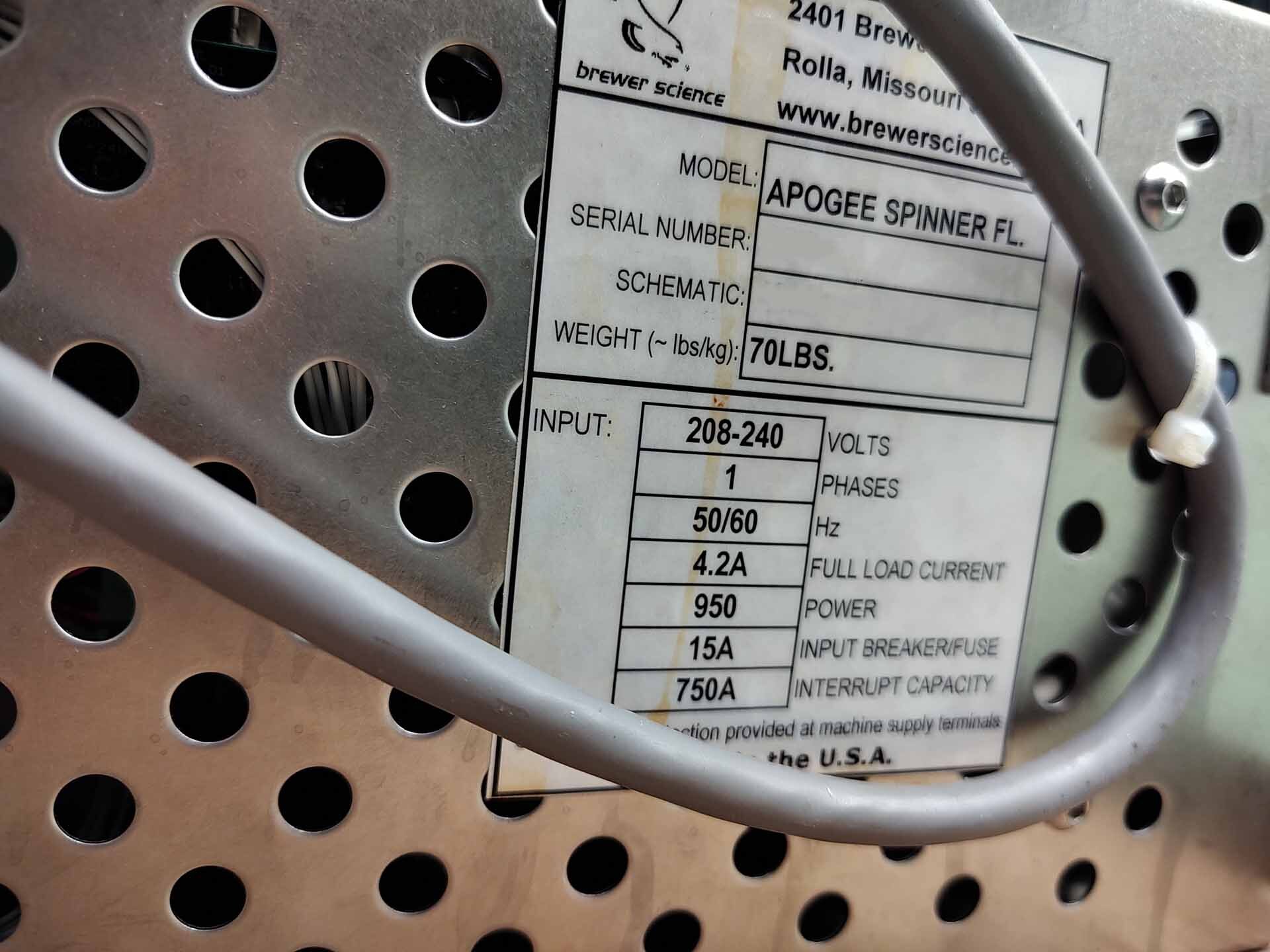

Used BREWER SCIENCE Apogee spinner FL #293651589 for sale

URL successfully copied!

Tap to zoom

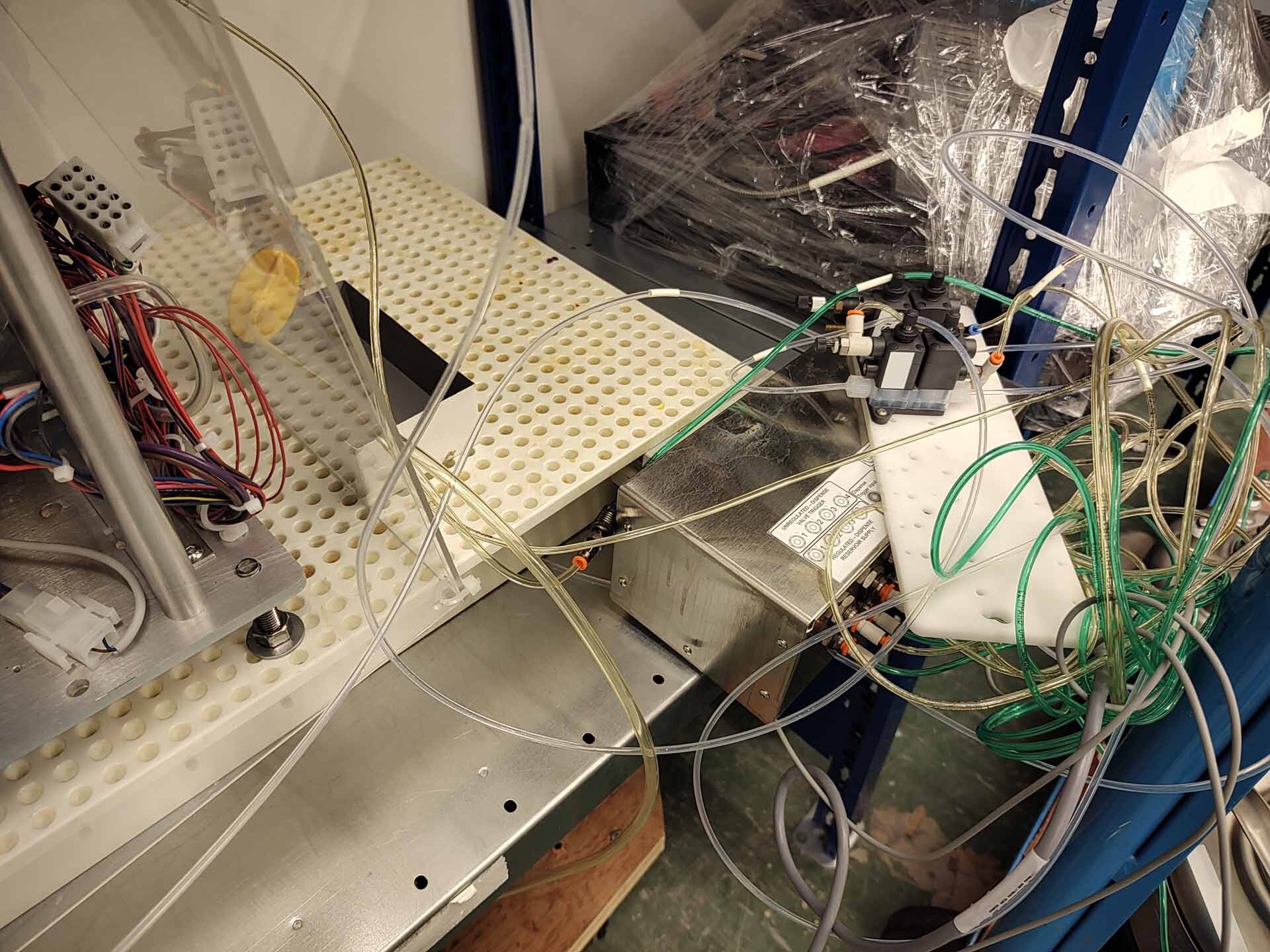

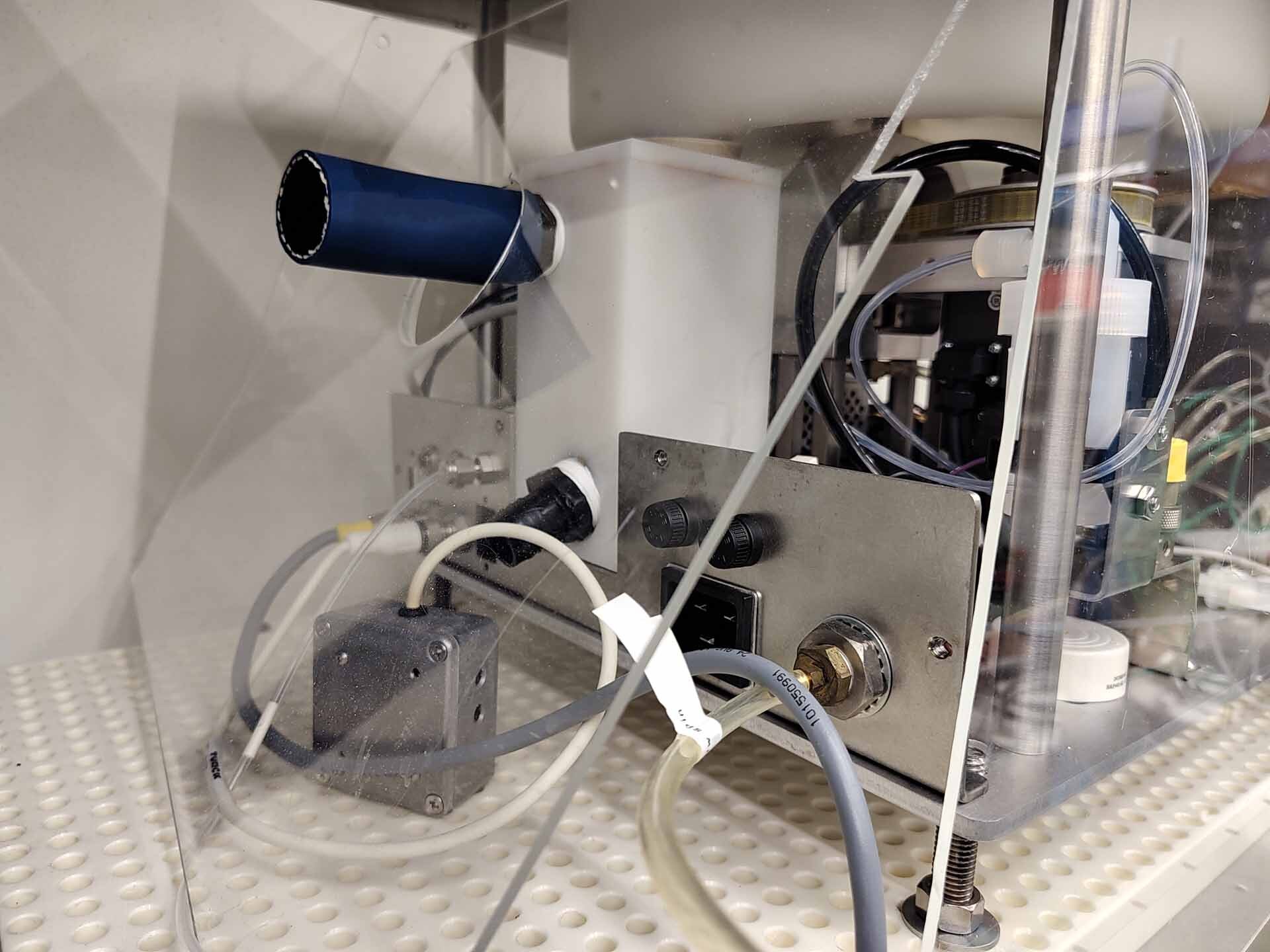

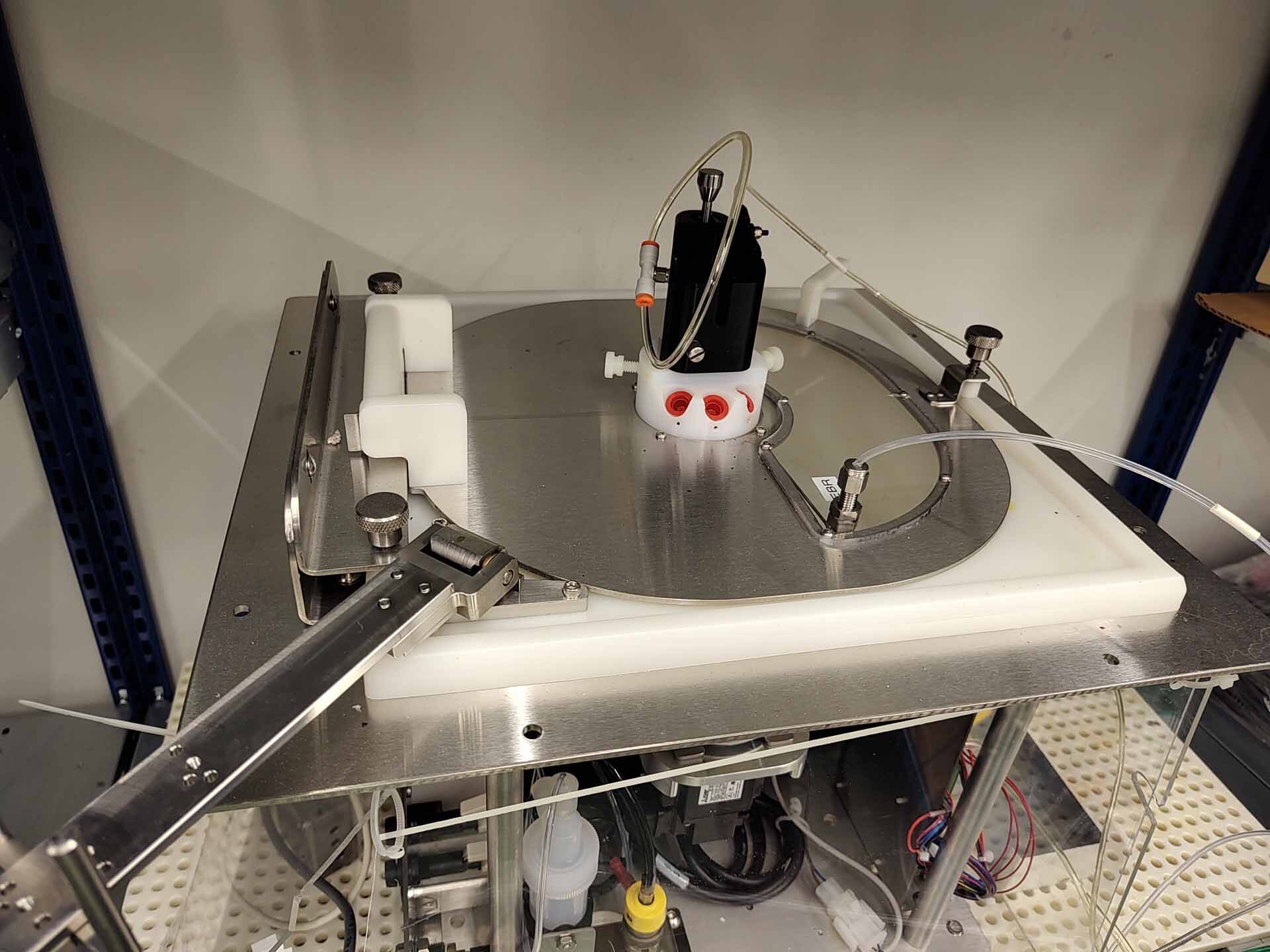

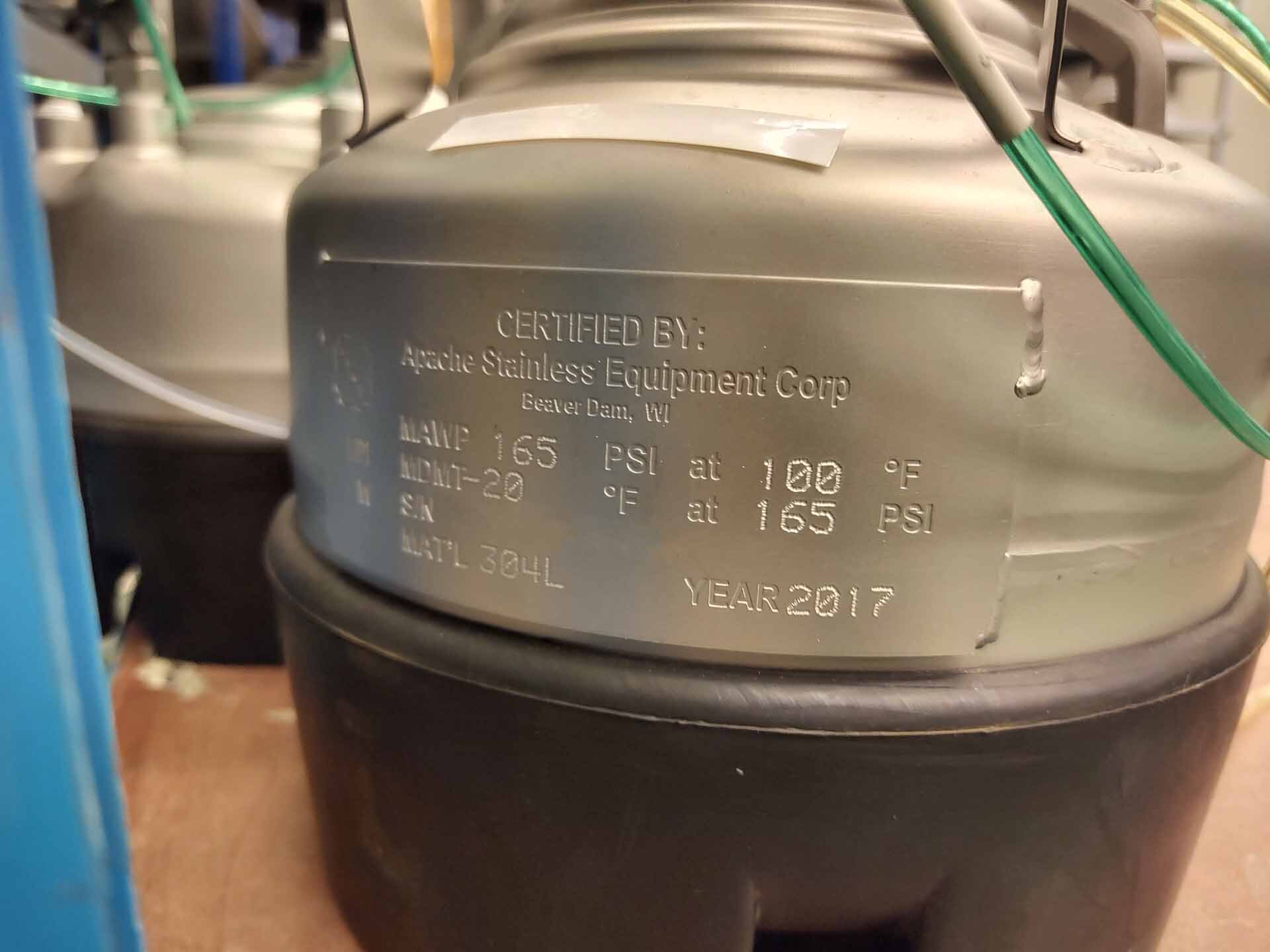

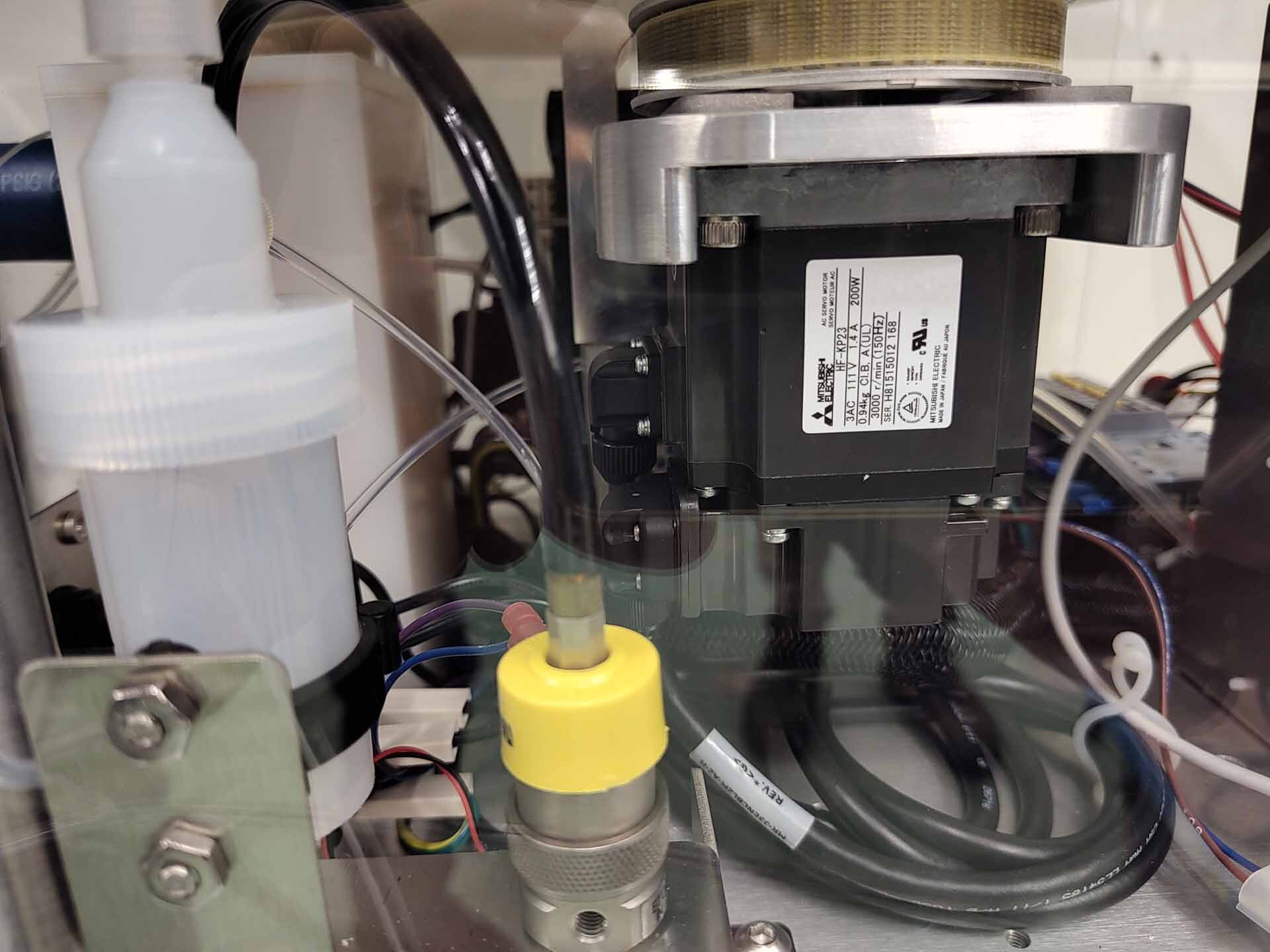

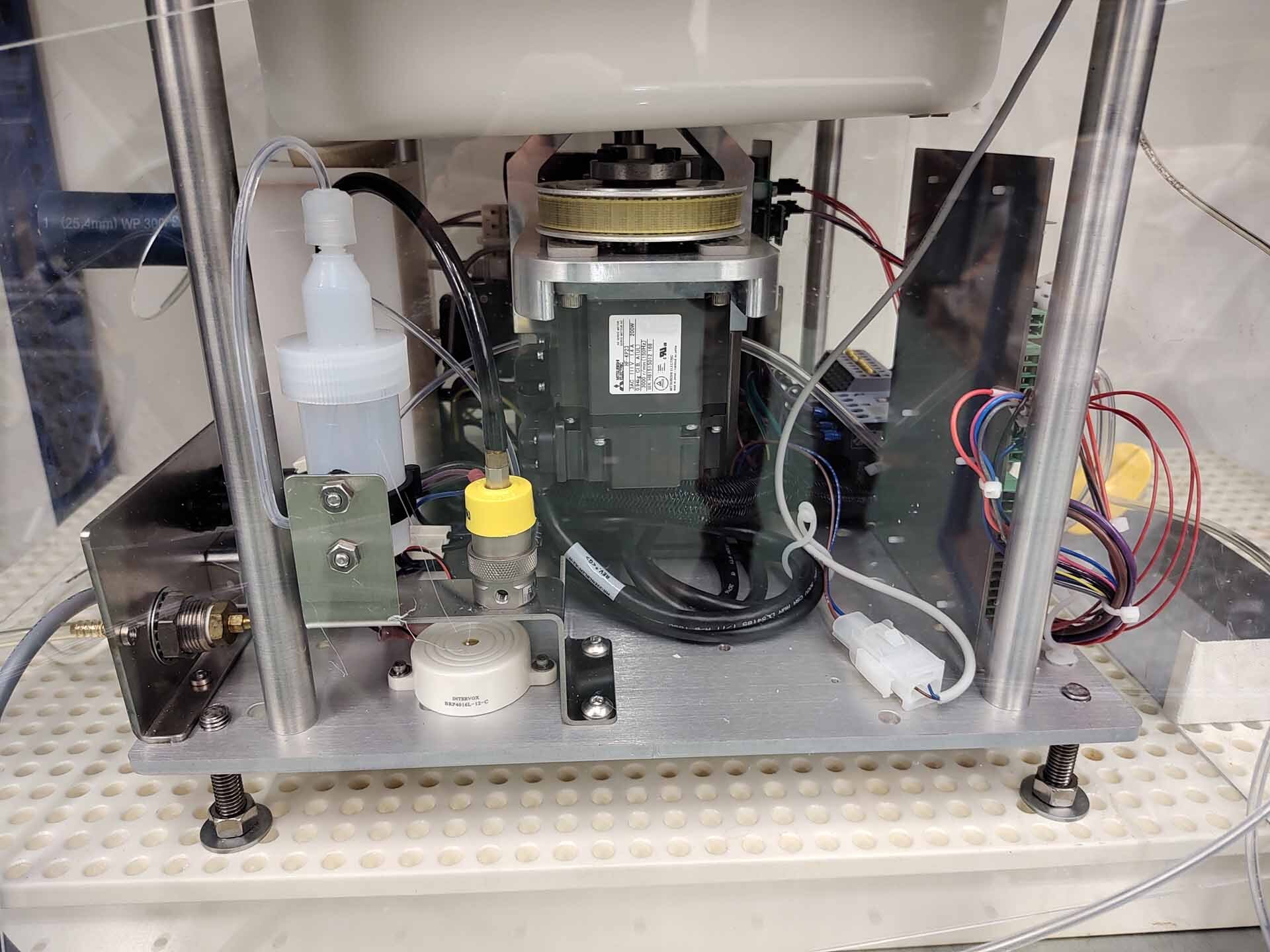

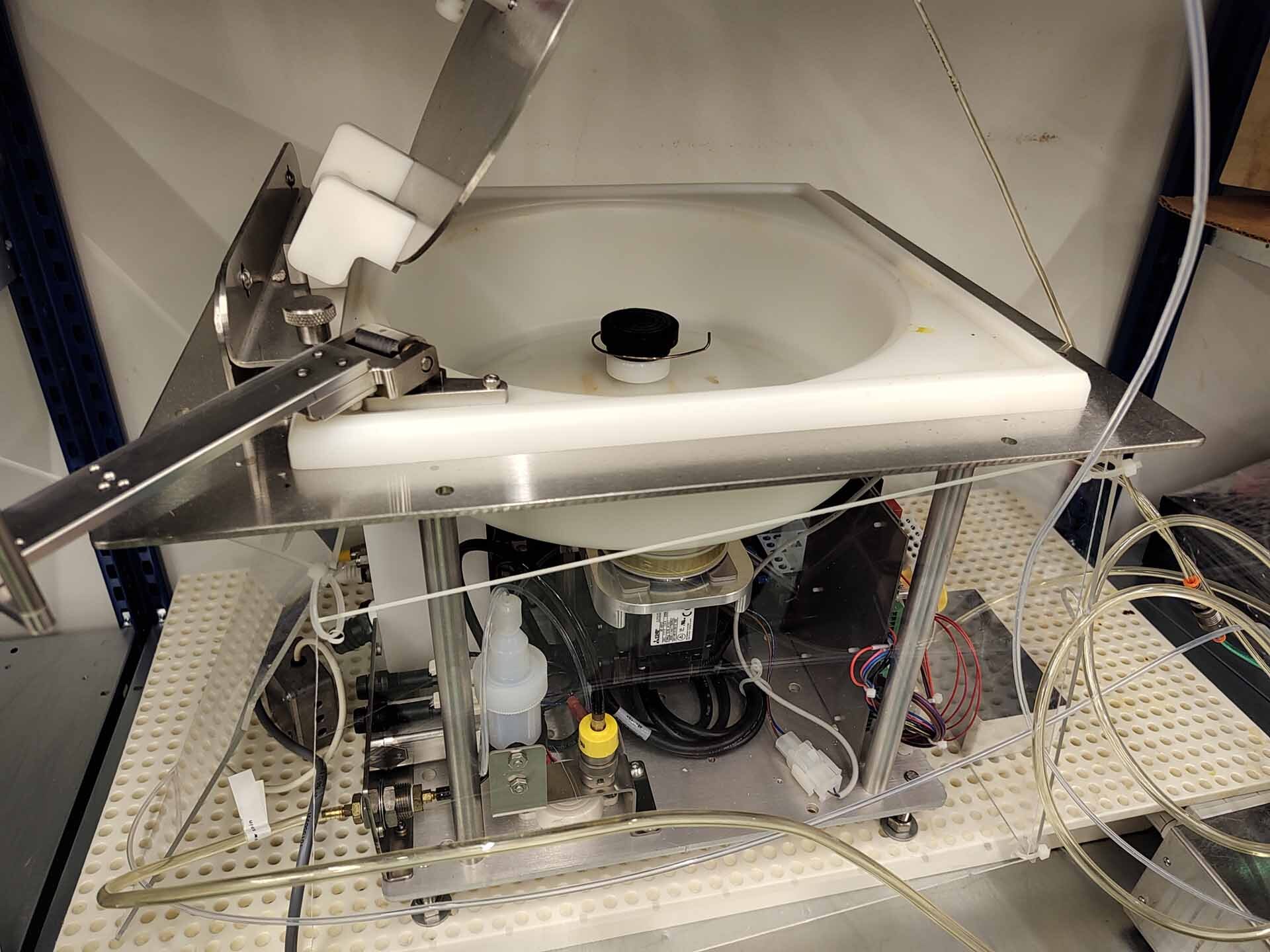

The Brewe Science BREWER SCIENCE Apogee spinner FL is a photoresist equipment designed for industrial spinner lithography processes. It is a cost-effective, frequency-controlled photoresist coating system capable of coating substrates ranging in size from 4" to 12" in diameter. The unit is equipped with one or two dispense chambers, each of which can simultaneously dispense molten photoresist and various liquids or mixtures for spin coating up to four substrates. This allows for the application of photoresist with a uniform thickness across the entire surface area of the substrate, reducing the time and cost associated with traditional spin-on resists. The photoresist machine is comprised of a spindle, positioned directly beneath the rotating substrate. The spindle is driven by a frequency-controlled motor, which is connected to a stainless steel hose that carries the photoresist to the substrate. The end of the hose is equipped with a showerhead-like nozzle that precisely dispenses the molten photoresist. The molten photoresist is released just above the substrate and is propelled toward the surface by centrifugal force. This creates a uniform layer of photoresist over the entire surface area of the substrate. A high-intensity infrared (IR) lamp is mounted on the bottom of the spindle and is used to cure the photoresist as it is applied to the substrate. The IR lamp is powered by an external power source, usually a power invertor, which supplies the lamp with the necessary power to initiate the curing process. Additionally, the spinner is equipped with a temperature controller, which precisely regulates the temperature of the molten photoresist to ensure precise curing results. The photoresist tool is designed to be user-friendly and easy to operate, requiring minimal training and calibration. The asset features an intuitive user interface and a variety of display options for monitoring the process and ensuring optimal performance. Additionally, the model can be tailored to each customer's unique needs and requirements, making it an extremely versatile and cost-effective option for industrial spinner lithography processes.

There are no reviews yet