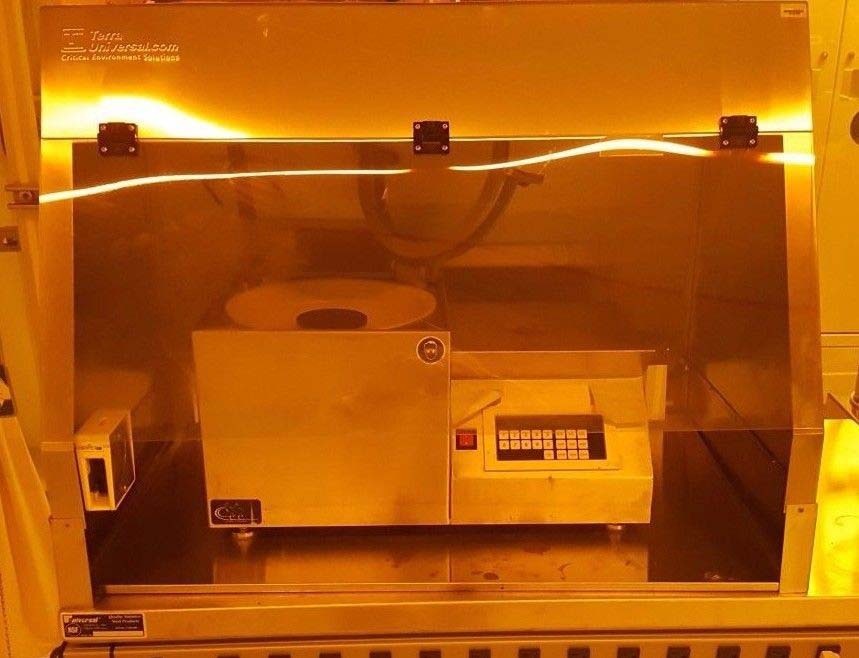

Used BREWER SCIENCE CEE 100 #9329155 for sale

URL successfully copied!

Tap to zoom

ID: 9329155

Hotplate / Spinner

Full load current: 3.2 A

Fuse: 15 A

Interrupt capacity: 10000

Power supply: 110-125 V, Single phase, 50/60 Hz.

BREWER SCIENCE CEE 100 is a photoresist equipment for lithographic processing, which uses light-sensitive polymers to create patterns on a substrate. The system uses a light-sensitive chemical, or photoresist, which is imagesensitive and can be selectively exposed to light or blocked from light. The photoresist is generally applied in a thin layer to the substrate and selectively exposed to light in order to create the desired pattern. The exposed photoresist is then washed away, revealing the underlying pattern in the substrate. BREWER SCIENCE CEE-100 takes this concept further by using a high-resolution, full-color printing unit. Through the use of a patented design, this machine produces patterns more quickly and with greater accuracy than traditional methods. It also eliminates the need to use solvents and other harsh chemicals during the printing process while still producing intricate designs. CEE 100 provides the ability to produce higher-resolution patterns than with other photoresist systems due to the use of a UV, or ultra-violet light source. This light source produces an intense beam of light that is further filtered through masks before reaching the substrate. This ensures that the photoresist is exposed only in the desired areas, allowing for the creation of incredibly detailed patterns. Additionally, CEE-100 includes a self-referenced optical drive tool, which is able to accurately position the substrates as well as the masks used for patterning. This ensures that all the elements are aligned properly during the process. This asset also enables users to accurately place patterns on the substrate for multi-layer applications or for further integration into additional processing steps. Overall, BREWER SCIENCE CEE 100 provides a user-friendly photoresist model for the creation of complex patterns with higher resolution than other systems. Its self-referenced optical drive equipment alongside the UV light source enable users to accurately and quickly produce patterns on a substrate with minimal use of harsh chemicals or solvents. This system is well-suited for a multitude of applications from printed circuit boards to the fabrication of microelectronic components.

There are no reviews yet