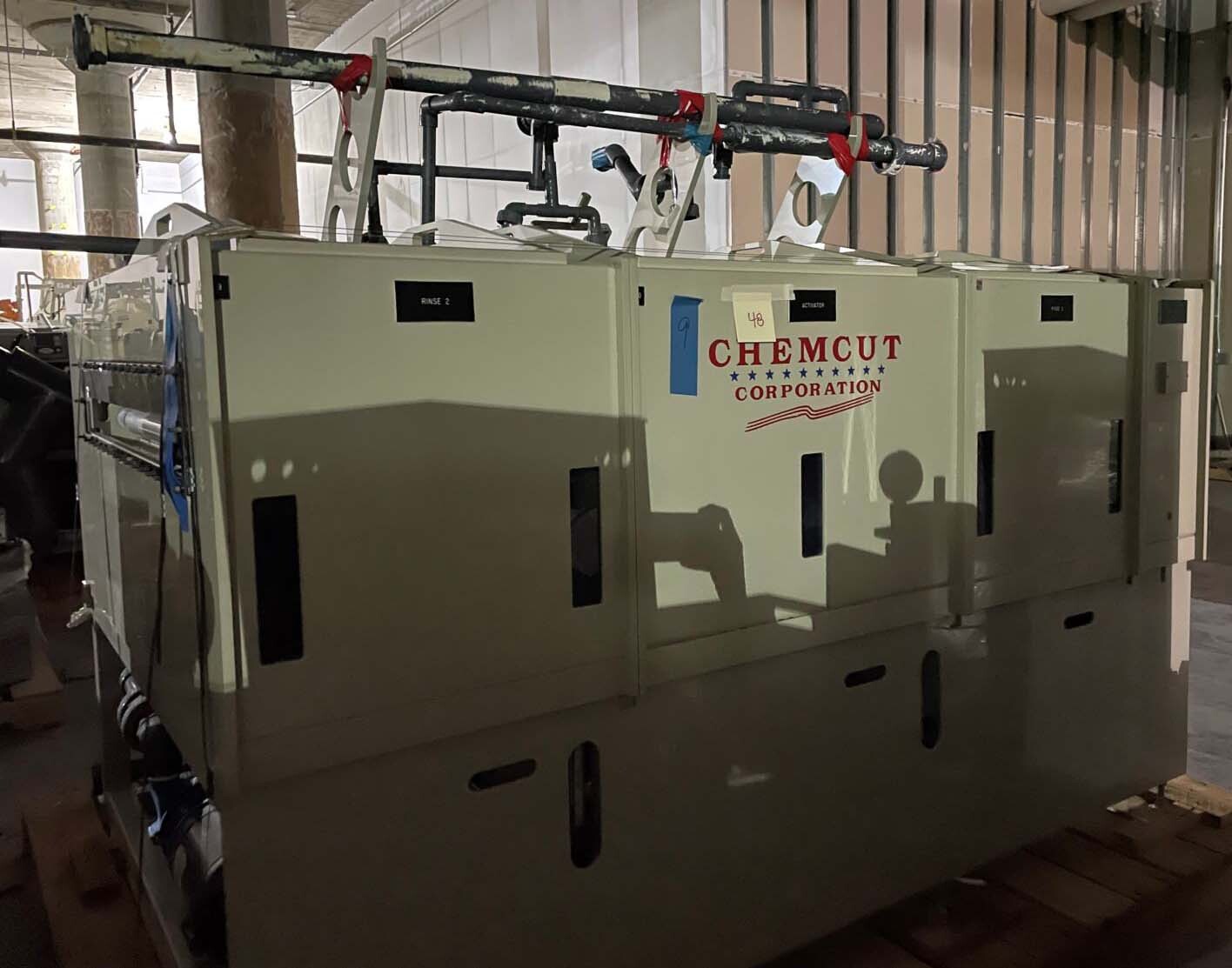

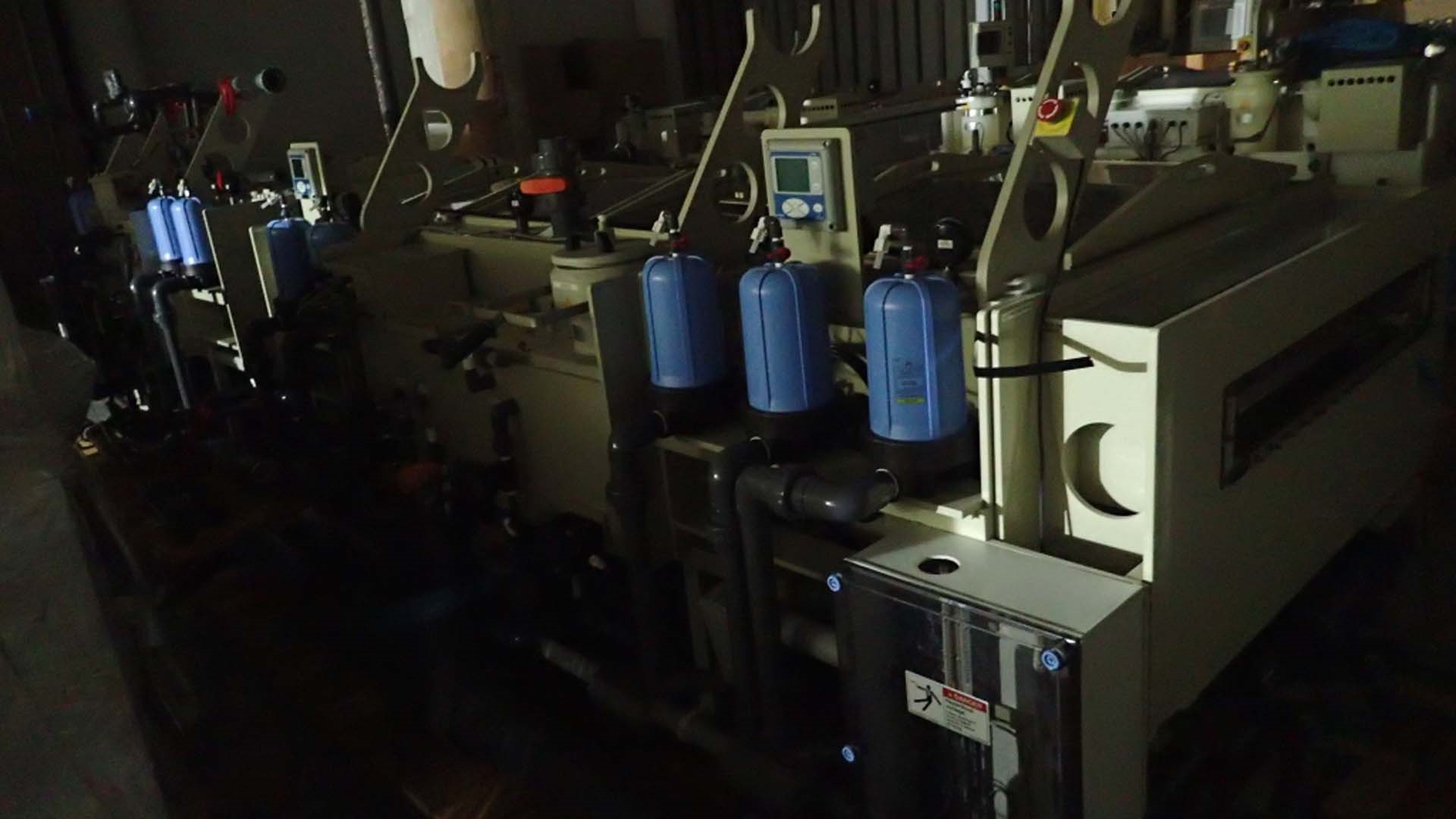

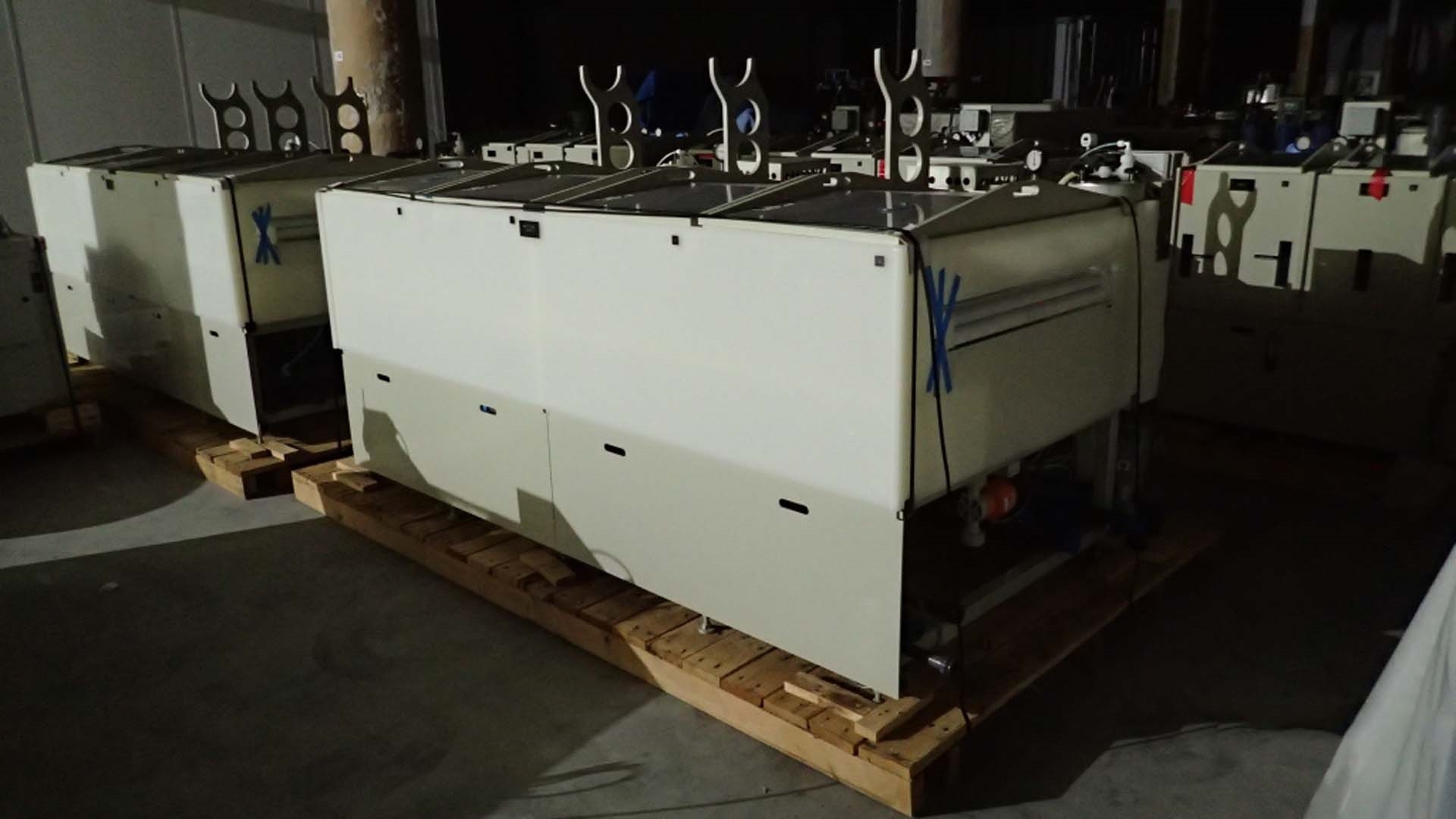

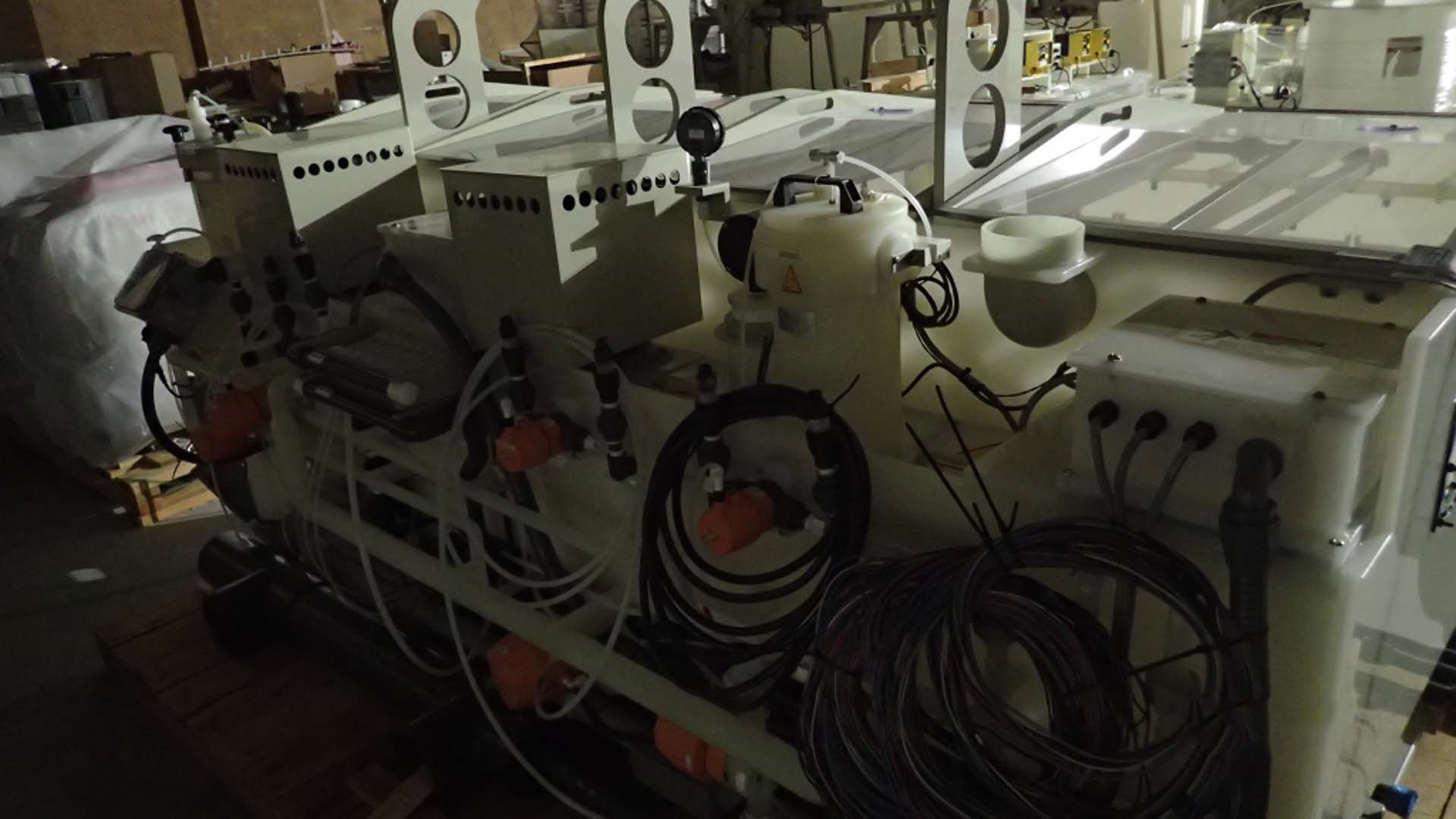

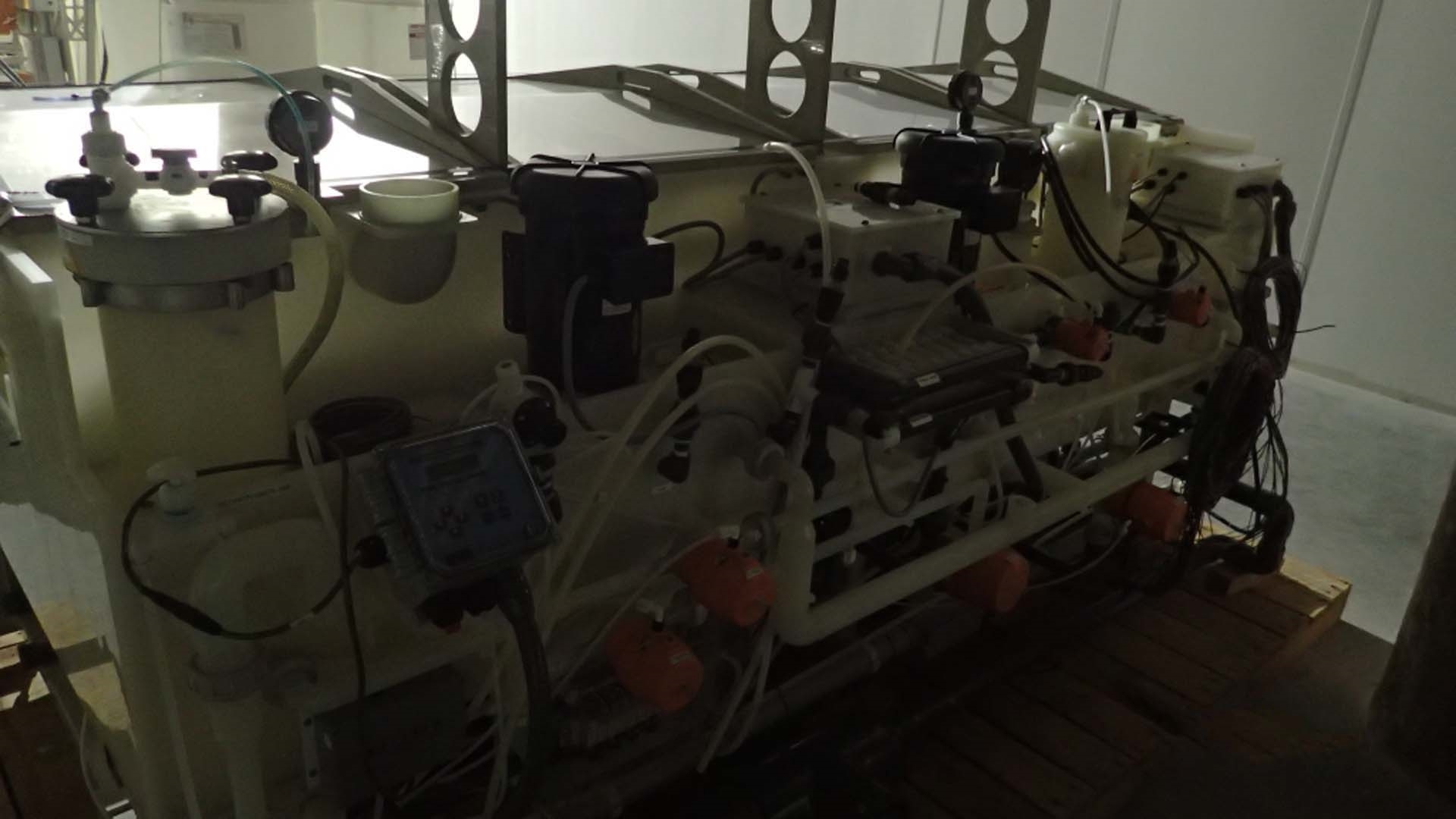

Used CHEMCUT Stations for CC8000 series #9217526 for sale

URL successfully copied!

Tap to zoom

ID: 9217526

Qty / Model / Description

(2) / BLEF313 / Load / Conveyor drive stations

(2) / PCSF3338 / Pre-treat stations

(2) / PCRF301 / Single stage water rinse stations

(2) / PIF3160 / Electroless copper etching stations

(2) / PIF3110 / Electroless copper etching stations

(2) / PISF310 / Inspection / Conveyor drive stations

(2) / PCRF303 / 3-Stage water rinse stations

(2) / PCSF348 / Activator stations

(2) / PCRF302 / 2-Stage water rinse stations

(2) / PISF310 / Inspection / Conveyor drive stations

(2) / PIF390 / Electroless nickle etching stations

(2) / PCRF302 / 2-Stage water rinse stations

(2) / PCSF3018 / Anti-tarnish stations

(2) / PCR302 / 2-Stage water rinse stations

(2) / PPDF303 / Triple head dryer stations

(1) / ALLEN-BRADLEY / Panelview 1000 / Input conveyor

(1) / - / Cleaner station

(1) / - / 2-Stage water rinse station

(1) / - / Inspection / Conveyor drive station

(1) / - / Electroless copper etching station

(1) / - / 2-stage water rinse station

(1) / - / Activator station

(1) / - / 2-Stage water rinse station

(1) / - / Inspection / Conveyor drive station

(1) / - / Electroless nickel etching station

(1) / - / Anti-Tarnish Station

(1) / - / PCR302 / 2-Stage water rinse station

(1) / - / PCR302 / 2-Stage water rinse station

(1) / - / PPDF303 / Triple head dryer station

(1) / - / PREF318 / Conveyor drive / Unload station

(4) / - / 4-Stage water rinse stations

(2) / - / Control cabinets

(5) / - / Cleaning systems.

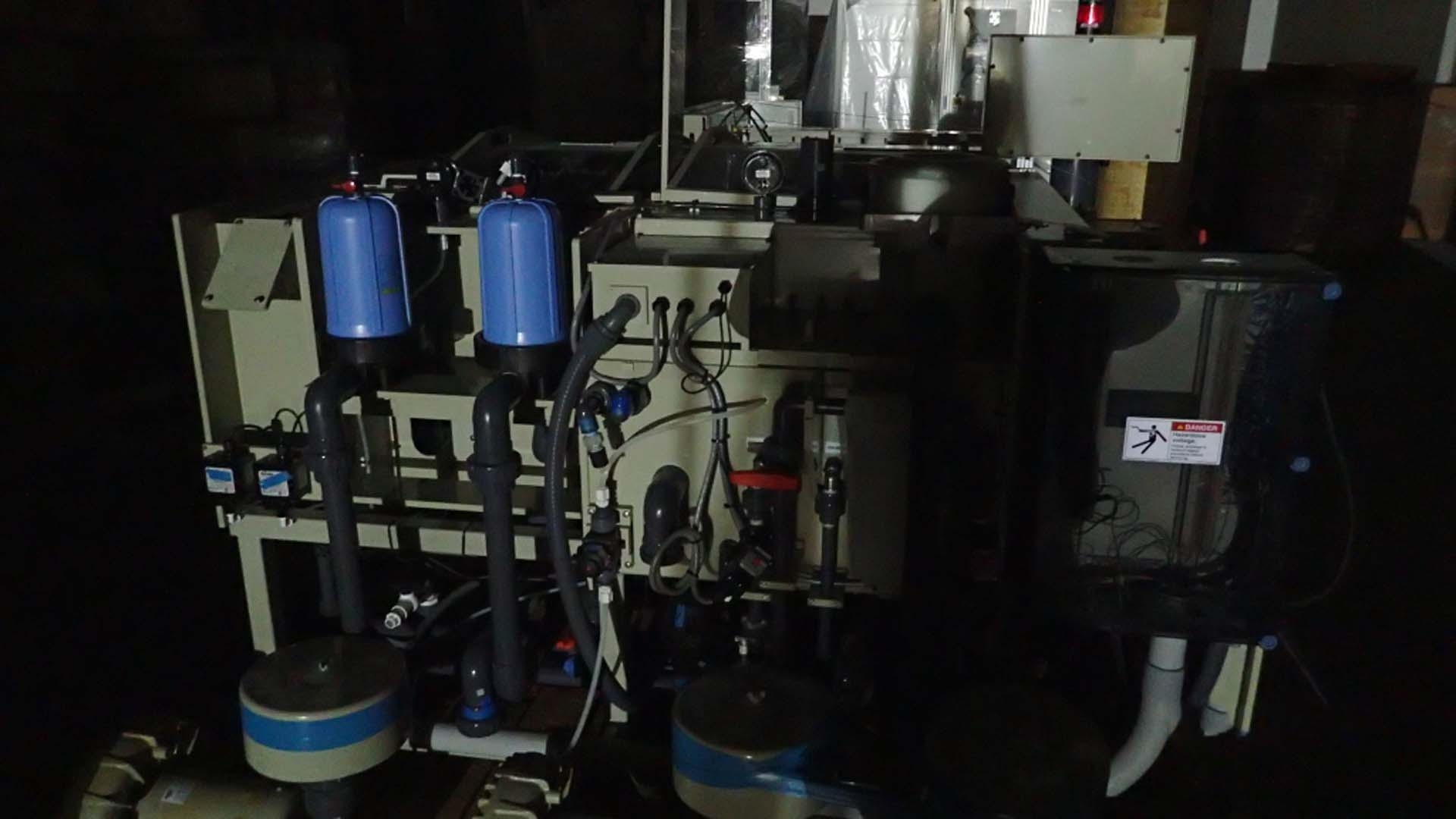

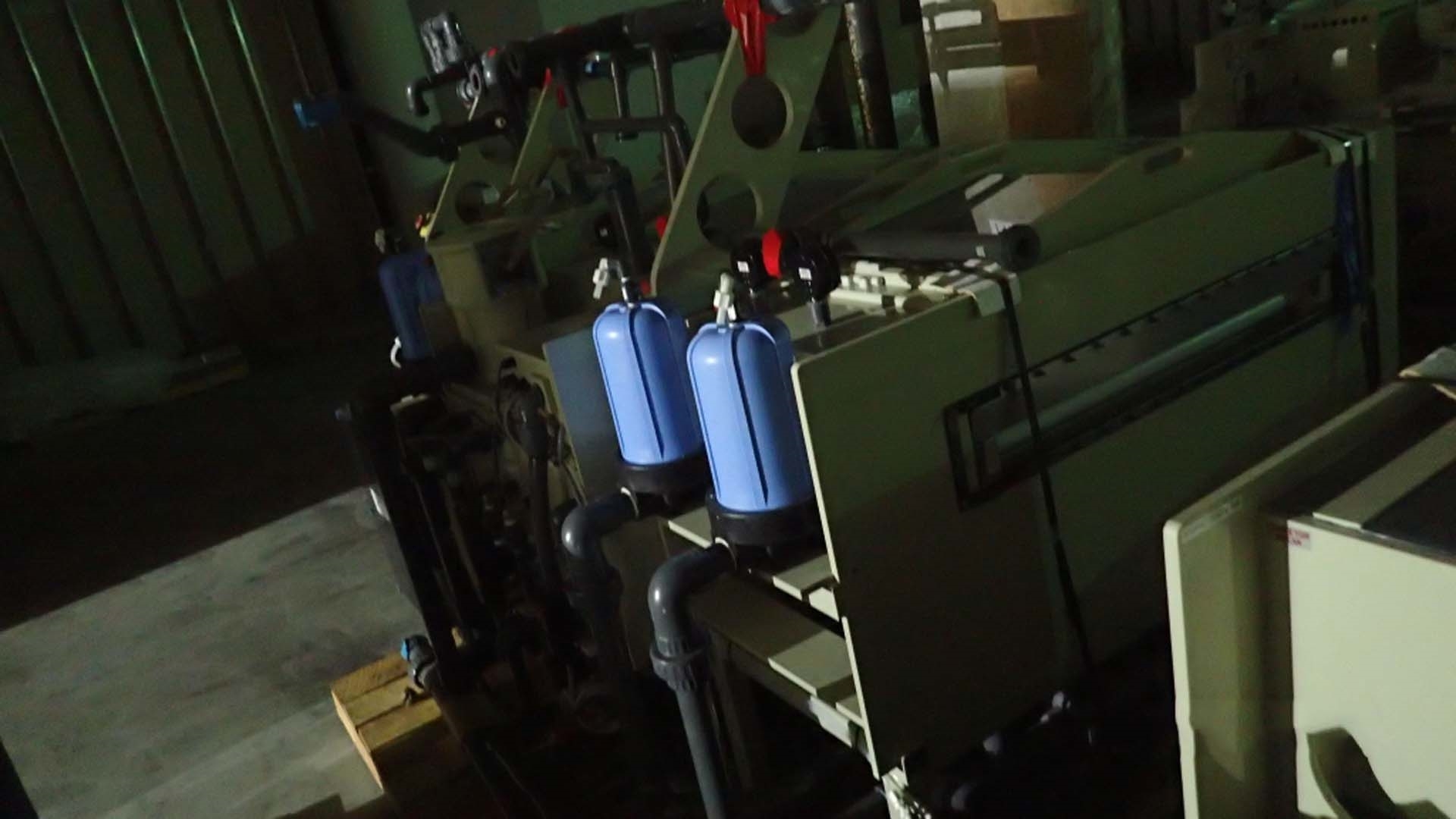

CHEMCUT Stations for CC8000 series is a photoresist equipment used to create finely detailed resist patterns in substrate surfaces. This system is suitable for a range of applications, from creating nanoscopic features for semiconductors to decorative art patterns. The core of the unit is the CC8000, a precision dispenser that uses precisely timed micro-dispense technology to apply a wide range of resist materials onto a substrate. The CC8000 offers an exceptionally detailed contamination-free pattern application, as well as a fast particle-free buildup process. With an advanced micro-dispense technology that allows for greater precision in resist pattern placement, this machine offers exceptional pattern repeatability. The CC8000 is integrated with two different types of stations, allowing users to customize their tool to meet their unique application needs. The manual station allows for manual operation of the dispenser, with an intuitive user interface that offers easy setup and control over the processes that are applied to substrates. The automated station, on the other hand, offers an integrated setup that is designed to optimize the processes used by the CC8000. One of the advantages of Stations for CC8000 series is its compatibility with various resist types, from both organic and inorganic materials. The asset is also designed to be compatible with a variety of substrates, from traditional glass or wafers to nanograting or compound semiconductor surfaces. By utilizing an image-based mapping model, the CC8000 can also detect surface defects, allowing for precise pattern control. CHEMCUT Stations for CC8000 series also features an integrated monitoring equipment that enables users to monitor every step of the process. This system allows for detailed analysis and monitoring of each micro-dispense process as it takes place. Additionally, the unit can produce detailed reports in order to track processes and help improve operational efficiency and accuracy. Overall, Stations for CC8000 series offers a reliable and highly precise photoresist machine for a wide array of applications. By providing accurate and repeatable patterns, this tool enables users to create finely detailed resist patterns on various surfaces quickly and easily. The user-friendly interface, combined with the integrated monitoring asset, ensures that each process is optimized to produce the highest quality patterns and substrates.

There are no reviews yet