Used CONVAC 6000 #293595958 for sale

URL successfully copied!

Tap to zoom

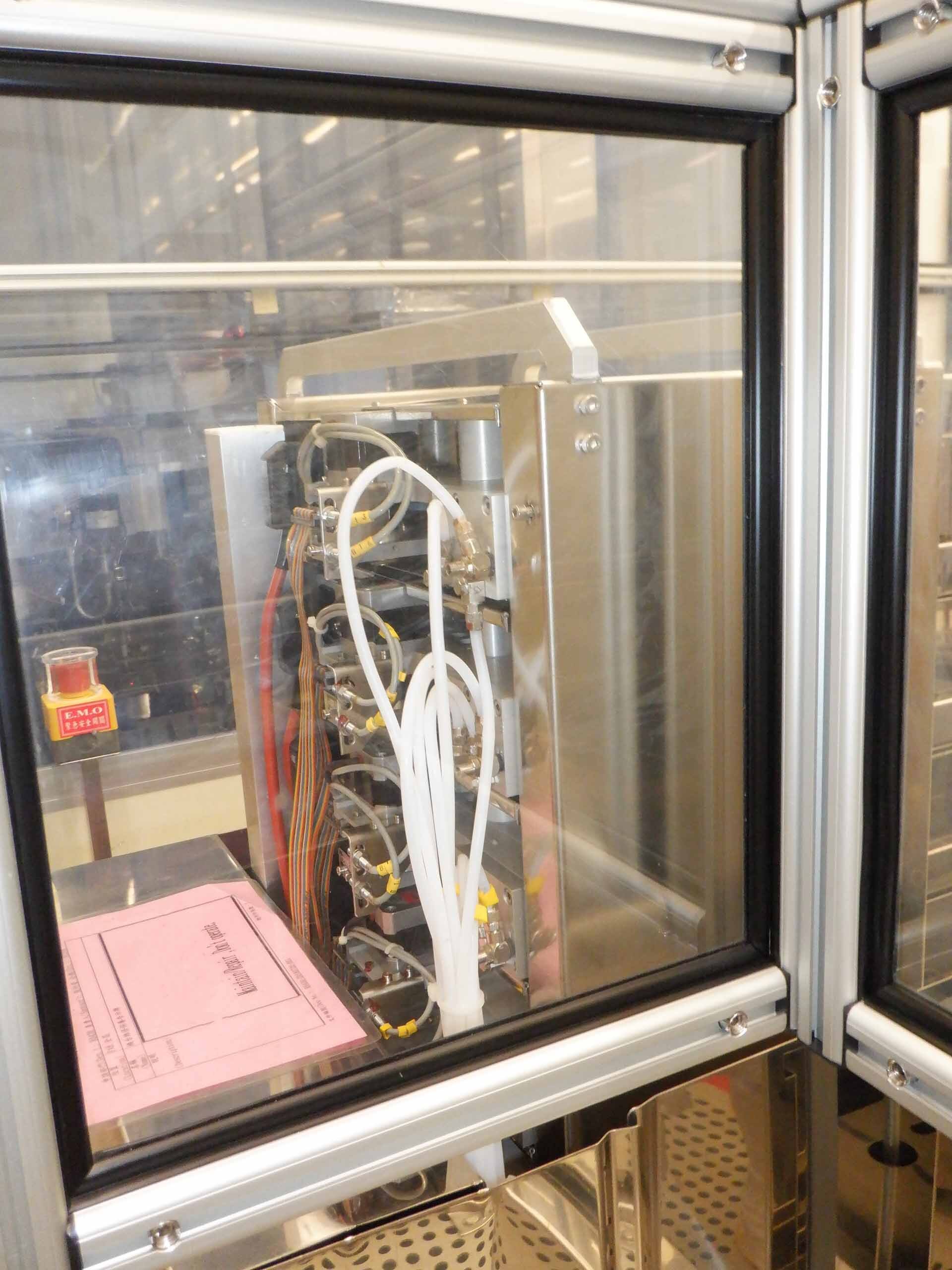

CONVAC 6000 is a powerful, high-precision photoresist equipment developed by Micralyne Inc. It uses the proven technology of photoresist processing to precisely copy patterns onto layers of metal or other substrate materials. This system makes use of advanced hardware and software to provide superior performance and accuracy when compared to other forms of photoresist processing. The unit is designed to meet the needs of advanced industrial applications, providing a large number of image processing and development techniques for complex etching, plating, and pattern replication jobs. The machine is composed of four main modules, capable of handling up to 32 different processes. These include the Tool Controls Unit (SCU), the Pattern Controller, the Developer, and the Vision Acquisition and Analysis Systems (VAAS) software package. The Asset Controls Unit (SCU) is the primary hardware component, controlling all operations of the photoresist model. It is capable of operating both an automated photoresists station and a manual mask manipulator. It contains both environmental and safety monitors, providing a secure interface for handling photoresist processes. The Pattern Controller is the computer processor used to control the etching process. It holds the complete pattern information and is capable of automatically scaling, rotating, and duplicating patterns. This allows for fast and accurate etching of components with very tight tolerances. The Developer is the main software component of the photoresist equipment. It is responsible for controlling the entire formula and processing steps, from preparation to light exposure. It provides sophisticated features such as pattern cutting for advanced etching, plating, and other image processing techniques. It also offers a number of tools for editing, resizing, and converting images. Finally, the Vision Acquisition and Analysis Systems (VAAS) software package is a powerful set of tools for capturing and analyzing images. The package includes an imaging library, image analysis tools, and advanced image processing tools. It is used for analyzing the etched surface of components and providing feedback to improve process performance. Overall, 6000 photoresist system is a precision unit designed to meet the needs of advanced industrial applications. It combines a powerful hardware platform with powerful software solutions to maximize performance and accuracy. With CONVAC 6000, industries can make more reliable components, while also reducing costs and turnaround times.

There are no reviews yet