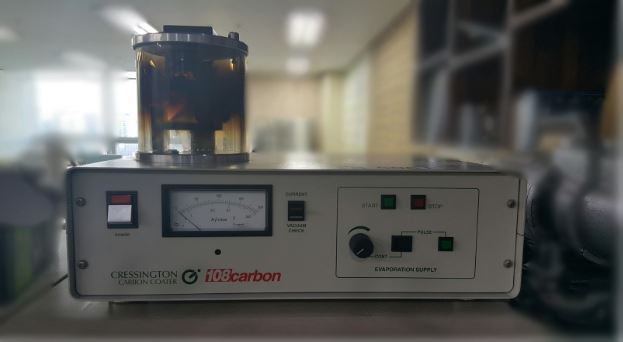

Used CRESSINGTON 108C #9159246 for sale

URL successfully copied!

Tap to zoom

CRESSINGTON 108C is a photoresist equipment used to create intricate patterns of circuitry on a substrate or other material. The system uses light to define the size and shape of patterns. The unit is used mainly in the production of electronic components, such as integrated circuit boards and chips, as well as other products that require precision-patterned products. To start the machine, a substrate is placed in the tool's light source and exposed to ultraviolet (UV) light of a specific wavelength. The light source is managed by a laser diode coupled to a microprocessor. The microprocessor is programmed to regulate the amount of light and the number of pulses emitted. Once exposed to the light, the substrate is covered with a photoresist material. Upon exposure to the light, the photoresist material undergoes a chemical reaction and forms a photomasking layer. This layer serves as a barrier, protecting the substrate from etching chemicals. Once a photomask is created, the substrate is ready to be transferred into 108C. In the asset, an automated pick-and-place robot is used to manipulate a thin metal stencil, which is fitted with a pattern of holes. This robot is used to place the perfect amount of photoresist material on the substrate. After the photoresist is applied, the substrate is then placed in a preprogrammed chemical bath to etch the desired pattern into the material. This process is also known as photolithography. Once the etching is complete, the substrate is ready for the next step. This may involve further etching and patterning, or it could be ready for assembly and application. Overall, CRESSINGTON 108C photoresist model is a useful tool for creating reliable, duplication-free, precise patterns on electronic components and other materials. The equipment is highly efficient, with low cost and effort, making it an invaluable tool in the production of many products.

There are no reviews yet