Used DMC SA/3m #143322 for sale

URL successfully copied!

Tap to zoom

ID: 143322

Wafer Size: 8"

Vintage: 2006

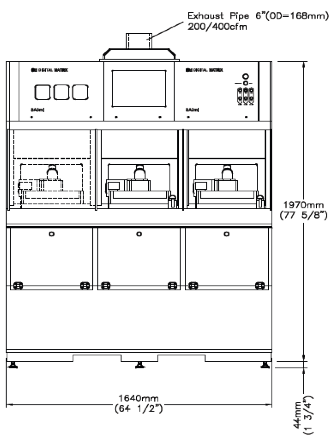

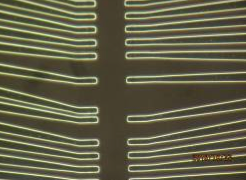

Wafer-level Electro Plating system, 8"

Used for Stamper and micro pattern electro-plating

Can be implement as high uniformity

Using cathode head rotating system can produce high-quality products

This equipment can be applied to MEMS type and performed on the trench fill electroplating

Process automation can be set with Independent program for each cell

Various plating condition can be set with Independent program for each cell

DC, pulse, pulse- reverse current can be supplied in the resolution ±1 mA

Ni, Ni-CO, Cu Electroplating can be performed with this equipment

Total solution volume: 500 liters

Features:

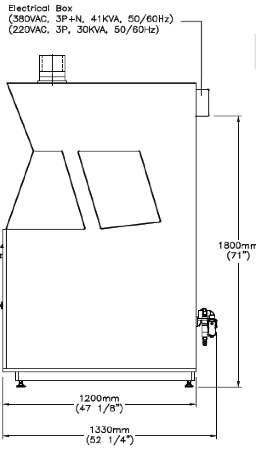

Small Footprint

Independent Pump/Filtration for each cell

Patented adjustable cathode head and workholder for precise control of thickness variation

Front access for maintenance

Integrated all-in-one design, integrated sump & electronics

Enclosed work area for process control

Industrial PC control with large flat panel touch-screen display

Switch mode rectifiers

Easy operator interface

All digital Control system

(Qty 3) Cells:

Pump: 1 HP

Heater: 6 kW

Rectifier: Standard 65 Amps, 24VDC

Filtration: 2 Stage

Pre-filter: 5 micron DOE, 20"

Final-filter: 0.45 micron DOE, 20"

Flow: 50 liter max (Adjustable)

2006 vintage.

DMC SA/3m is a state-of-the-art photoresist-based equipment designed for precision light exposure. This system is specifically designed to meet the requirements of advanced microcircuit manufacturing processes. Its features include high accuracy image mask alignment, precise manual positioning, a powerful x-ray source, and high-resolution imaging capability. DMC SA/3m produces strong, consistent images through the use of its three-axis motorized fiber optics mask alignment unit. This machine enables it to precisely align the imaging position and accurately locate the alignment guide frame to the mask. Its high-powered source is also capable of providing high-intensity light from multiple angles, ensuring consistent illumination on a single surface. DMC SA/3m is highly precise in its positioning. It is able to accurately place and measure the exact position of the mask for each exposure, regardless of the size of the mask. Its x-ray source can be adjusted to provide multipass exposures to create more complex images. Its ultra-high-resolution imaging tool is also capable of capturing information down to a resolution of 5.2 nanometers. In addition to its image reproduction capabilities, DMC SA/3m is also capable of performing coating and develop process integration. Its integral coating asset is designed to ensure consistent image resolution across the entire substrate. Its develop process integration enables high-sensitive imaging on large areas. This model can also be used in combination with other substrate technologies such as etch, deposition and lithography. Overall, DMC SA/3m is a sophisticated photoresist-based equipment for demanding microcircuit manufacturing applications. It offers precise image positioning, multi-axis motorized mask alignment, and powerful x-ray sources. Its imaging capabilities are of a high resolution and the system can be used in combination with other substrate technologies. Thus, DMC SA/3m is an ideal solution for those who need precision and accuracy in their imaging and manufacturing processes.

There are no reviews yet