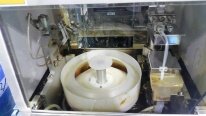

Used DNS / DAINIPPON SC-W60A #9115318 for sale

URL successfully copied!

Tap to zoom

DNS / DAINIPPON SC-W60A Photoresist Equipment is a complete solution for developing, exposing, and etching ultra-thin photoresist layers that are used in the manufacture of semiconductors. DNS SC-W60A combines high precision exposure beam alignment, adjustable overlapping exposure masks, plus high precision wafer positioning and vacuum holding to deliver superior photoresist processing results. The system's architecture is based on a three-axis high precision positioning unit, consisting of a base, a tilt stage, and a wrist joint, which provide exact placement of each wafer within a mask work station. This machine is engineered to ensure exact overlapping of mask layers, and is adjustable to accommodate any size wafer. Additionally, in order to ensure maximum uniformity, DAINIPPON SCW-60A leverages a patterned exposure array, which takes advantage of an upper and lower level scanner to create high-quality images. Additionally, this tool is specially designed to guarantee that each wafer surface is completely free of particles. To optimize photoresist layers as much as possible, DNS SCW-60A utilizes a high-pressure delivery asset, which uses a mechanical shutter to blow pressure at differing levels. This controlled process helps to ensure photoresist patterns adheres uniformly to the substrates. Additionally, an auto focus model is implemented to deactivate particles and monitor the entire process, while a corrosion-resistant stainless steel chamber helps ensure accuracy during continuous use. During etching, DNS / DAINIPPON SCW-60A uses an RF generator and a chemical source to deliver high-performance reactive ion etching. The RF generator is designed to produce a high-frequency wave, which is then sent to the wafer to create a reaction in which ions in the chamber are attracted to the wafer and then create patterns in the photoresist. The chemical source ensures that the etching process is quick and precise. In order to ensure accuracy and high-quality results, SCW-60A is designed to monitor each process. The equipment has multiple sensors and equipment that track particle deposition, temperature, pressure, photoresist layers, and etch concentrations, and automatically display the results on a LCD monitor. Additionally, an algorithm-based matching system ensures that each wafer adheres precisely to the predetermined pattern. Overall, DAINIPPON SC-W60A Photoresist Unit is an excellent choice for semiconductor manufacturers who need precise, consistently high-quality results during their photoresist and etching processes. By leveraging the machine's high precision components, accurate monitoring systems, and automated processes, users can rest assured knowing they are working with a reliable and advanced photoresist solution.

There are no reviews yet