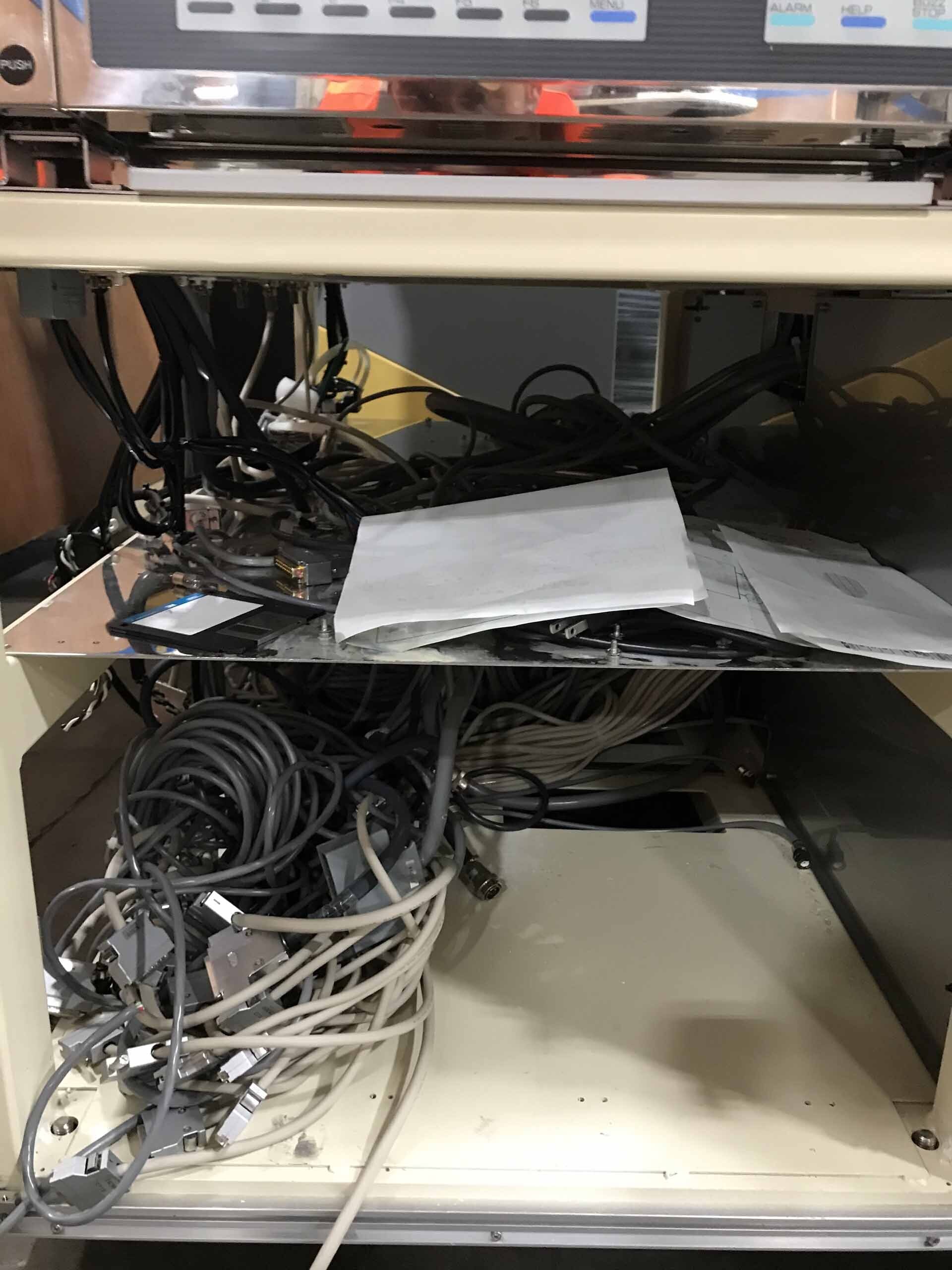

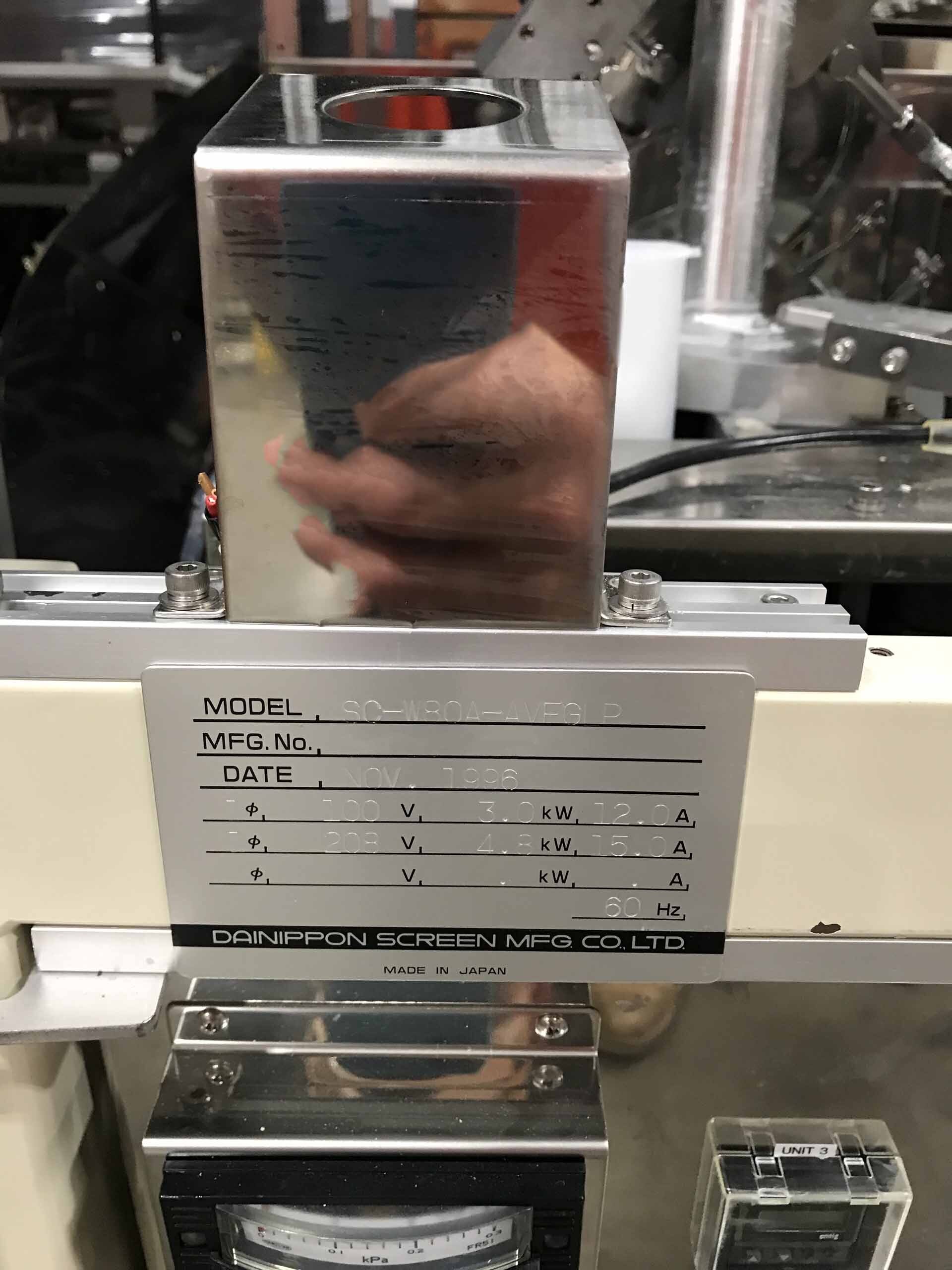

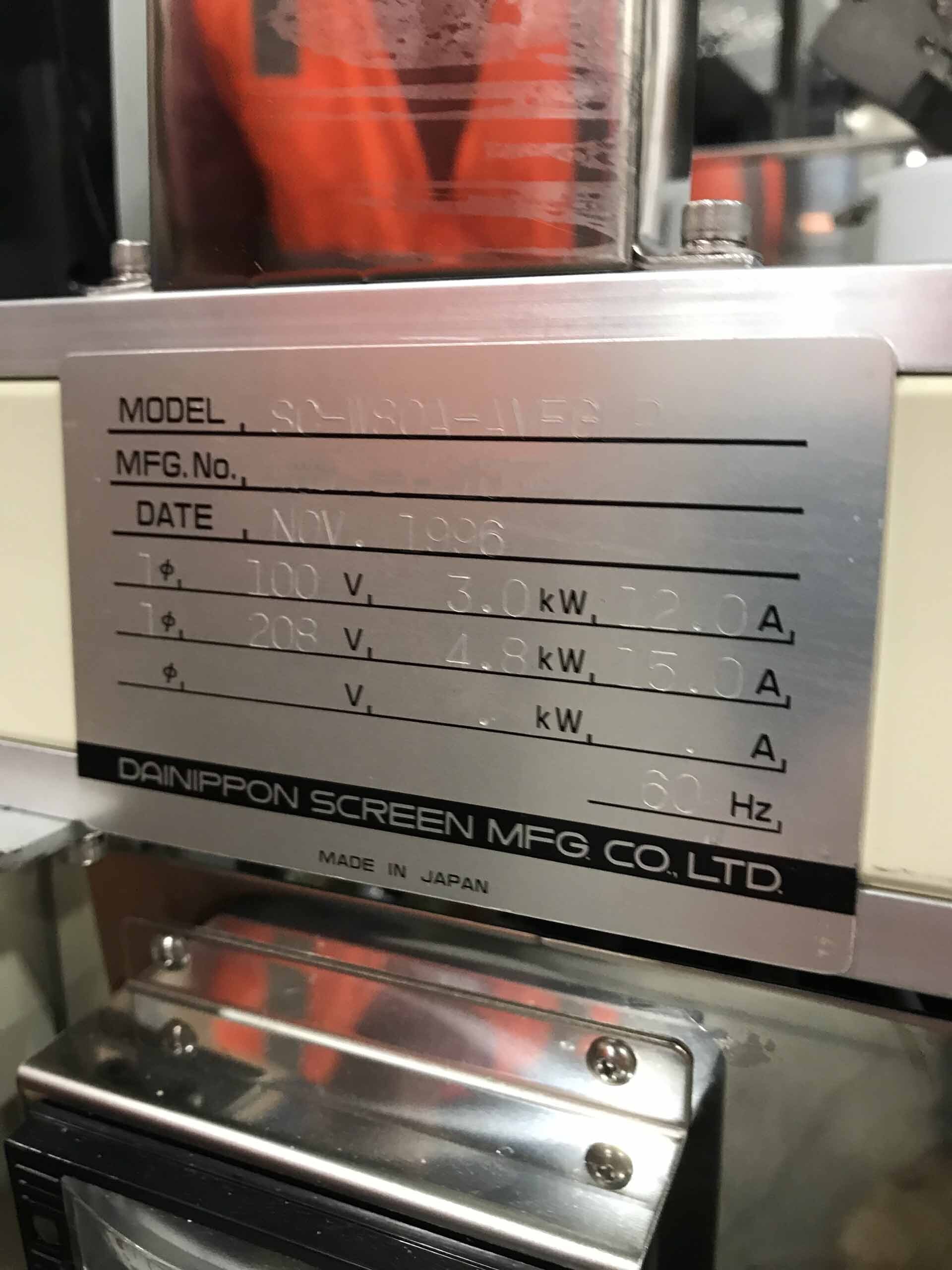

Used DNS / DAINIPPON SC-W80A-AVFGLP #9300629 for sale

URL successfully copied!

Tap to zoom

ID: 9300629

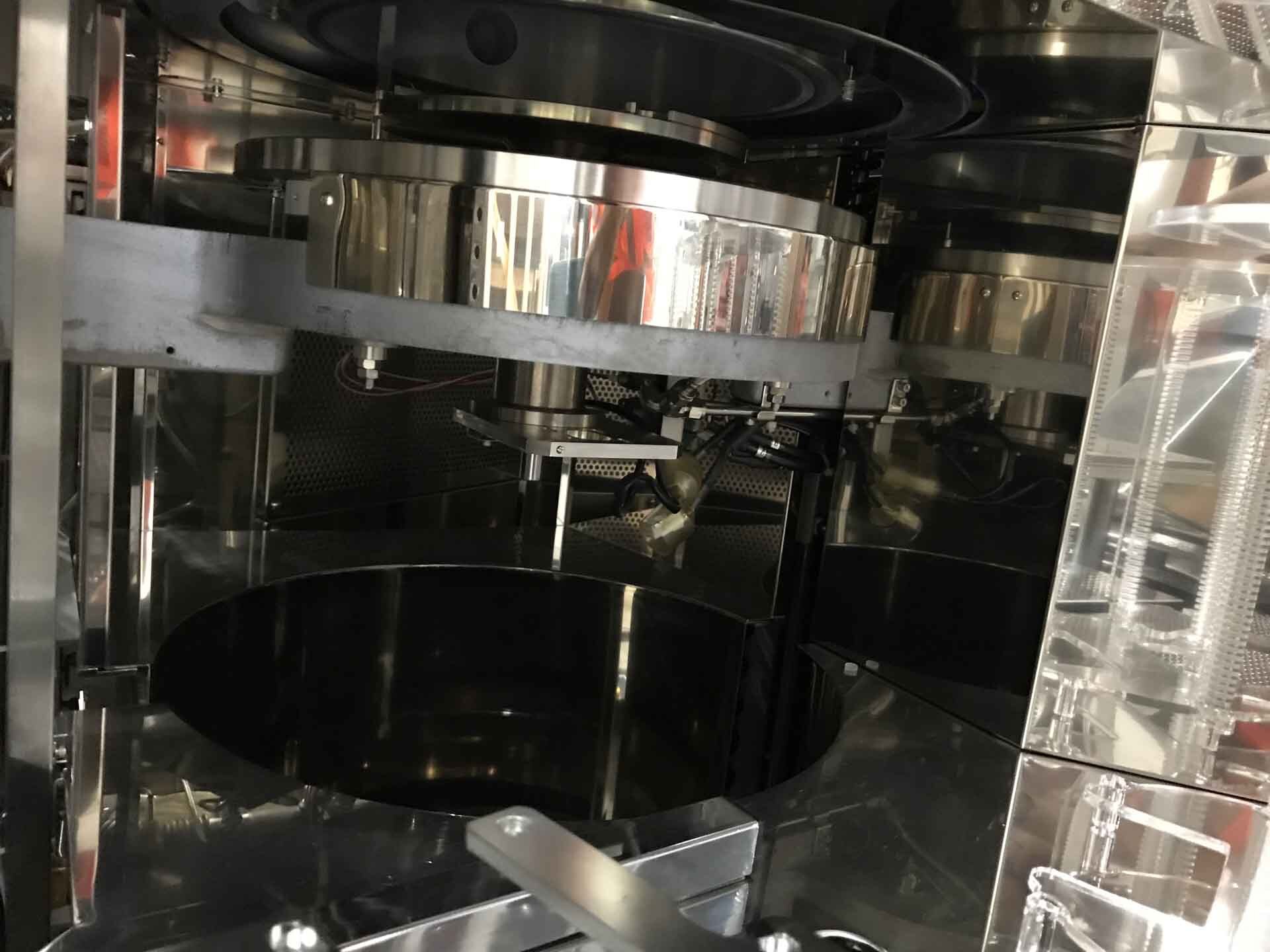

Wafer Size: 8"

Vintage: 1996

SOG Curing furnace, 8"

Cassette to cassette

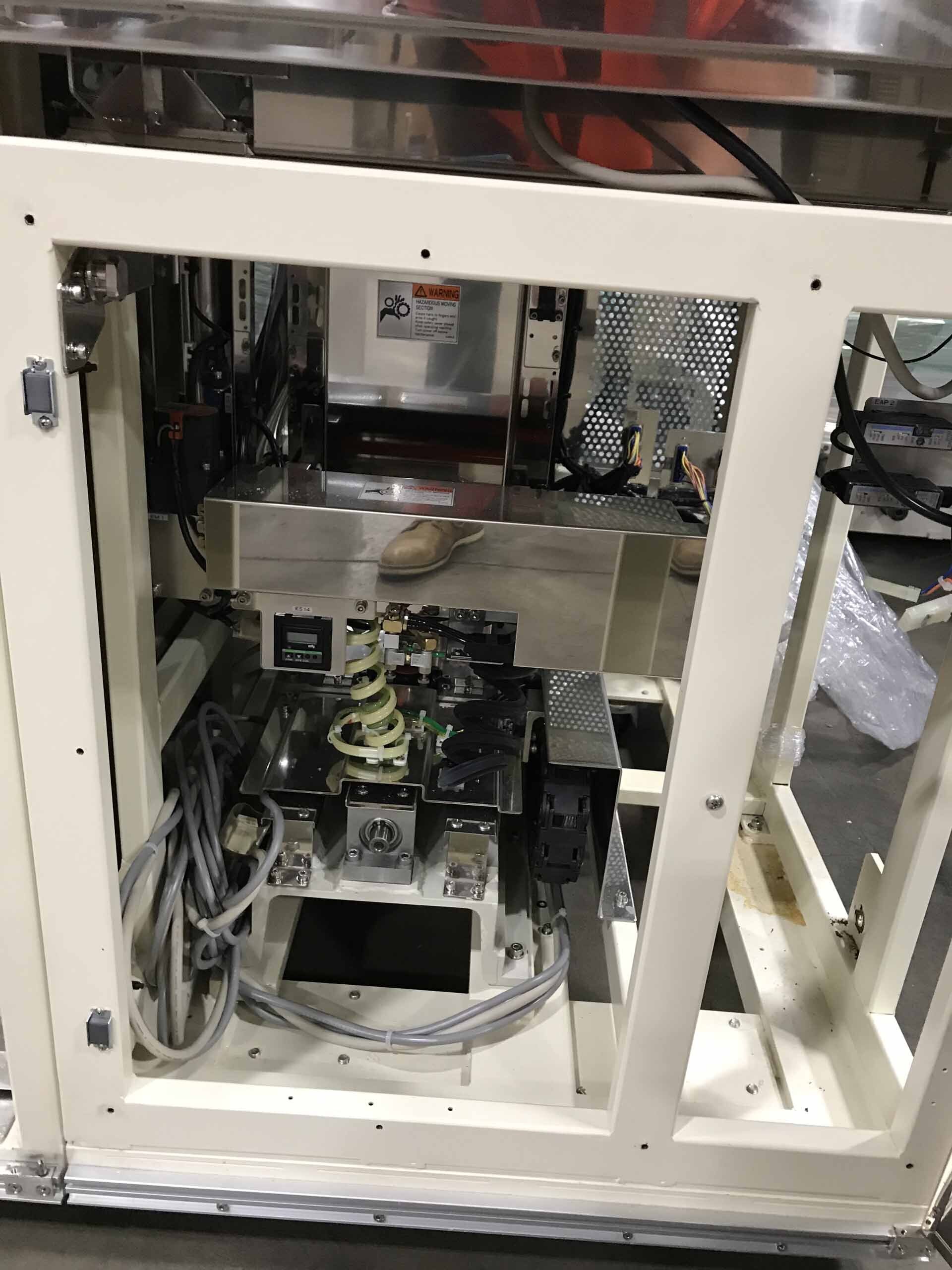

Buffer indexer interface between SOG Track and furnace

Vertical / Horizontal laminar flow loader station

(3) Zone vertical tube furnaces

1996 vintage.

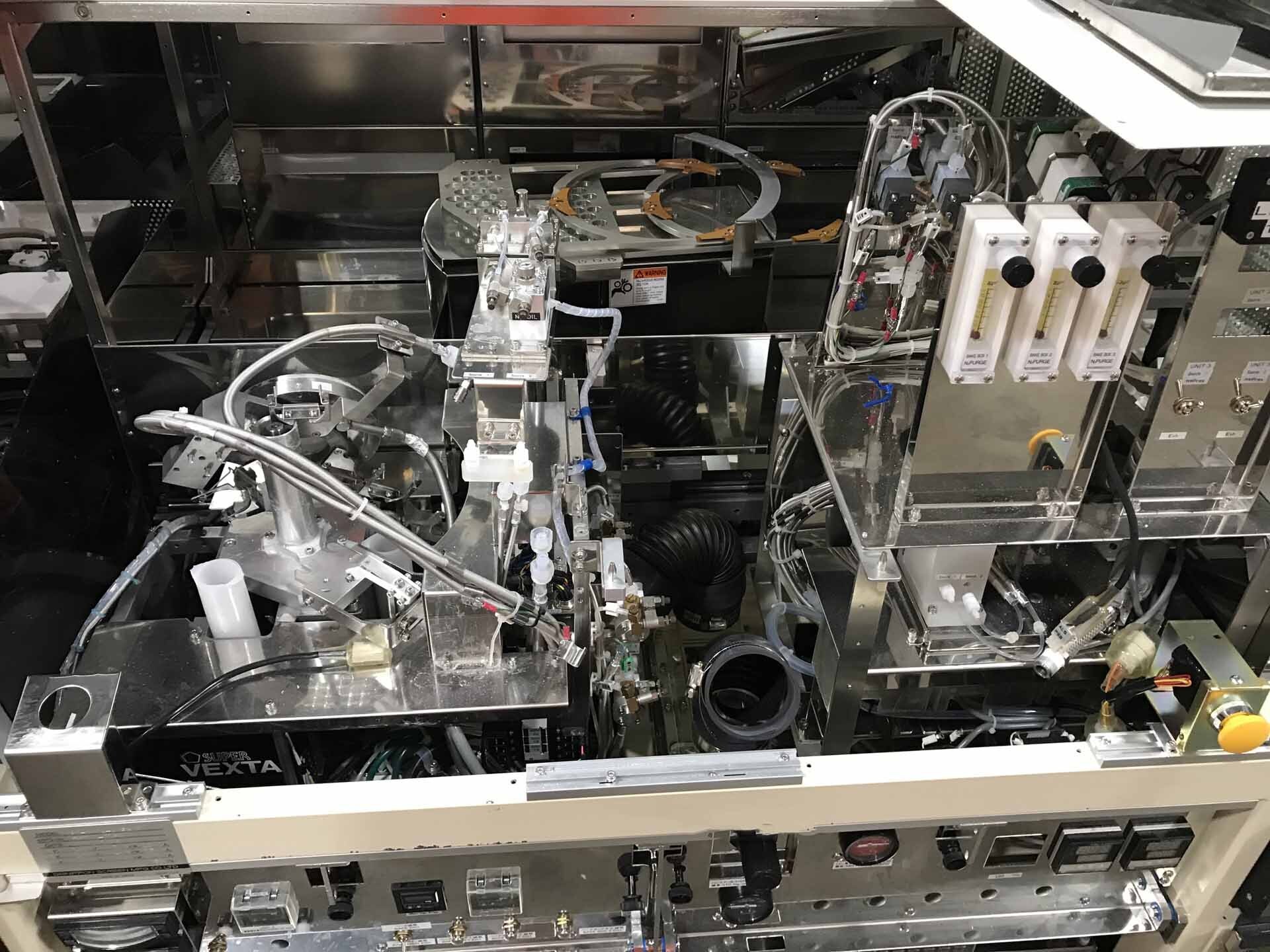

DNS / DAINIPPON SC-W80A-AVFGLP is a photoresist equipment designed for high volume production processes in the microelectronics industry. It is an advanced tool combining the latest in photo-resist technology with automated process enabling capabilities to deliver the highest possible yields while maintaining process control. The system consists of two parts, the pre-treatment unit and the wafer processing unit. The pre-treatment unit is designed to lay a film of photoresist material onto the wafer before the processing takes place. This film helps to ensure a uniform coating which is necessary for reliable yields. The wafer processing unit is designed to use photolithography to define patterns on the wafer surface. This is achieved by further treatment to the photoresist and cleansing in a photoresist stripper. DNS SCW-80A-AVFGLP features a high precision stepper motor to precisely align pitches on a wafer's surface. This ensures an accurate and uniform pattern on the wafer. Other features include laser aligners for more precise movements and a variety of optical and electronic sensors and processes to ensure high yield. The unit also features an automatic sorter to quickly sort processed wafers. The performance of DAINIPPON SC-W80A-AVFG(LP) is reported to be accurate and reproducible due to the automation provided by the machine. The software controls the parameters, such as temperatures, exposure times, process materials and process steps. This helps deliver uniform results option time. The tool is also designed for high throughput, with the stepper motor able to process up to 6 wafers per second. In summary, DNS / DAINIPPON SCW-80A-AVFGLP is a high-end photoresist asset designed for high throughput production in the microelectronics industry. The combination of the laser aligners, automation, and precision motion and process control, enables it to deliver accurate, reproducible results with high yields.

There are no reviews yet