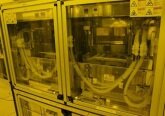

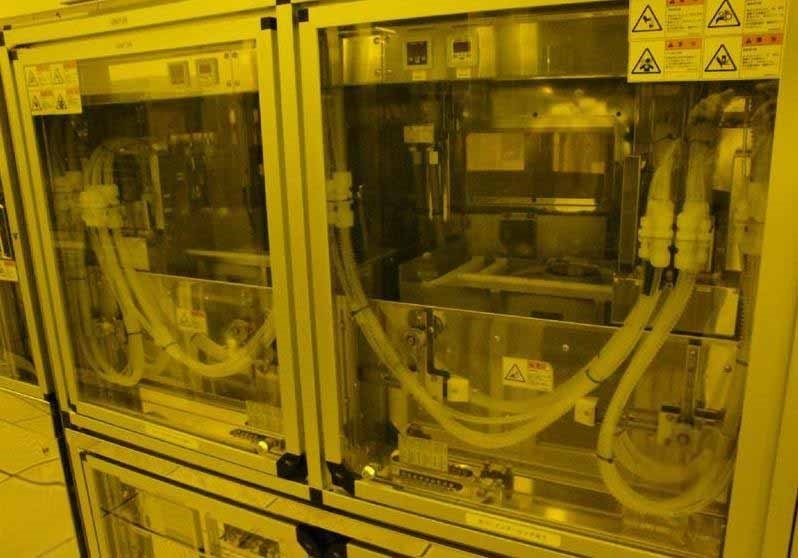

Used DNS / DAINIPPON SK-2000 #9277248 for sale

URL successfully copied!

Tap to zoom

ID: 9277248

Wafer Size: 8"

(4) Coater / (4) Developer systems, 8"

Resist temperature system

Resist Pump

Wafer shape: SNNF

Wafer cassette: 8" PP MIRAIAL

(2) Process blocks

(2) Coater heads

(2) Barc coater heads

(4) Develop heads

(2) Adhesion chambers

(10) Cooling plates

(12) Rapid hot plates

(3) Hot plates

(1) EEW

(1) EEFT

(1) IFB

(1) Source bottle cabinet

(1) Chemical box (HMDS/Solvent/NMDW)

(1) Controller cabinet

(1) Power box

(1) Handling unit controller

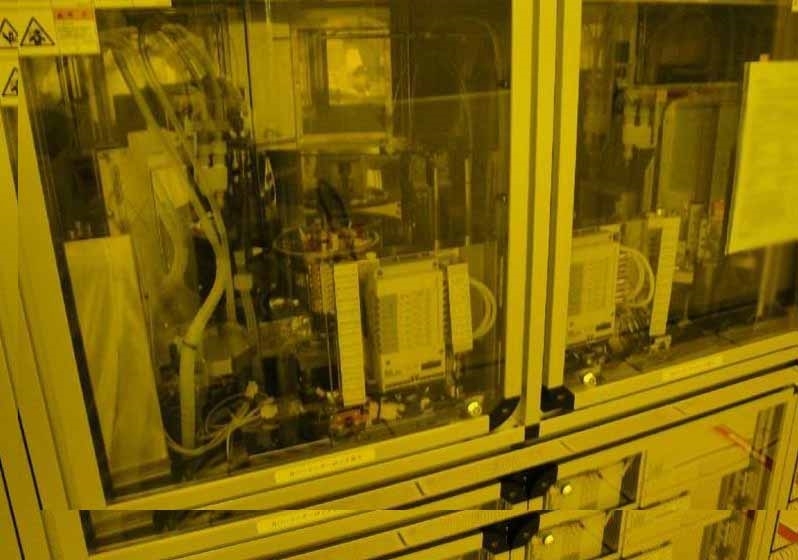

(1) Carrier station

(6) Nozzle

Cup:

Top cup material: PP

Middle cup material: PP

Bottom cup material: PPS

Spin chuck:

Material: Peek

Back rinse flow meter with flow sensor

Mist nozzle flow meter with flow sensor

Edge cleaner flow meter with sensor

With VPS+ option

Solvent solution supply

Drain central

Barc

Nozzle slit scan nozzle

Develop solution supply Central supply

Developer Cup PVC

Spin chuck PEEK

Develop nozzle flow meter with sensor

Develop nozzle wash meter with sensor

Rinse nozzle flow meter with sensor

Back rinse flow meter with sensor

Develop temperature System

Control for 1 line x 2

Drain central

Adhesion

Method vapor prime by N2 bubbling

Hot plate 60-150 deg by 0.1 deg pitch

HMDS solution supply central supply

Hot plate

Method proximity bake with ceramic ball

Hot plate 50-180 deg by 0.1 deg pitch

Cooling plate

Rapid hot plate.

DNS / DAINIPPON SK-2000 is a digital photoresist equipment that uses lasers and a novel optical system to enhance the accuracy of exposure patterns and helps to ensure that features can be accurately reproduced accurately on substrates with feature sizes as small as a few hundred nanometers. DNS SK2000 utilizes a pulsed laser beam that is focused to a spot size of 5 um on the substrate and is mounted on a x-y galvanometer scanner. The pulse width is programmable from 2 to 12ns and the energy is programmable from 50mJ to 1J. The laser is mounted on a vertical scanner that is connected to a precision x-y galvanometer scanner. The laser and scanner are synchronized to create accurate exposure patterns on the substrate. The exposure pattern is then defined by the user interface, which allows for the drawing of exposure patterns on the substrate. DAINIPPON SK 2000 also utilizes a proprietary optical unit that combines the exposure pattern with the film thickness of the substrate. This allows for accurate exposure patterns on substrates with feature sizes as small as a few hundred nanometers. Additionally, the exposure patterns can be optimized for a specific substrate, allowing for greater accuracy and precision. In addition to its laser and optical systems, DNS / DAINIPPON SK 2000 is equipped with a temperature control unit which allows temperature-sensitive substrates to be used in the exposure process. This allows for a higher resistivity and heat tolerance of the exposed material. In addition to its precision and accuracy, DNS SK-2000 offers a broad range of exposure patterns that can be used. It is designed to be used in a variety of processes including photolithography, deposition techniques such as chemical vapor deposition, and dry etching. Its wide range of exposure patterns allow for improved throughput and shorter process times. DNS SK 2000 is an advanced photoresist machine. It utilizes several unique features including a pulsed laser, an advanced optical tool, a precision scanner, and a temperature control unit. These features enable the accurate and precise reproduction of exposure patterns on substrates with feature sizes as small as a few hundred nanometers. Additionally, the wide range of exposure patterns it offers enable faster throughput and shorter processing times. This makes DNS / DAINIPPON SK2000 an ideal choice for a wide range of applications in photolithography, deposition techniques, and dry etching.

There are no reviews yet