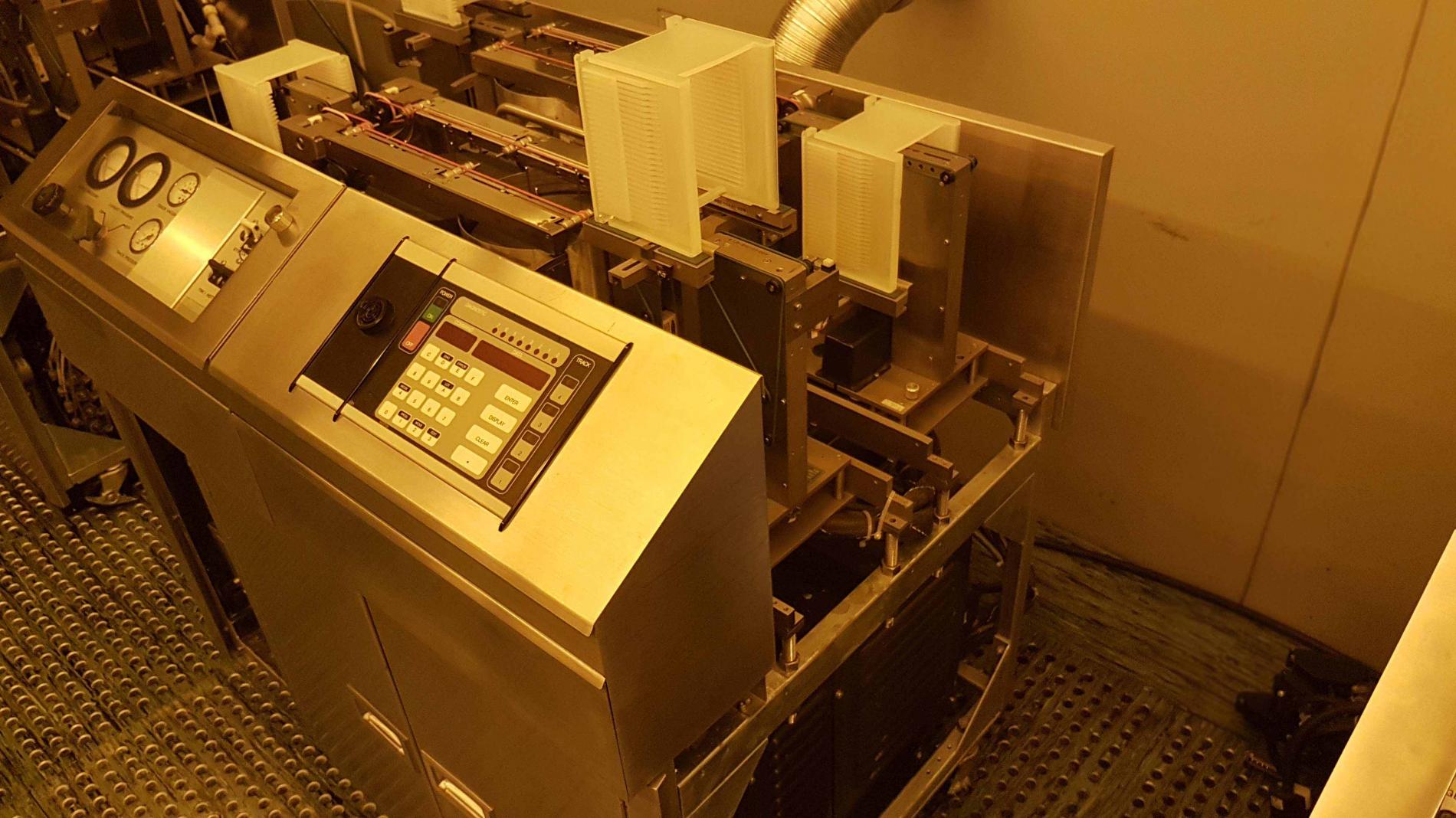

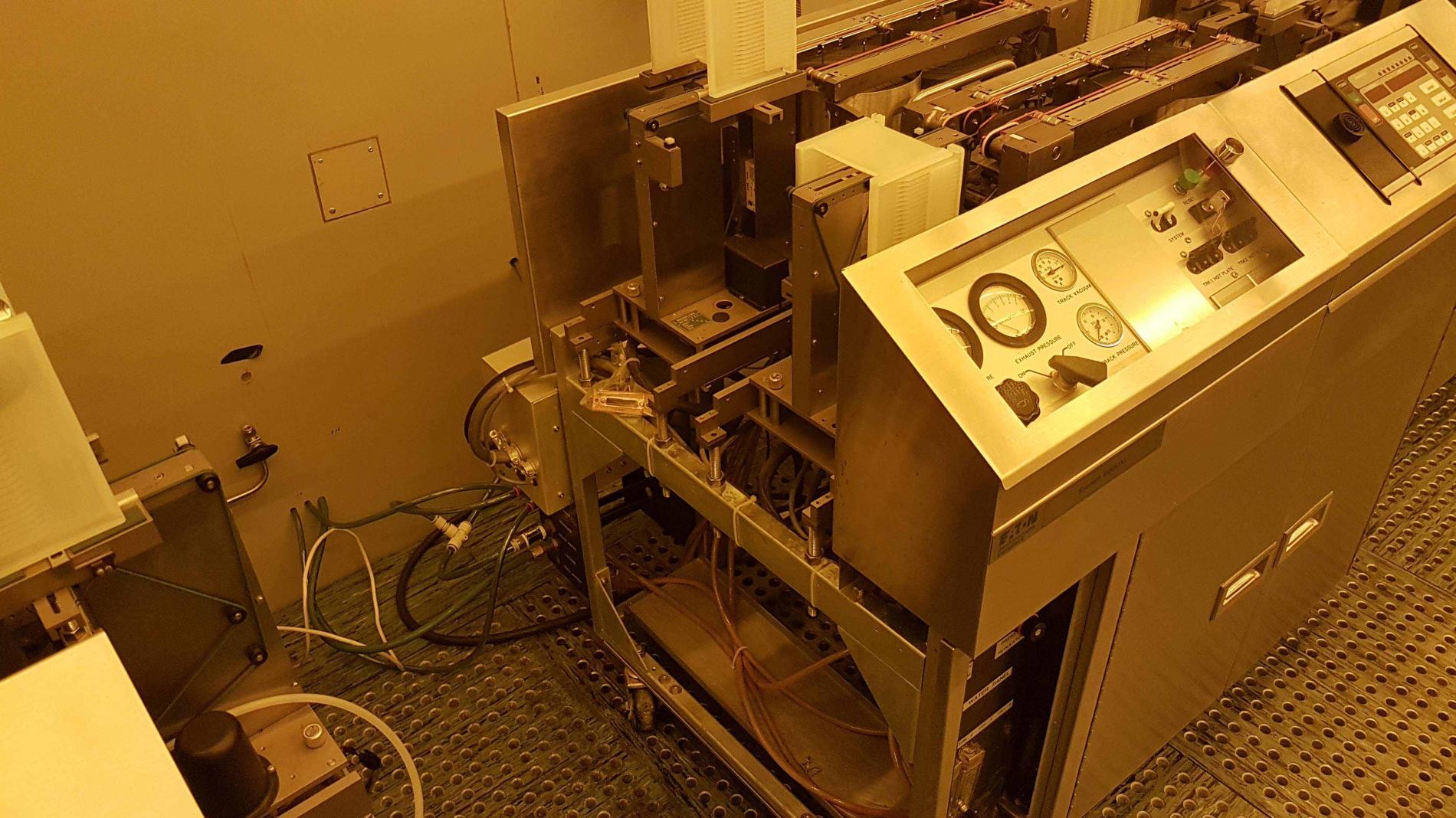

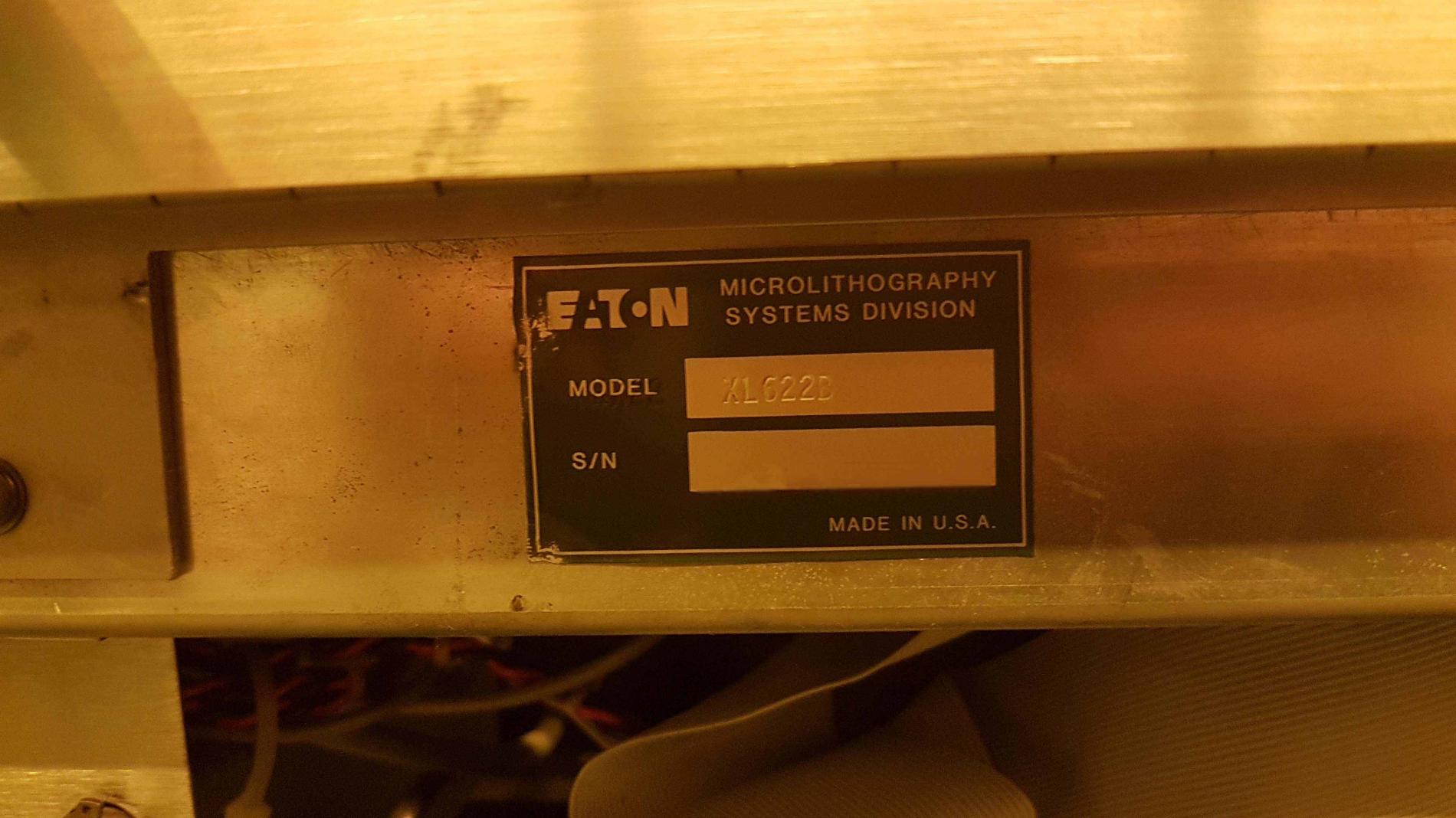

Used EATON XL622B #9180703 for sale

URL successfully copied!

Tap to zoom

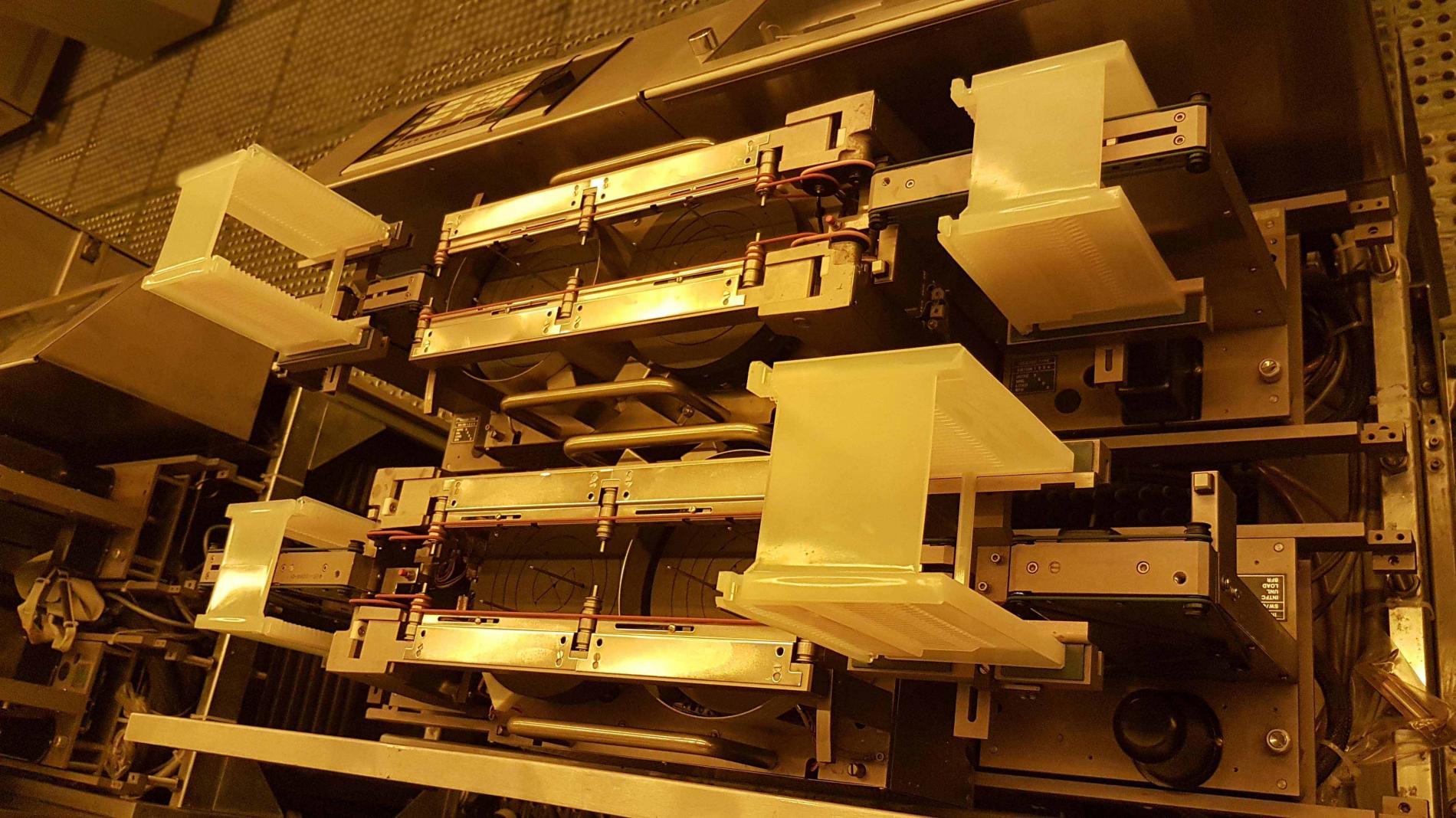

EATON XL622B is a photoresist equipment that helps produce precision glass and ceramic substrates for the production of microelectronic components. It is designed to provide a uniform, high quality product for a variety of microelectronic applications. XL622B utilizes a liquid polymeric-based photoresist and is a modular system that features an integrated dosing platform, infrared process chamber, substrate movement, process control, and integrated positioning systems. The process chamber is an enclosed area with an adjustable temperature range from room temperature up to 250°C (482°F). It has an easily adjustable atmosphere with precise air flow balance and temperature controlling functions. The integrated dosing platform is a vital component in the machine. It features a unique design that can accurately dose small amounts of photoresist into the process chamber. The platform also provides a precise environment for controlling temperature, flow, and even exposure time of the photoresist. The unit is controlled by an advanced software machine that can be easily altered and configured to specific requirements. This allows for precise programming, with thresholds and triggers that are easily customized. The software as well allows for accurate data tracking and logging of all parameters of the production process, providing further oversight and control of the process. EATON XL622B also features an integrated movement tool. This consists of an optimized conveyor asset designed to work with both air and vacuum handling. The movement model can accommodate any size substrate within the equipment's constraints. Finally, the system features an integrated positioning unit. This is an advanced mechanism that helps ensure accurate alignment of the substrates in the process chamber. It also helps match the orientation of the substrate to that of the photoresist. This is particularly important since it helps to ensure that the best quality product can be achieved with each production run. Overall, XL622B provides an efficient, automated machine for producing precision glass and ceramic substrates. It's advanced technology and customizable features ensure uniform, high quality performance for a variety of microelectronic applications.

There are no reviews yet