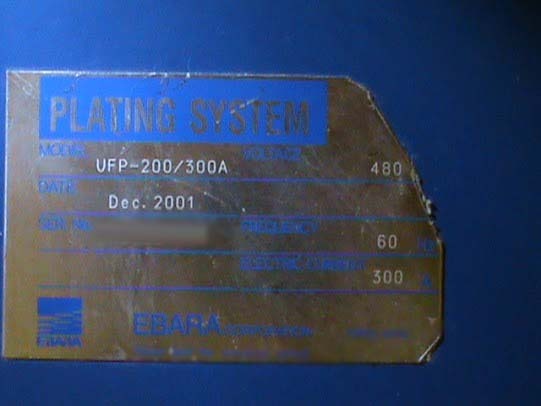

Used EBARA UFP 200 / 300A #9132640 for sale

URL successfully copied!

Tap to zoom

ID: 9132640

Wafer Size: 12"

Vintage: 2001

Bump plating machine, 12"

Wafer electroplating tool

(3) Chemistry capabilities

Plating plater

PbSn

Lead tin

Missing parts

2001 vintage.

EBARA UFP 200 and 300A Photoresists are advanced photoresists developed to ensure high resolution patterns and usability in the semiconductor manufacturing process. These two systems offer users high resolution patterning on any layer of the wafer, and feature high-speed operation capabilities. EBARA UFP 200 / 300A uses laser beam projection technology to record the desired patterns to be exposed onto the photoresist layer. At the heart of the equipment lies its X-Y scanning and projection optics, which allow large-scale patterning with a minimum of 0.25microns in pitch. This feature allows high resolution atomic force microscopy imaging applications to be performed with greater accuracy. The system further incorporates additional features such as an automatic wafer conveyor and an automated alignment unit, which enables automated patterning. This ensures that patterns are accurately and consistently transferred from the control computer to the resist layer. For optimum protection, the machine also features various optical filtration systems, which help protect the photoresist from the laser source, resulting in a higher throughput and less waste when working with high-speed processes. A damping tool also helps to reduce fatigue and provide additional protection when recording the exposures. EBARA UFP Photoresist systems are compatible with a wide range of resist coatings, including positive and negative photoresist and advanced multi-layer metal hardmask systemresists offering production flexibility and cost savings. The systems are also compatible with both KrF and ArF Laser sources, ensuring that they can provide a wide range of patterning depths and exposures. Finally, its process control software is designed to provide users with a range of sophisticated tools to help monitor the process and ensure consistent results every time. This includes a comprehensive suite of analysis and control tools, such as real-time wafer analysis and histogram control, as well as an extendable library of recipes and recipes with recommended parameters, helping users to optimise their process flow.

There are no reviews yet