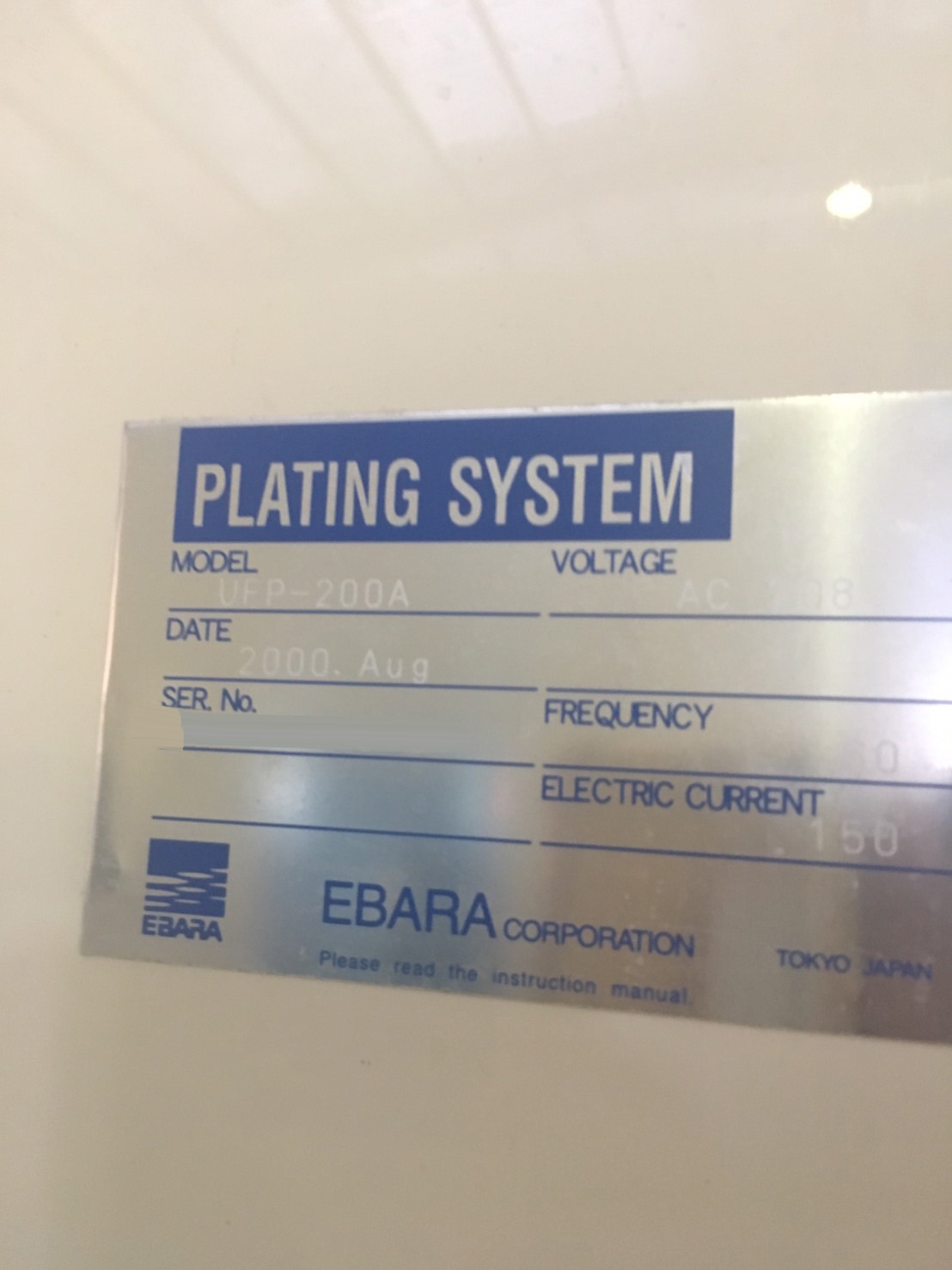

Used EBARA UFP 200A #9192490 for sale

URL successfully copied!

Tap to zoom

EBARA UFP 200A is a fully automated photoresist equipment that has been designed for the deposition of photoresist on semiconductor wafers. It is capable of depositing and spinning photoresist on the entire wafer surface without manual intervention. The system uses a spin-on chemical precursors to deposit a uniform layer of photoresist on the wafer. UFP 200A unit features an in-line process chamber designed to facilitate a uniform coating of the entire wafer surface. Its wafer heating machine allows for greater accuracy in the precision of the resist layer. The tool also includes an integrated spin speed and time monitor to ensure a uniform distribution of the resist layer on the entire wafer surface. EBARA UFP 200A asset also comes with an integrated post exposure bake module, which delivers post bake temperatures of up to 200°C with a uniform temperature distribution across the entire wafer. Additionally, the model comes with an atomic force microscope, allowing for precise measurements of resist thickness and surface roughness following exposure. UFP 200A equipment also features a high-precision, closed-loop stepper system for alignment of the wafer during the exposure process. This ensures that the exposure will be aligned accurately in both vertical and horizontal directions. Moreover, the unit also features a safety interlock that prevents the machine from starting the process until the entire wafer has been properly aligned. This ensures that the process is performed accurately and efficiently. Finally, EBARA UFP 200A tool is designed to provide an easy and efficient way of exploring new photoresist processes. The asset is capable of quickly and accurately performing the deposition and spinning steps of the process, allowing for shorter turnaround times in the exploration of new photoresist recipes.

There are no reviews yet