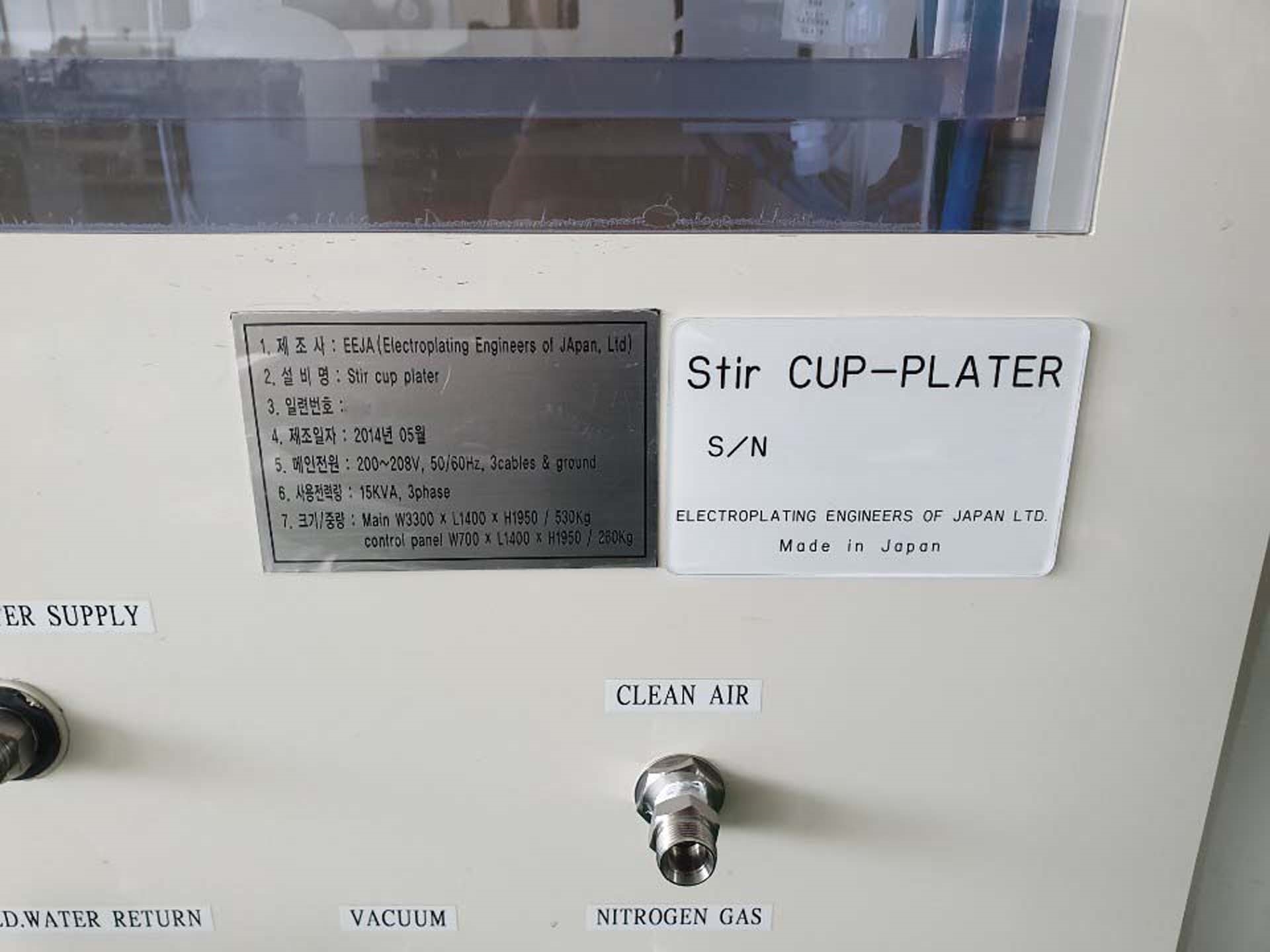

Used EEJA / ELECTROPLATING ENGINEERS OF JAPAN Cup-Plater #9249621 for sale

URL successfully copied!

Tap to zoom

ID: 9249621

Vintage: 2014

Electro Chemical Deposition (ECD) system

Used for gold plating

2014 vintage.

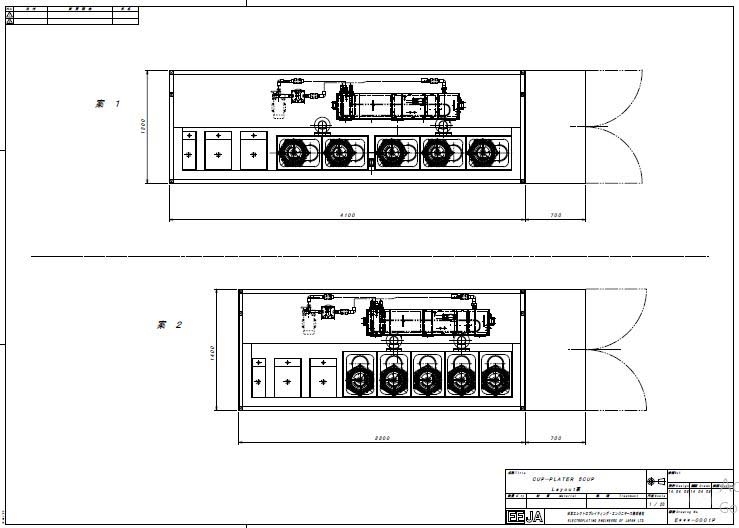

EEJA / ELECTROPLATING ENGINEERS OF JAPAN Cup-Plater is a 'photoresist' equipment designed to produce high-precision, tight tolerance components with accuracy and repeatability. The system uses a process of electrically charged particle deposition, which deposits a layer of metal that adheres tightly to a substrate. This is followed by a photoresist coating, which subsequently requires a UV exposure to either create or remove the metal layer from the substrate. The unit offers a number of advantages over traditional electroplating or coating processes. First, it eliminates the need to handle corrosive chemicals, as the electrical charging of the particles eliminates the need a chemical solution. This makes the machine an exceptionally safe option for use in a manufacturing environment. Secondly, the photoresist tool provides greater accuracy and resolution, allowing for the development of parts that require minimal post-finishing work. This allows for time and cost savings, as highly precise parts can be produced without the need for significant post-finishing or secondary processes. EEJA Cup-Plater utilizes a self-contained unit in which the substrate is inserted. The substrate is then subjected to a high-voltage environment, allowing for the deposition of the metal onto the surface of the substrate. The deposited metal layer is then subjected to a UV exposure, which selectively binds the metal particles to the substrate. ELECTROPLATING ENGINEERS OF JAPAN CUP PLATER allows for a range of applications in industries such as automotive, electrical, and medical. These parts range in level of complexity from simple two-dimensional parts to three-dimensional parts, which can be used in a number of applications. The asset can also be used for a variety of different materials, from aluminum to titanium. ELECTROPLATING ENGINEERS OF JAPAN Cup-Plater is a valuable tool for producing high-precision components quickly, safely, and accurately. The model eliminates the need for the use of corrosive chemicals, and its precision allows for time- and cost-savings in the production process. The equipment allows for a range of applications, and can be used for various metals and materials.

There are no reviews yet