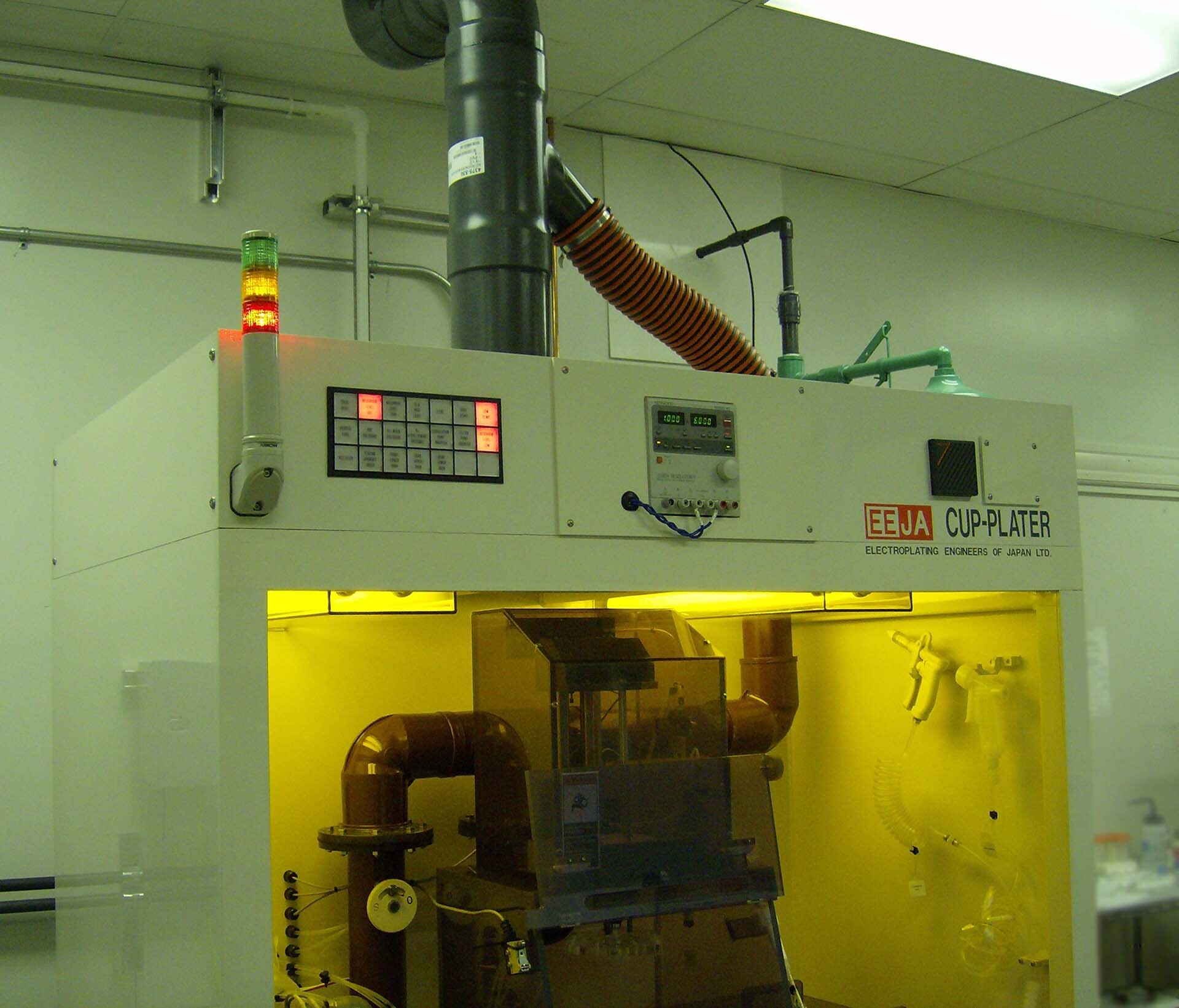

Used EEJA / ELECTROPLATING ENGINEERS OF JAPAN Cup-Plater #9279353 for sale

URL successfully copied!

Tap to zoom

EEJA / ELECTROPLATING ENGINEERS OF JAPAN Cup-Plater is an automated electroplating equipment that enables the simultaneous application of multiple thin metal layers. It is an ideal tool for producing devices with thick layers of either organic or conductive metal patterns. The system is built around a photoresist platform, where light is used to etch into the metal substrate, allowing the topmost layer to be covered in a single pass. EEJA Cup-Plater unit is equipped with an LED light source to irradiate an array of photoresist substrates. The light is then guided to the sensors on the substrate which register the pattern and efficiently create a thin metallic film on the substrate surface. The etching process is then used to store the pattern in the metal layer. ELECTROPLATING ENGINEERS OF JAPAN CUP PLATER's photoresist platform comprises of three different light sources - ultraviolet, infrared and visible radiation. The ultraviolet radiation is used to conduct the basic pattern registration, while the infrared radiation is used to etch into the metal layer. The visible radiation is then used to ensure accurate layer deposition and etching during the patterning process. ELECTROPLATING ENGINEERS OF JAPAN Cup-Plater's automated control machine allows for very precise and uniform deposition of multiple layers. The tool can be programed to apply multiple layers with equal thicknesses, and it can also be programmed to apply different patterns at different times. This makes it an ideal solution for producing devices with extremely thin layers with high reproducibility. For optimum performance, EEJA / ELECTROPLATING ENGINEERS OF JAPAN CUP PLATER asset uses an olefin-based photoresist material that offers high adhesion to the metal substrate. The model is also equipped with multiple electrodes specifically designed to facilitate the even application of the photoresist material and to ensure a clean etching process. CUP PLATER equipment is extremely easy to operate, as all the steps are automated and easy to follow. It is also equipped with a built-in debris collection system to reduce losses from scratching. Furthermore, the unit can be easily customized to suit a wide variety of applications and thicknesses. Overall, EEJA CUP PLATER is an invaluable tool for achieving uniform layers of thin metals. It enables rapid patterning with accurate results, and it is a highly efficient solution for producing devices with thick layers of metal patterns in a single pass.

There are no reviews yet