Used EEJA / ELECTROPLATING ENGINEERS OF JAPAN Posfer-E series #9290814 for sale

URL successfully copied!

Tap to zoom

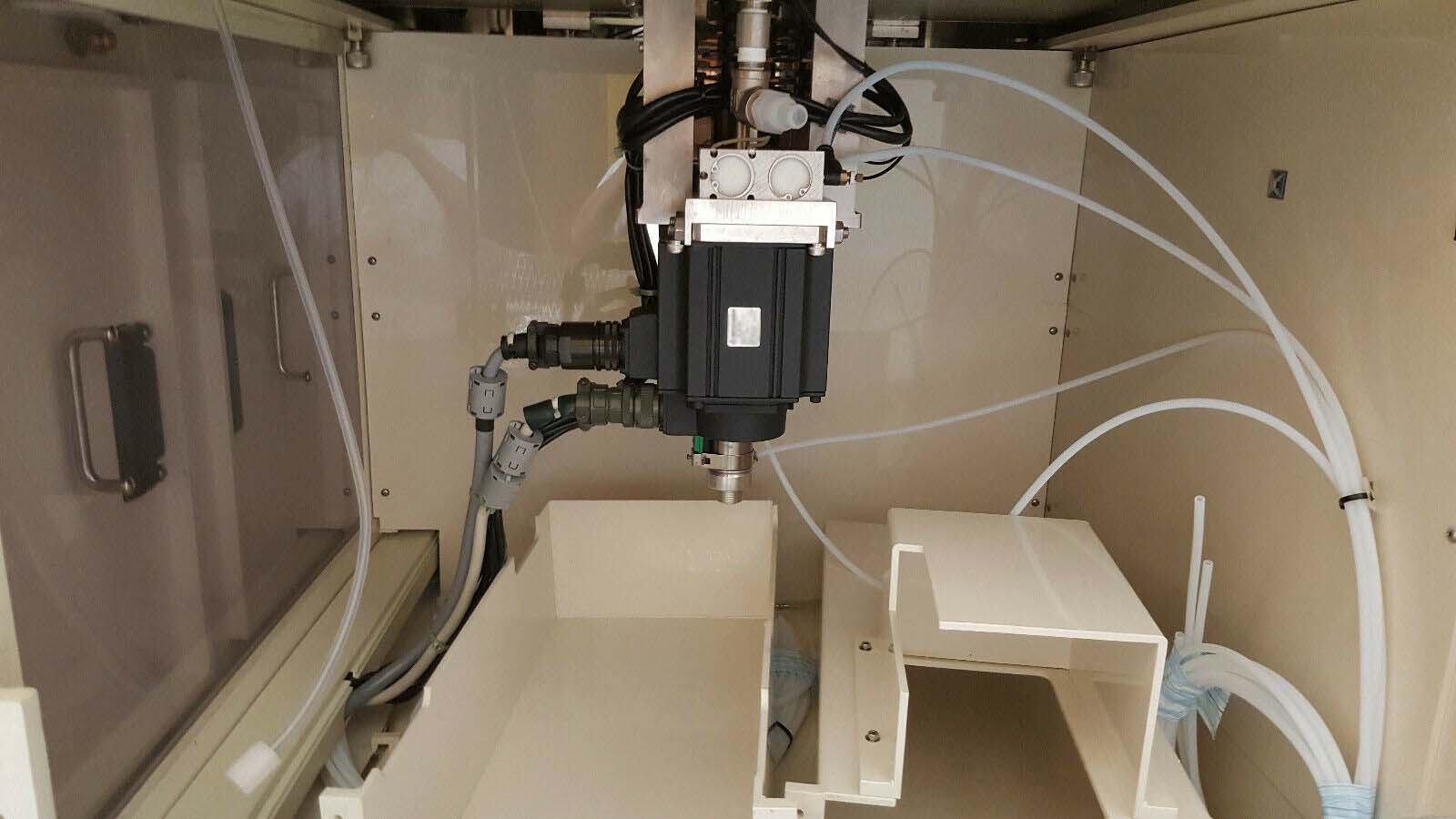

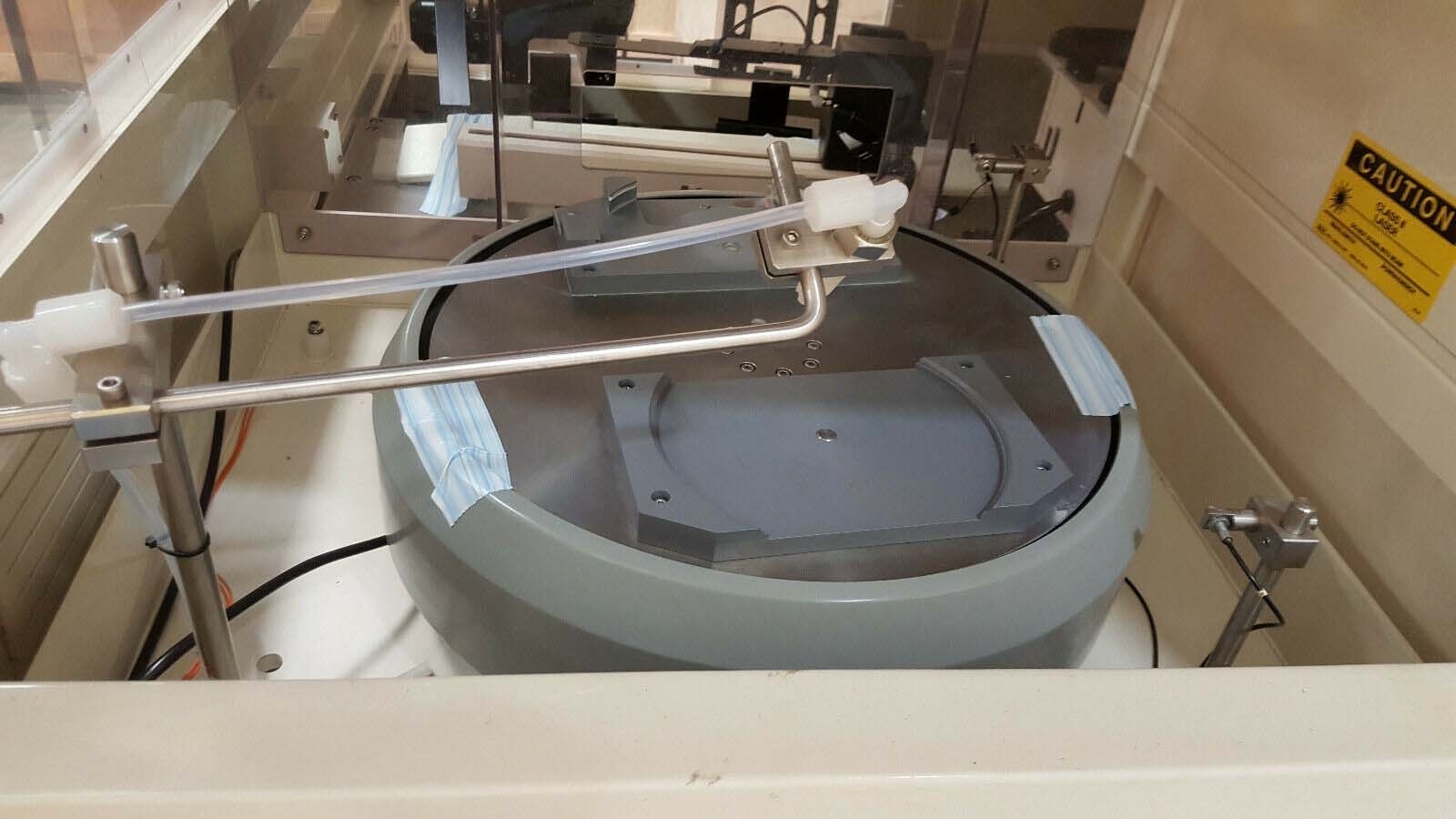

EEJA / ELECTROPLATING ENGINEERS OF JAPAN Posfer-E series is a photoresist equipment developed by EEJA. It is designed to provide a cost-effective electroplating process that is suitable for high volume production as well as small- to medium-sized jobs. The system utilizes a light-sensitive material known as "photoresist" which can be applied to circuit boards using a specially designed applicator. After the photoresist has been applied, a light source is used to selectively etch the board in order to create desired surface features or patterns. EEJA Posfer-E series consists of a variety of different photoresists which are suitable for a wide range of applications. The main types of photoresist include negative tone, positive tone and diazo sensitized (DZ) patterning. The unit also offers different types of light sources and a wide range of accessories such as photomask frames and vacuum exposure systems. Negative tone photoresists are ideal for applications where a high level of feature definition is desired. They can enable high resolution patterns with sharp lines and improved depth of field. Positive tone photoresists on the other hand are best for applications requiring more flexibility in terms of the design of the desired patterns. Lastly, DZ patterning enables the use of a variety of different etch techniques, including plasma etching or chemical etching. In order to ensure the optimal performance of ELECTROPLATING ENGINEERS OF JAPAN Posfer-E series, a variety of process conditions need to be taken into consideration. These include the etch depths, etch times, etch rates, temperature of the resist, and the types of photoresist being used. It is also important to use appropriate safety equipment and to perform regular maintenance on the machine in order to extend its service life and reduce the risk of any accidents occurring during operation. Posfer-E series provides cost-effective electroplating and photolithography processes that are suitable for both high volume production as well as smaller jobs. The various types of photoresist used in the tool can enable high resolution patterns with sharp lines and improved depth of field. Furthermore, taking into consideration the various process conditions is essential in order to ensure the optimal performance of the asset.

There are no reviews yet