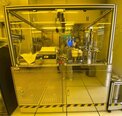

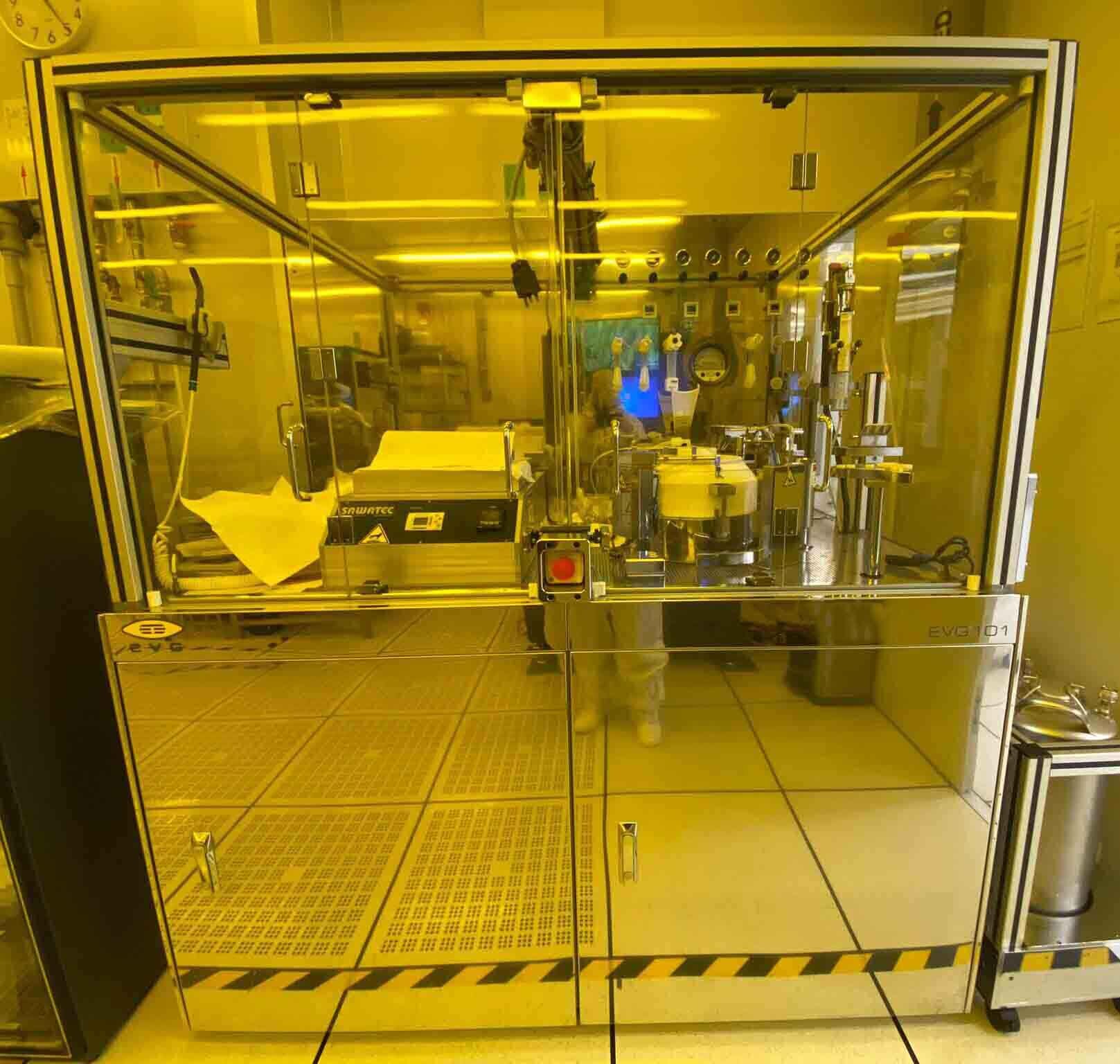

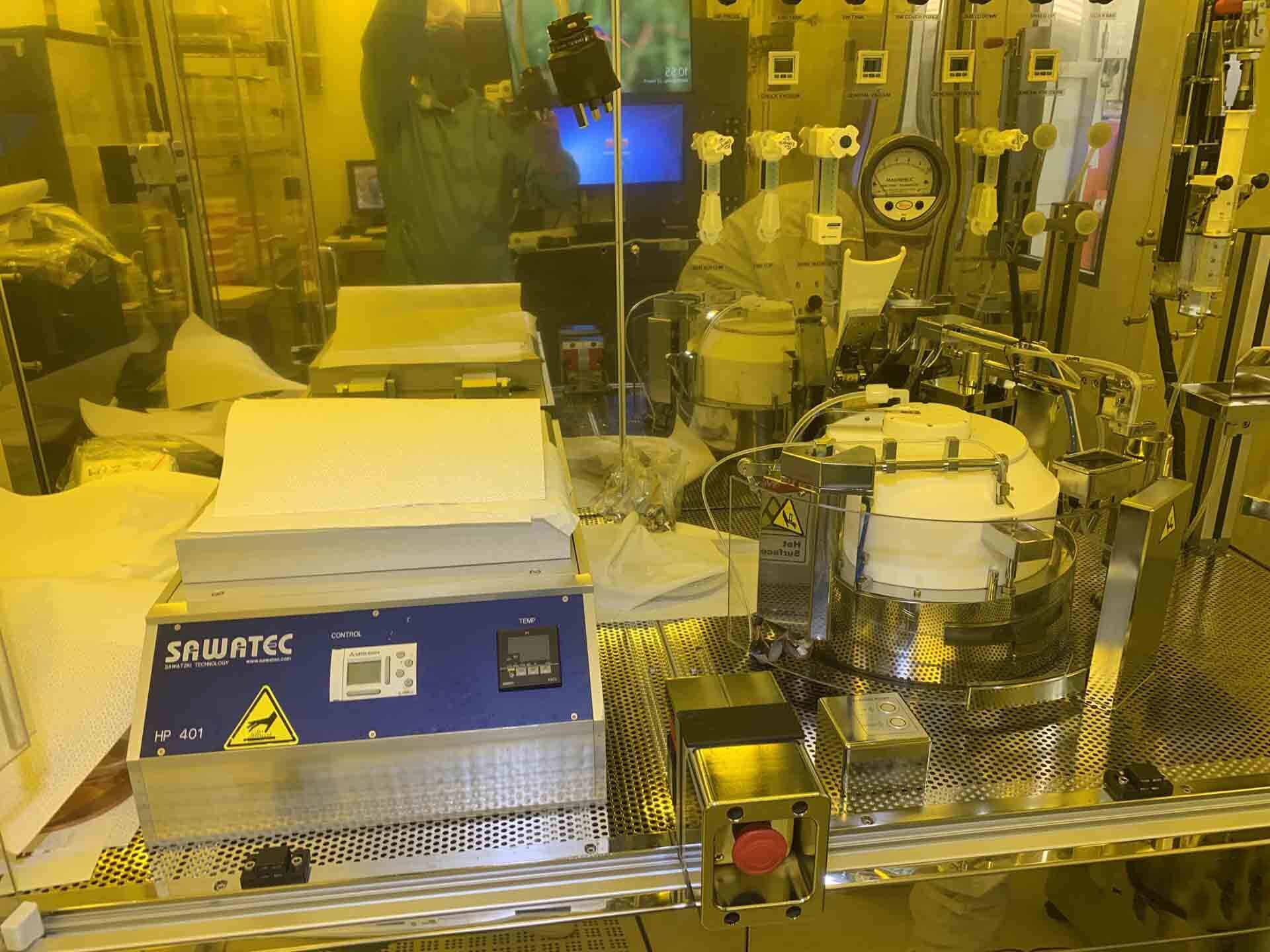

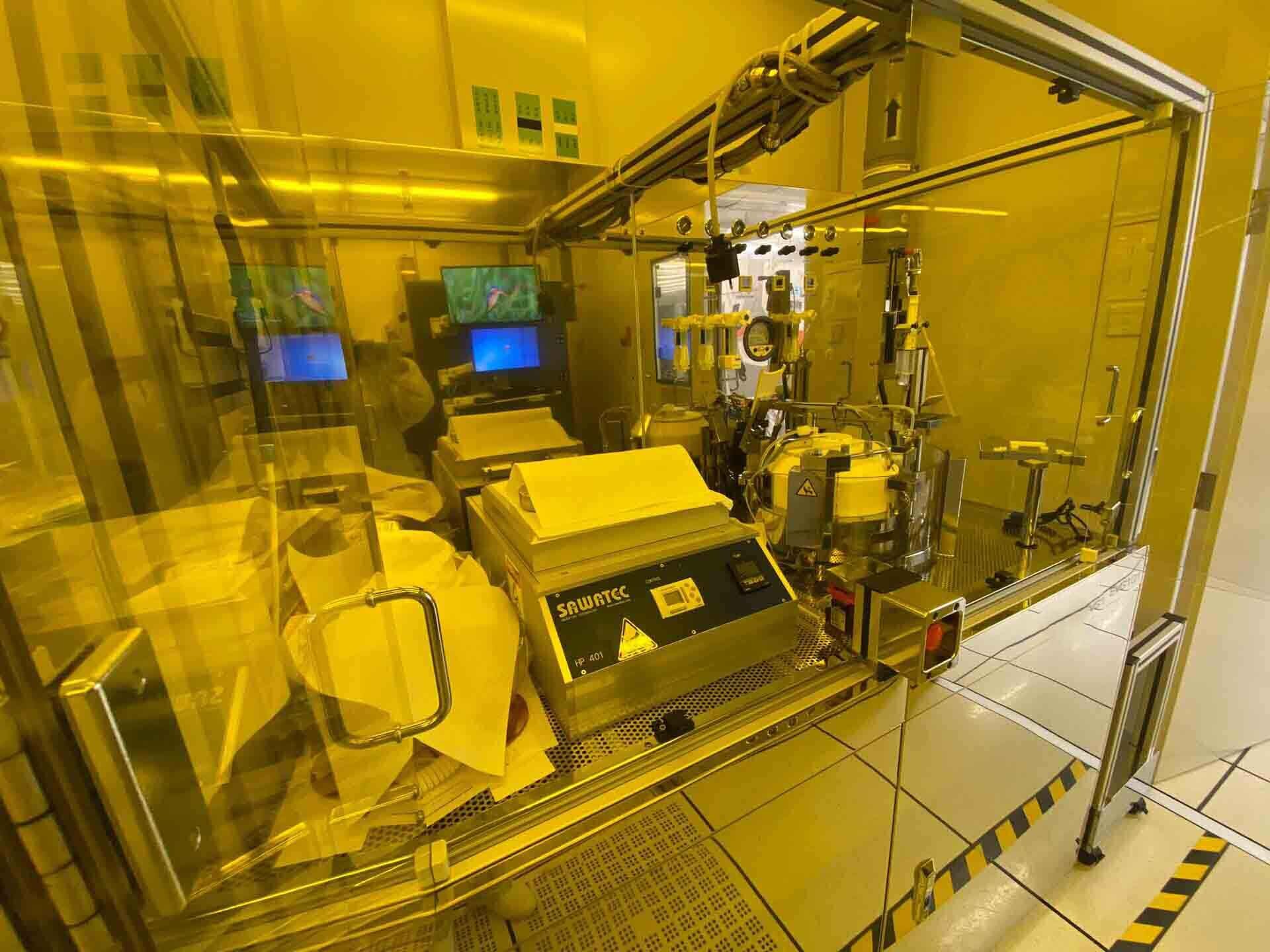

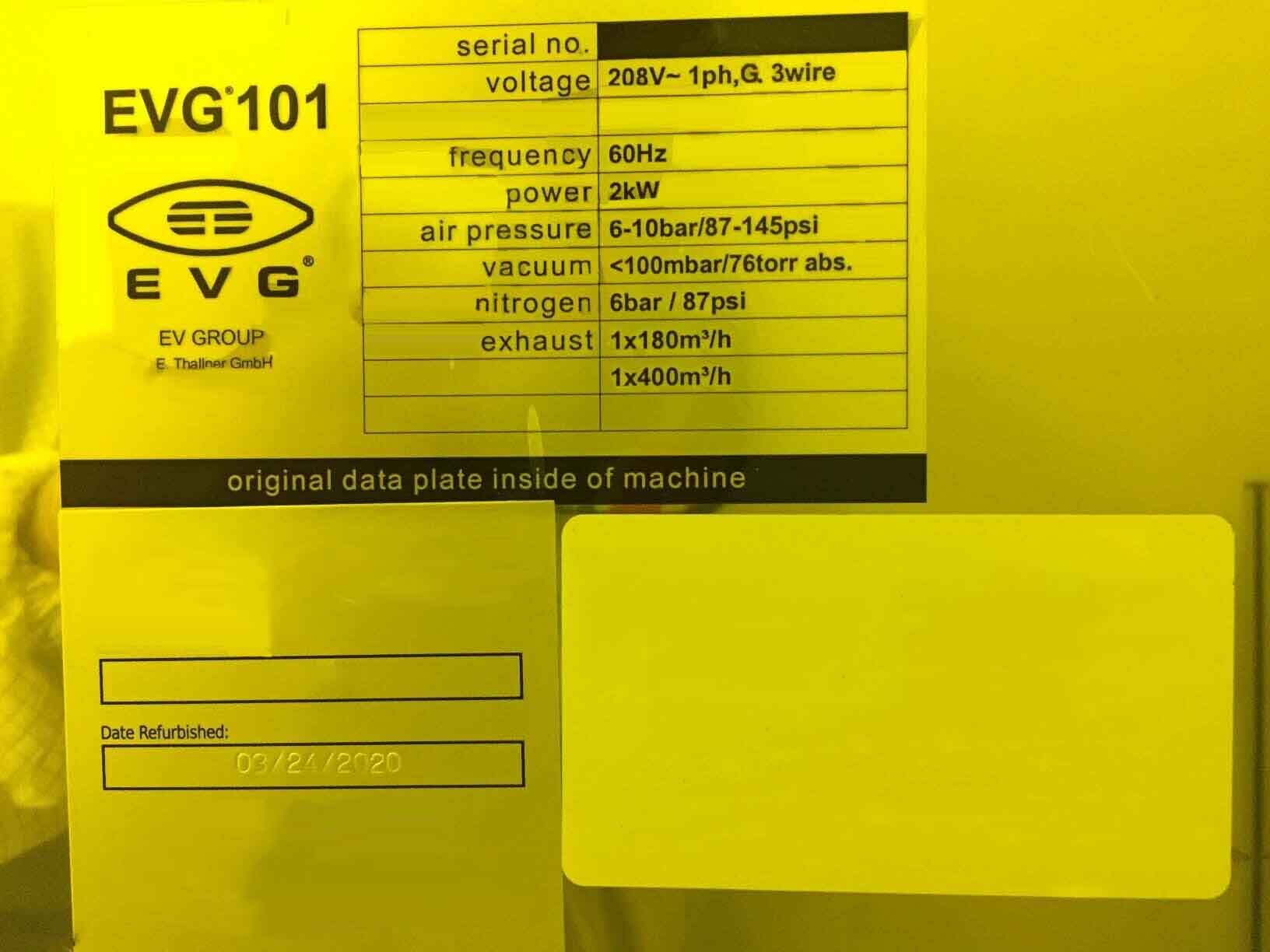

Used EVG / EV GROUP 101 #293657969 for sale

URL successfully copied!

Tap to zoom

ID: 293657969

Wafer Size: 4"-6"

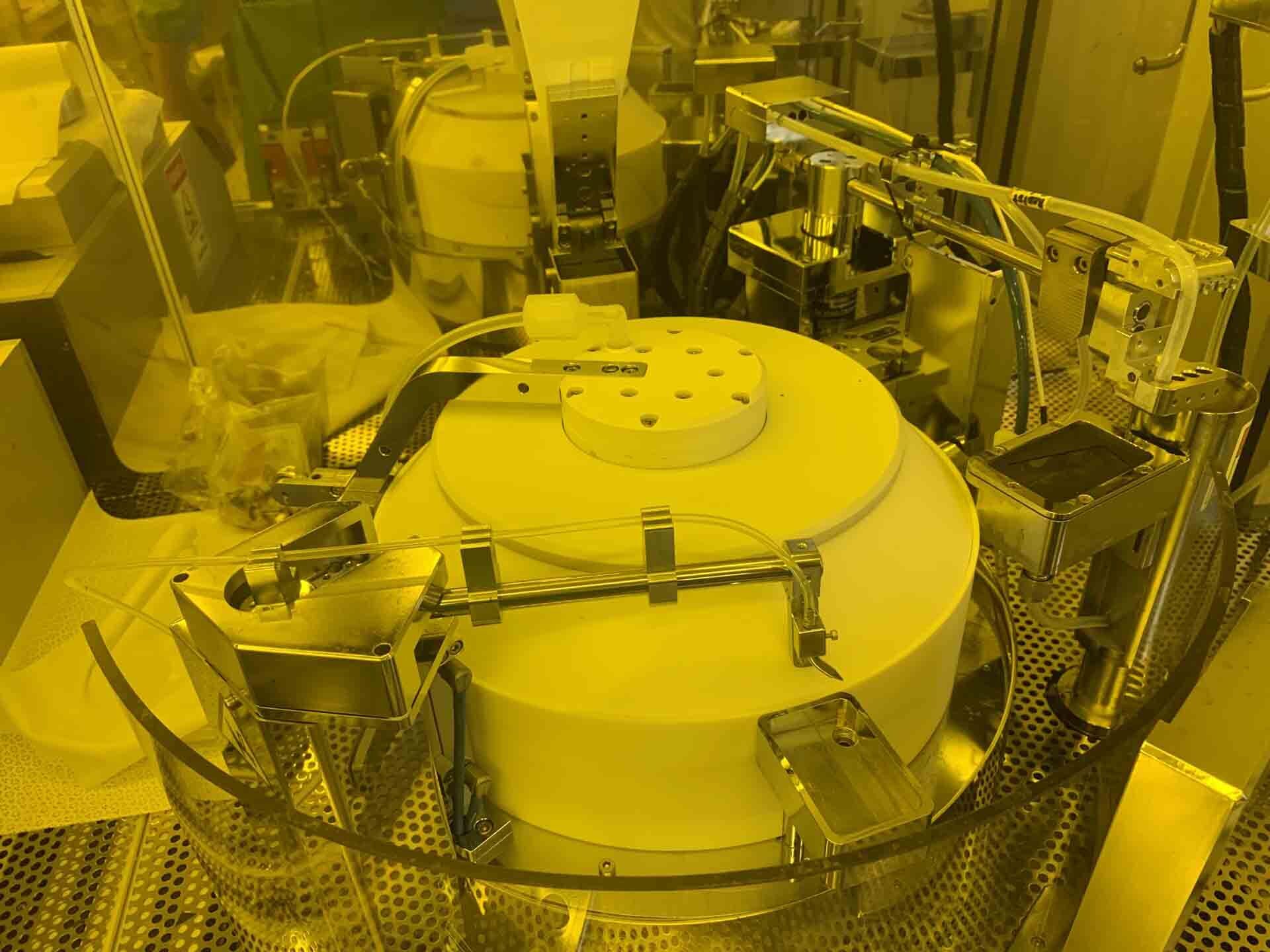

Spray coater, 4"-6"

Semi automatic with manual loading

Suitable for wafer sizes, 3"-8" (With proper chuck)

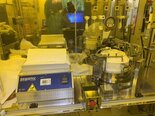

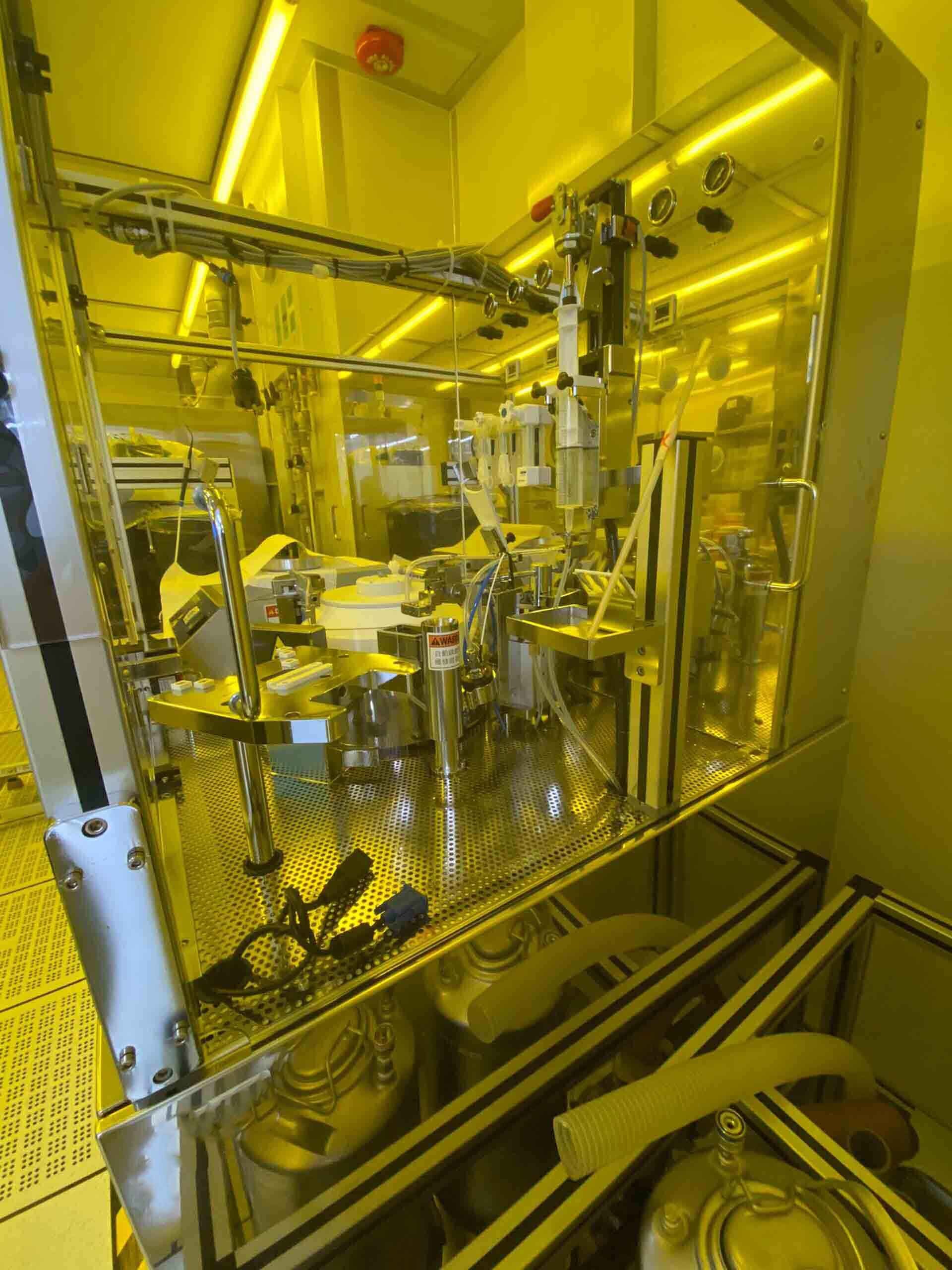

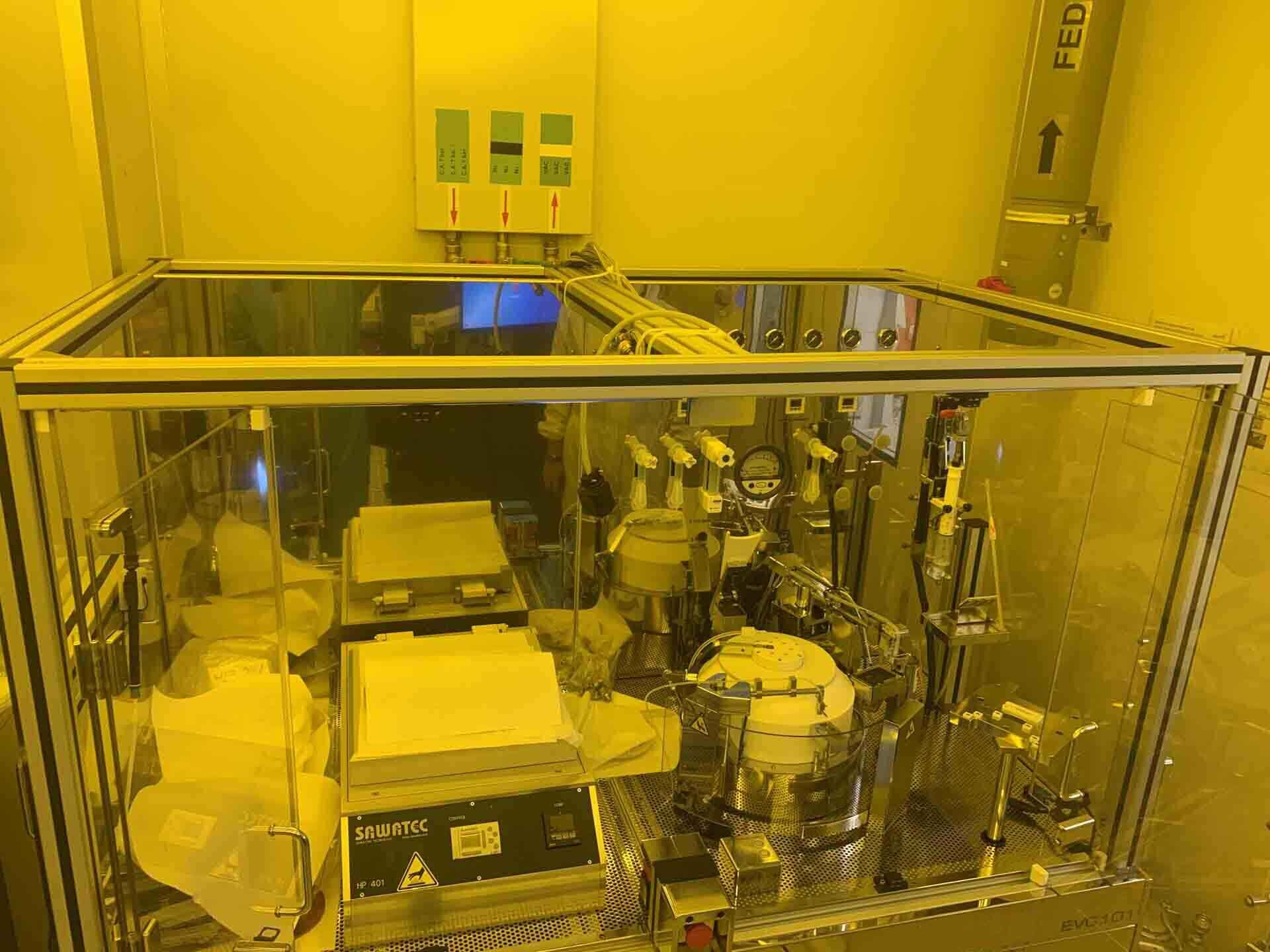

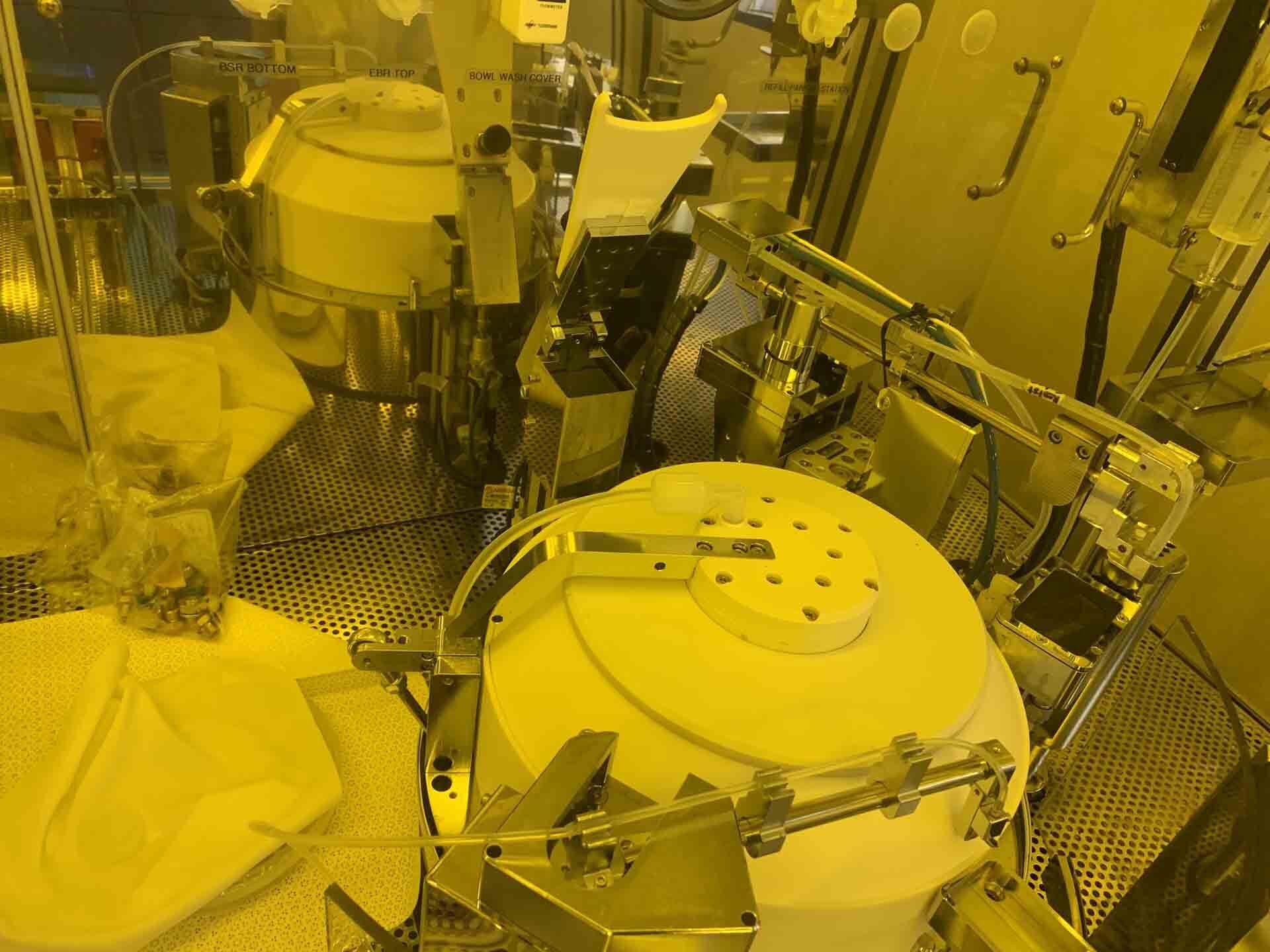

Coat module

Manual loading and mechanical pre-aligner (Pneumatically actuated)

Password protected access levels

PTFE Coat chamber for spin coating

Programmable rotational speed for substrate

Programmable arm for resist dispense and topside EBR

Cybor pump

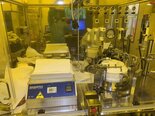

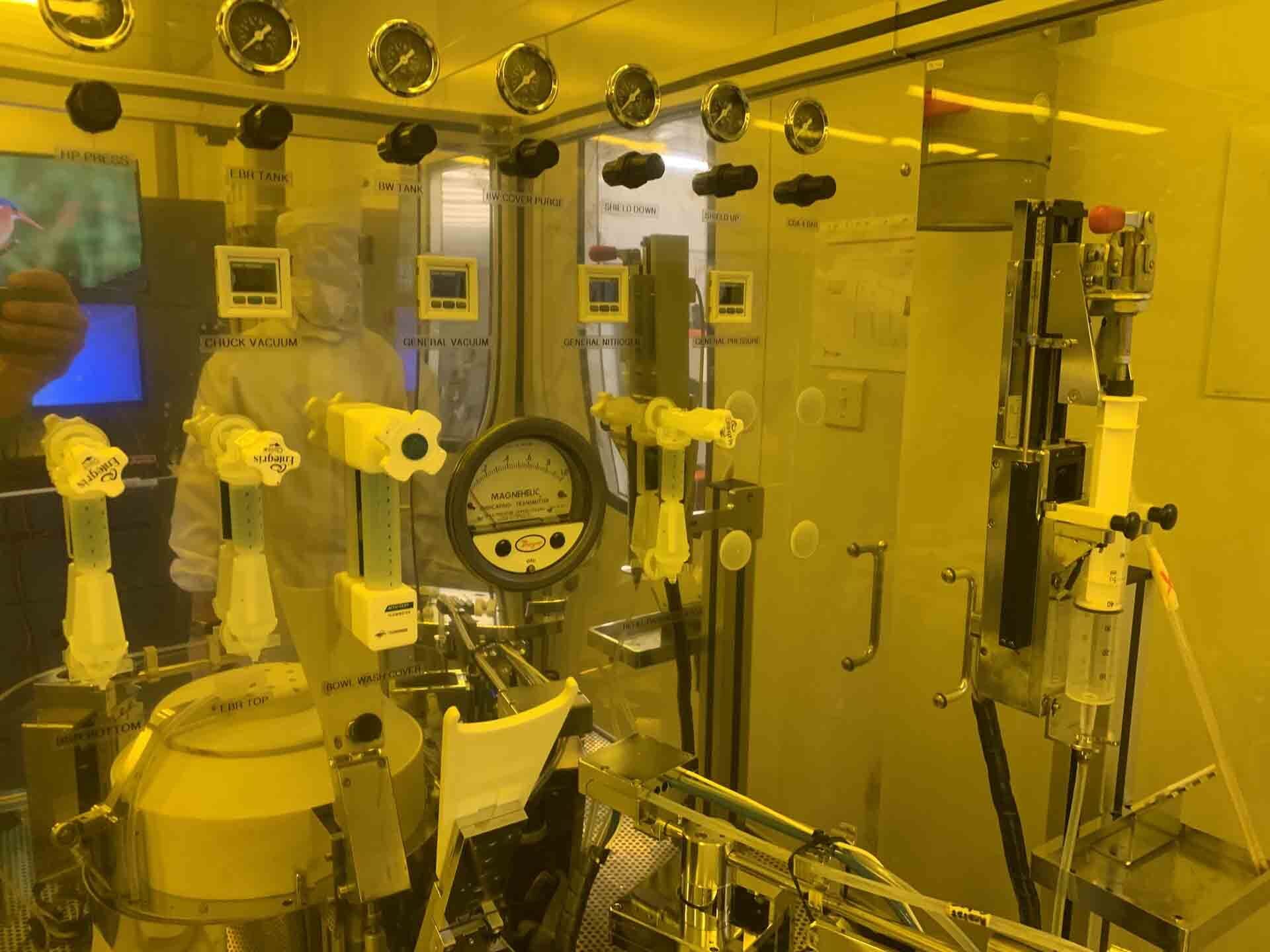

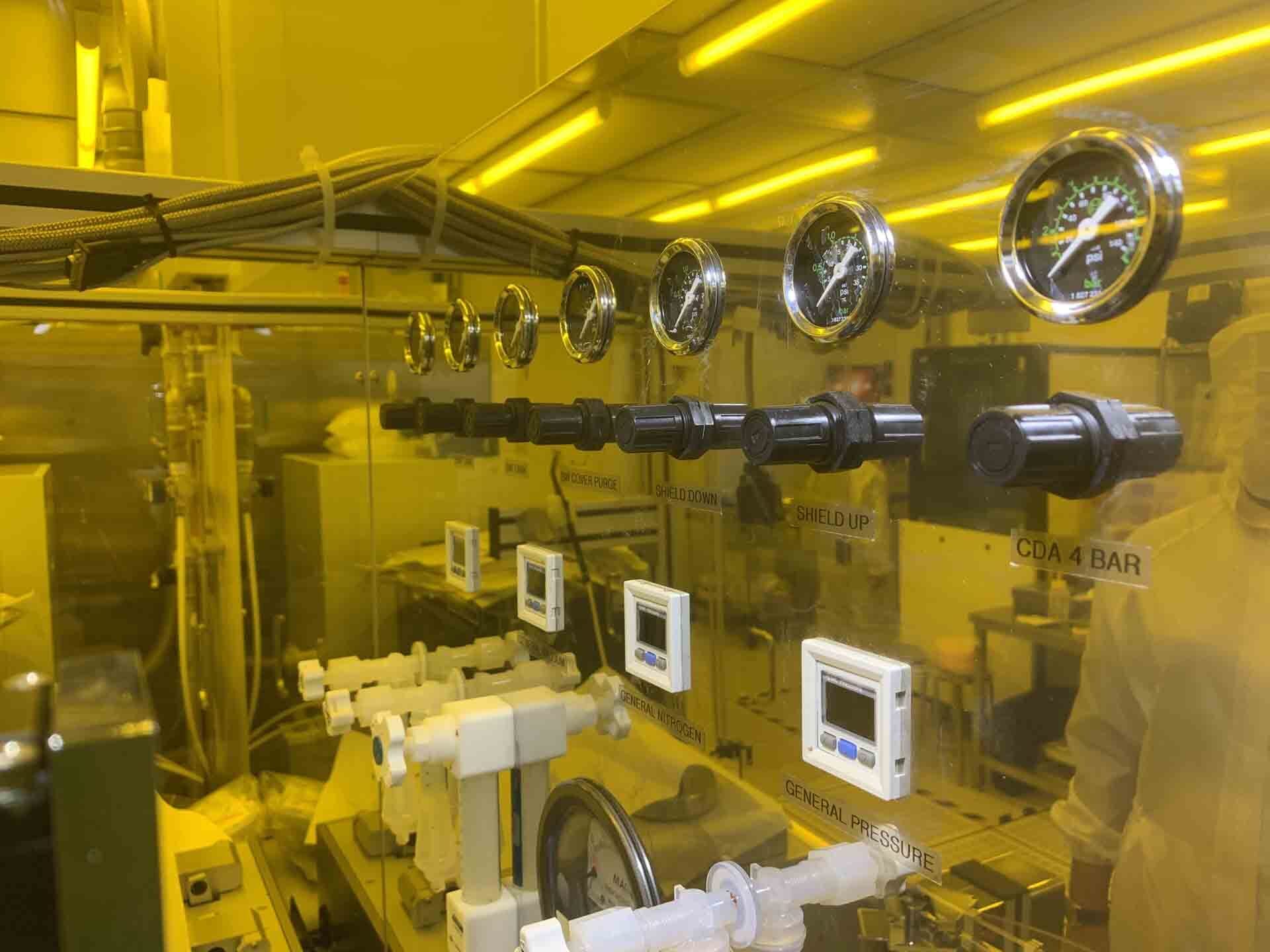

(2) Solvents for external chemical cabinet

Previously used chemistry: 1813, 1827, Acetone and IPA

Hotplate

Resist processing module:

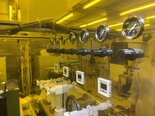

All electronics

Pneumatics

Tubing for solvents

Drain or dump container

Exhaust lines

Syringe dispense option

Operations manual and documentation.

EVG / EV GROUP 101 is a photoresist equipment designed for use in semiconductor industries. The system is designed to enable precise etching of thin films of materials onto wafers. The etching is done using a photoresist masking process. This process works by exposing the wafer to a pattern of light. The light source causes a photoresist coating to harden in areas where the light is exposed, while in other areas it remains soft. This soft material can then be easily etched away to create a pattern on the wafer. EVG 101 photoresist unit includes a number of components. The machine begins with a light source which is used to cast a pattern of light onto the wafer. This light source can be a laser, a high-intensity light emitting diode (LED) array, or any other device capable of providing a precise light pattern. A photomask is then used to selectively block the light from reaching certain areas of the wafer. This creates a pattern for etching. The next step in the process is the application of a photoresist to the wafer. This photoresist is a thin film of material that will coat the wafer and protect it from the etching process. It hardens in areas exposed to the pattern of light, while remaining soft or etchable in areas blocked by the mask. Different photoresists can be used depending on the type of material being etched. EV GROUP 101 photoresist tool also includes a reaction station for the photoresist. This station is designed to provide a controlled environment for the photoresist. It consists of a vacuum chamber, temperature control asset, and a UV light source to activate the photoresist. The model also comes with a laser station which is used to create the photomask. This laser station works by projecting a pattern of light onto a mask, and then etching away areas that are exposed to the light. The photomask can be used multiple times to create the same pattern on other wafers. The last component of 101 photoresist equipment is an etch station. This is where the etching process is performed. The etching process is done using a combination of a vacuum chamber and chemical treatments. EVG / EV GROUP 101 photoresist system is essential for creating precise patterns on wafers used in the semiconductor industry. The unit allows for accurate pattern control and excellent results. The machine is also easy to use and can be operated by even inexperienced personnel. For these reasons, EVG 101 photoresist tool continues to be a popular choice for many semiconductor manufacturers.

There are no reviews yet