Used FSI / TEL / TOKYO ELECTRON 2134N #9109608 for sale

URL successfully copied!

Tap to zoom

ID: 9109608

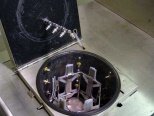

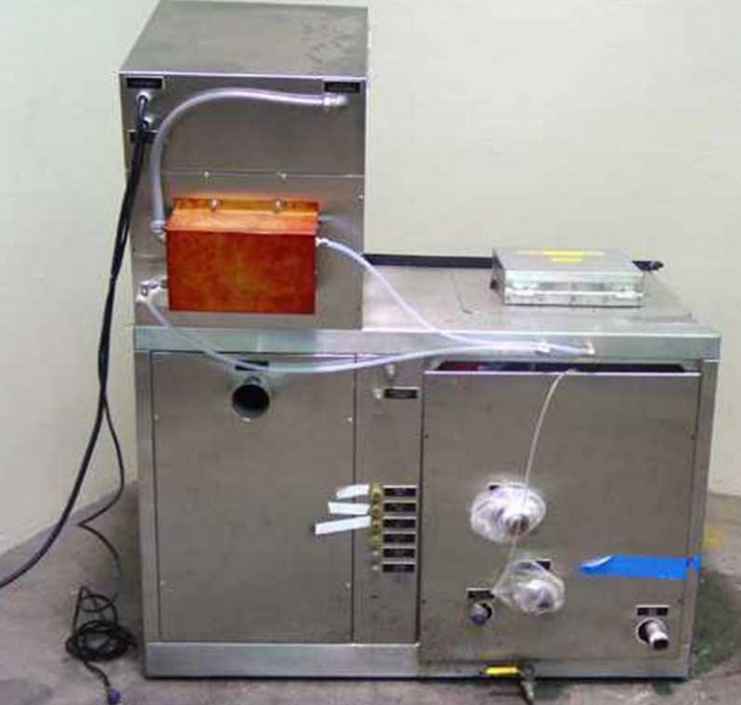

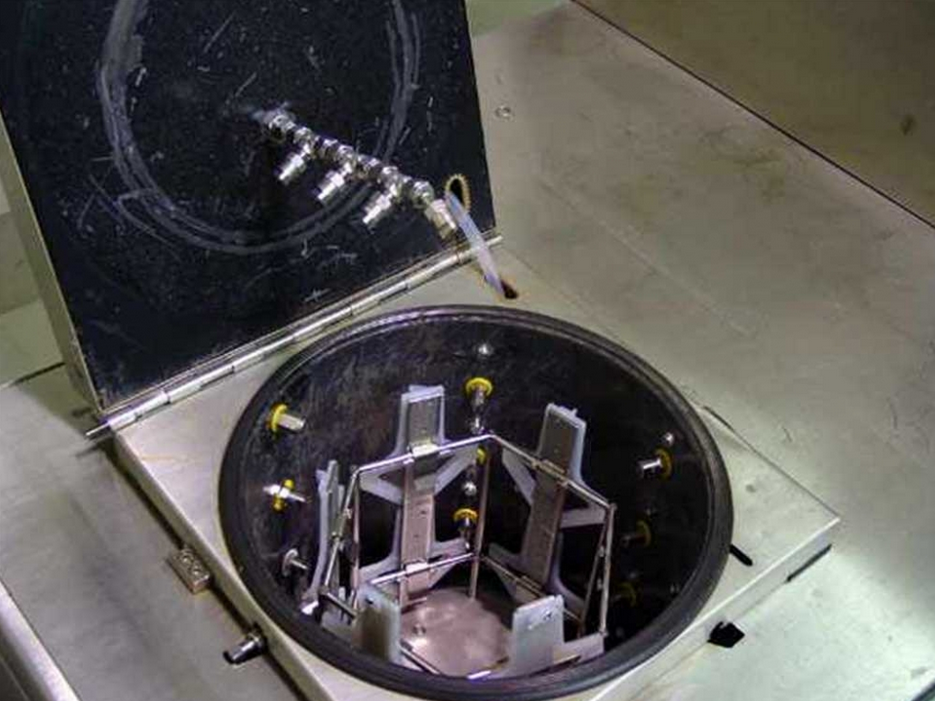

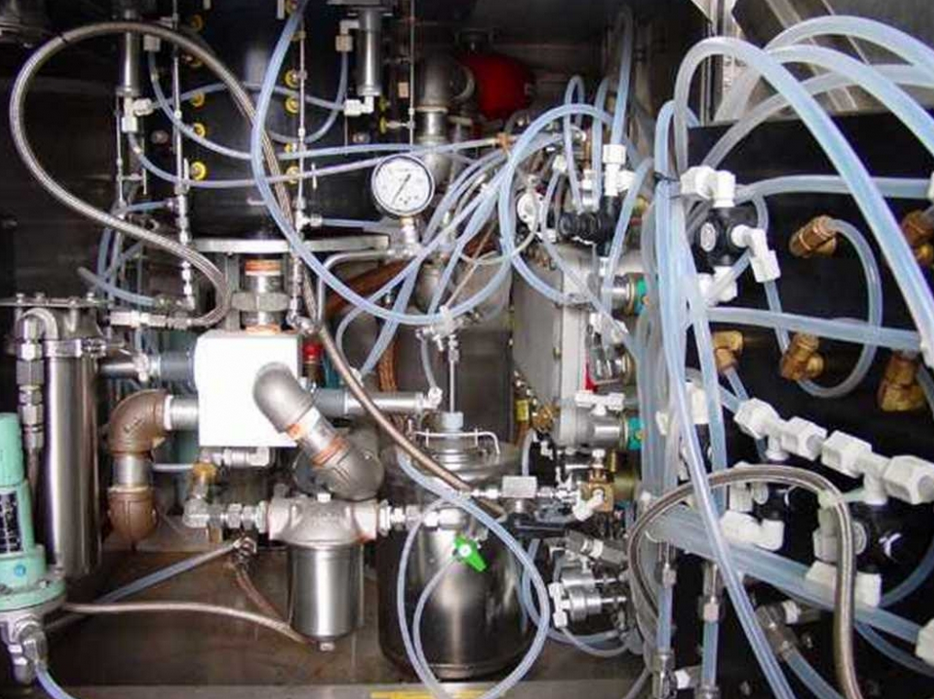

Wafer acid cleaning solvent system

Includes controls, pumps & flow valves/meters.

FSI / TEL / TOKYO ELECTRON 2134N is a photoresist equipment used in the fabrication of micro-electronic components. This system is an advanced unit that features integrated process control, high resolution and precision imaging, and automated substrate handling solutions. FSI 2134N uses advanced imaging technology to provide high resolution and precision imaging. This enables the photoresist layer of a device to be accurately and quickly exposed. Additionally, the machine includes advanced features like a laser tool that uses direct laser writing, an exposure control asset for accurate uniformity control, and a high-speed accumulation model that enables rapid response. TEL 2134N also features integrated process control. This includes an innovative in-situ laser interferometer that allows for precise measurement of critical dimensions. Additionally, the equipment includes an automated substrate handling system which facilitates the loading and unloading of substrates, as well as a fully automated set-up and operation process. 2134N provides high levels of accuracy and precise control over production during the photoresist unit fabrication process. The machine features a range of options for controlling the exposure and etching processes, including various parameters like the dose, exposure time, etch rate, focus depth, substrate temperature, and etch pressure. Additionally, the integrated process control allows for improved process repeatability and yield. Additionally, TOKYO ELECTRON 2134N can be configured with a range of options for automation. This includes a variety of automated substrate handling solutions, an automated calibration unit, and a fully automated set-up and operation process. Overall, FSI / TEL / TOKYO ELECTRON 2134N provides advanced imaging technology, integrated process control, automated substrate handling solutions, and precision control over production during the photoresist tool fabrication process. This enables users to achieve highly accurate and repeatable production results.

There are no reviews yet