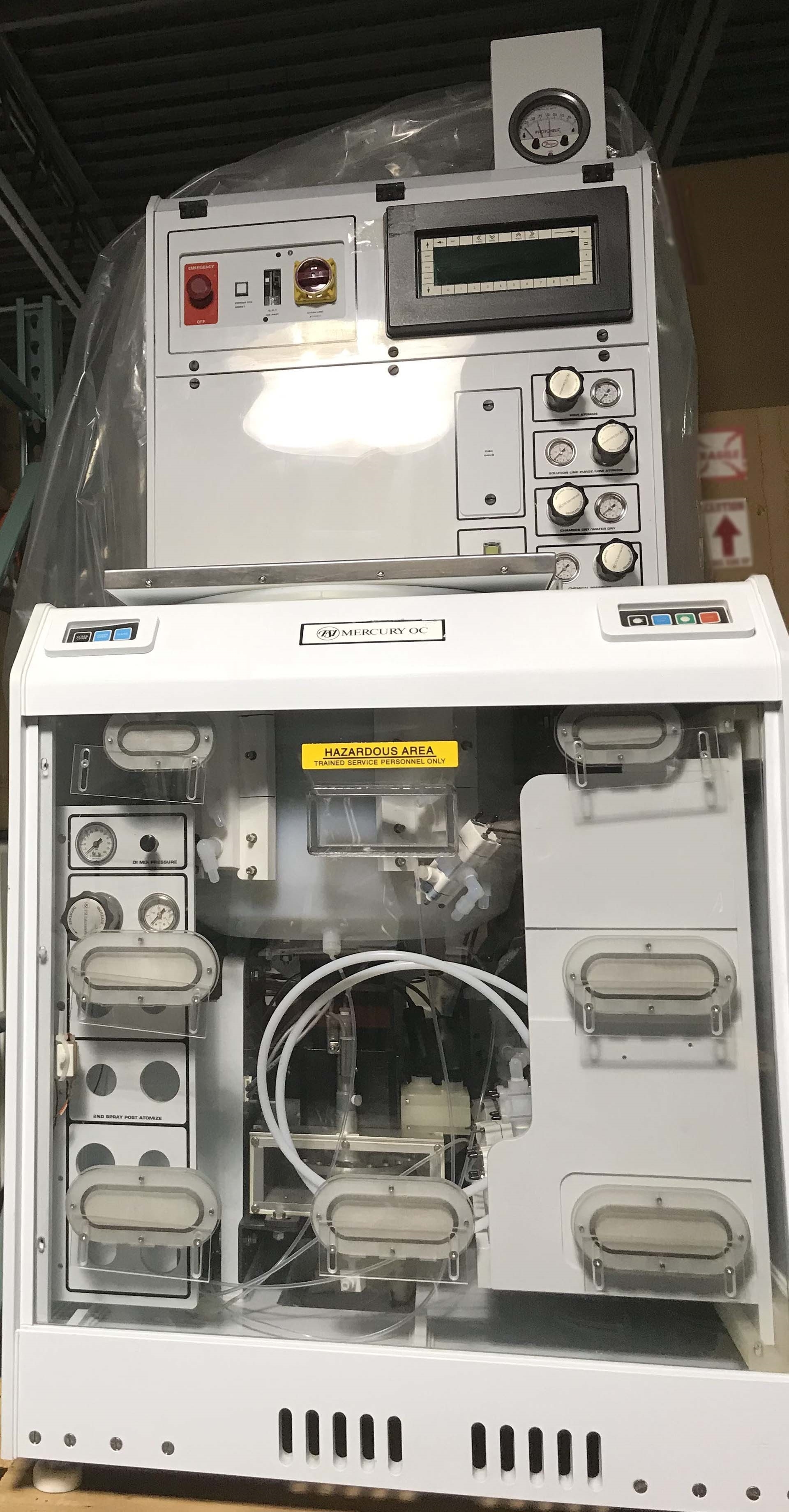

Used FSI / TEL / TOKYO ELECTRON Mercury OC #9233654 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9233654

Wafer Size: 5"

Spray processor, 5"

Single cassette, 6"

Diameter, 14"

Rotor / Turntable, 6"

Fed from central chemical distribution set up

No separate chemical carts with chemical canisters.

FSI / TEL / TOKYO ELECTRON Mercury OC is a photoresist equipment that uses a micro-processor-controlled rotating evaporation source. This system provides a reliable distribution of photoresist, allowing for more precise deposition than traditional systems. It utilizes a vacuum unit to evaporate a micron-thin layer of photoresist onto a substrate. The evaporation source is mounted on a rotating platform and is contained in a vacuum chamber. The evaporator contains a controlled source of thermal energy and is capable of heater temperatures up to 235°C. The evaporation source is then spun to distribute the photoresist evenly onto the substrate. The evaporation rate can be controlled based on the speed of the evaporation source and the amount of thermal energy that the evaporation source draws. The machine also features a pulse-tuning feature that adjusts pulse frequency and pulse width to achieve increased resolution of the photoresist. This advanced feature increases the flexibility of the tool and can be adjusted to meet different process requirements. The asset is designed to be used with standard, single-chamber photoresist materials, such as DUV (Deep UV) and I-Line photoresists. It is capable of processing a wide range of substrates, including silicon wafer, glass, quartz, and metal. The model has been designed to provide reliable and repeatable results. It features a quality monitoring equipment that can calibrate and constantly adjust the pulse-tuning parameters to ensure accurate results. It also has an integrated system that helps users easily monitor and manage the manufacturing process. The unit is also scalable, so it can be adapted to different requirements. FSI Mercury OC provides an efficient and accurate way to process photoresist. Its versatile design and adjustable settings offer flexibility and reliability to ensure a successful processing of the photoresist. The machine offers superior results, including uniform deposition, a highly controllable thermal source, and precise control of the pulse-tuning parameters. This tool is suitable for a wide variety of applications and ensures repeatable and reliable results.

There are no reviews yet