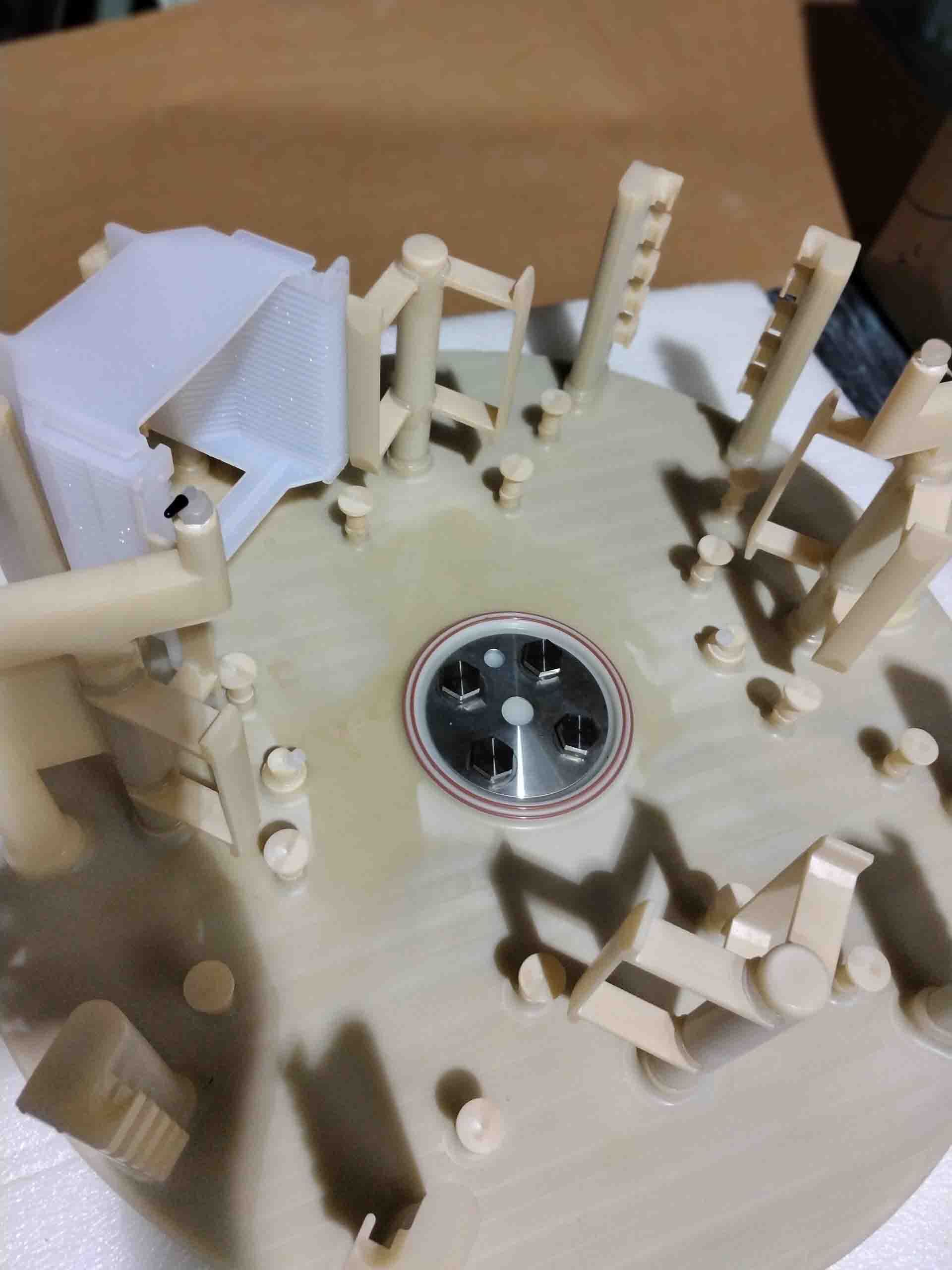

Used FSI / TEL / TOKYO ELECTRON PVDF Turntable for Mercury #9354313 for sale

URL successfully copied!

Tap to zoom

FSI / TEL / TOKYO ELECTRON PVDF Turntable for Mercury is an automated, self-contained photoresist equipment designed for OEM integrators and first-level users. It is a cost effective solution that provides automated spin coating and baking capabilities with output rates up to 75 wafers per hour. The system includes an 11.8" spin track turntable with a 12-degree tilt for uniform dispersion of photoresist over the wafer. The PVDF turntable is rotatively driven for up to 3000 rpm with a top-plate acceleration of 500 rpm/sec2. The adjustable table has a fluid inlet temperature range between 25°c and 65°c, and a backside heating temperature of up to 100°c. This PVDF turntable is designed for a variety of photoresists, including positive and negative resists, high-temperature photoresists, post-coating treatments, and other related process materials. The large capacity design allows for maximum throughput with minimal setup time. Integrated PLCs and a touch-screen operator interface allow for easy, precise control of the liquid delivery unit. The machine is UL-certified for safe operation and built to meet the highest standards for durability. The turntable has an in-line diagnostic tool that monitors key functions, including vacuum, plate temperatures, resist uniformity and pressure on the substrate. A unique software package automates the entire resist coating cycle, from dosage control to wafer loading. Advanced data logging and recipe management features are also included, providing for precise process compliance in a single click. To prevent chemical buildup, the PVDF turntable is equipped with a single use, self-cleaning nozzles and drainage asset that promotes the use of clean resist. The model is also designed to minimize spin-off waste with an effective sprayer design and integrated quencher. FSI PVDF Turntable for Mercury is the ideal solution for a broad range of photoresist processing needs. With its robust design, integrated safety features, and automated, efficient operation, it is the perfect choice for photoresist users.

There are no reviews yet