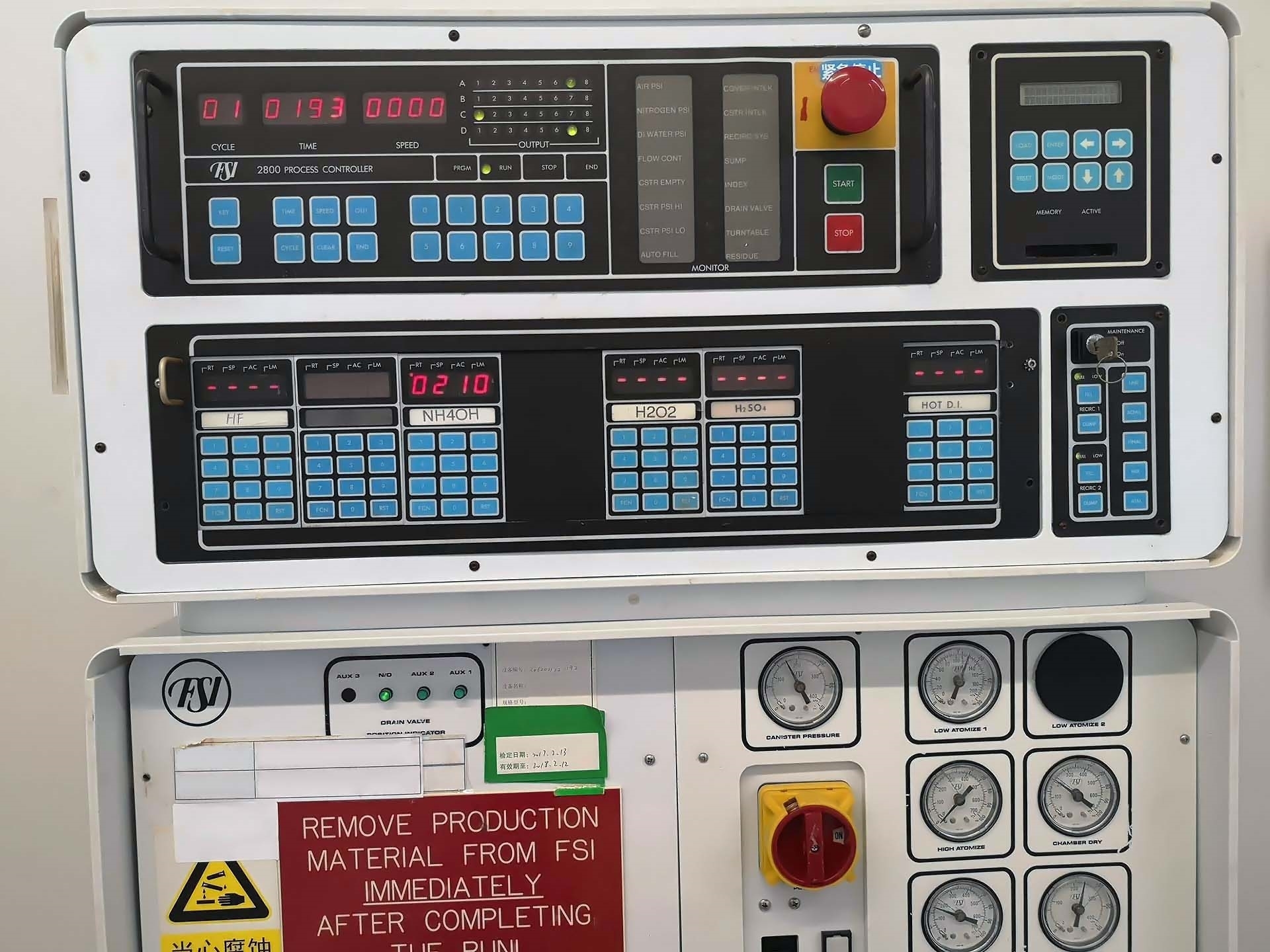

Used FSI / TEL / TOKYO ELECTRON Saturn #9237266 for sale

URL successfully copied!

Tap to zoom

FSI / TEL / TOKYO ELECTRON Saturn is a photoresist equipment that is used to manufacture and engineer integrated circuits. The system is specifically designed for chemical mechanical planarization (CMP) processes, which involve the chemical etching and physical polishing of substrates. This unit is used to increase the performance, reliability, and yield of semiconductor devices. FSI Saturn machine is composed of three main components: a spin coater, a develop track, and an automatic wafer metrology tool (AWMS). The spin coater is used to apply a photoresist film to wafers. The develop track is responsible for developing the photoresist. The AWMS determines the amount of spin speed and time for the spin coater, as well as the temperature and time for the develop track, to ensure optimal performance of each etching and polishing process. TEL Saturn asset is capable of performing various CMP processes, including physical polishing, chemical etching, etching and polishing, baking and hardbaking, spincoating, and washing. All of these processes are controlled using the model's software. By optimizing the CMP process parameters like speed, pressure, and temperature, the equipment helps improve the performance, reliability, and yield of semiconductor devices. The system also features a variety of post-process functions, such as edge passivation, bulk resist etch, and side wall image transfer. In terms of safety, Saturn meets all the requirements of a photoresist unit. It is equipped with multiple safety sensors, which detect any possible risks and alarms operators of any danger. An emergency stop function is also included, along with an instruction manual and a safety guide to help operators understand the machine and follow safety procedures. In conclusion, TOKYO ELECTRON Saturn is an advanced tool for designing and fabricating integrated circuits. It features optimized CMP parameters, as well as post-process functions, to ensure a reliable and high-quality output. The asset also provides numerous safety features, making it a safe and effective solution for engineering and manufacturing microchips.

There are no reviews yet