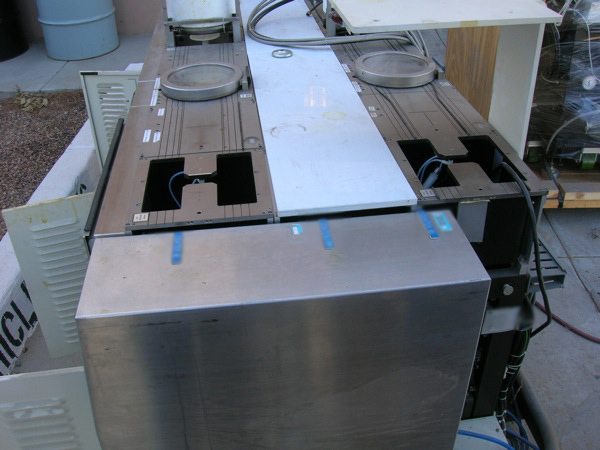

Used GCA / TROPEL Wafertrac 1006 #171562 for sale

URL successfully copied!

Tap to zoom

GCA / TROPEL Wafertrac 1006 is a photoresist equipment designed to provide precise alignment and handling of semiconductor wafers. The system is especially adept at processing large substrates and features a variety of features that make it one of the most dependable and reliable systems on the market. The core of the unit includes a powerful 6-axis controller, which is capable of precise alignment of wafers and substrates, while an additional ARM servo amplifier enhances the accuracy of the positioning process. This ensures that the machine can handle a wide range of substrates, including glass, silicon, and metal. To ensure accuracy, GCA Wafertrac 1006 includes a range of positioning techniques, including diameter compensation and actuator-level compensation. This allows the tool to compensate for any size distortion and misalignment, resulting in more precise positioning of materials. Additionally, the asset has a feature called the "optical mask" which provides enhanced edge detection and prevents particle contamination, improving the overall quality of the output. In addition, TROPEL Wafertrac 1006 is designed with a high-resolution CCD camera, providing precise and accurate positioning of substrates. Its high-resolution imaging and inspection capabilities also allow for precise and accurate photoresist application, making it ideal for near-field imaging and applying chemical and biological agents. The Wafeertrac 1006 also includes an array of vibration control systems, ensuring the model is stable, noise-free and providing excellent repeatability. It features a low air flow equipment that minimizes particulate debris and allows for precise control of the photoresist material. Furthermore, the 1006 includes precise automatic wafer handling, supporting multiple wafer carriers and a wide range of robots. This drastically reduces process times and makes it very efficient in ultra-high production environments. In summary, Wafertrac 1006 is an advanced photoresist system designed to provide precise alignment and handling of semiconductor wafers. The unit is adept at processing large substrates and uses a variety of positioning techniques, such as diameter compensation and actuator-level compensation. It also includes a high-resolution CCD camera for precise photoresist application, as well as an array of vibration control systems for stable and repeatable processes. The machine also supports multiple wafer carriers and a wide range of robots, making it an ideal tool for ultra-high production environments.

There are no reviews yet