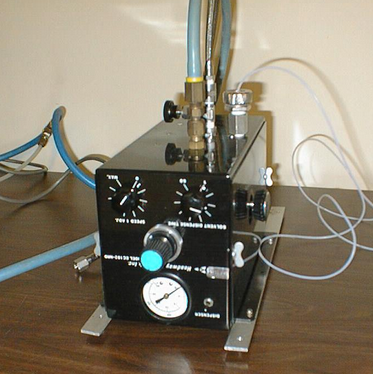

Used HEADWAY EC 102 Type 2 #10832 for sale

URL successfully copied!

Tap to zoom

HEADWAY EC 102 Type 2 photoresist equipment is a process of developing high precision electronics components by forming and curing a thin protective layer over the desired area. It is a widely used method in the production of integrated circuits, flat-panel displays and other ultra-precision electronics devices. EC 102 Type 2 system involves application of a photoresist material on the substrate. Photoresist is a polymer material, typically a photosensitive polymer, which reacts to ultraviolet or other radiant energy such as light or heat in order to create an addressable pattern. This pattern is then used to transfer the pattern directly to a new substrate. The substrate is then heated at a high temperature in order to cure the photoresist material and to form the desired pattern. Additionally, the use of oxygen-based plasma can be used to further enhance the results of the pattern formation. Once the pattern is formed, the substrate is then exposed to the appropriate light source (usually UV) in order to overexpose the pattern and create a strong photostationery layer. This layer serves as a permanent cover designed to protect the underlying components. HEADWAY EC 102 Type 2 photoresist unit is used in many industries including automotive, aerospace and consumer electronics. For integrated circuit production, the process is used to ensure highly uniform coverage and to reduce defects caused by uneven coating. It also improves the robustness of the process, making it more resistant to environmental factors. The process is relatively simple, yet has high yields that minimize product waste and maximize usable yields. Since the exposure process is repeatable and offers consistent results, the use of the same photoresist technique can be applied to different IC process layers, ensuring that pattern formation and curing is uniform across layers. These features allow EC 102 Type 2 machine to provide the high resolution and precision needed in today's advanced electronics production. The process offers a high reliability and is often used in combination with other processes such as photolithography to further improve yields and reduce cost. Overall, HEADWAY EC 102 Type 2 photoresist tool is an established and reliable method for producing integrated circuits, flat-panel displays, and other highly precision electronics components. The asset offers high resolution, low levels of variability, and can be applied to a wide range of substrates. This makes it an ideal choice for industries demanding consistent and high quality results.

There are no reviews yet