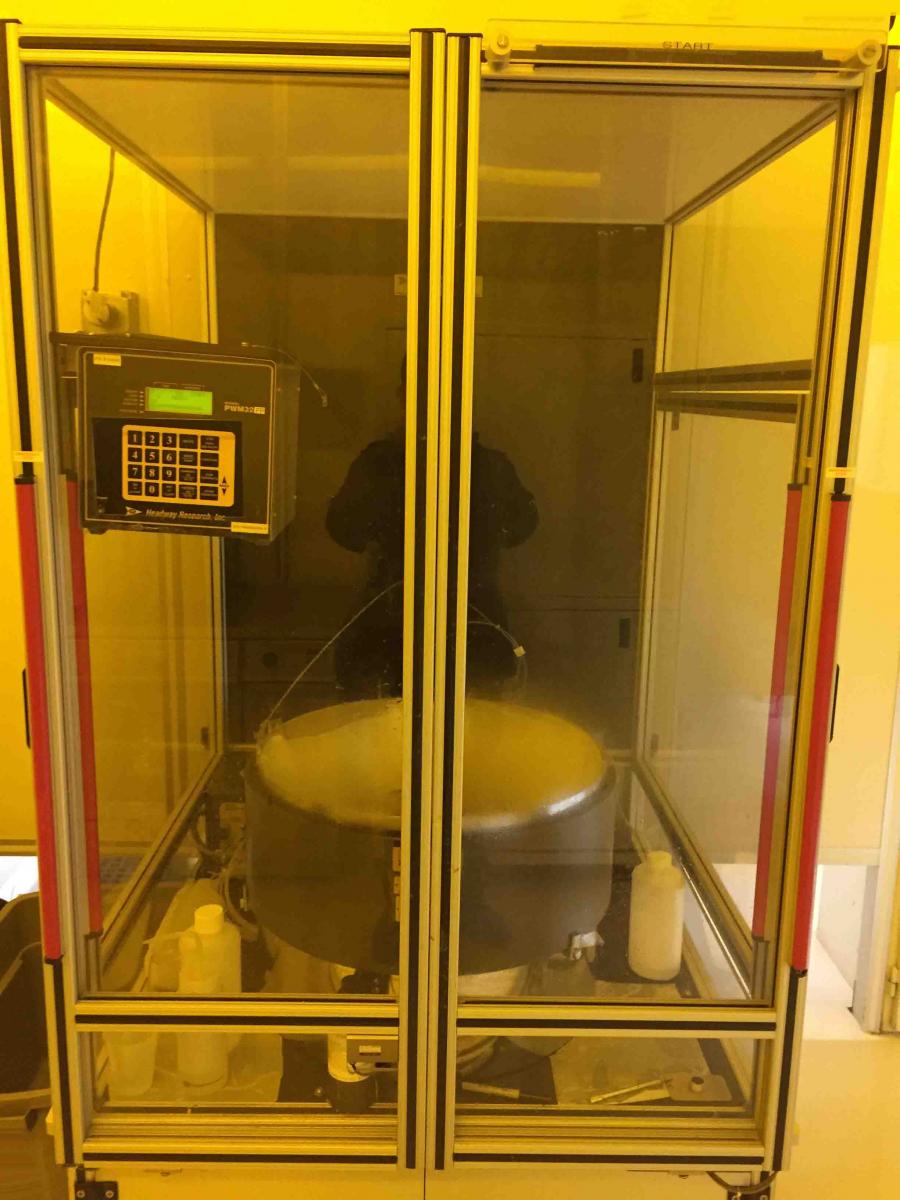

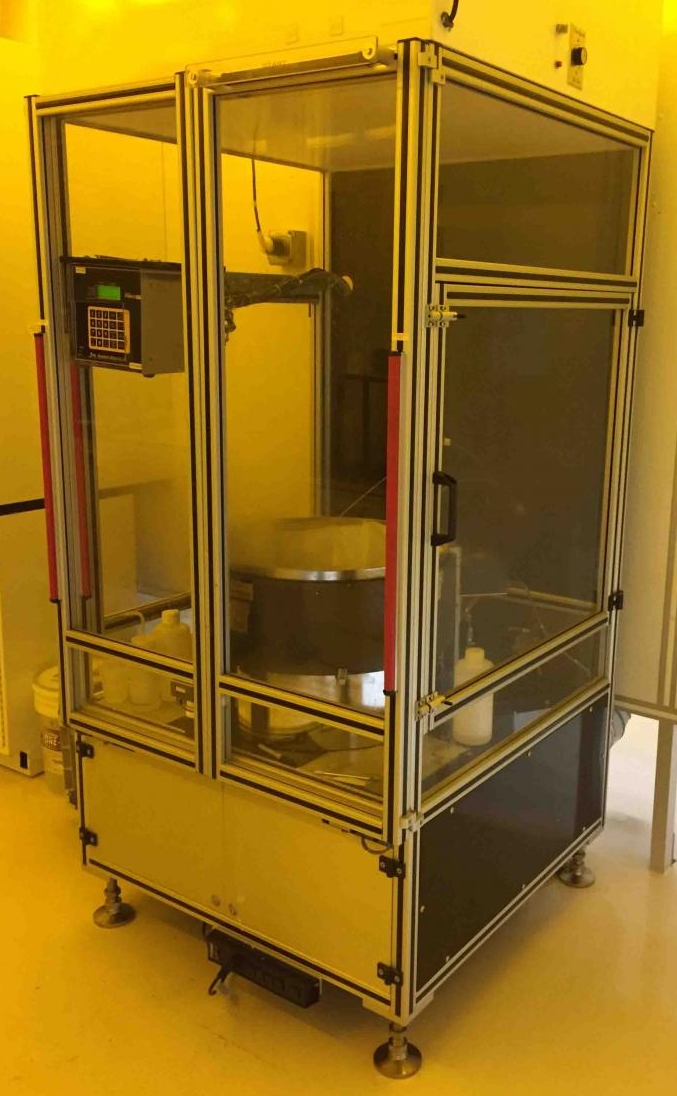

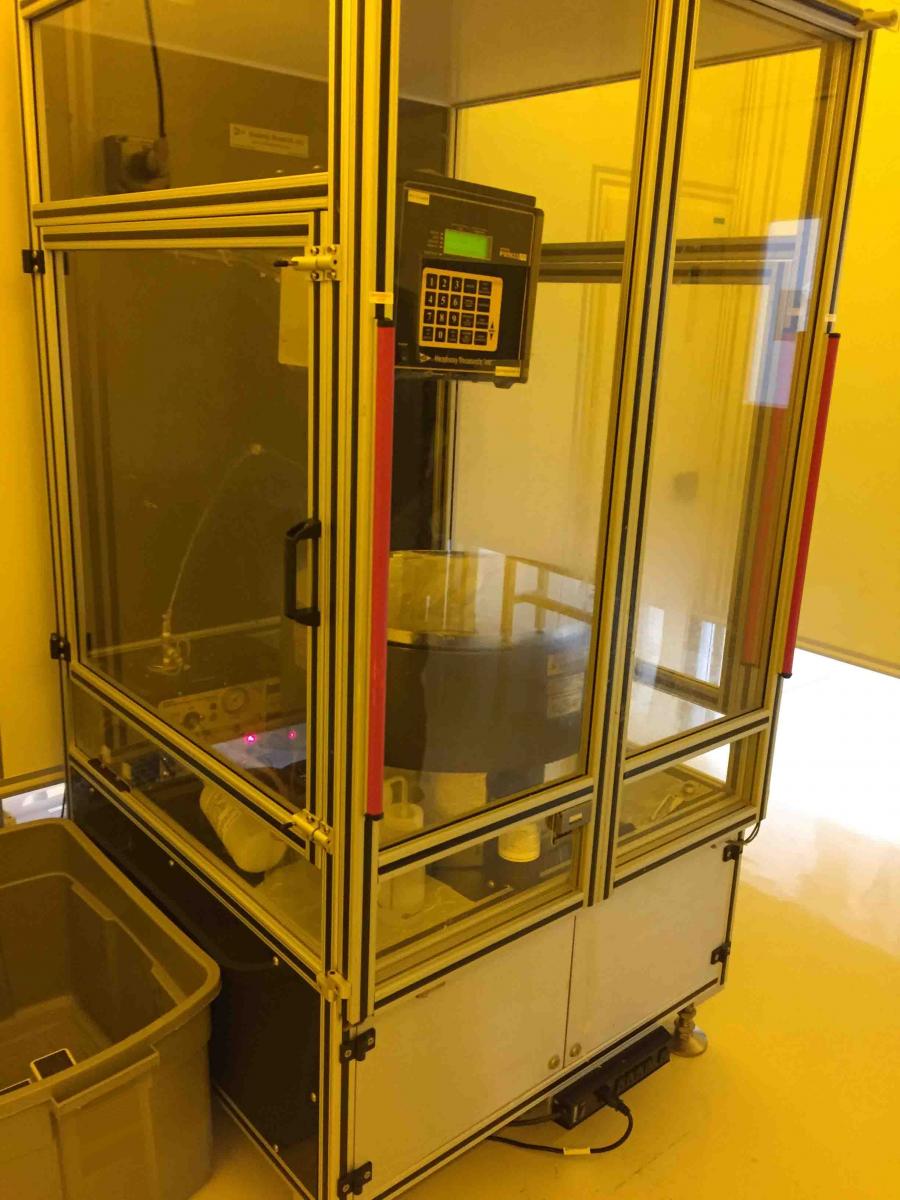

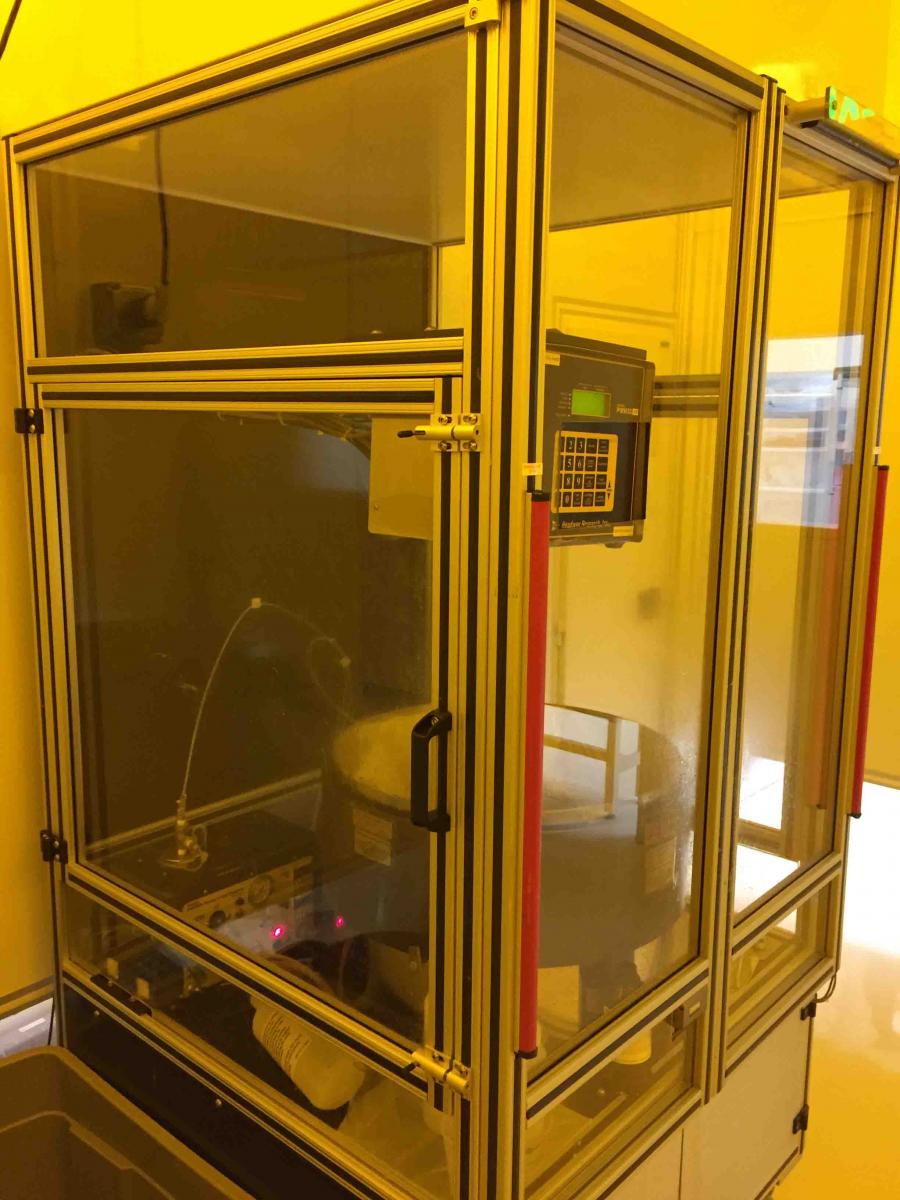

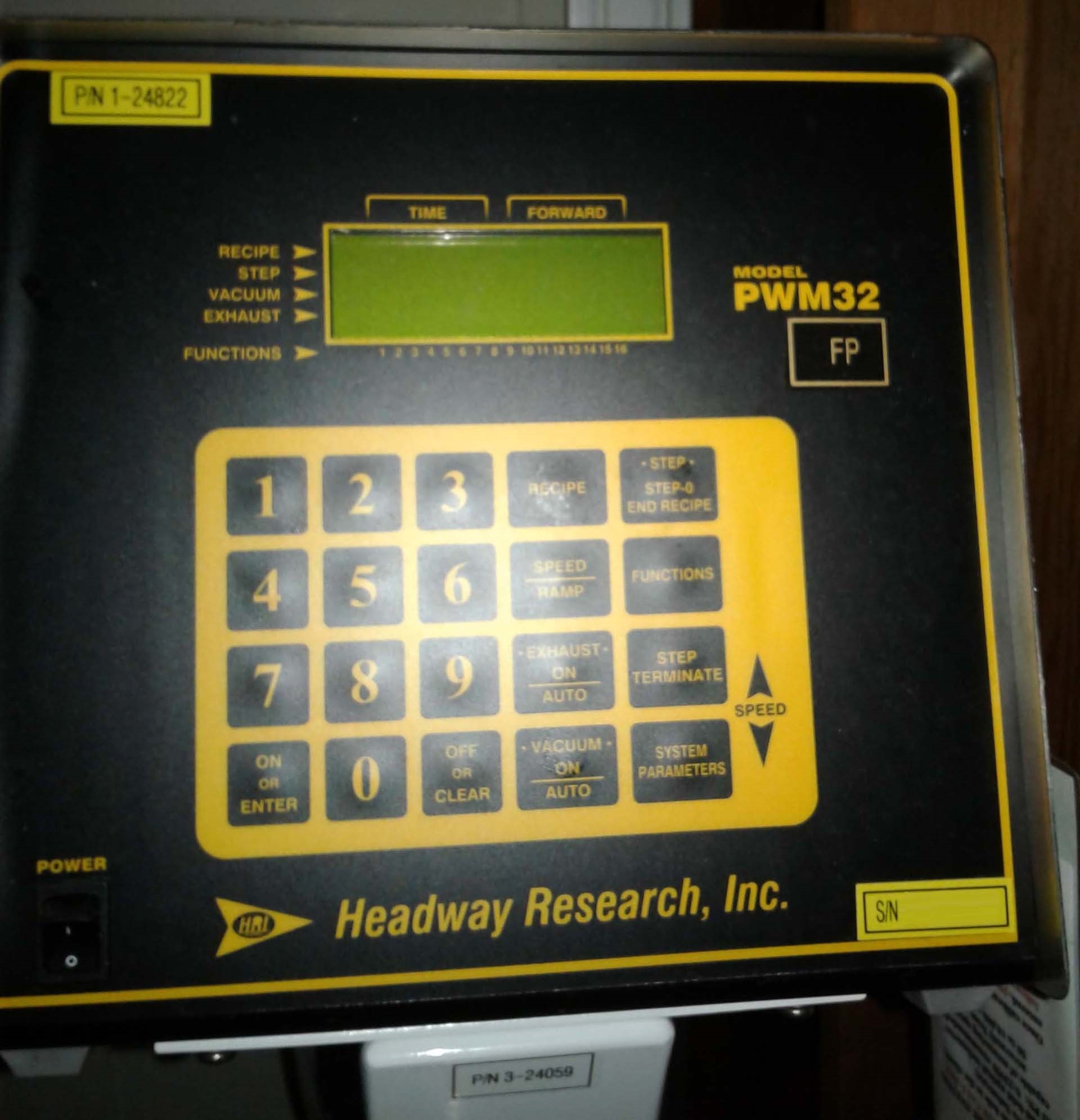

Used HEADWAY PWM 32 #9173711 for sale

URL successfully copied!

Tap to zoom

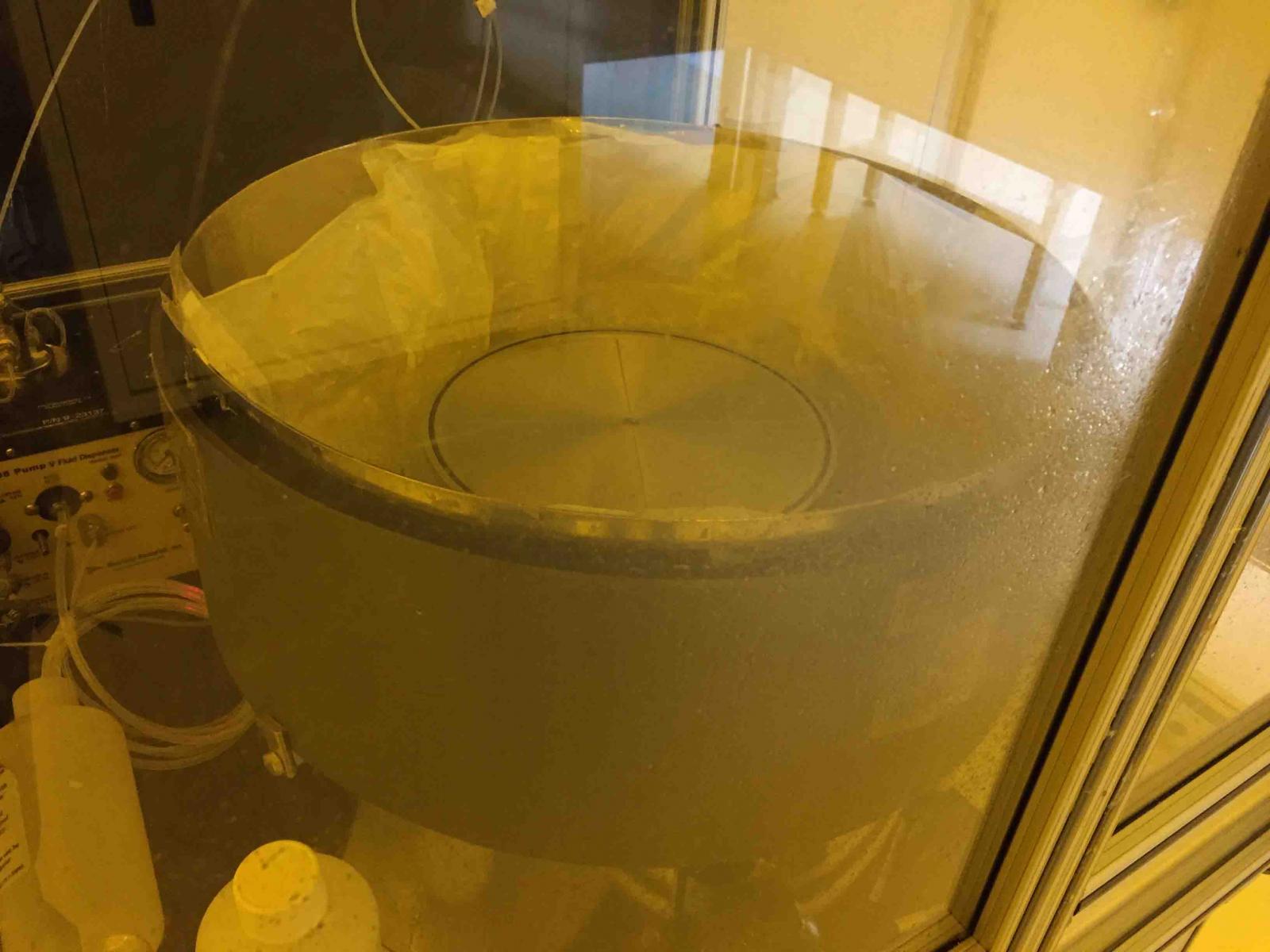

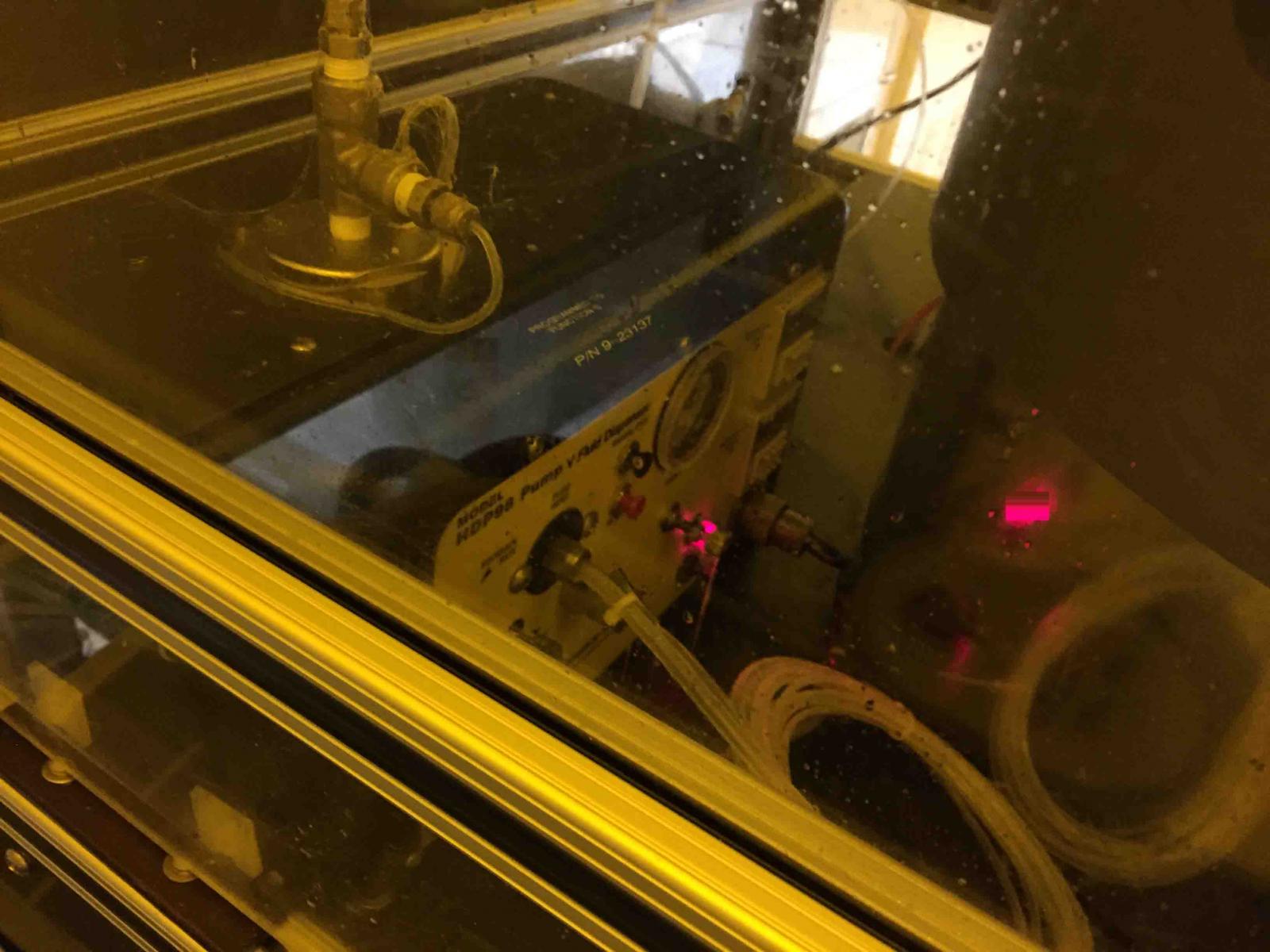

HEADWAY PWM 32 is a photoresist equipment which offers a fast, easy and cost-effective way to produce accurate and consistent high-quality electronic components. This system uses the principle of photoresist, a process in which a thin layer of light-sensitive material is exposed to light and then developed with a developer solution. Photoresist systems are commonly used in industries such as electronics, PCB manufacturing, and other surface technologies. HEADWAY PWM32 is an optimized version of the popular MULTITOOTHwave unit. It features a compact console design, a high-precision sensor head, and an easy-to-use software user interface. The machine includes a laser-based light source which is used to expose the photoresist layer. The exposure is controlled by a 32-bit microprocessor that is capable of controlling the power output of the laser as well as the exposure time. This allows for fine adjustments in order to achieve optimal results. The tool comes with two individual mask plates which hold the photoresist layer. These plates are connected to an automated transport asset which moves them through various steps of the photoresist process. The transport model is also equipped with a safety shield, which prevents any stray laser light from causing damage to the photoresist layer. PWM 32 also includes a high-precision vision equipment which is utilized to detect any irregularities in the photoresist layer. The vision system allows for precise monitoring of the layer during the course of the process. Quality control is further enhanced by the in-depth testing process that is incorporated into the unit. This process includes a series of tests to ensure that the photoresist layer is of the highest quality and is consistently within specification. PWM32 is a highly reliable and accurate solution for photoresist applications. It provides an efficient, easy-to-use, and cost-effective way to achieve consistent and high-quality results in the production of electronic components. With its automated process and advanced vision machine, this tool yields superior results every time.

There are no reviews yet