Used KARL SUSS / MICROTEC ACS 200 #9213836 for sale

URL successfully copied!

Tap to zoom

ID: 9213836

Wafer Size: 8"

Vintage: 2000

Coater / Developer system, 8"

Material Handling Unit (MHU):

GENMARK Gencobot 8Y robot

Robot end effectors

Robot cassette scanner

Auto-sizing cassette holder

Manual-sizing cassette holder

Universal centering station

Optical prealigner

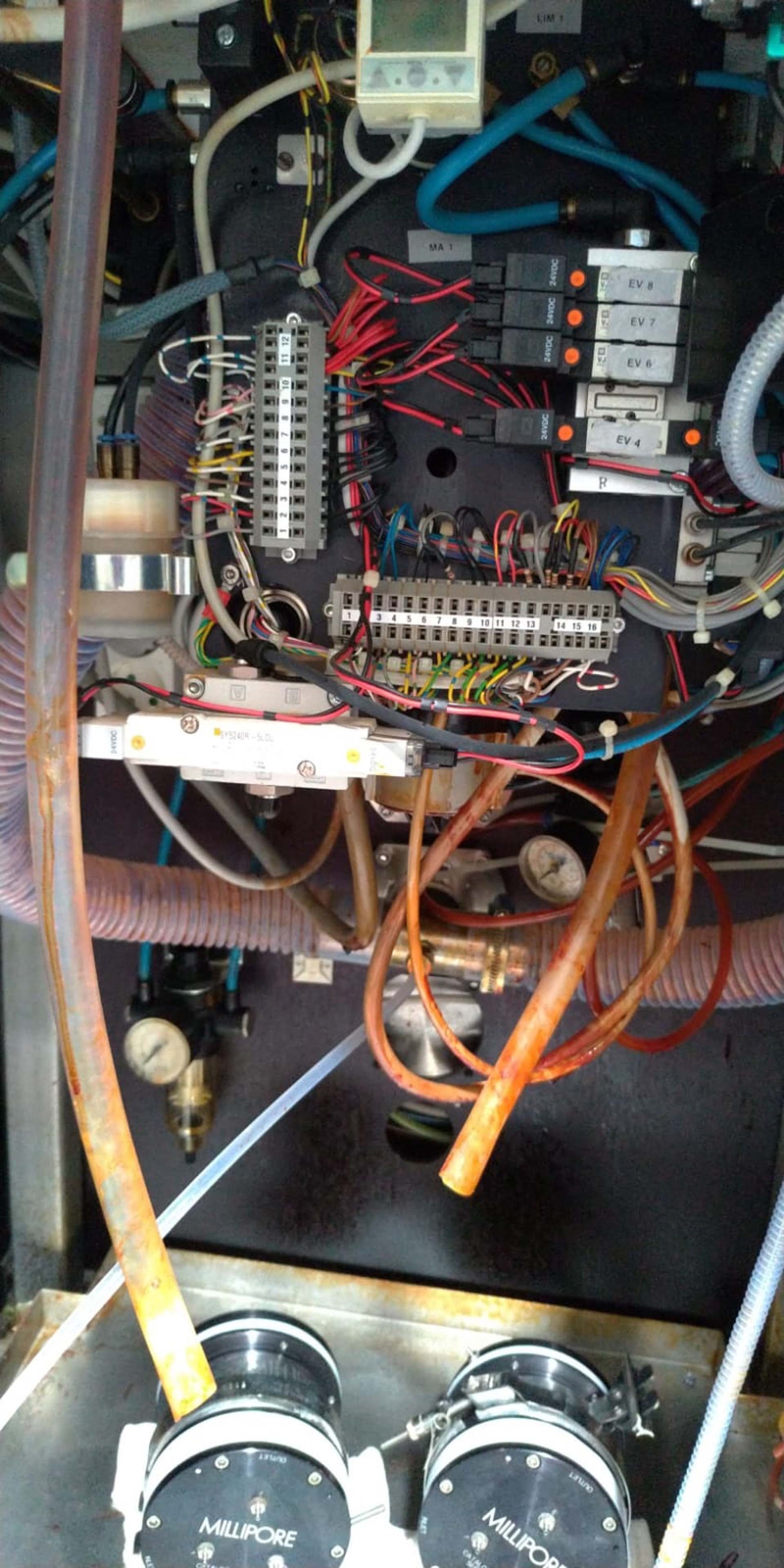

Spin coat module:

GYRSET RC 8 Spin coater

Spent chemical monitoring scale

VULCAN Dispense pump

Virgin dispense pump

MILLIPORE Wafergard Gen-2 plus pump

MILLIPORE Wafergard Chemical dispense system

Timed pump

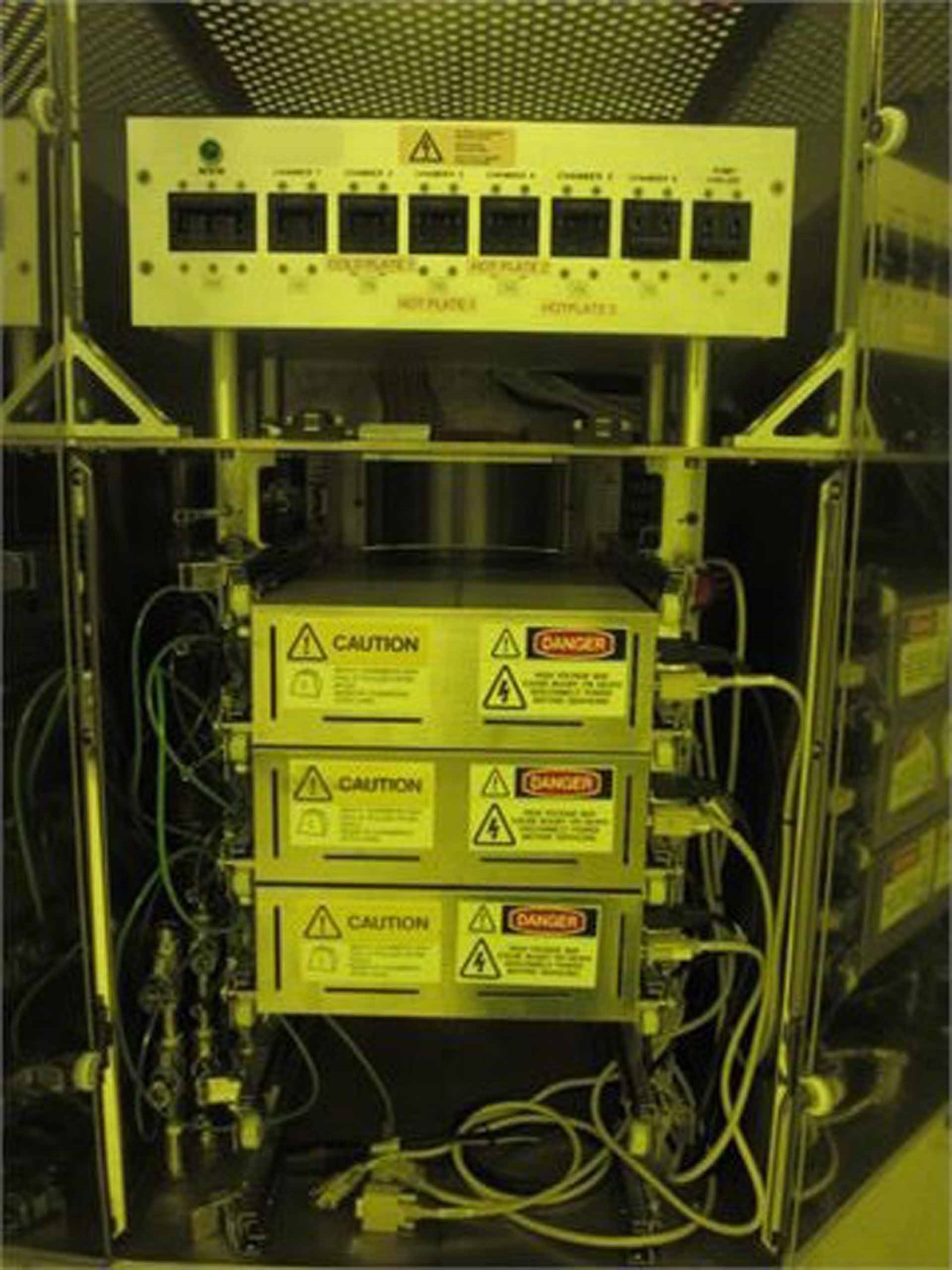

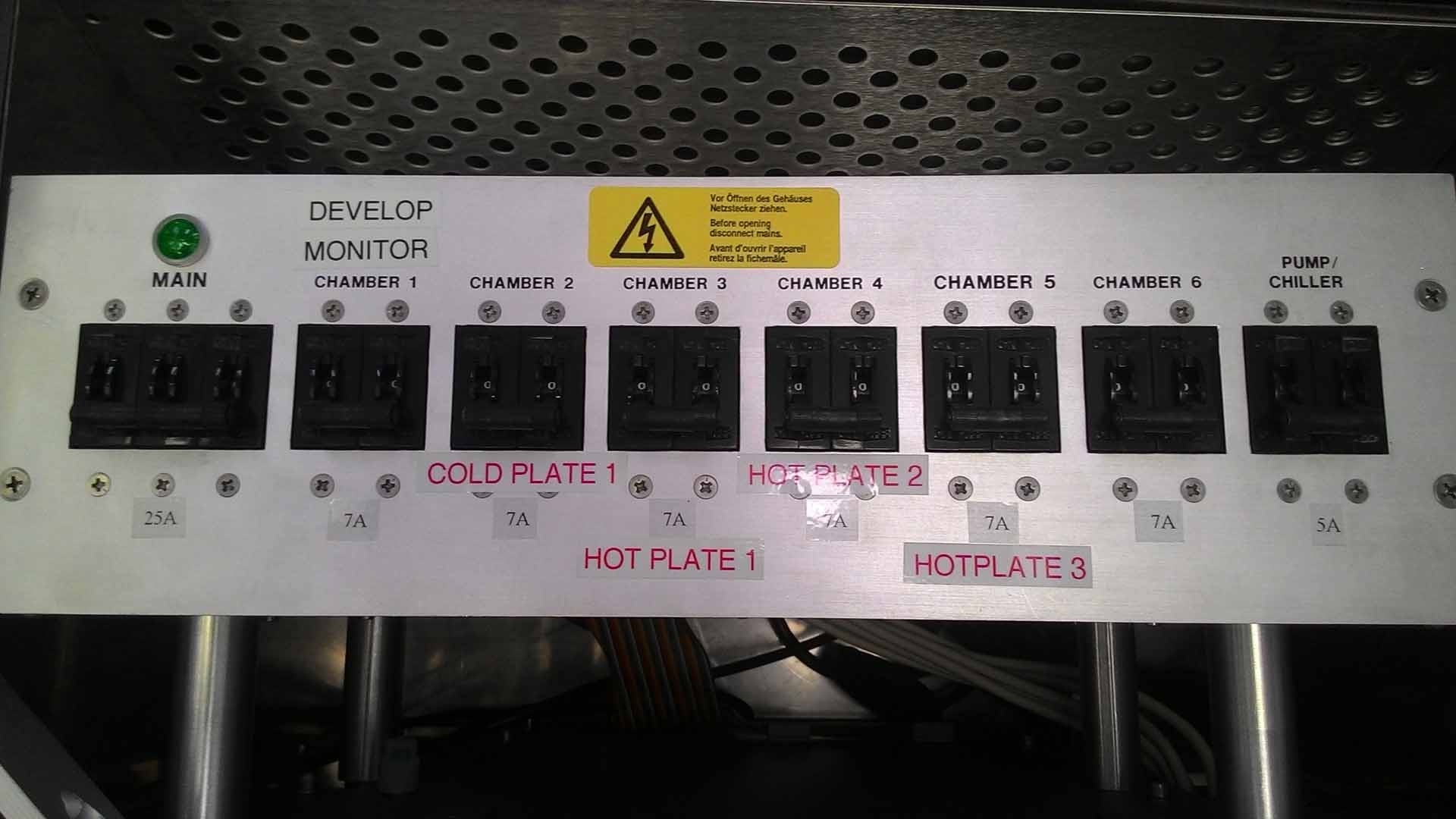

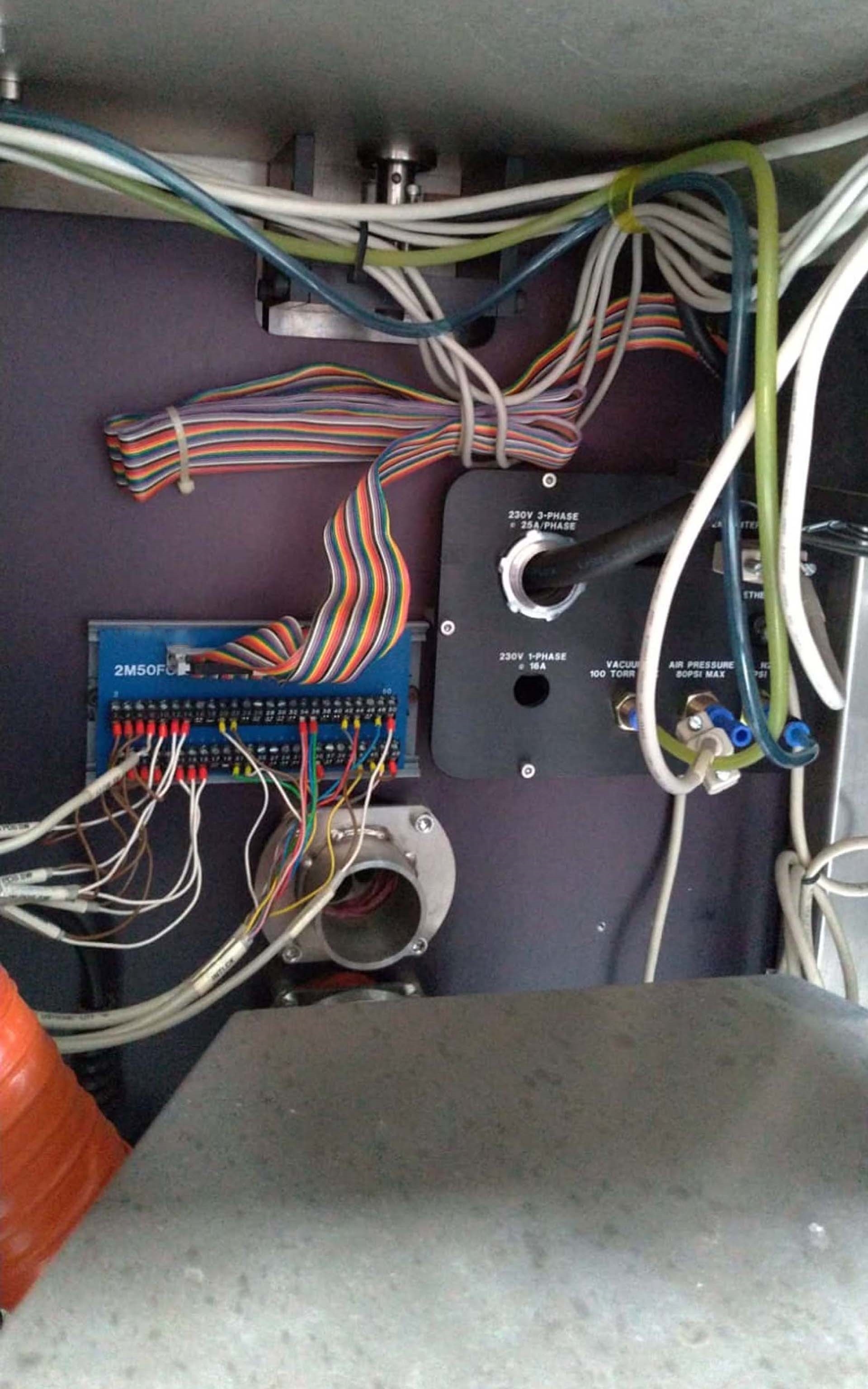

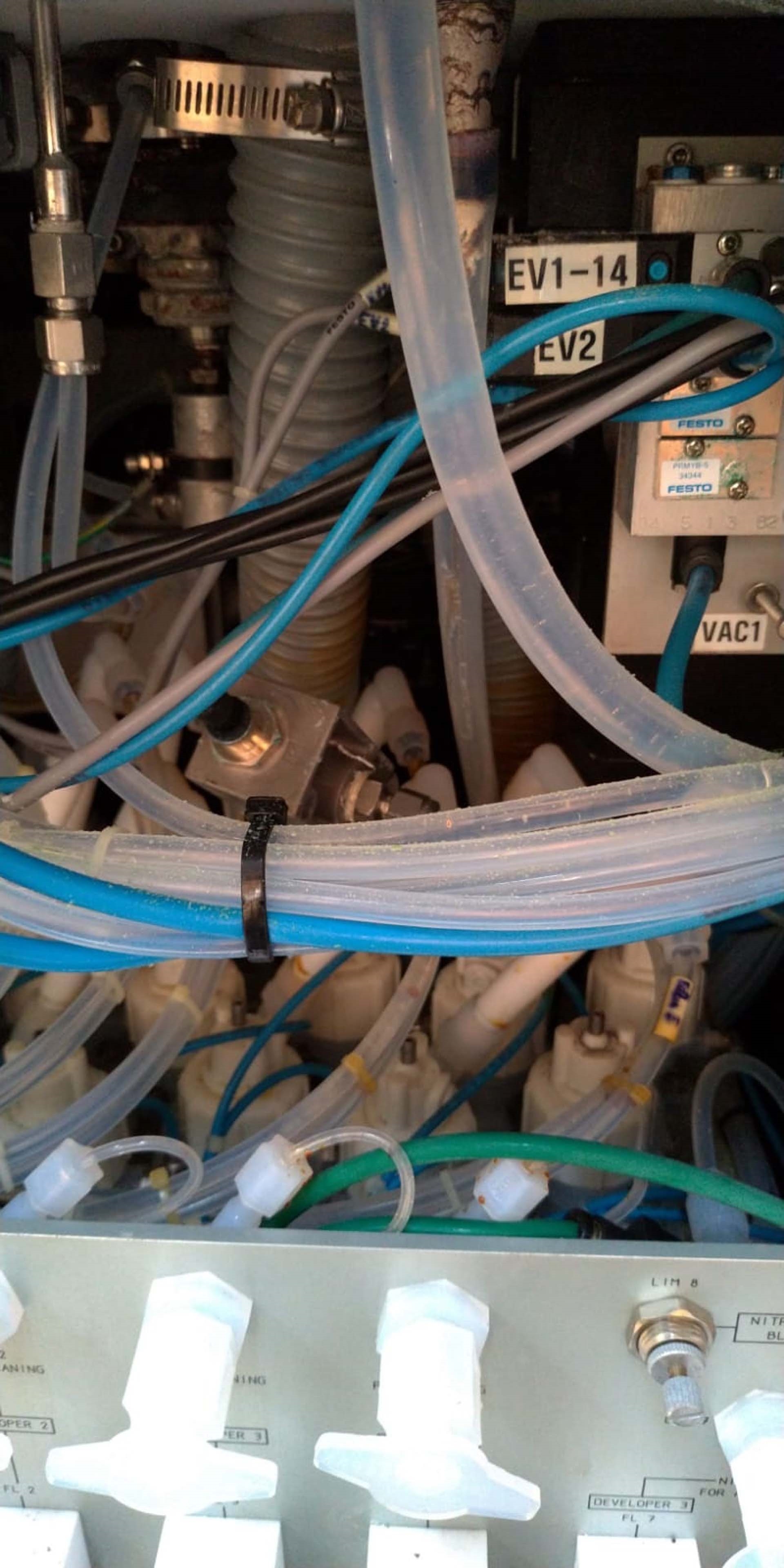

HCV Module:

Hot plate chamber

Cold plate chamber

Vapor prime chamber

Cassette module:

Auto-sizing cassette holder

Manual-sizing cassette holder

Filler module

Chemical dispense module

Aqueous based developer module

2000 vintage.

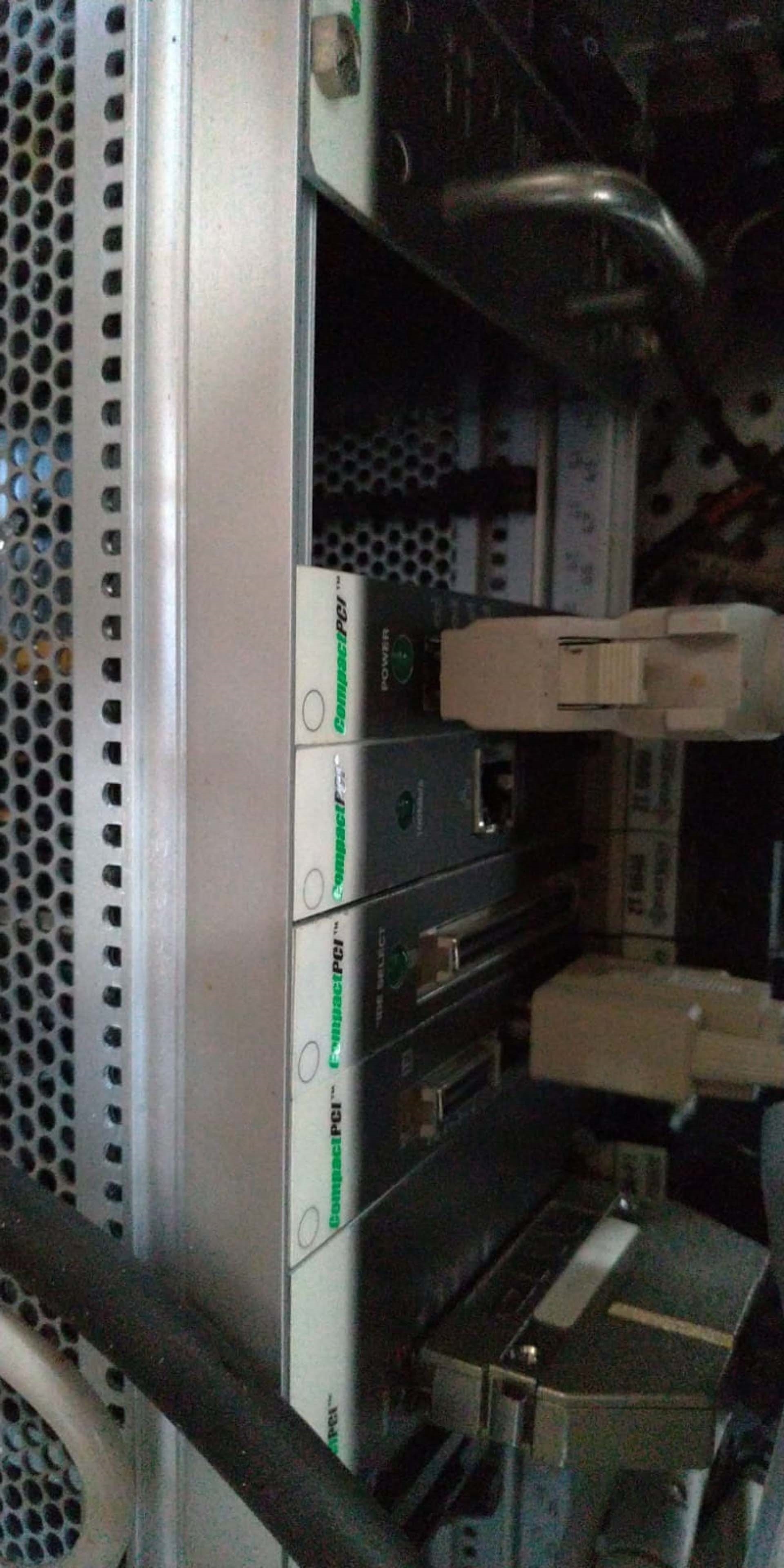

KARL SUSS / MICROTEC ACS 200 is a photoresist system used for patterning photoresist materials in the fabrication of integrated circuits and other semiconductor devices. It consists of three main components: a light source, a lens, and a substrate stage. The light source is an argon-ion laser which produces coherent ultraviolet (UV) light in the wavelength range of 350-460 nm. The lens focuses this light onto the substrate, creating a two-dimensional (2D) image of the desired pattern. The substrate stage holds the photoresist-coated substrate while the laser beam is electronically scanned to form the pattern. MICROTEC ACS200 provides superior photoresist resolution and repeatability due to its high-energy, high-power, single-wavelength laser source, which reduces pattern deformations caused by overlapping of exposures. The pattern size is adjustable from 1μm to 10mm and the spot size can be varied in 0.1μm steps. The substrate stage can be tilted during exposure to control the angle of the incident beam, which is important for controlling the size of the pattern. KARL SUSS ACS-200 is suitable for photoresist material types such as photoresist glasses, polymer microlenses, and epoxy-based resists. The system also includes built-in cooling to reduce heating of the substrate during exposure and a 'stone'-type focus laser adjustment, which minimizes aberrations and allows the user to achieve sub-micron resolution. Furthermore, KARL SUSS / MICROTEC ACS200 is user-friendly with graphical user interface and the user can monitor exposure parameters such as power, speed, and exposure time from the command line or via the GUI. The flexibility of KARL SUSS / MICROTEC ACS-200 allows multiple applications to be performed, such as exposing two-dimensional photomasks and contact hole arrays used in the sub-micron range. Overall, ACS200 is an easy to use photoresist system that provides superior resolution and repeatability in the fabrication of microelectronic devices. It is robust and reliable, and suitable for various photoresist material types.

There are no reviews yet