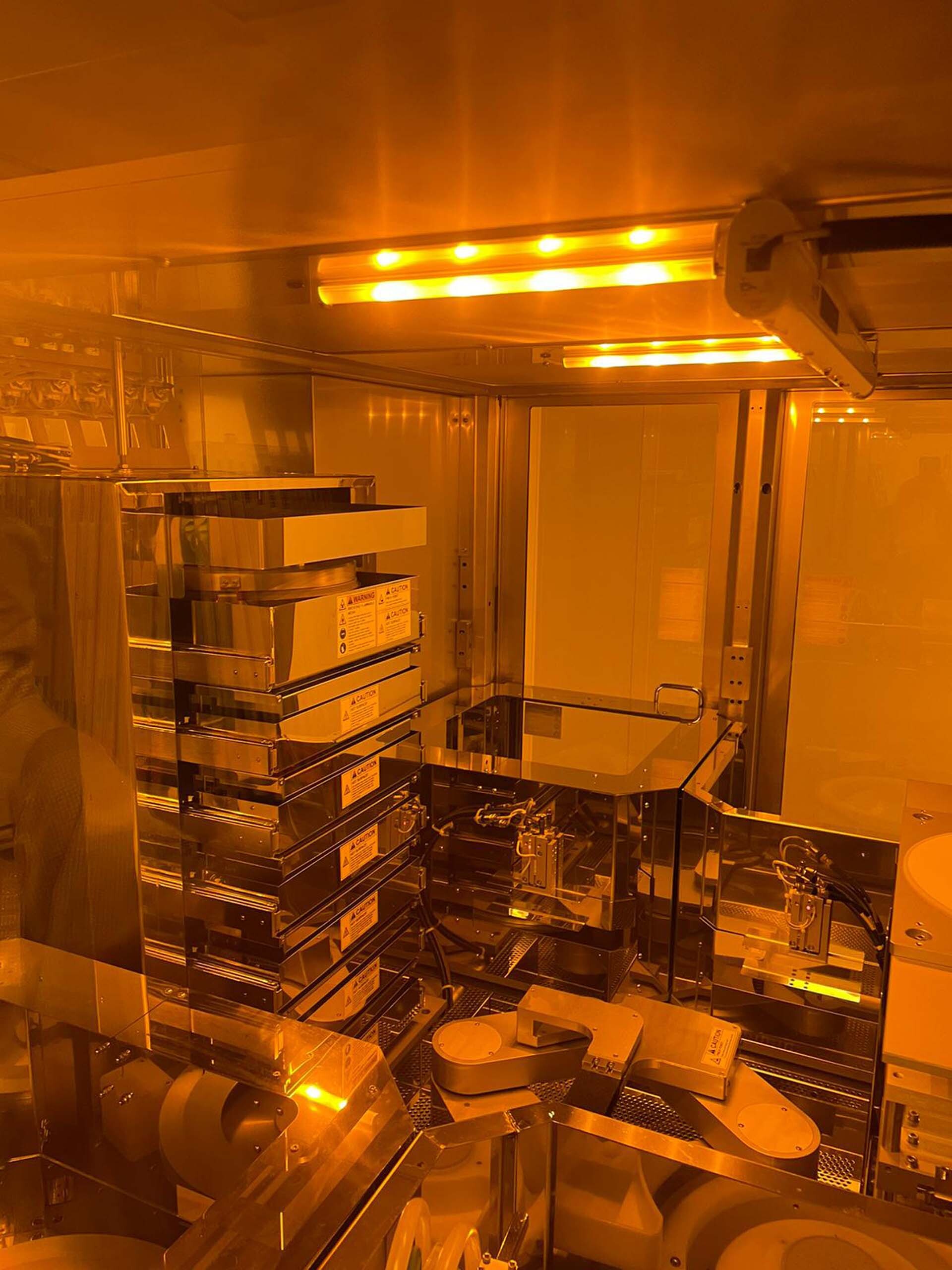

Used KARL SUSS / MICROTEC ACS 200 #9355505 for sale

URL successfully copied!

Tap to zoom

ID: 9355505

Wafer Size: 8"

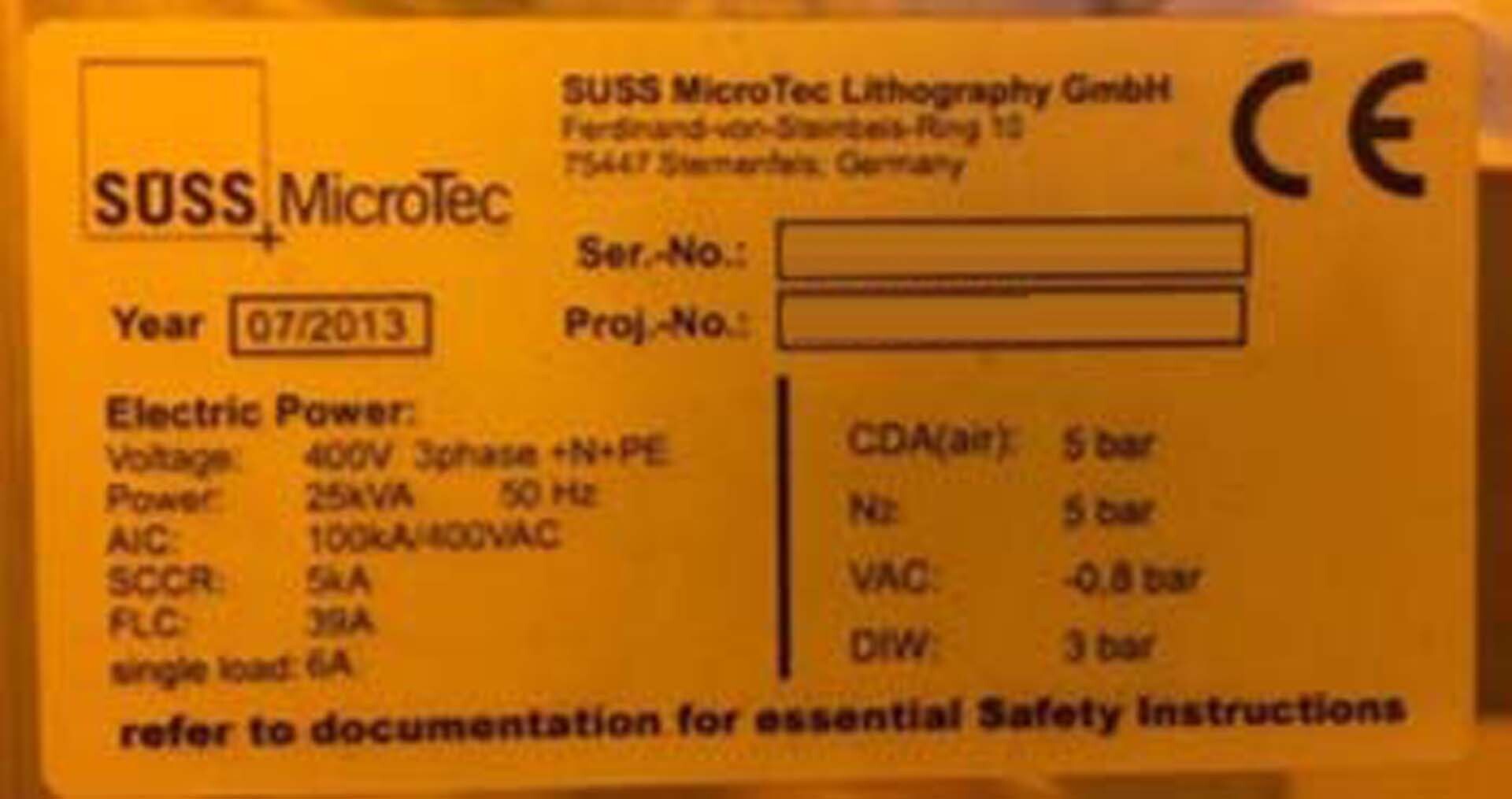

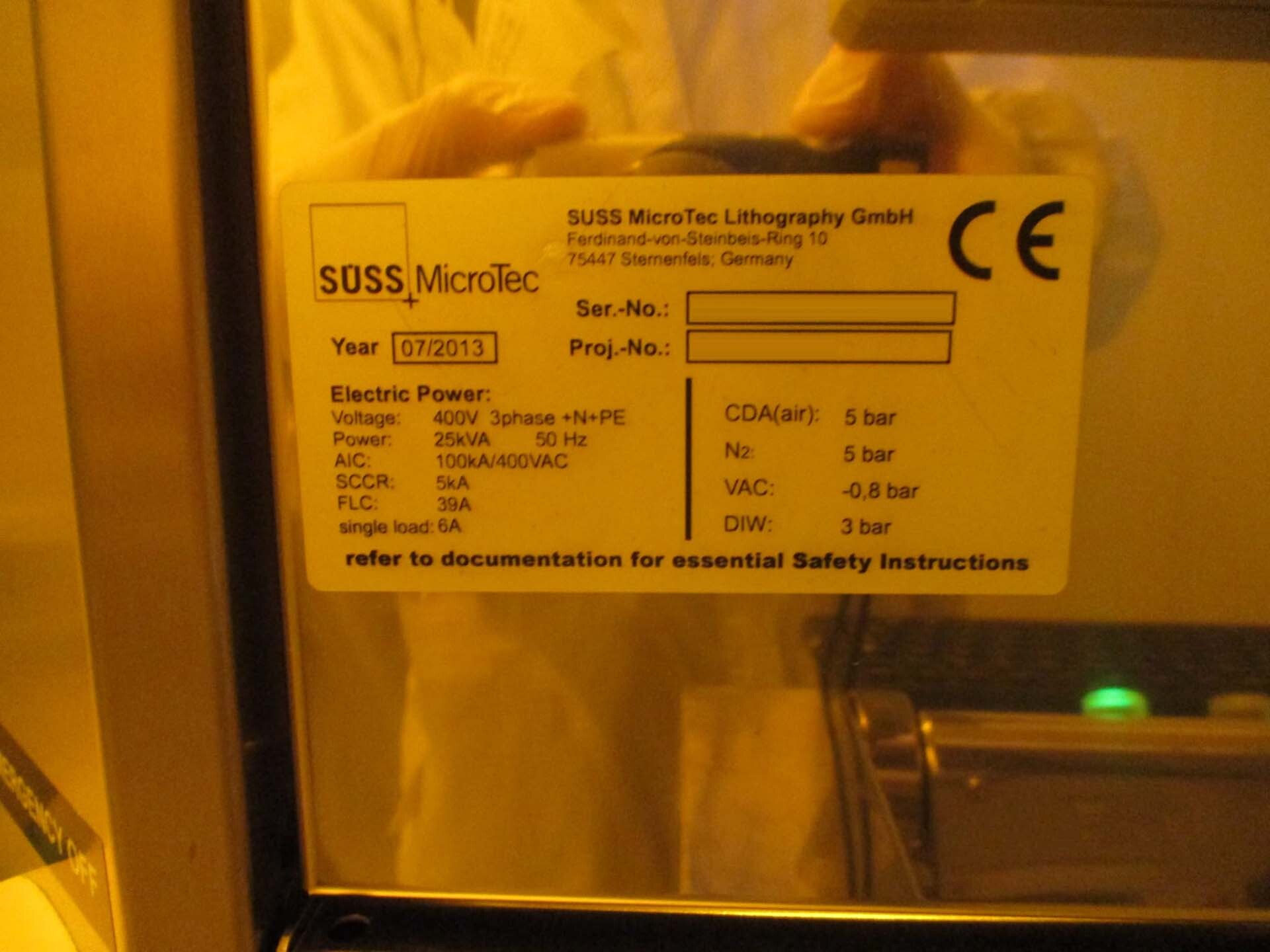

Vintage: 2013

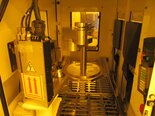

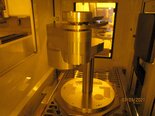

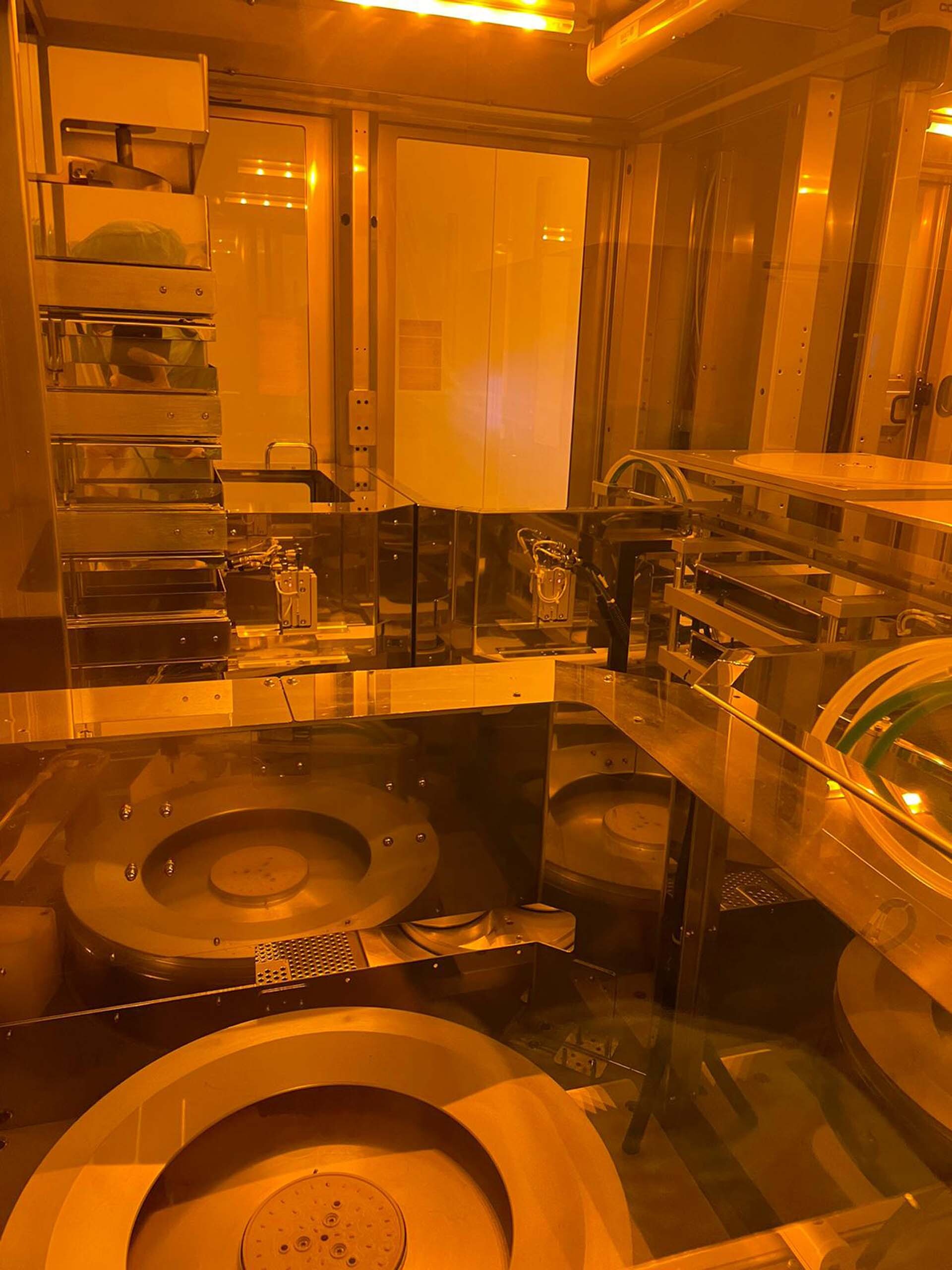

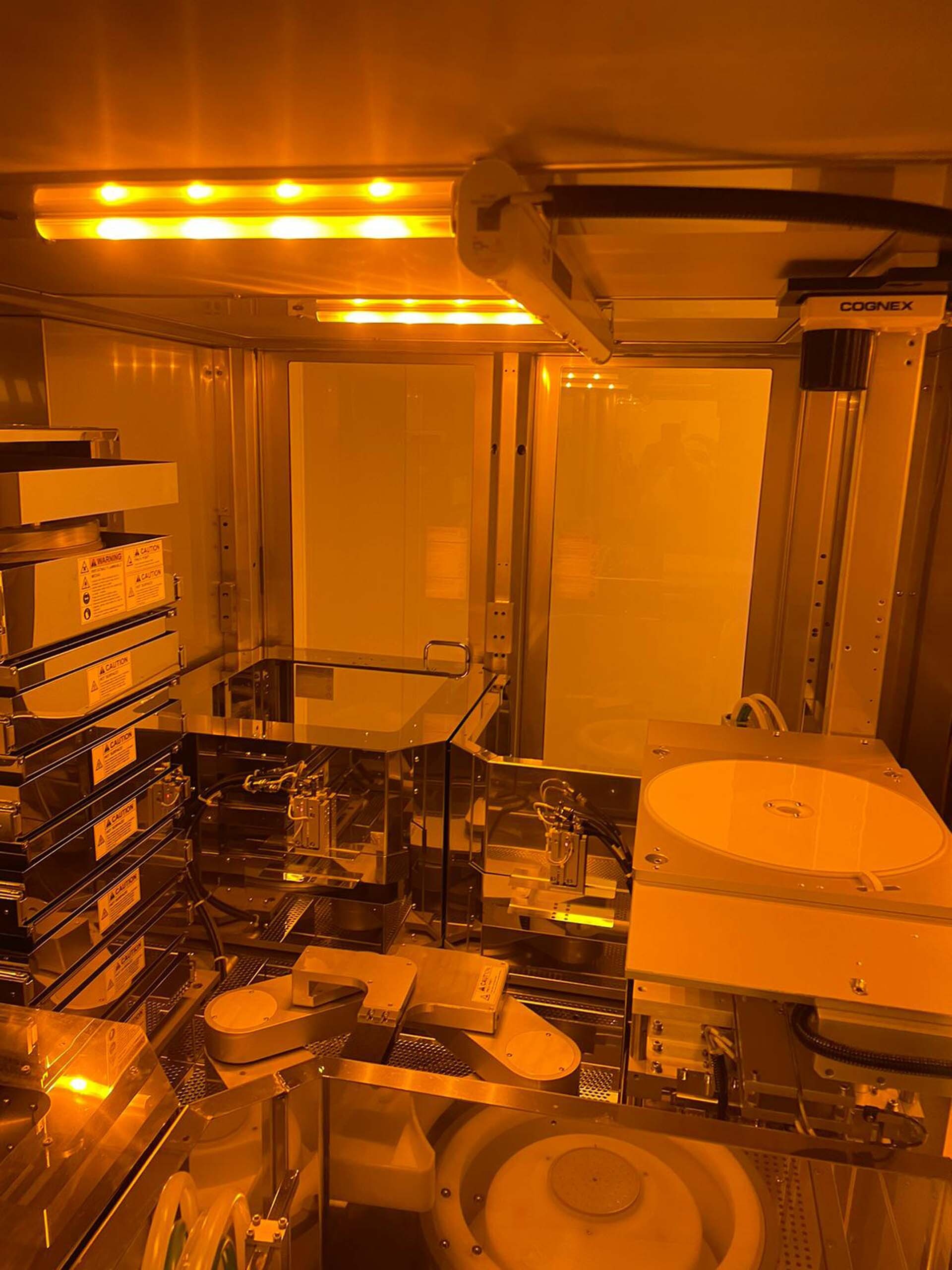

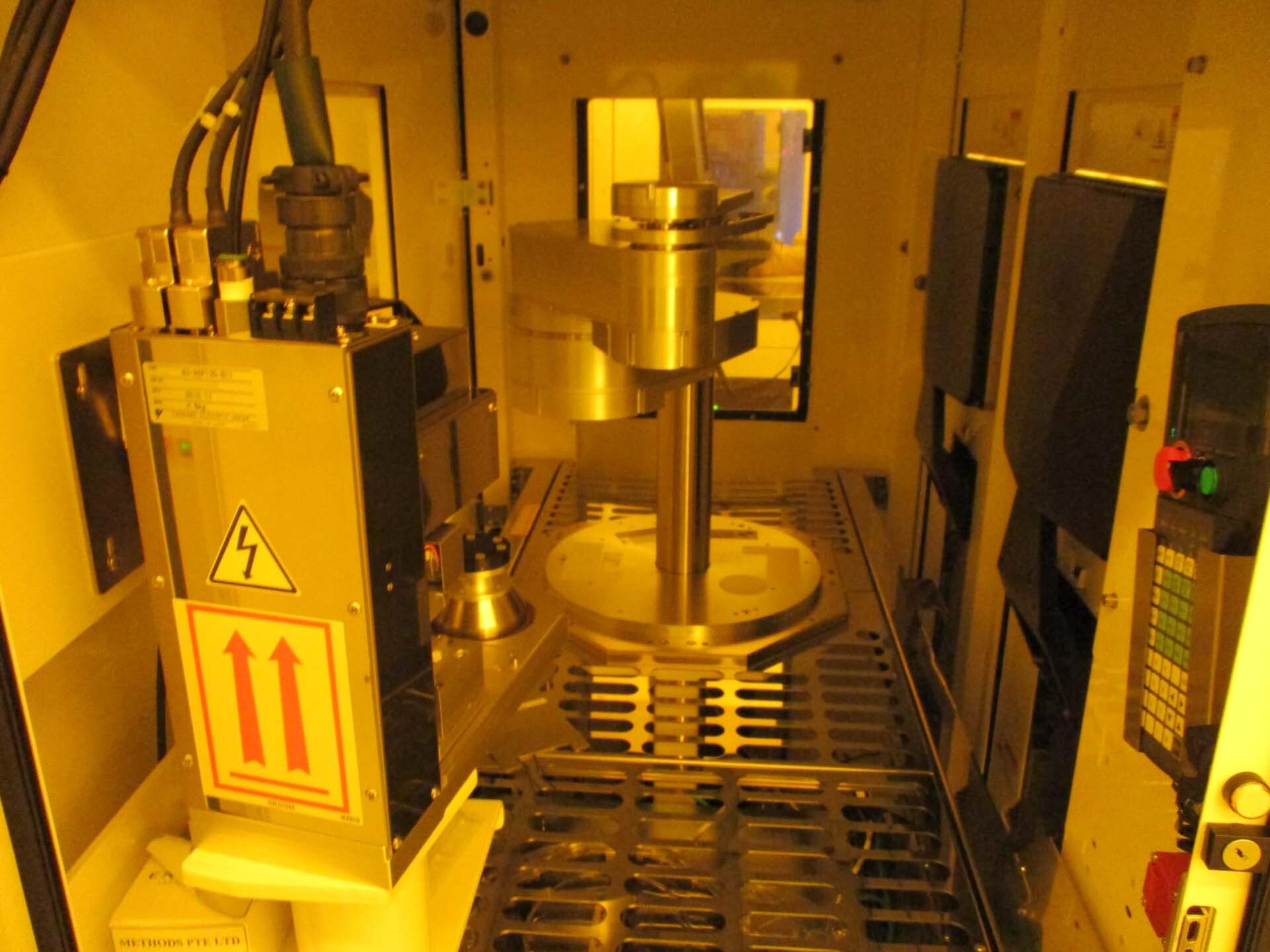

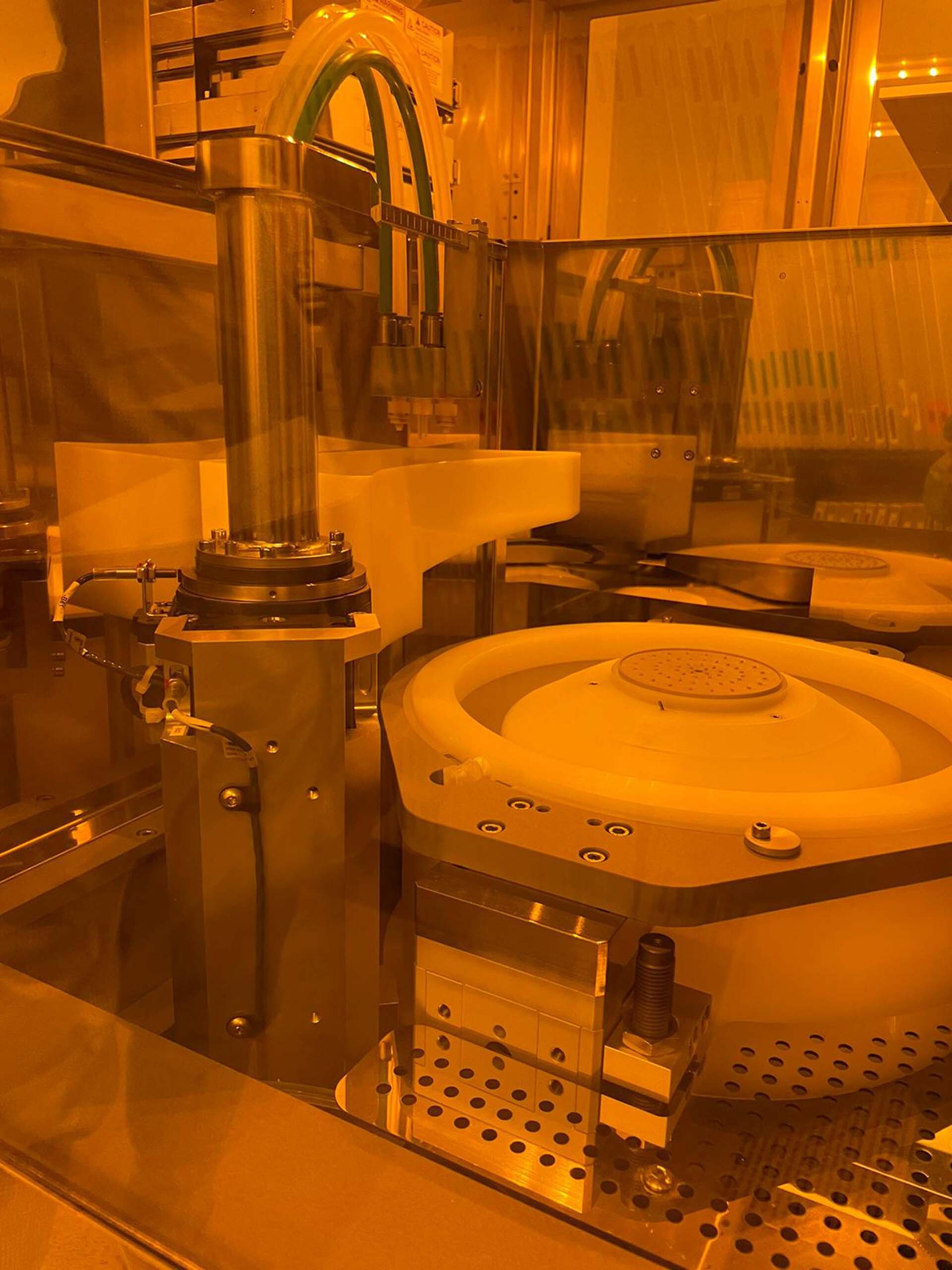

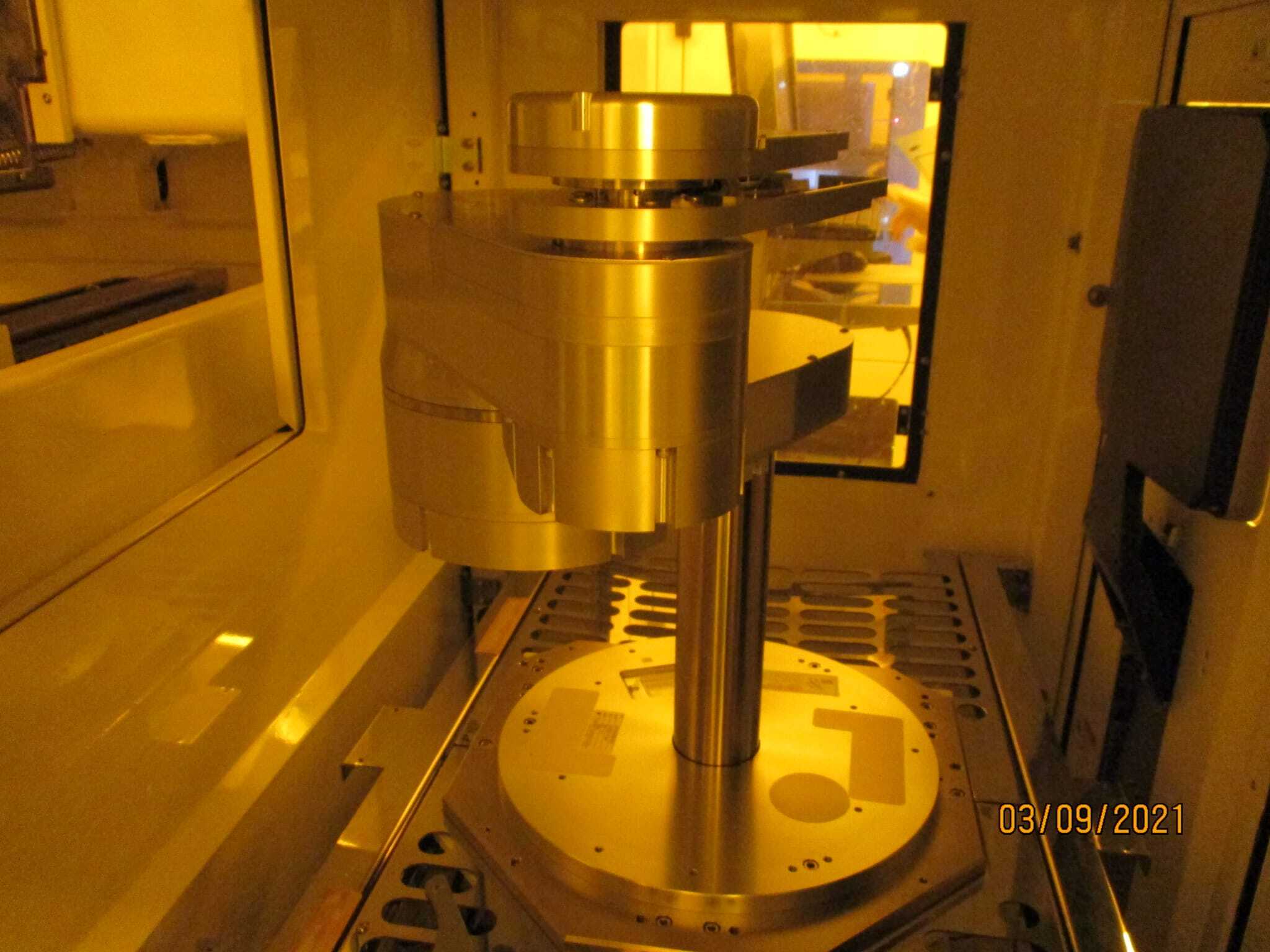

Coater / Developer system, 8"

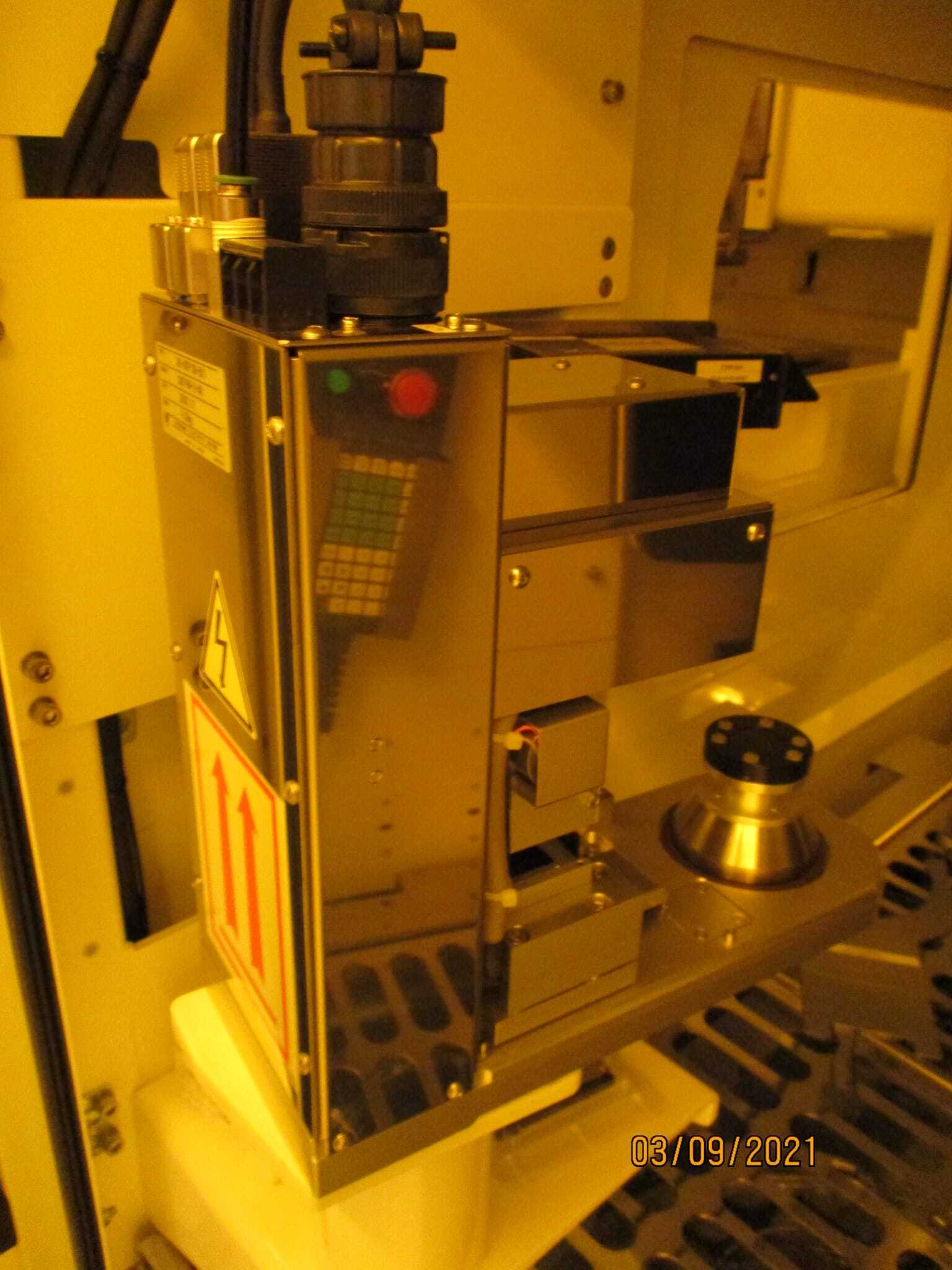

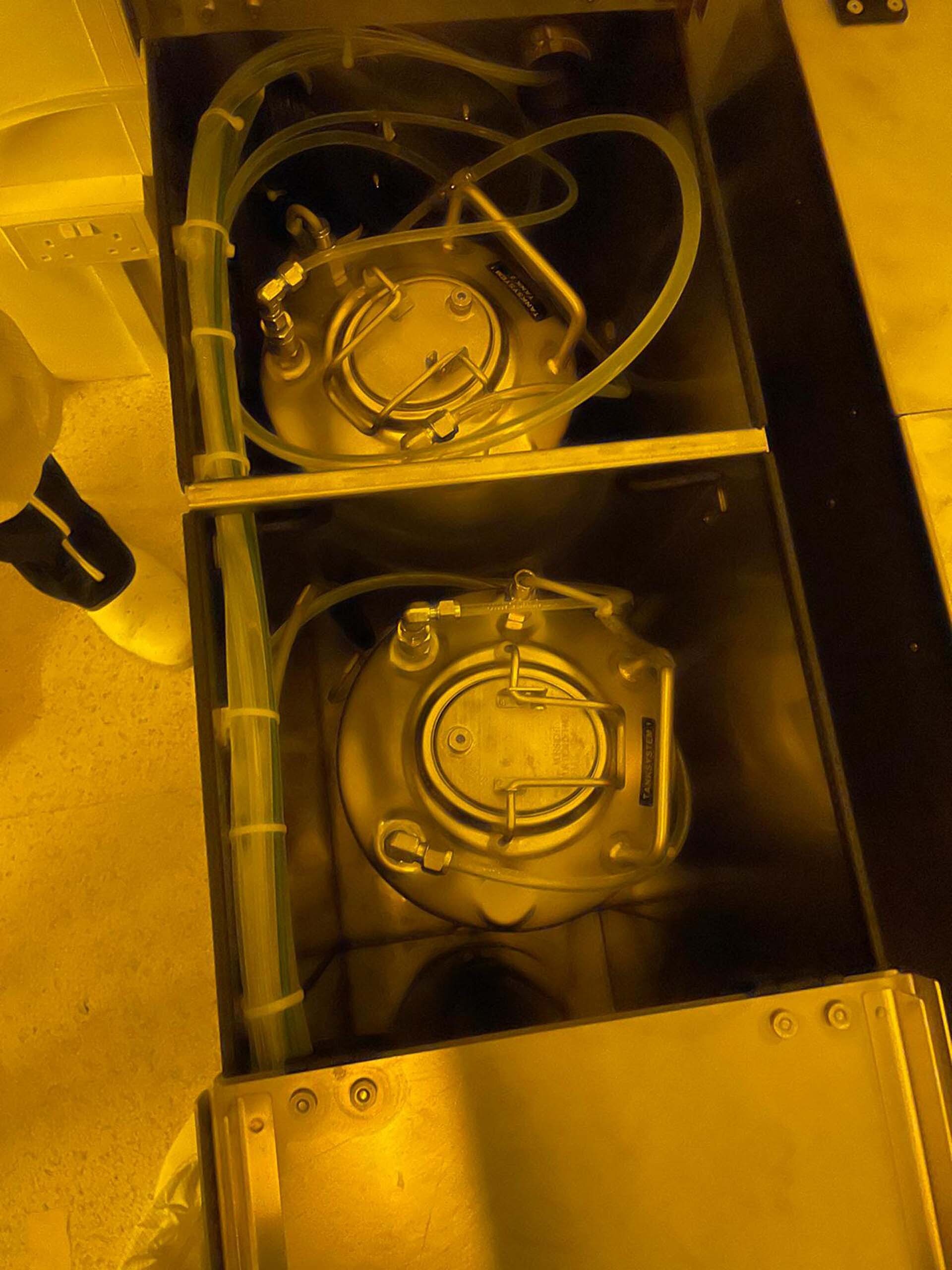

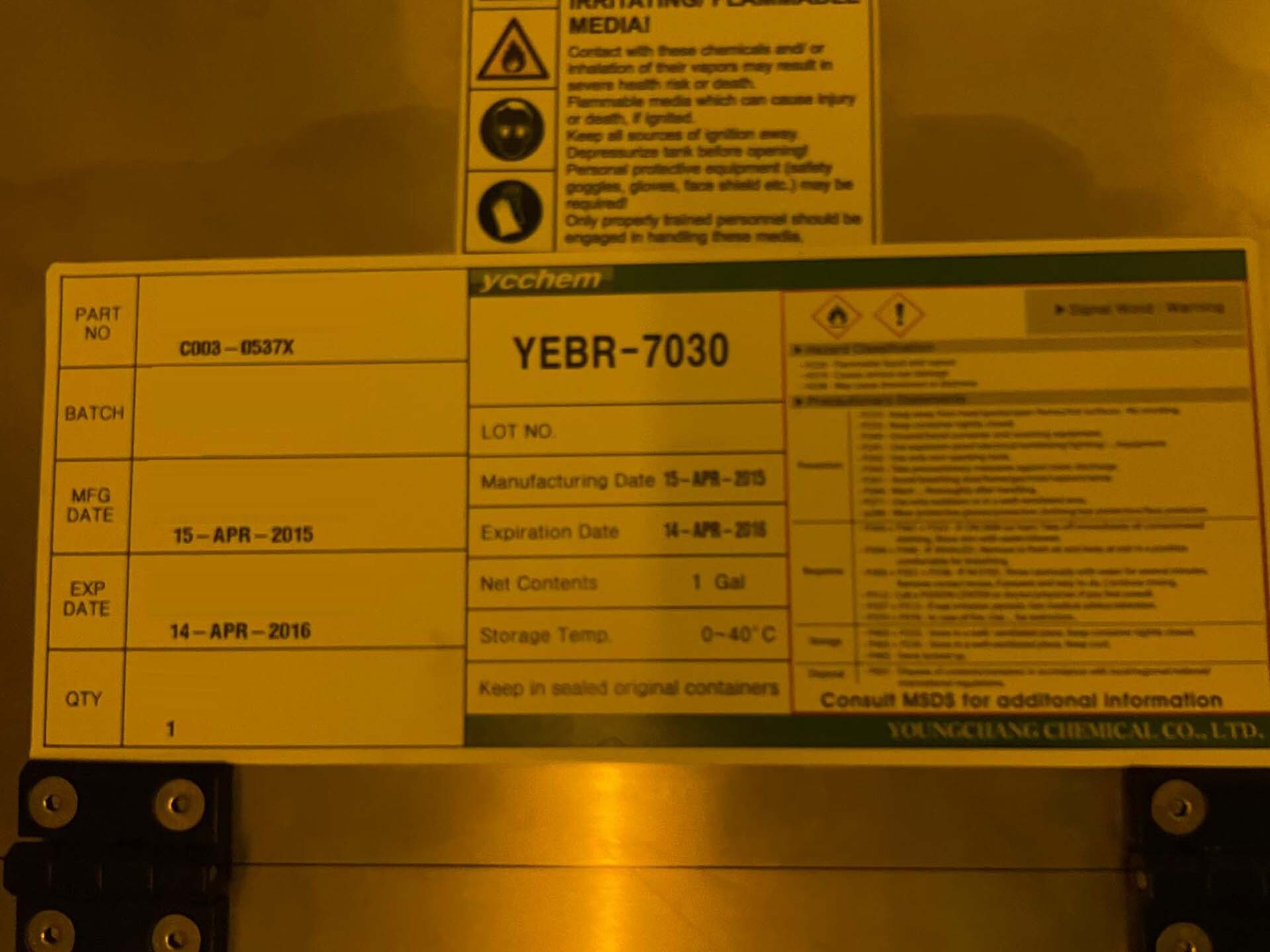

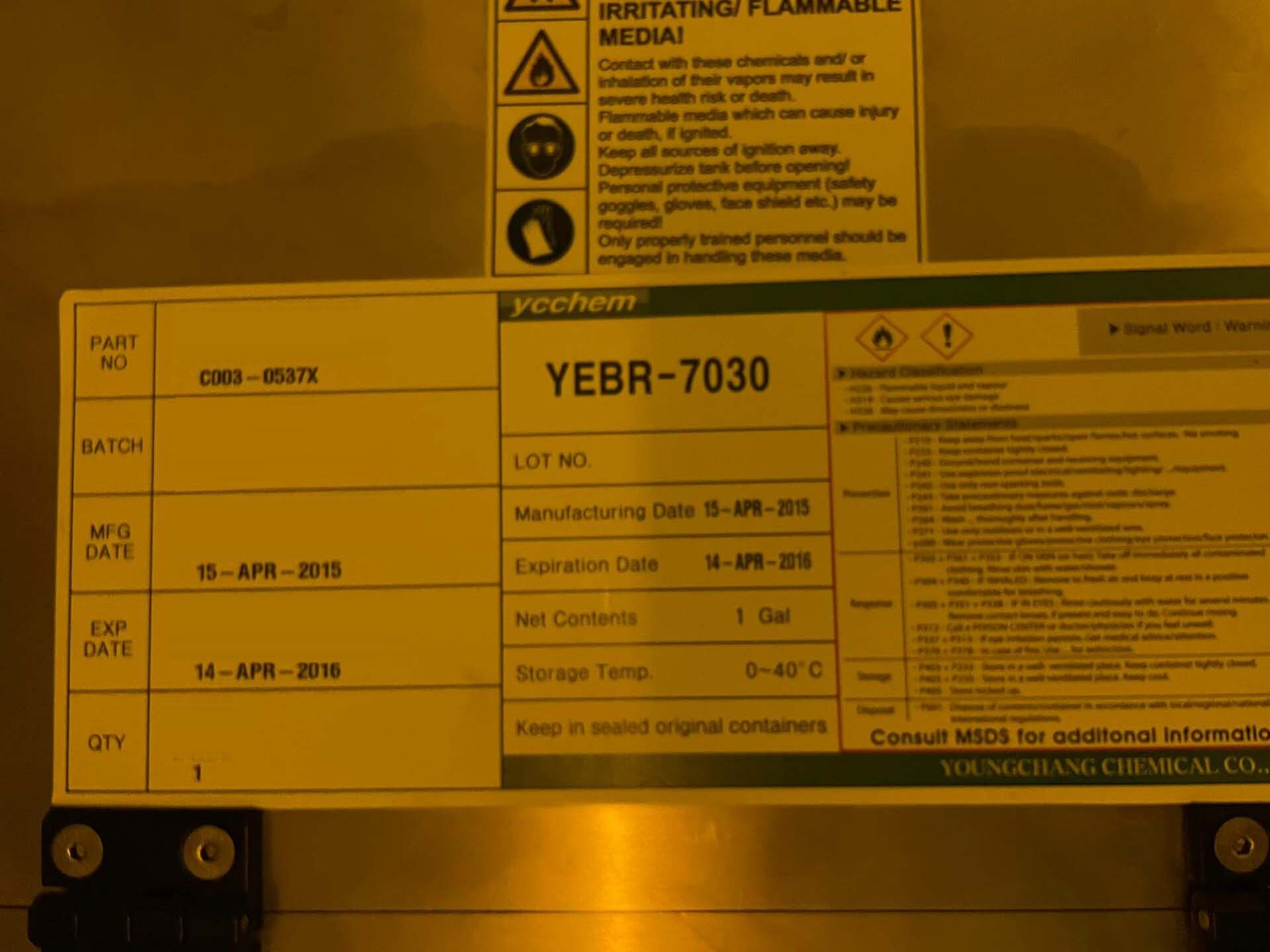

Resist pumps

(6) Chillers

(4) Load ports

(2) Coater cups

(2) Developer cups

HMDS Module

(6) Hotplates

(3) Coolplates

(2) SANKYO SC5000 Robot controllers

Power rack

2013 vintage.

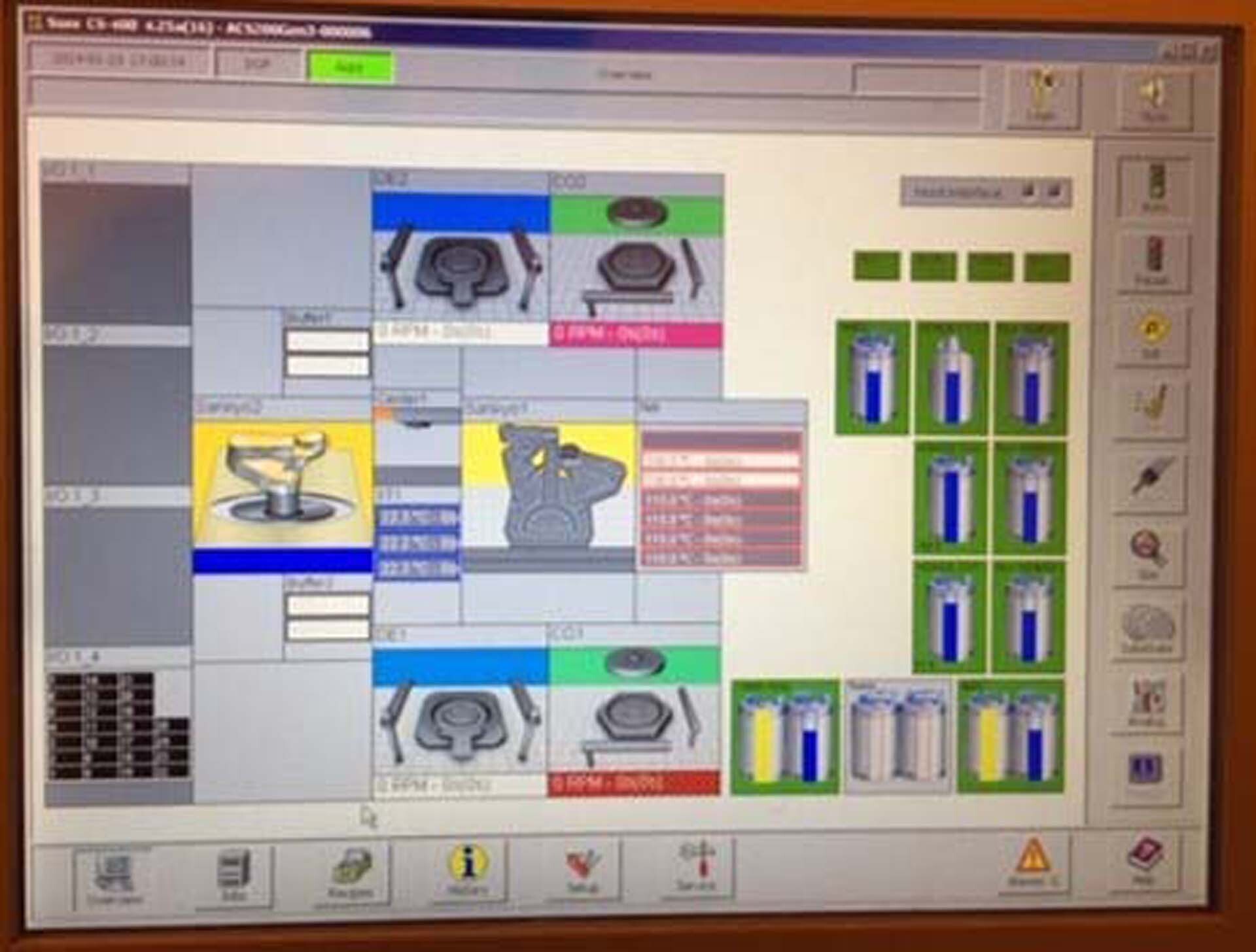

KARL SUSS / MICROTEC ACS 200 is a world-renowned photoresist equipment designed for lithography research, development and production of semiconductor devices. The system features a stepper motor that has a range of 4.0 mm stroke with a high accuracy of 0.5 µm. The unit is also equipped with a 2-Axis shear tool that reduces the fabrication time and cost of devices. The machine is designed to maximize productivity for both wafer-level and mask-level processes. It is also capable of supporting a variety of substrates in various thicknesses and sizes. MICROTEC ACS200 is designed to keep track of numerous parameters that determine photo process parameters at the wafer or masks level. It is equipped with a wafers chuck with piezo autofocus, which ensures wafer repeatability. The tool is also able to support several exposure sources. It uses an LED or Xenon light source for exposure that also features light intensity stabilization and a variable exposure band with an active image size of up to 465mm². In addition, it is equipped with auto shutter and a mask stage that ensures precision alignment of the layout pattern onto substrate or mask surface. KARL SUSS ACS-200 is also equipped with a built-in, intuitive, high throughput software controller that provides user-friendly operation. The controller is capable of operating multi-step repeatable exposures and processes. This allows users to benefit from its flexible controls and data analysis capabilities. Furthermore, a built-in programmable interface can be used to easily customize the asset for additional process requirements. The model also provides a high quality environment to ensure optimal performance. It is designed to reduce relaxation and vibration during operation to ensure optimum results. The equipment also helps to reduce photoresist erosion in order to increase the lifetime of the device. KARL SUSS ACS 200 is an advanced photoresist system designed to provide users with seamless lithography capability. It is equipped with a range of features that ensure precision alignment of the layout pattern onto substrate or mask surface, and provide efficient data analysis capabilities. Moreover, its intuitive control and interface make it easy to operate and customize for user specific requirements. The unit is also designed to provide a snug environment that reduces vibration and photoresist erosion in order to maximize device lifetime and product yields.

There are no reviews yet