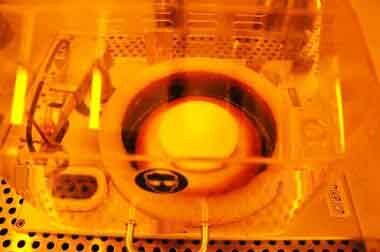

Used KARL SUSS / MICROTEC Delta 20T2/150VPO #9124419 for sale

URL successfully copied!

Tap to zoom

ID: 9124419

Wafer Size: 8"

Vintage: 2001

Manual coat spinner, 8"

Delta 150 VPO hot plate

Brushless servomotor

Spin speeds: 10,000 rpm

Storage capacity in the controller: Up to 10 recipes with 10 steps

LCD display

Hot plate: up to 150C

Dispense pump (Delta 32) nitrogen purge HMDS

2001 vintage.

KARL SUSS / MICROTEC Delta 20T2/150VPO is an advanced photolithography/photoresist equipment designed for high-resolution, accurate patterning of semiconductor substrates. The system is engineered for advanced features such as multiple overlay and alignment accuracy up to 0.3 microns, as well as high-throughput production and extended product life for cost-effective patterning of semiconductor wafers. The unit features an integrated high-stability wafer stage capable of supporting 5" to 8" substrates, with a maximum speed of 3 cm/sec. The stage is mounted on air-strengthened rails and supported by a lightweight travel assembly to ensure accurate and reliable substrate movement. A multi-channel micro-processor controller independently monitors the stage and controls the position of the wafer at sub-micron precision. The machine is also equipped with variable illumination optics and a MicroStepper motorized projection tool, providing precise projection of high-resolution patterns onto the substrates. The asset can be configured to expose positive or negative photoresists, and the high-fidelity optics can produce patterns with high aspect ratios and resolutions down to the sub-quarter micron range. In addition, MICROTEC Delta 20T2/150VPO features a numeric-coded auto-focusing capability to ensure the highest resolution patterns even with thicker substrates. The auto-focus algorithm also provides highly accurate and repeatable focus conditioning with step sizes of less than 0.1 microns. This reduces exposure time and conserves power, increasing throughput. The model provides a variety of photolithography and clean-up tools, including deep-UV and soft-UV light sources, as well as a wafer edge-inspection equipment for detecting and reporting defects. Additionally, the system is equipped with load locks for quick and unobstructed substrate loading and unloading. KARL SUSS DELTA 20T2 / 150VPO is an advanced unit that uses photolithography and photoresist technology to produce high-quality, precision patterns on semiconductor substrates. Its impressive range of features and capabilities, as well as its cost-effectiveness, make it an ideal solution for semiconductor manufacturing and research.

There are no reviews yet