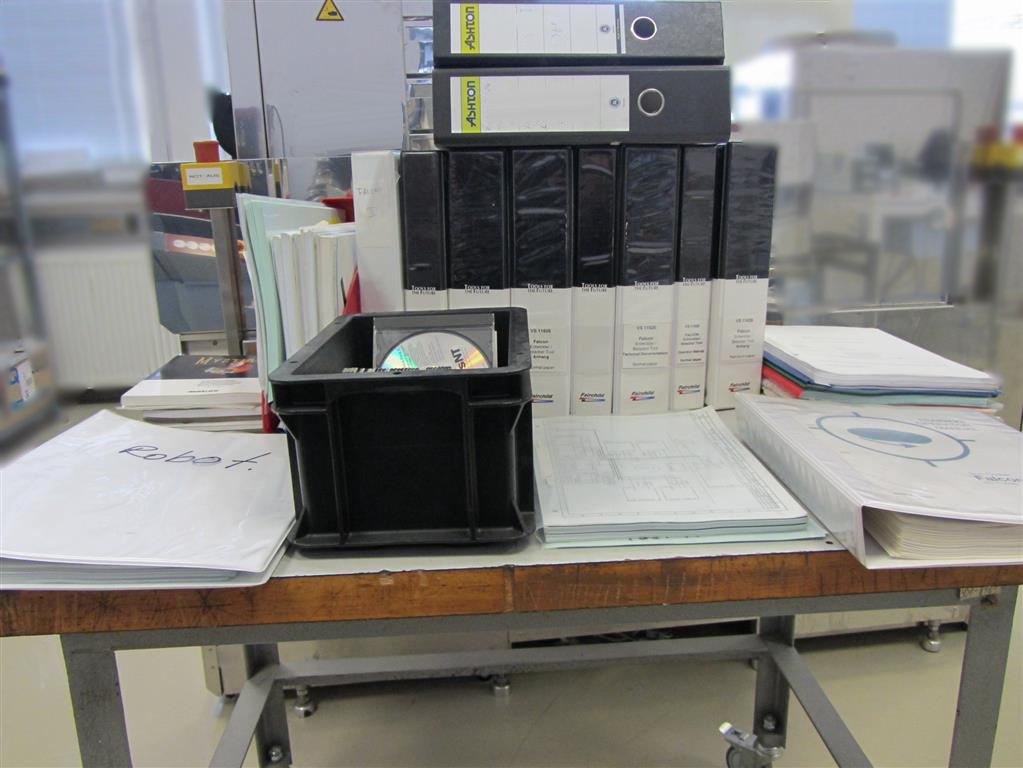

Used KARL SUSS / MICROTEC Falcon VS11626 #9114639 for sale

URL successfully copied!

Tap to zoom

ID: 9114639

Wafer Size: 8"

Vintage: 1997

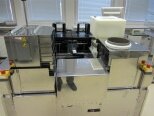

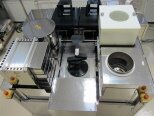

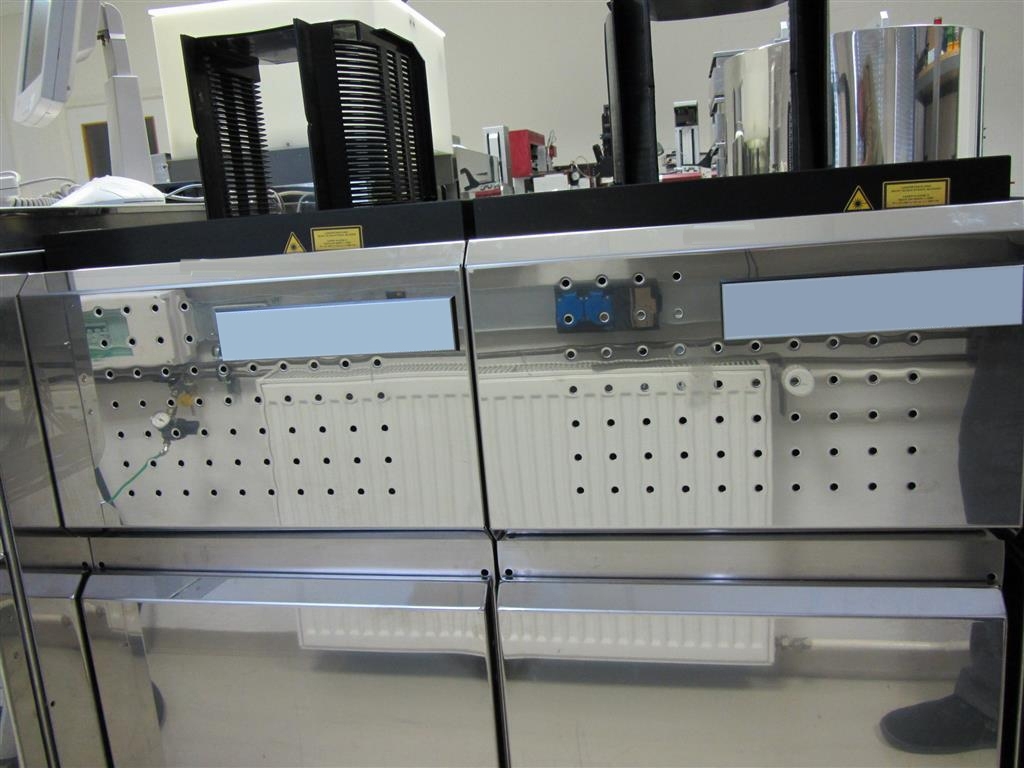

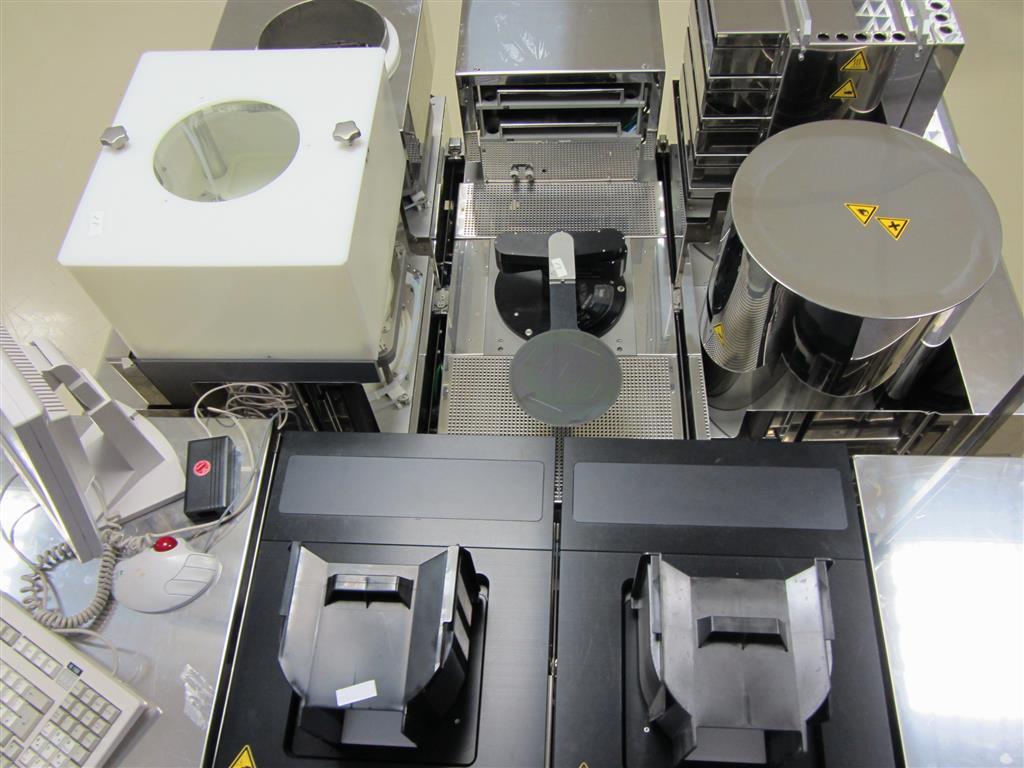

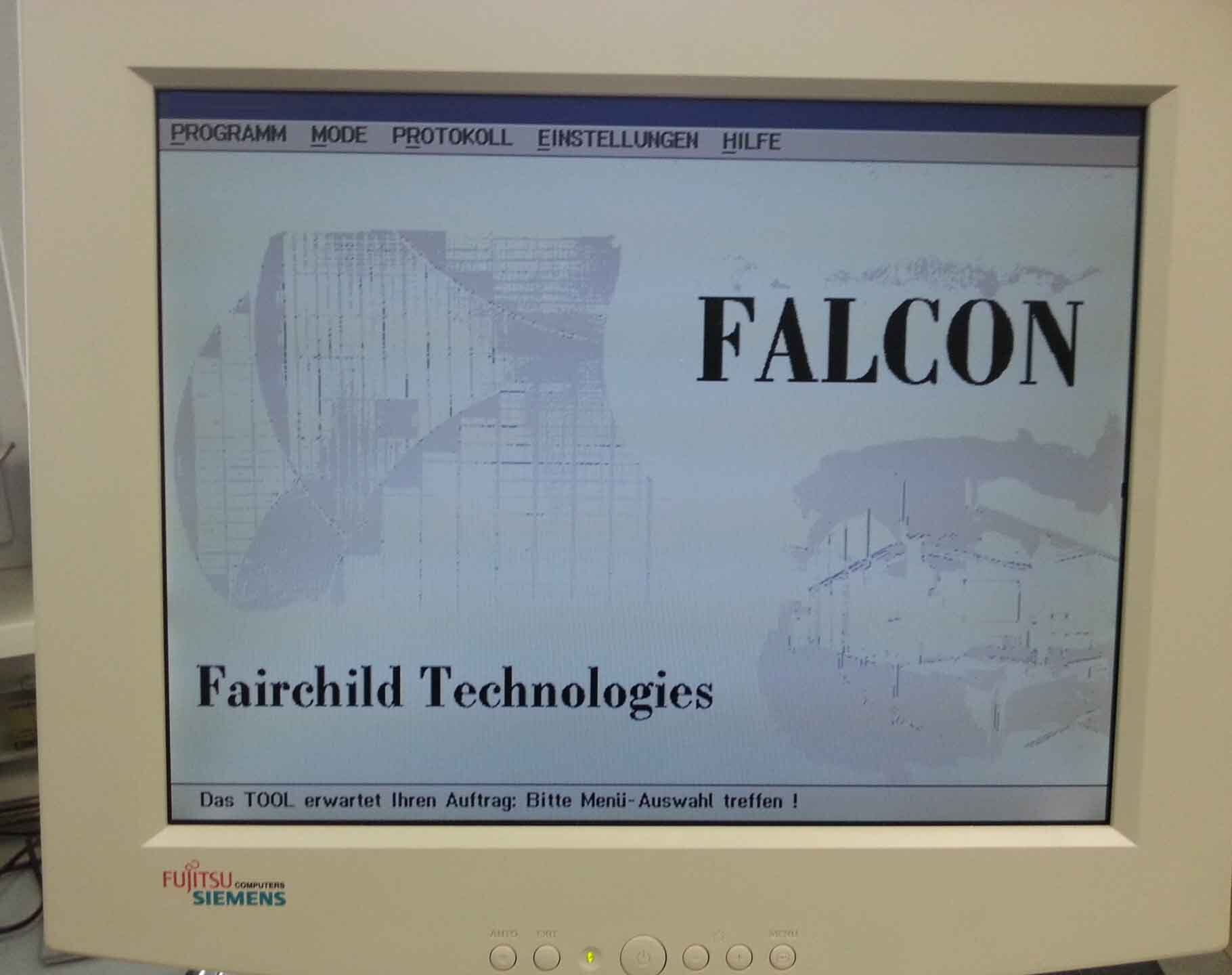

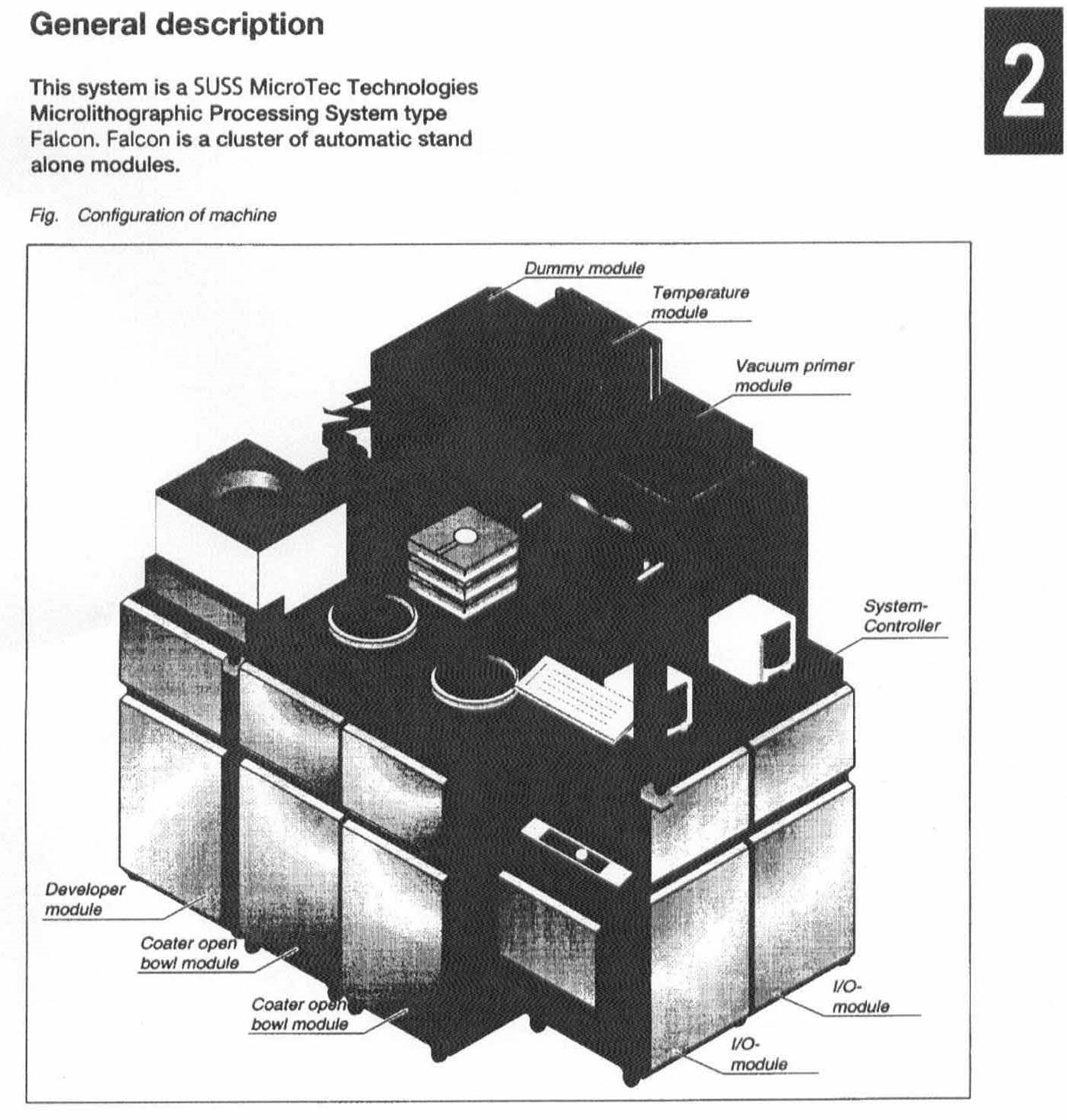

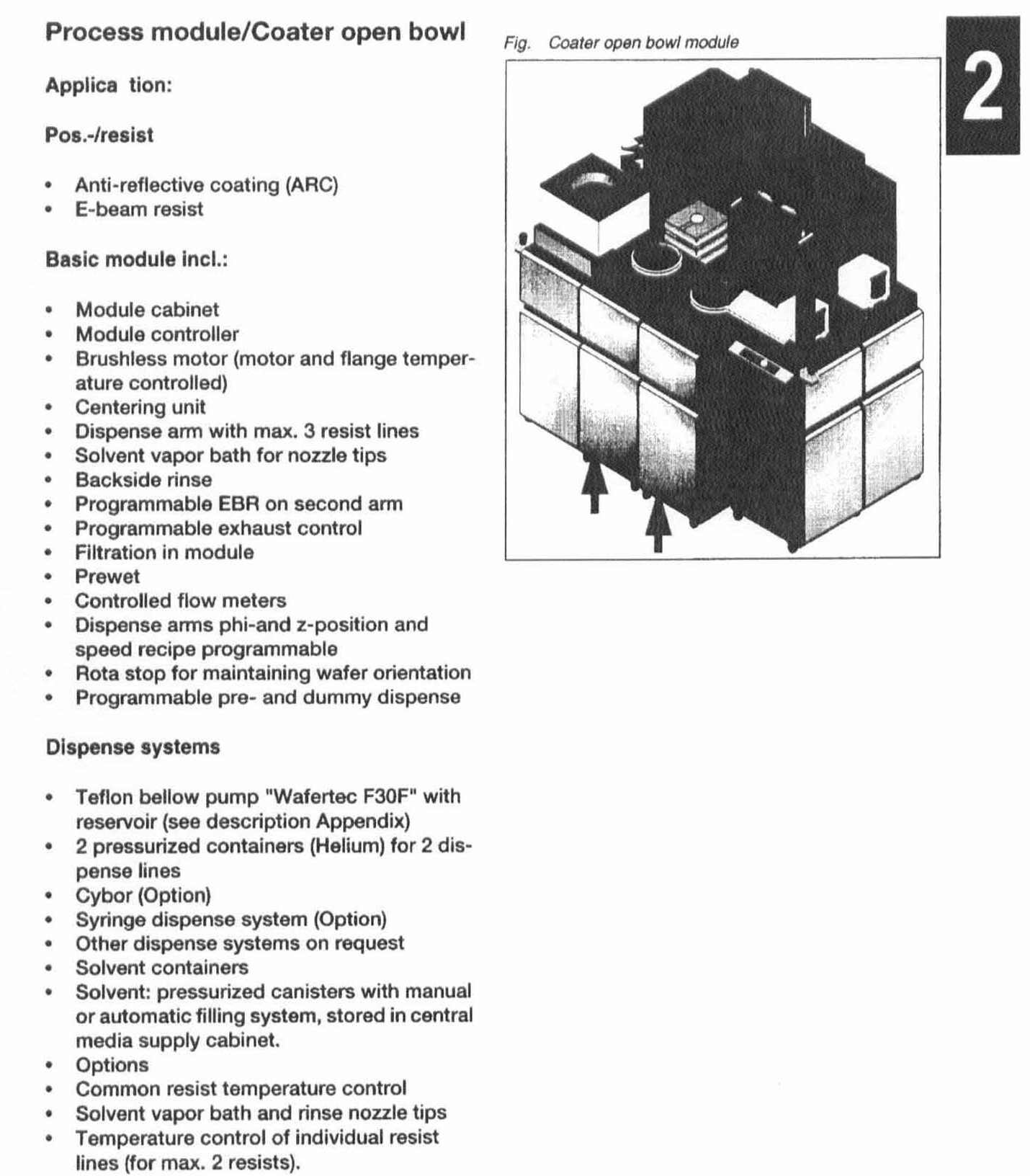

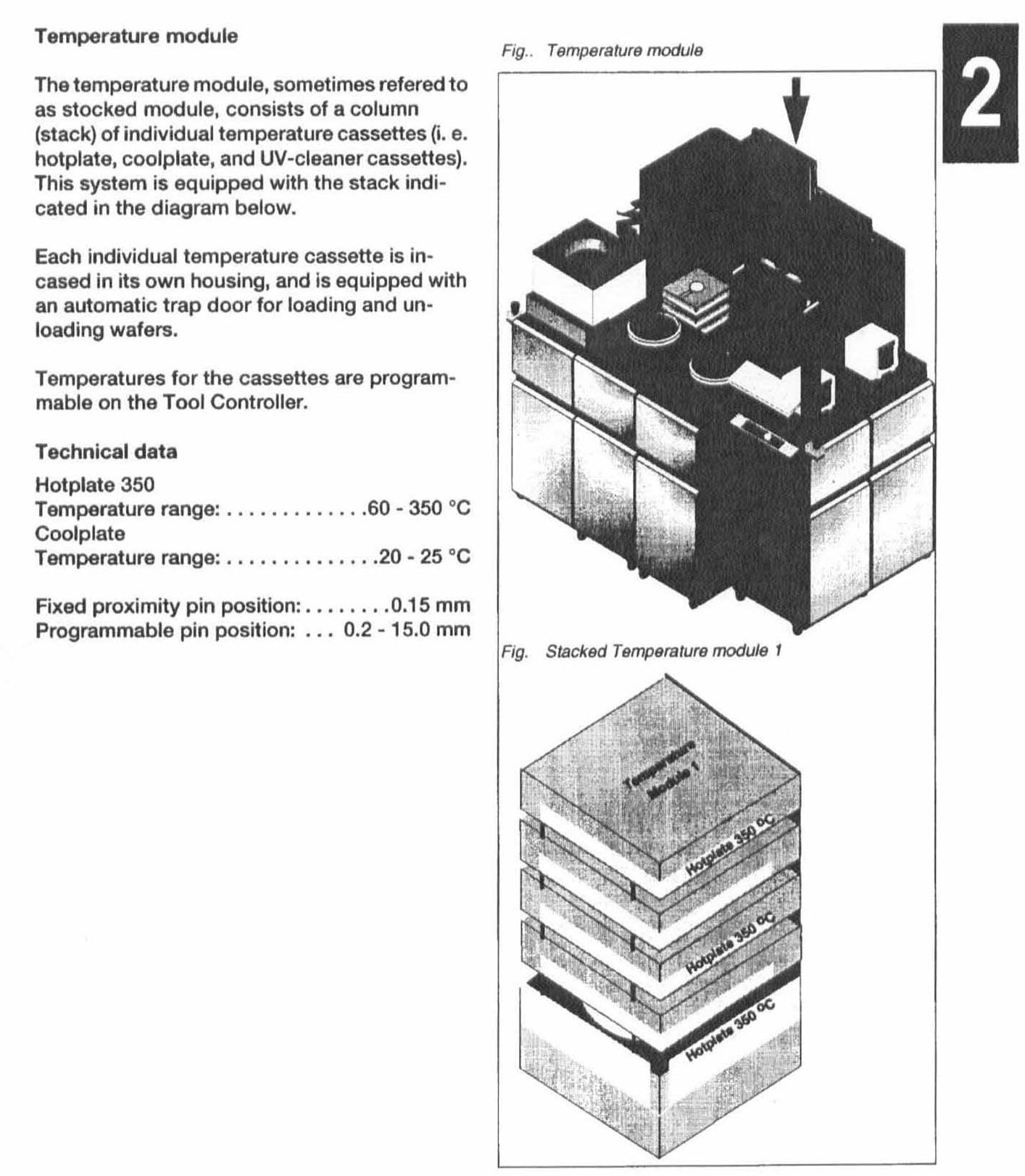

Photolithography line system, 8"

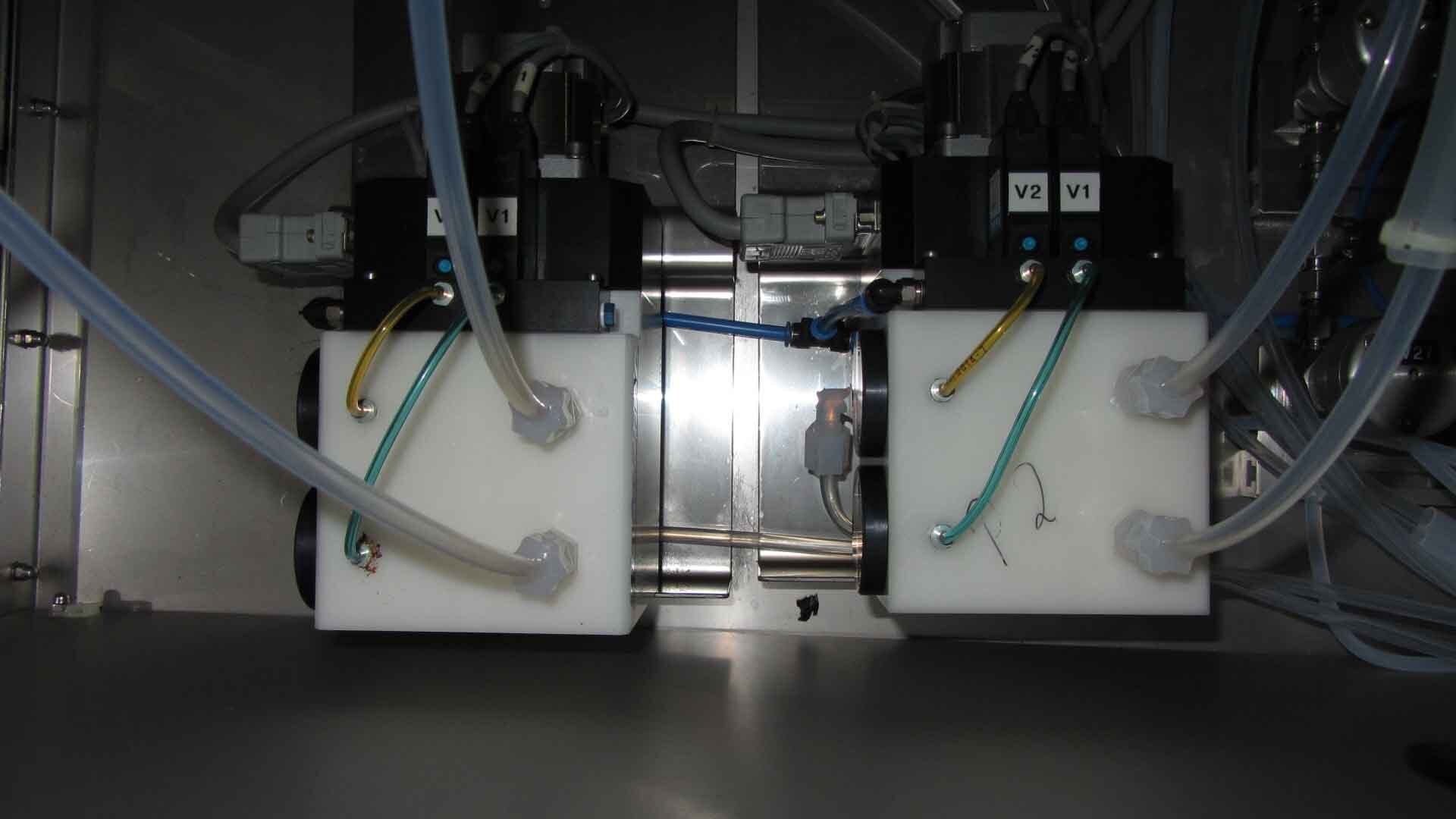

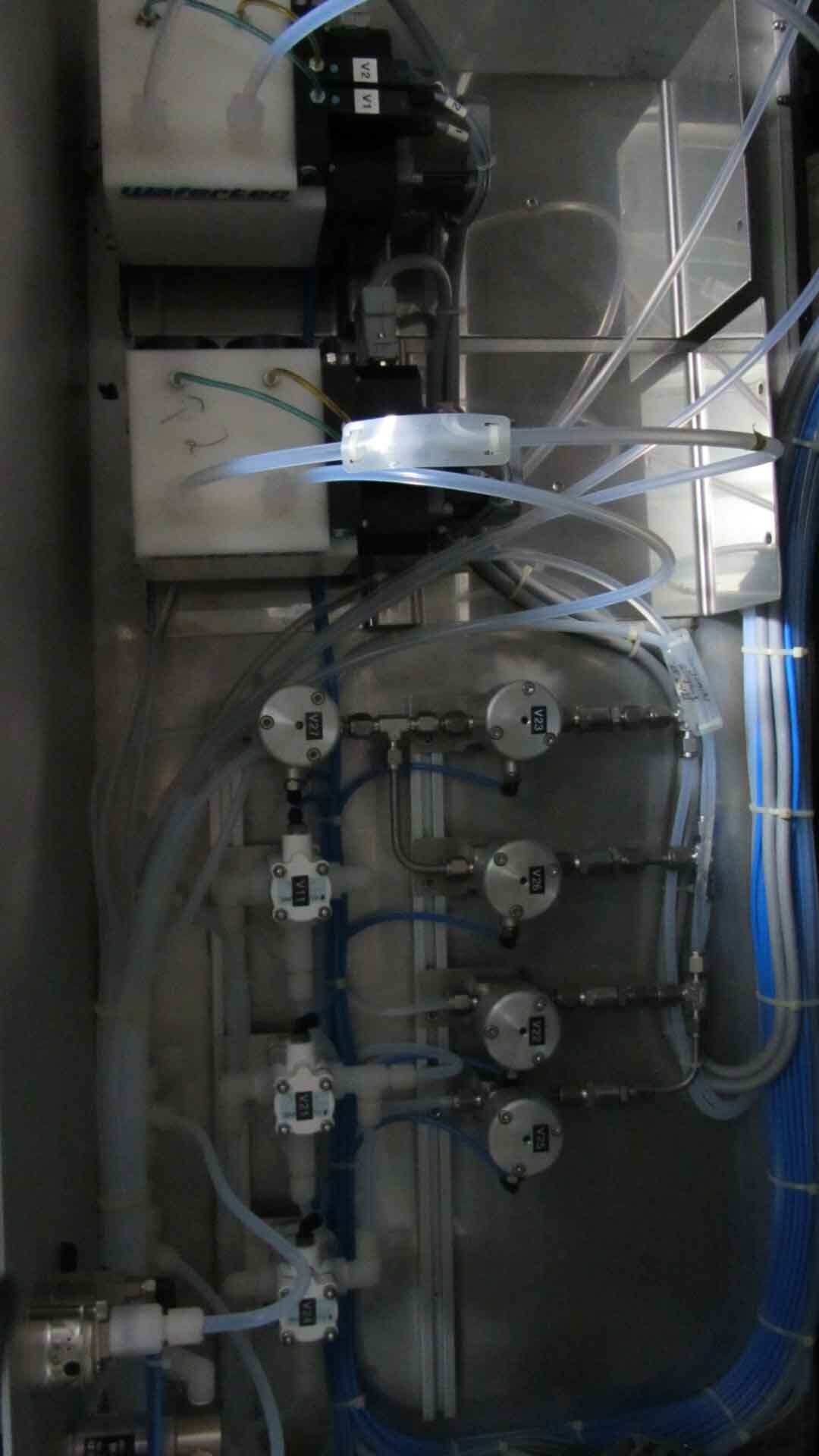

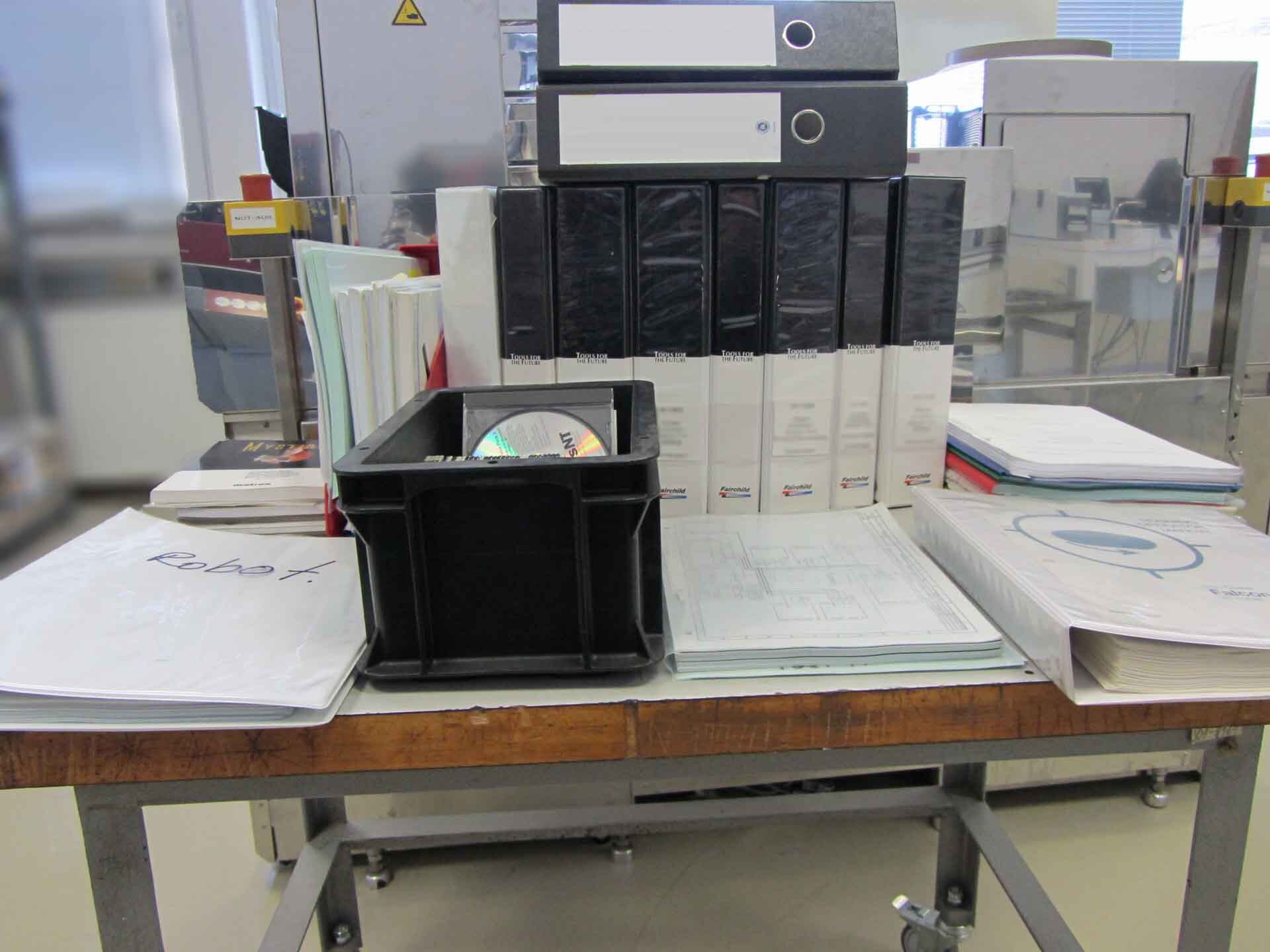

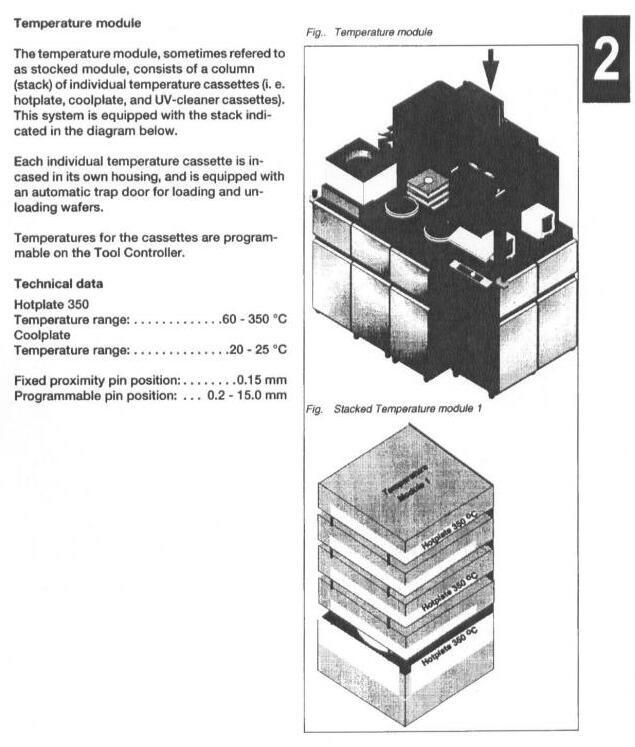

(2) Cold plates

(5) Hot plates

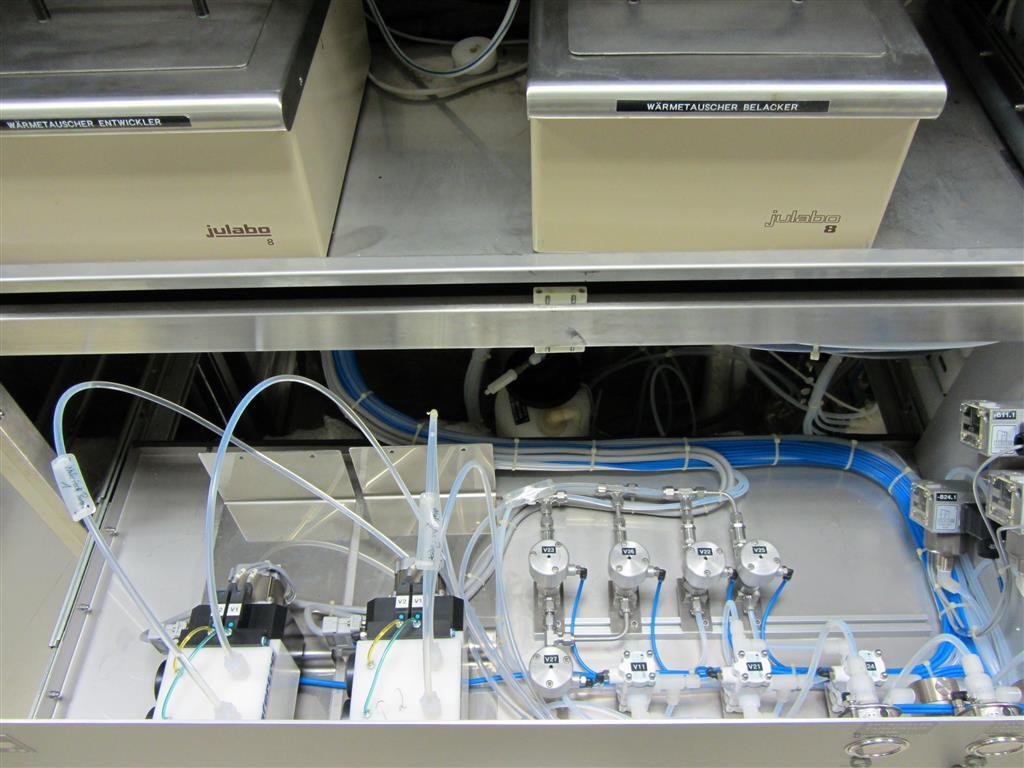

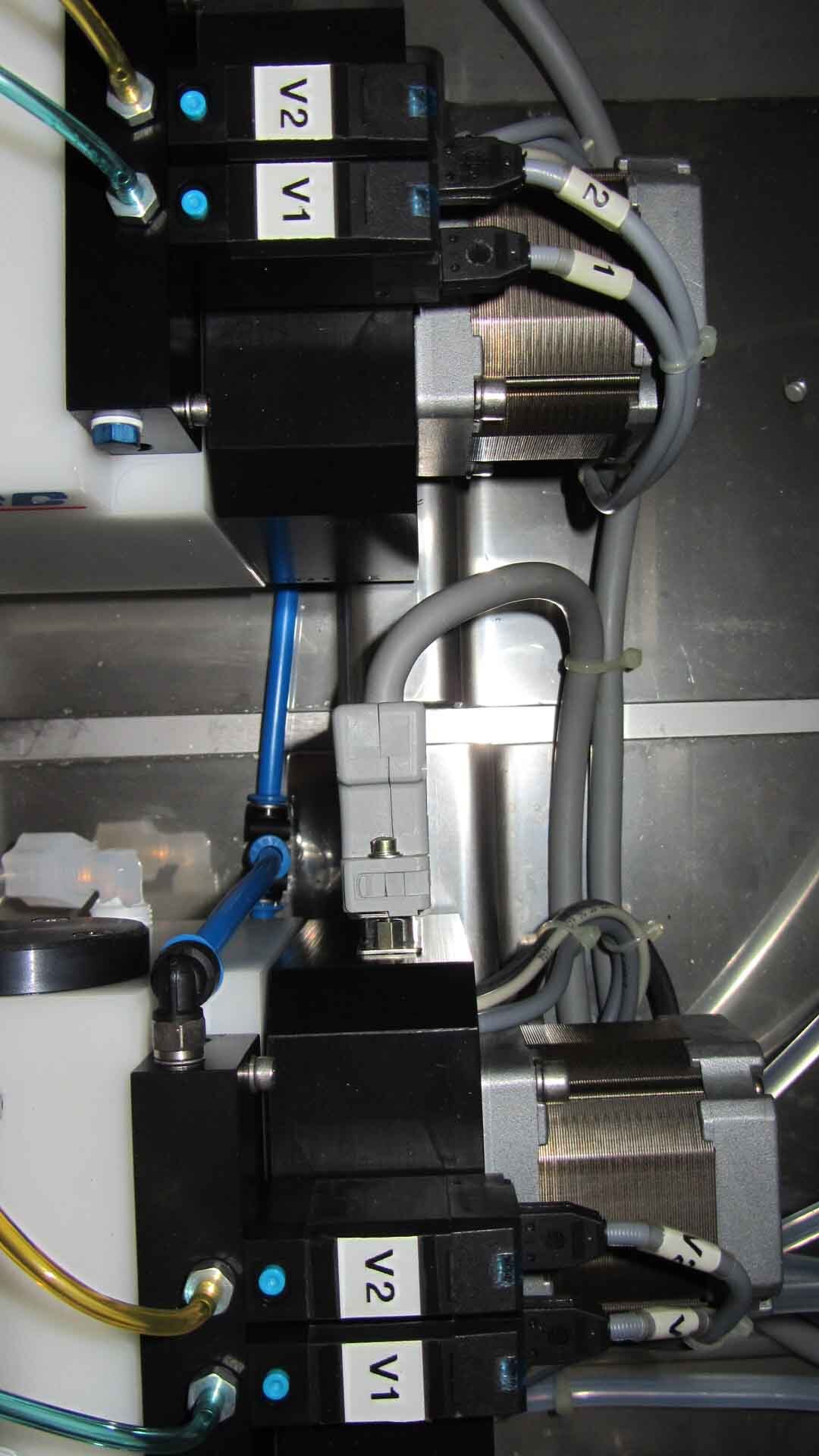

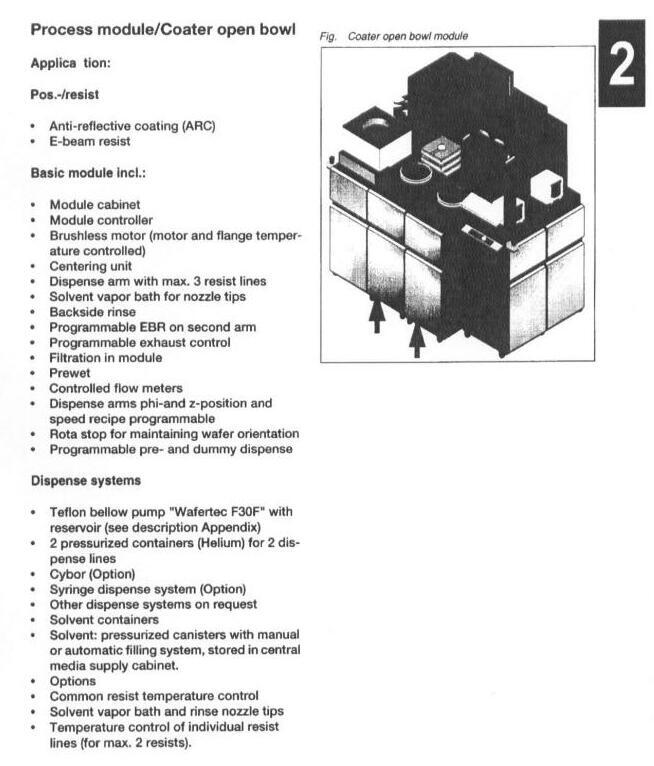

(2) WAFERTEC Pumping systems

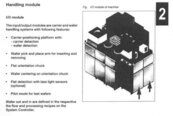

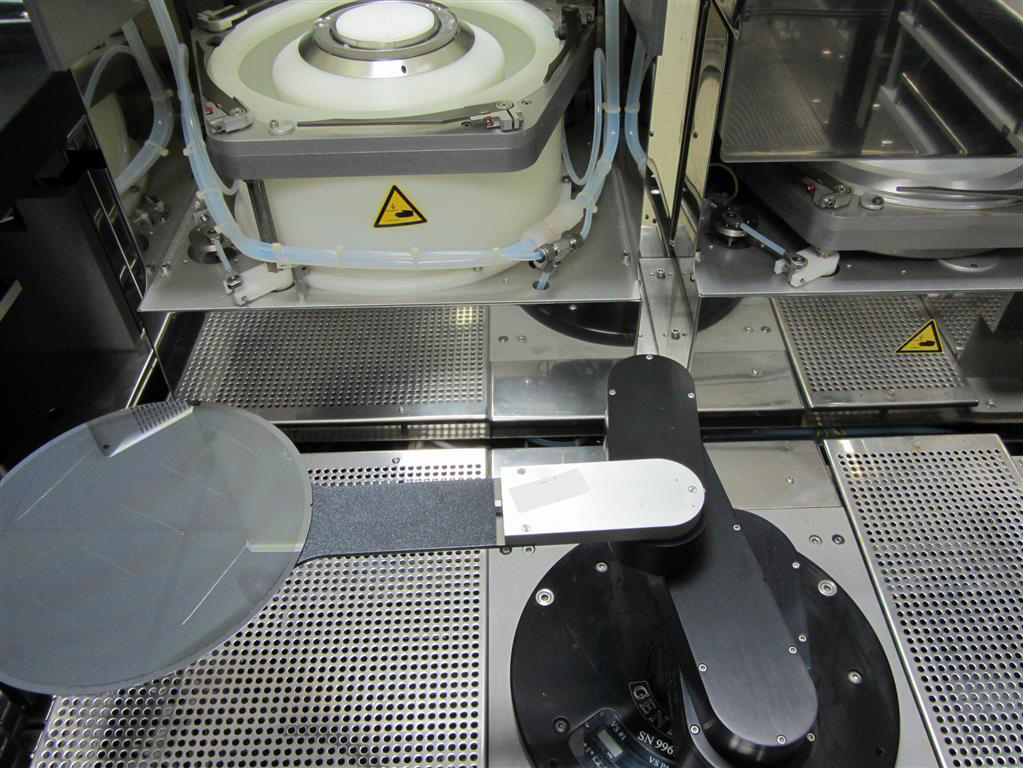

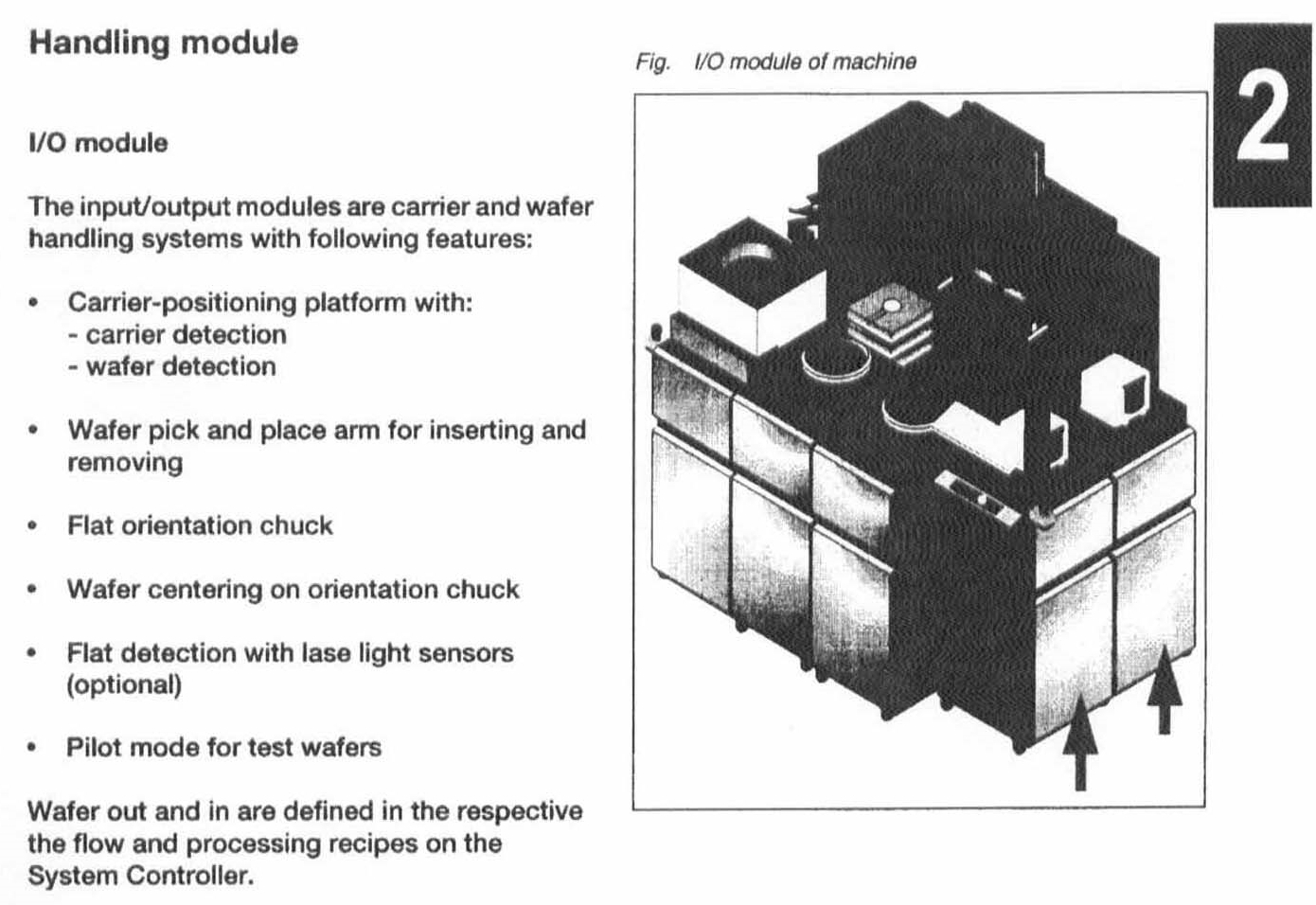

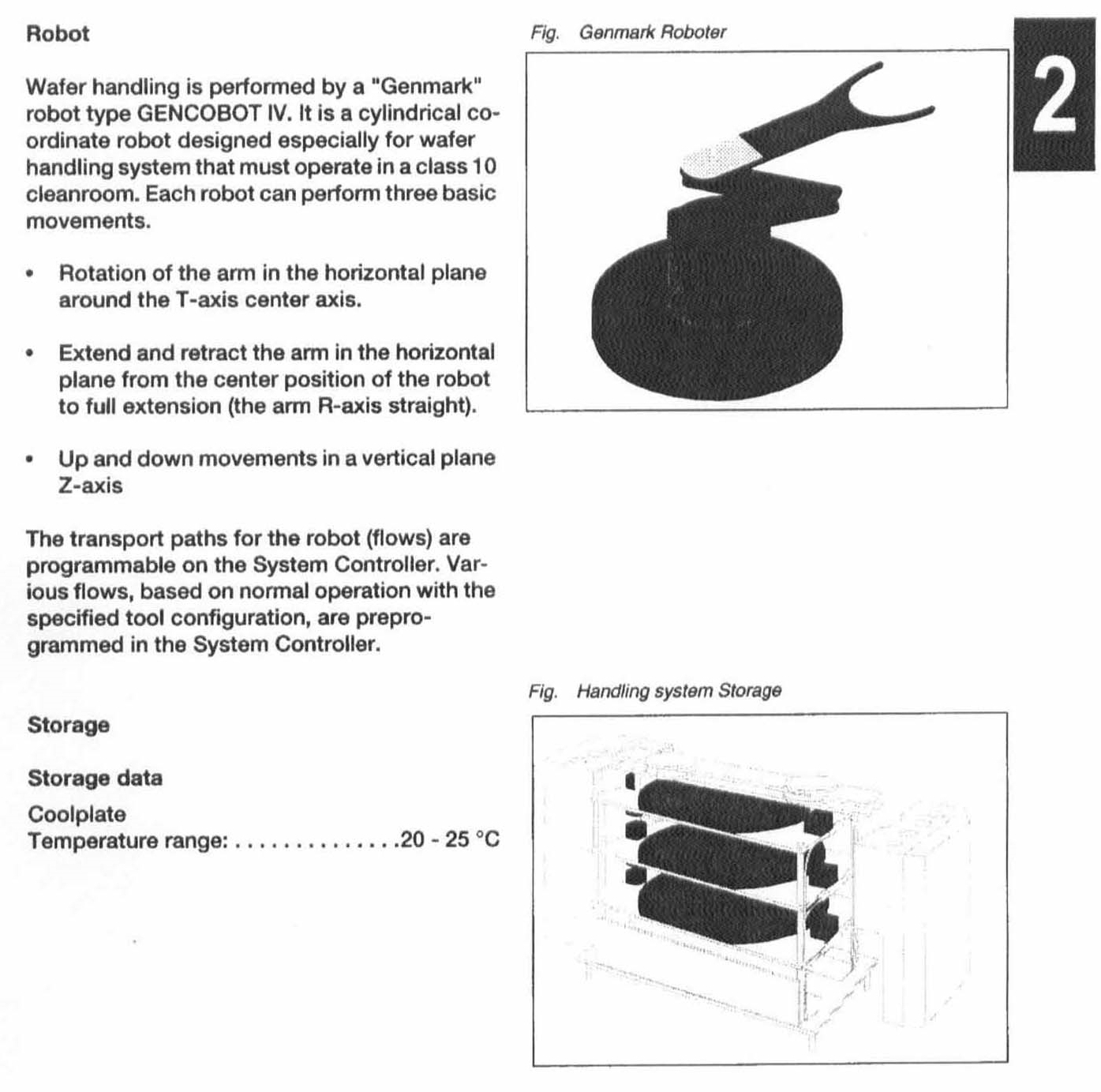

Robotic arm

Control box

1997 vintage.

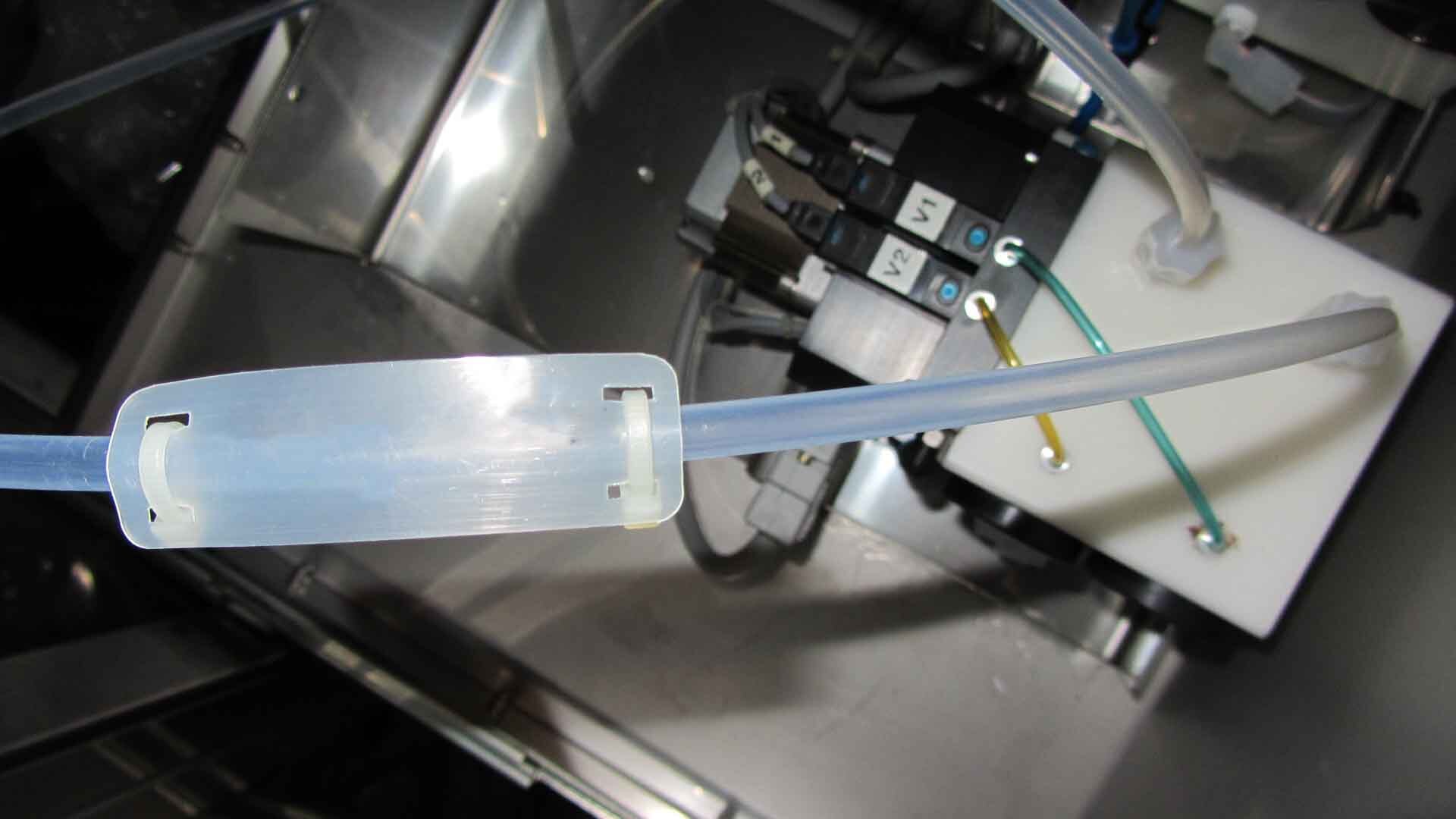

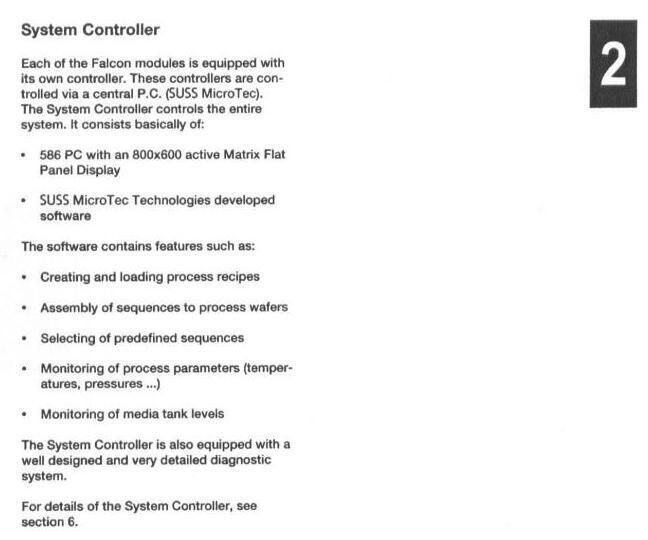

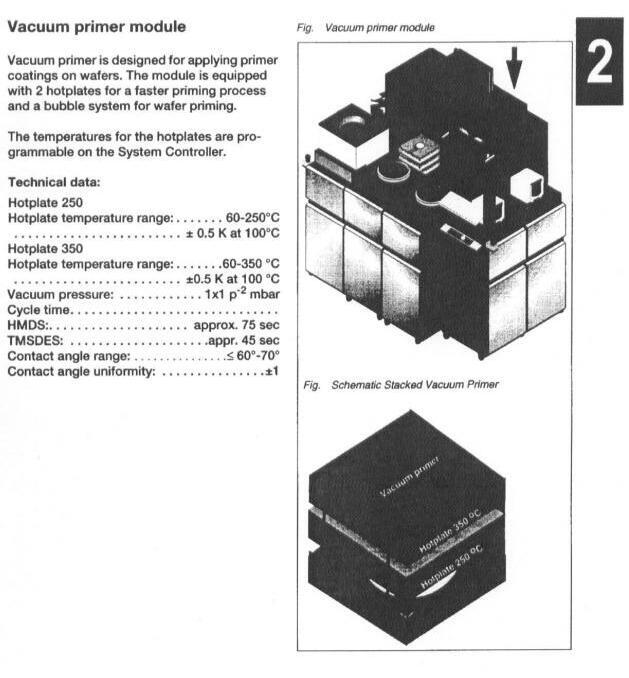

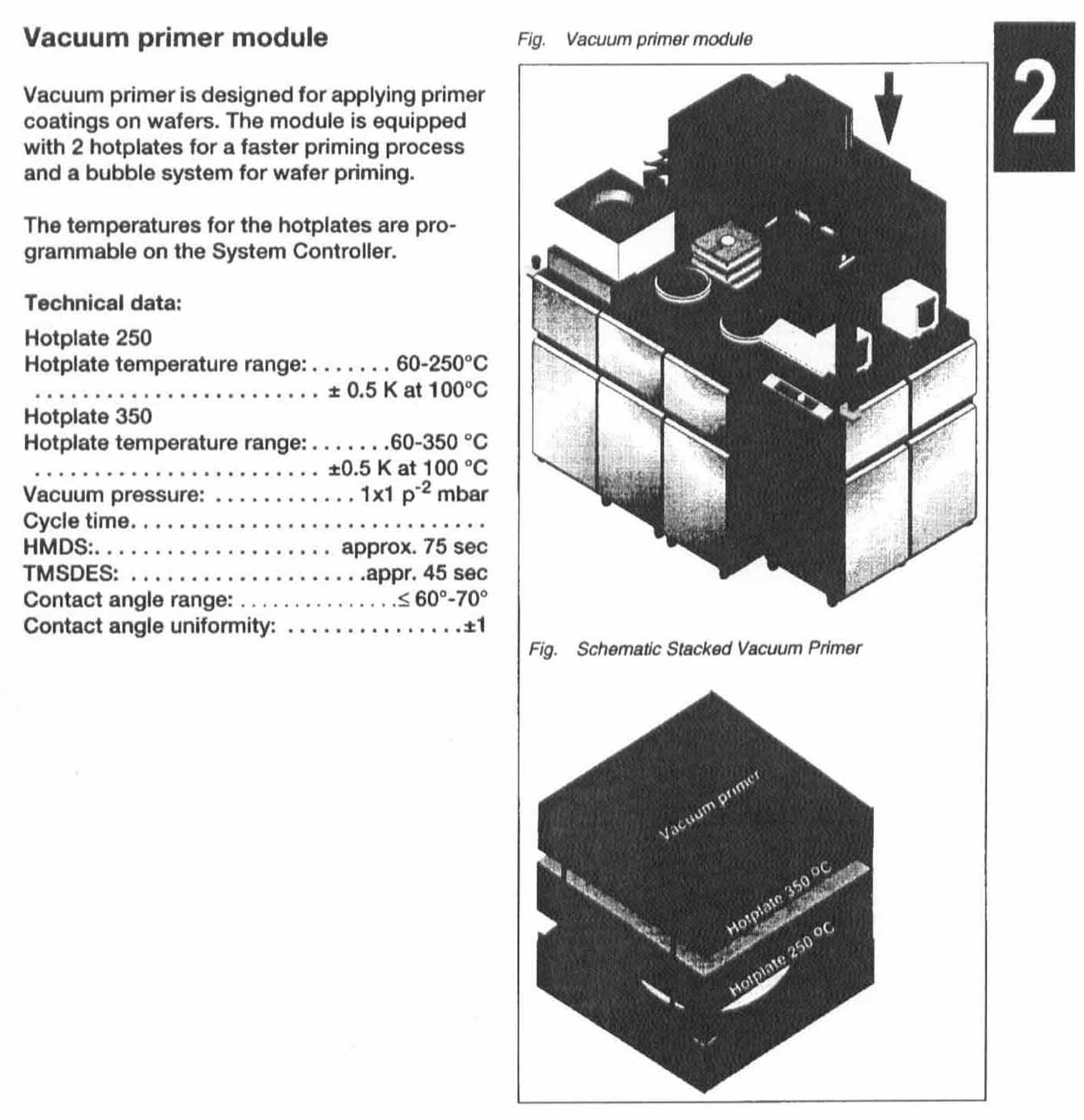

KARL SUSS / MICROTEC Falcon VS11626 is a photoresist equipment designed for the production and processing of lithography applications. The system is capable of coating, imaging and developing wafers up to 16" in size. MICROTEC Falcon VS11626 utilizes variable speed spinning and contains fully programmable alignment to achieve high-quality and repeatable results for a variety of different lithographic applications. The unit utilizes a vacuum-sealed chamber that optimizes air pressure, temperature and humidity which offers an extremely consistent processing environment. The machine also offers glancing incidence capability, which increases process yield and uniformity, as well as on-plate temperature control that assists in repeatable resist application. In order to achieve the best precision during lithography processes, the tool is also equipped with wet sprayer for application of chemicals such as hard or soft bakes, developer, or resist material. Additionally, KARL SUSS Falcon VS11626 is equipped with a manual arm for positioning the wafer which can be calibrated in the x, y, and z directions. In terms of imaging, the asset is capable of creating highly detailed images quickly and consistently. It provides consistent and repeatable imaging through a powerful and repeatable motorized alignment procedure, enabling up to 510 wafers per hour. This motorized imaging is highly accurate, as it is capable of producing 0.1µm resolution. Falcon VS11626 also features a built-in cleaning model. This equipment uses critical vapour deposition (CVD) technology to remove particles from the coating surface of the wafer. It is also equipped with a cleaning basket which allows wafers to be cleaned both outside and inside the system. Overall, KARL SUSS / MICROTEC Falcon VS11626 is a powerful and reliable photoresist unit designed to produce high-quality and repeatable results. The machine is capable of coating, imaging and developing wafers up to 16" in size, with a powerful motorized alignment tool and precise imaging capabilities. Additionally, the asset also features a built in cleaning model and a manual arm for positioning the wafer.

There are no reviews yet