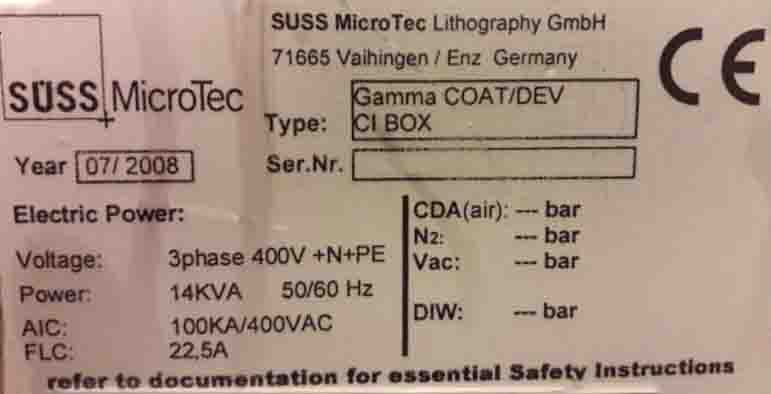

Used KARL SUSS / MICROTEC Gamma #293605215 for sale

URL successfully copied!

Tap to zoom

ID: 293605215

Vintage: 2008

Spin coater

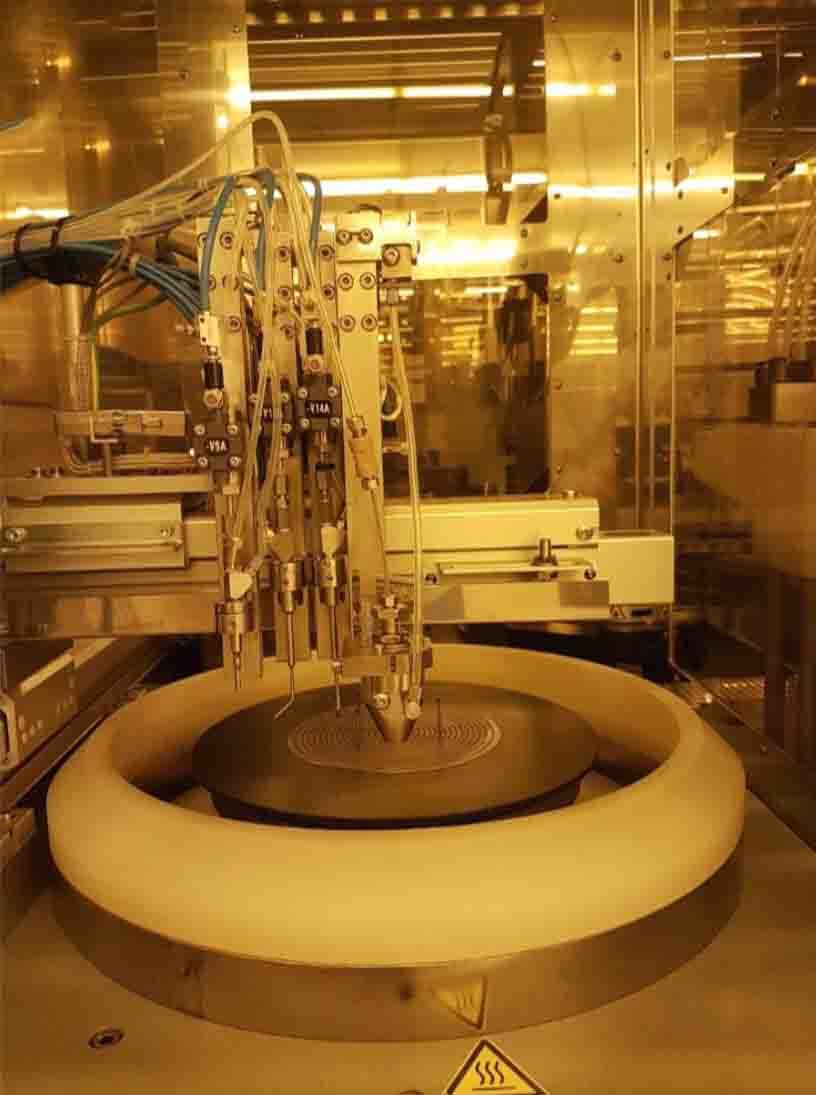

Spin coater module

Spray coater module

Developer module

Control panel

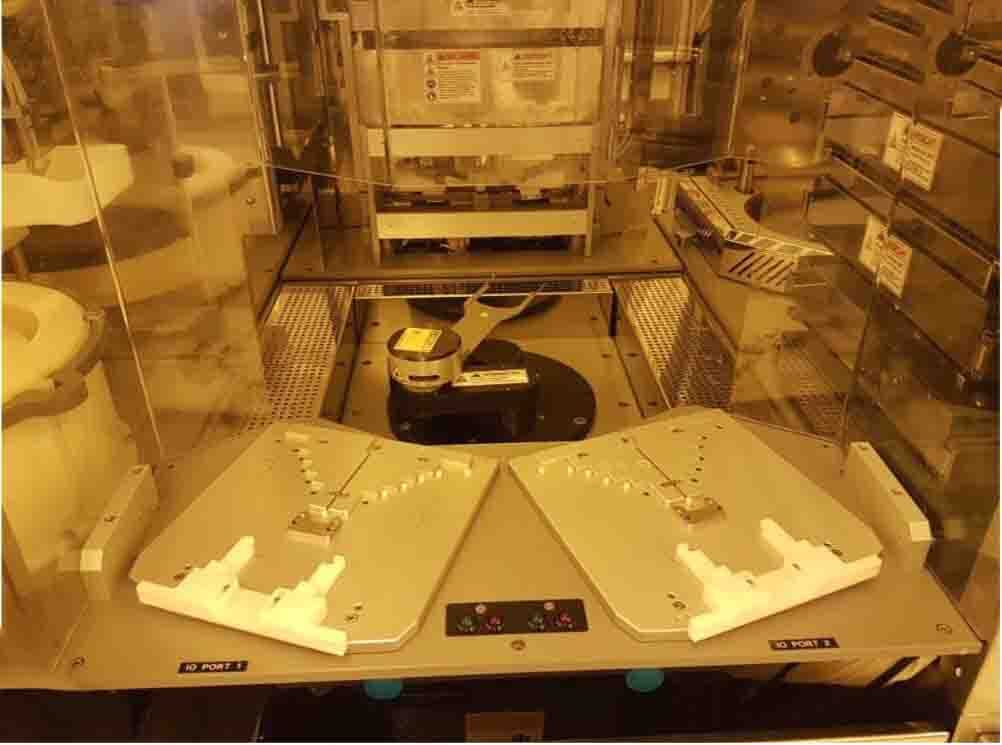

Load ports

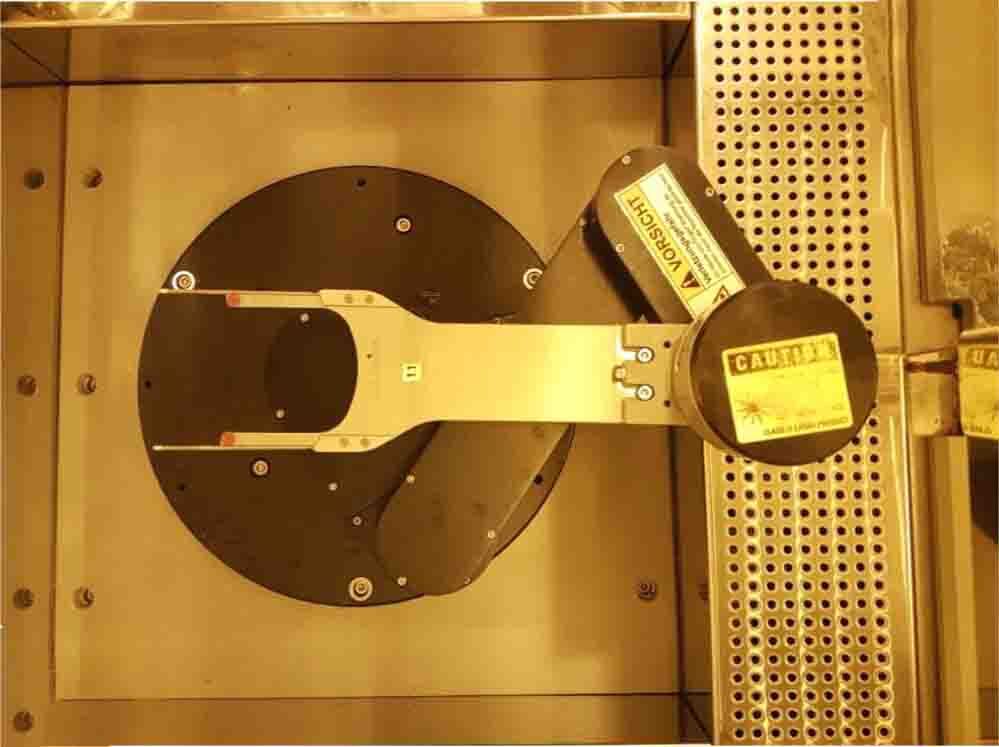

SANKYO Robot

HMDs tool

Slot centering tool

Media cabinets

Pressure control

Media cabinets: Tank System

JULABO Temperature controller

Anlagen PC

Operating system: Windows 7

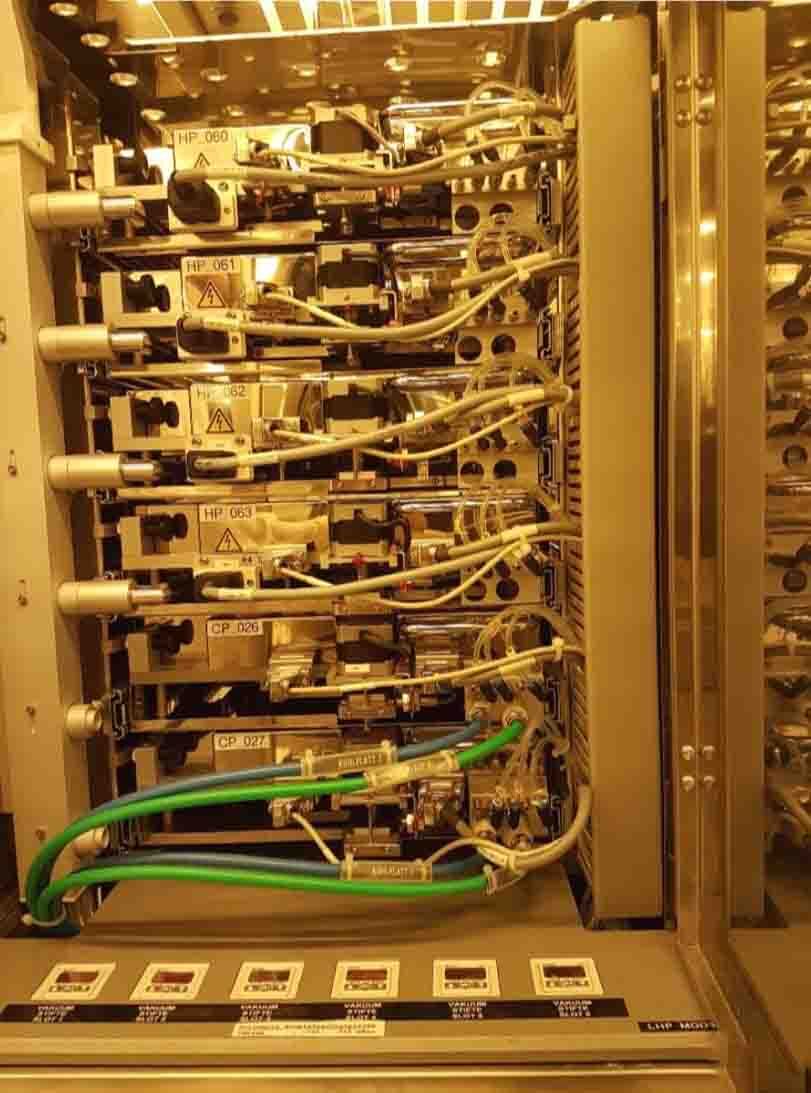

Temperature stack:

Hot plate

Cold plate

2008 vintage.

KARL SUSS / MICROTEC Gamma is a photoresist equipment designed to provide the highest accuracy and precision for advanced microfabrication processes. The system is a highly accurate and reliable platform for producing fine detailed, high-resolution photoresist structures. MICROTEC Gamma is equipped with a robotic arm, high-accuracy linear stages, an automated 8"x12" wafer loading unit, and a high magnification, full-field image capture capability. The machine is designed to process up to 350 wafer per hour, while maintaining a high degree of accuracy and repeatability. The photoresist process uses ultraviolet radiation to achieve desired structures on the wafer. A zoom control allows the user to change the magnification of the optical tool and the exposure times. The exposure asset is driven by the automated control of the exposure dose, dose rate and spot size as needed. KARL SUSS Gamma also features an integrated oven to improve the resolution of the exposure by controlling the exposure temperature. Gamma can be used for a variety of microfabrication processes, such as lithography, etching, sputtering, and planarization. Photoresist layers applied to the wafer surfaces can be removed manually or using automated cleaning systems. Additionally, KARL SUSS / MICROTEC Gamma can be used for the removal of photoresist layers before the application of new layers of photoresist. The integrated alignment model ensures high accuracy and repeatability when applying multiple layers of photoresist, or when performing exposure corrections. MICROTEC Gamma is also equipped with an advanced software suite which allows the user to analyze data from the exposure and store the results for future reference. The software can also detect exposure issues and automatically correct for various problems in the photoresist process. In conclusion, KARL SUSS Gamma is an ideal photoresist equipment for high-accuracy microfabrication processes. It offers a wide range of features which enable the user to achieve excellent results with a cost-effective setup. The automated wafer loading system, integrated oven, powerful software suite and automated controls create the ideal combination for advanced photoresist applications.

There are no reviews yet