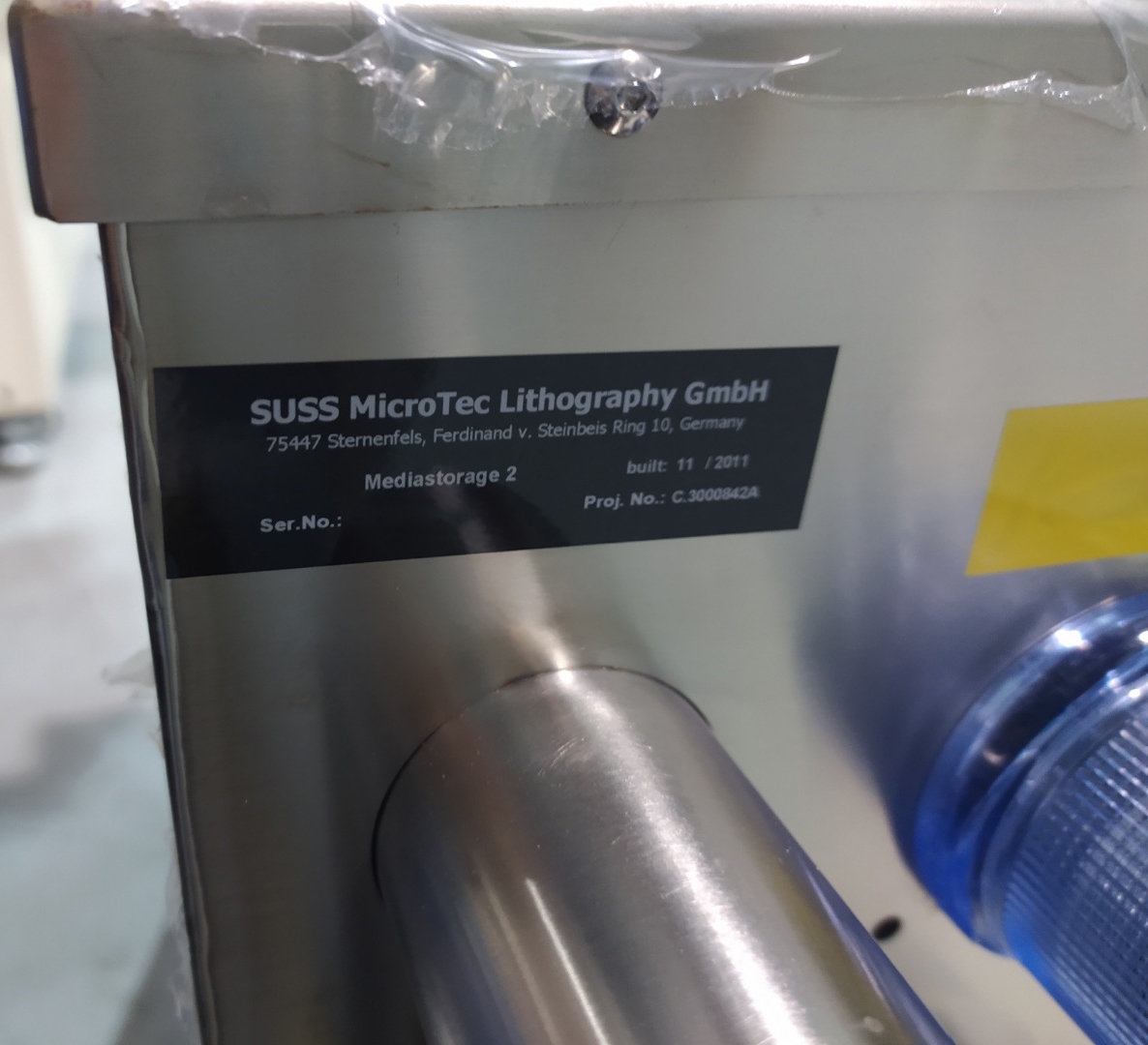

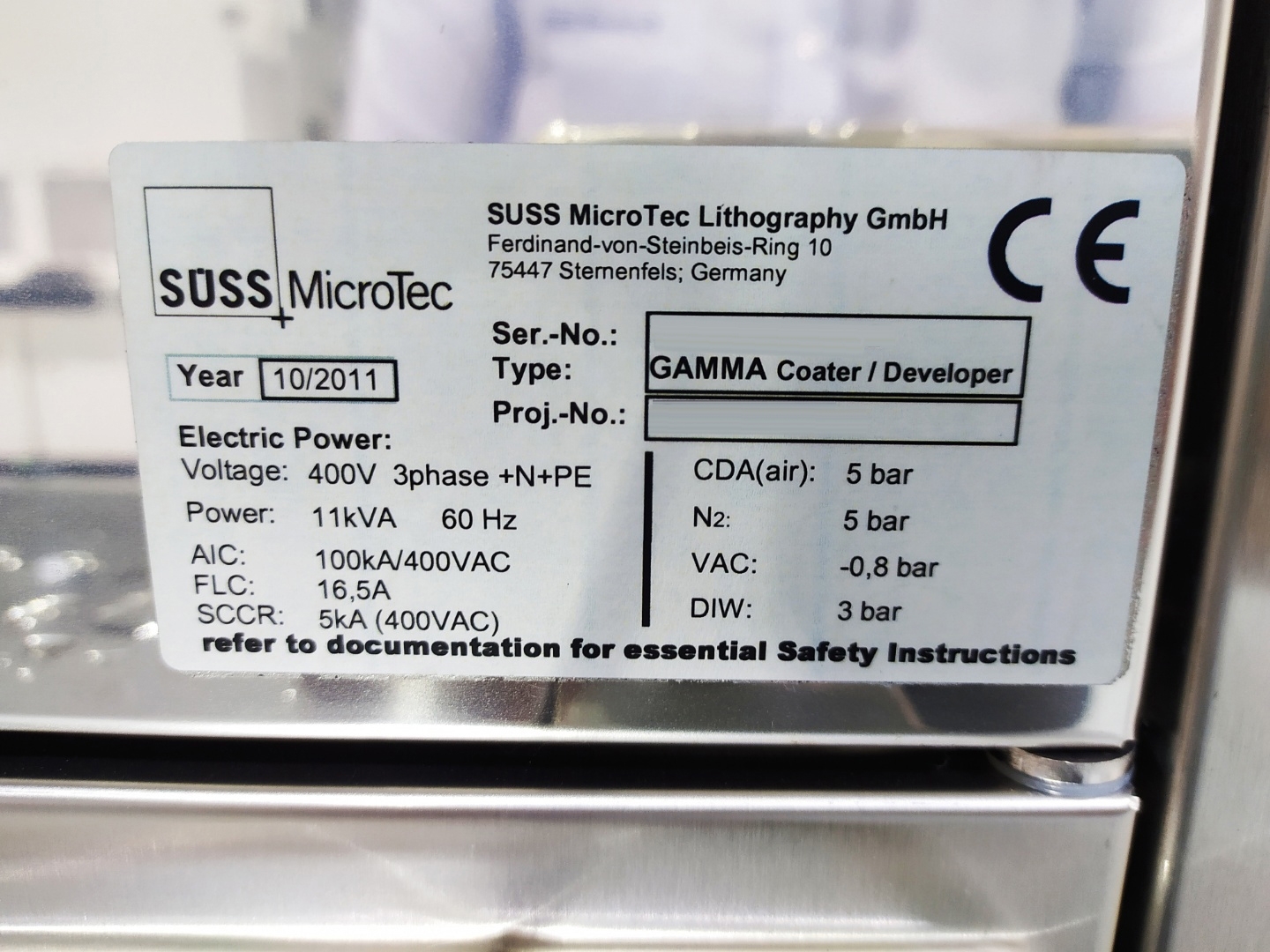

Used KARL SUSS / MICROTEC Gamma #9284546 for sale

URL successfully copied!

Tap to zoom

ID: 9284546

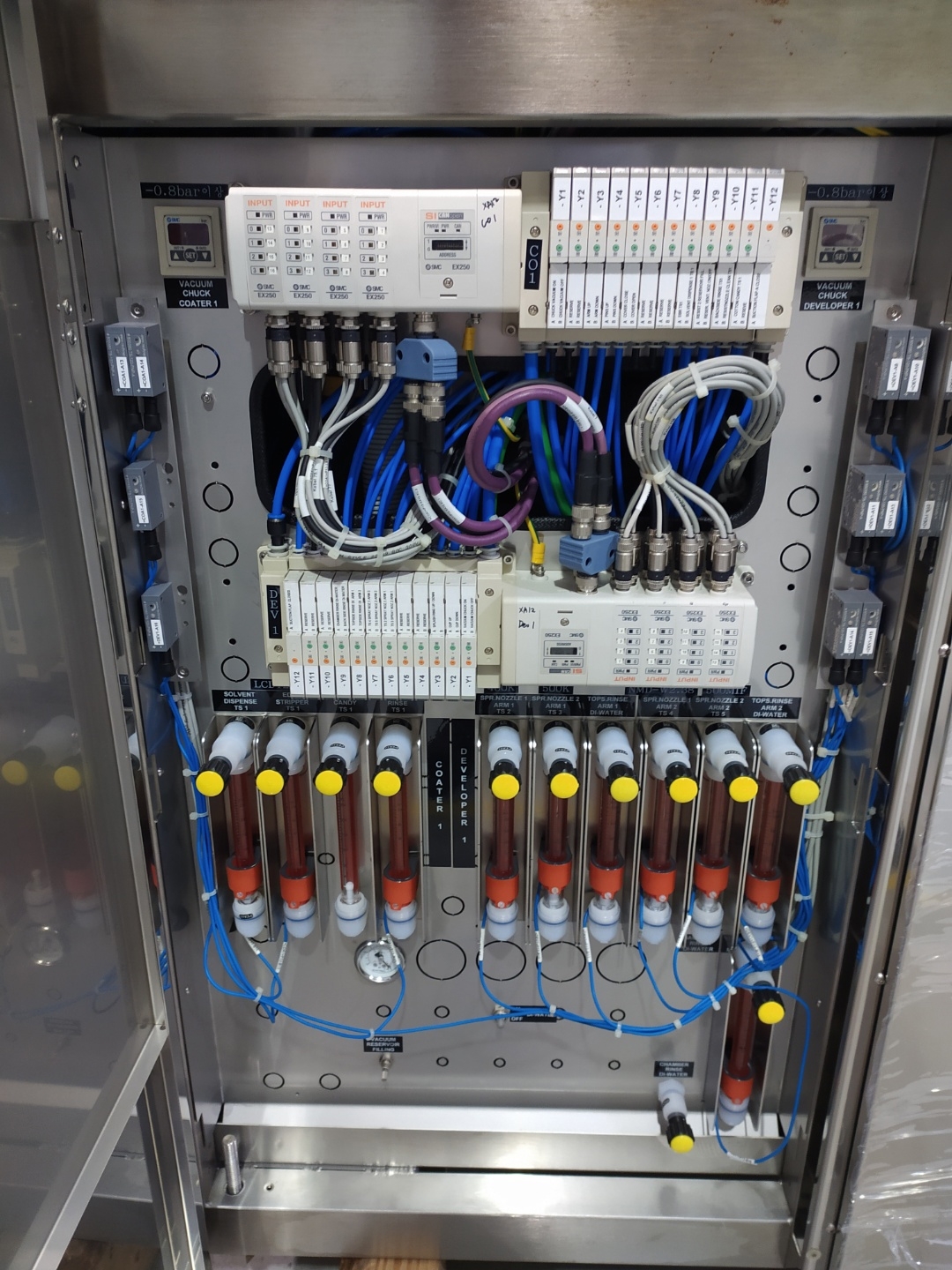

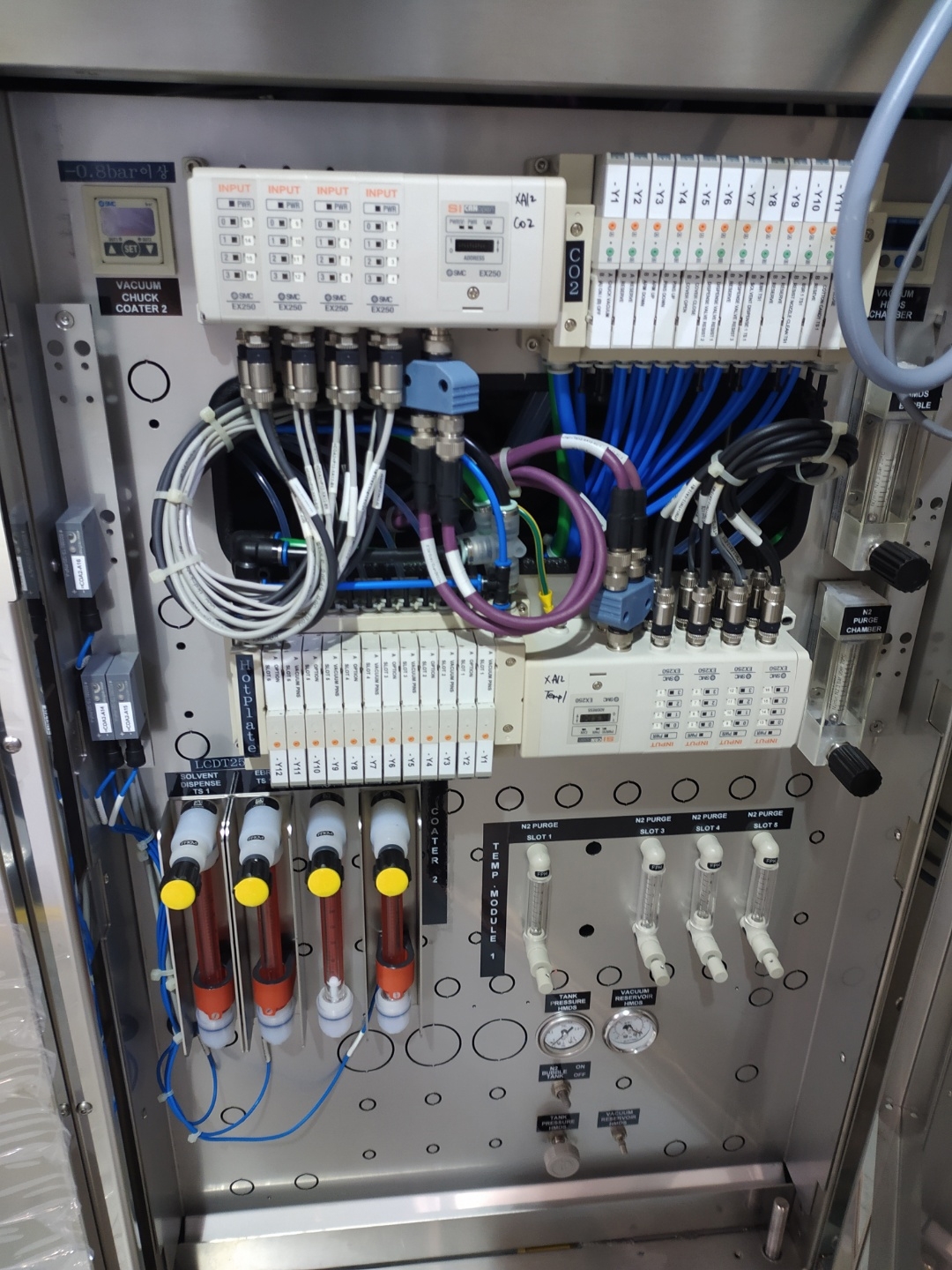

(2) Coater / (1) Developer system / (1) HDMS / (3) HP / (1) CP, 12"

Si Wafer, 8"

Coating uniformity: < 1.0%

Spin RPM: 0 ~ 6000 RPM

Maximum accuracy: 1 RPM

Acceleration: 10~30000 RPM/S

Temperature range:

3-HP: 60~250°C (±0.5)

CP: 20~25°C (±0.2)

HMDS: 60~200°C (±0.6)

2011 vintage.

KARL SUSS / MICROTEC Gamma is a dual beam photoresist equipment designed for high precision micro-structuring applications. It is capable of lithographically patterning substrates up to 200mm in diameter, with resolution down to a few nanometers. MICROTEC Gamma utilizes high resolution stepper optics to produce photomasks with very high fidelity and very low distortion. KARL SUSS Gamma is comprised of two electron beam systems, a photomask generator and an exposure system. The photomask generator uses an electron beam to draw features on a photomask. The resolution of the features drawn is determined by the beam energy, the beam size, and the current density of the beam. This photomask is then used to generate a chrome-on-glass mask that is patterned through a wet etching process. The exposure unit works by passing a beam of focused ultraviolet light through the photomask to expose the surface of the substrate. This light is very precisely modulated by focusing or defocusing the beam, thereby allowing for very detailed feature definition. The intensity of the light is determined by the beam's power, which is adjustable speed-wise. Once exposed, the substrate is developed in a conventional resist-based developing solution. Any features and patterns on the photomask will be replicated on the substrate as a result of this development process. Gamma has multiple advantages including repeatability, resolution, and unique features. Its electron beam technology increases accuracy and repeatability by controlling the placement and shape of each feature on the substrate. The machine's high resolution optics allow for features resolution below 10nm, enabling advanced applications. Further features include advanced corner and slope technologies, which allow for the fabrication of perfectly smooth photomask corners and optimized slopes, greatly increasing yield and improving feature fidelity. Overall, KARL SUSS / MICROTEC Gamma photoresist tool is a powerful and precise tool for lithography processes. The combination of its advanced electron beam optimization, high resolution optics, and robust development allows for top-notch micro-structuring and patterning applications.

There are no reviews yet