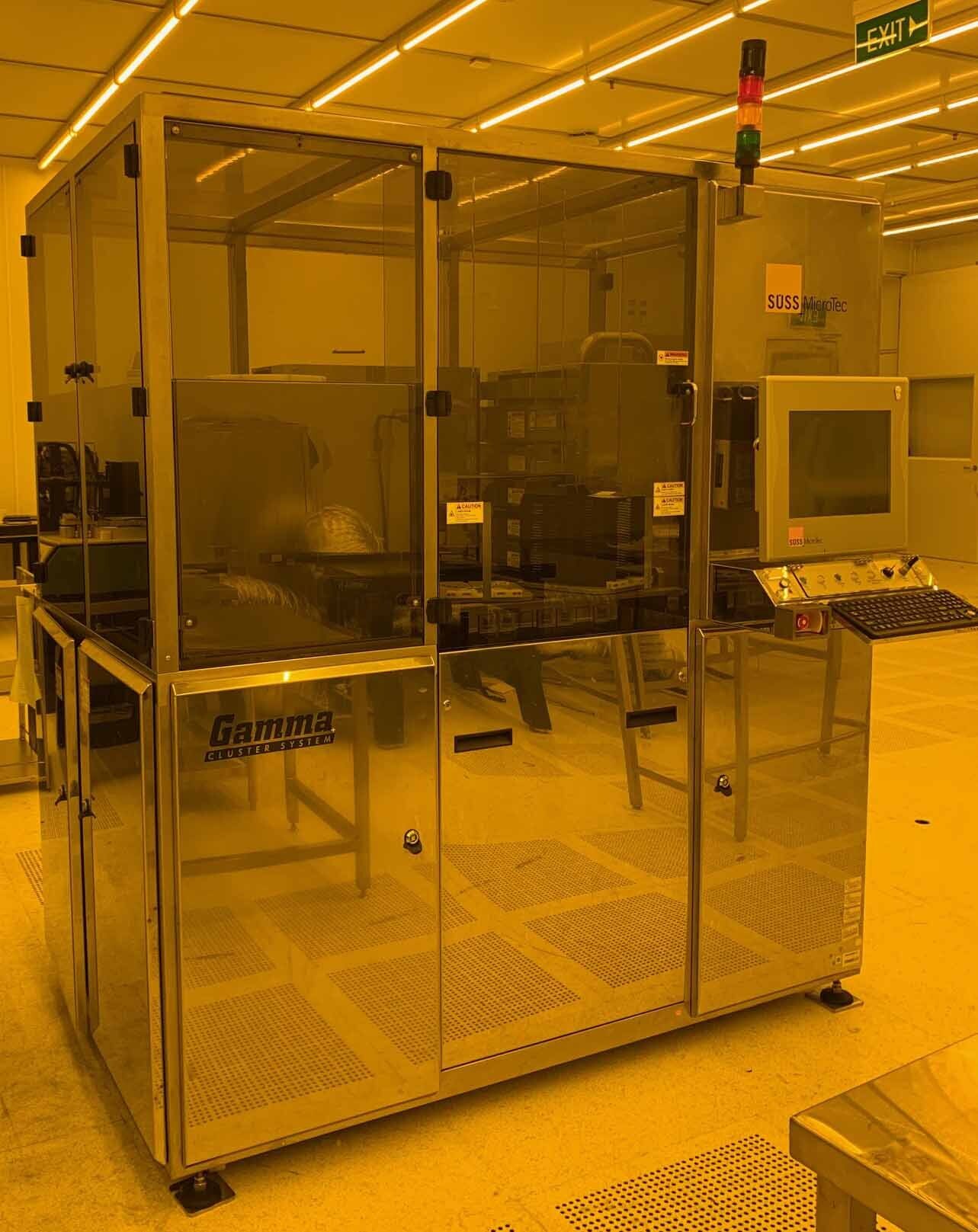

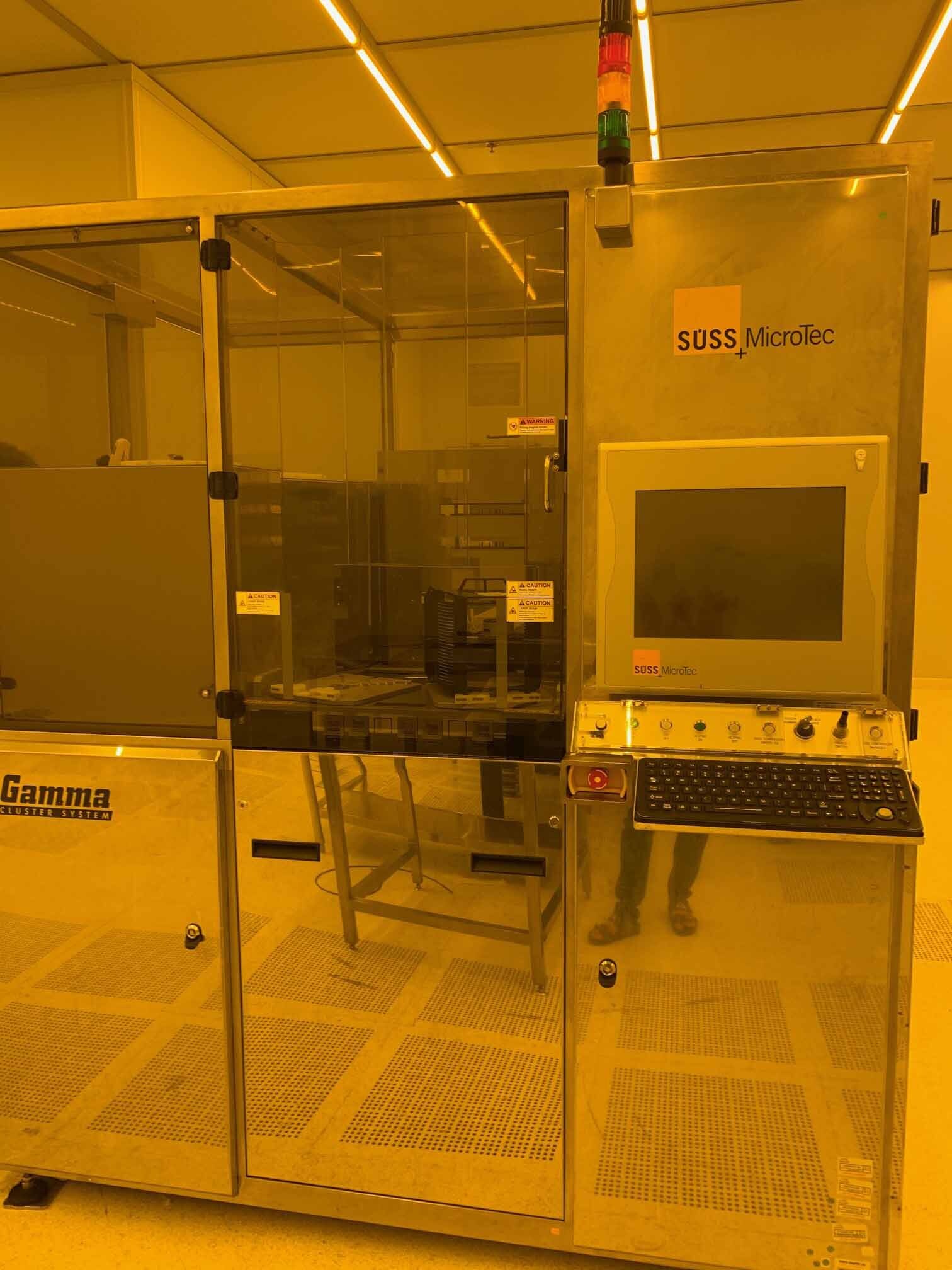

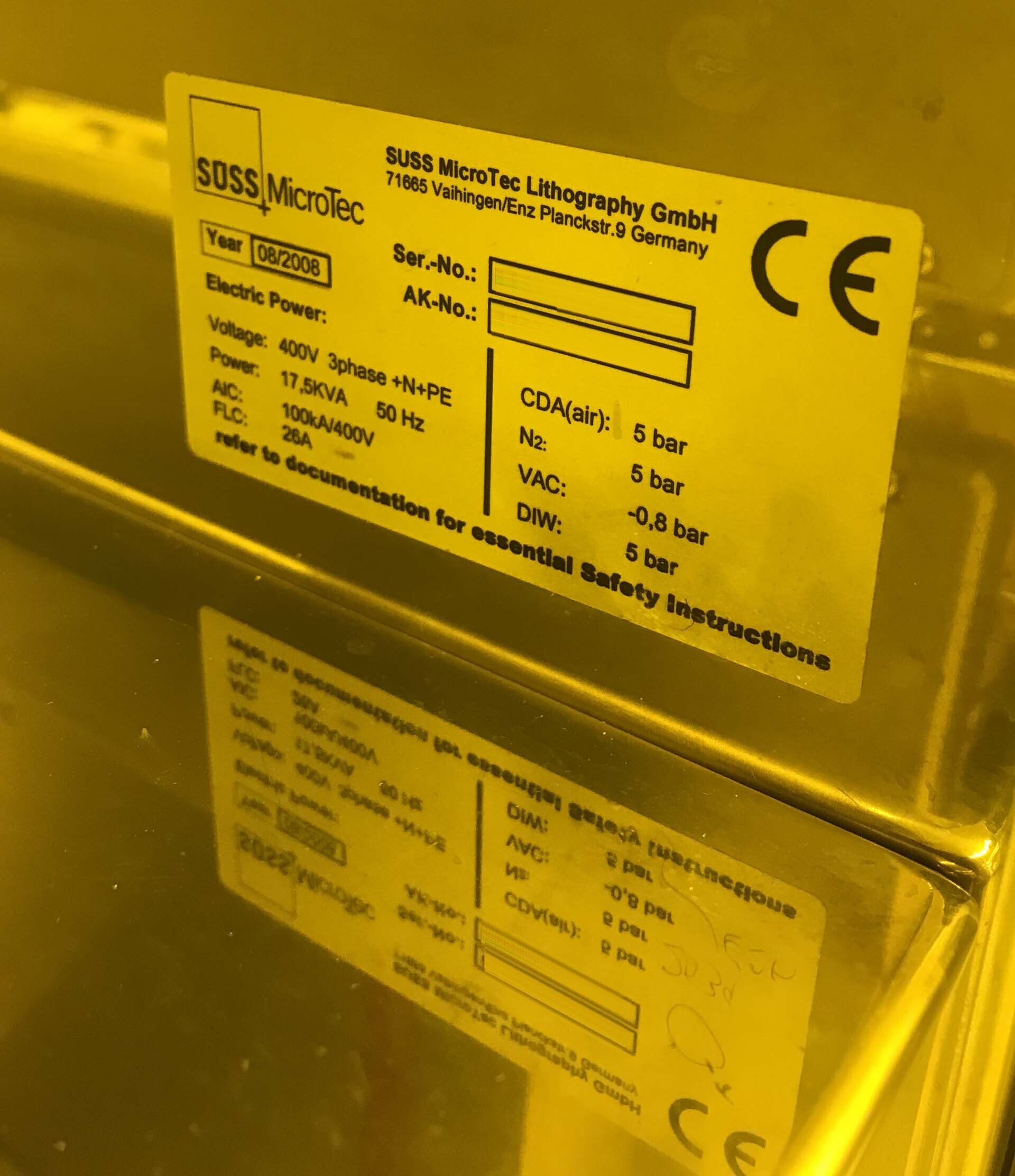

Used KARL SUSS / MICROTEC Gamma #9299570 for sale

URL successfully copied!

Tap to zoom

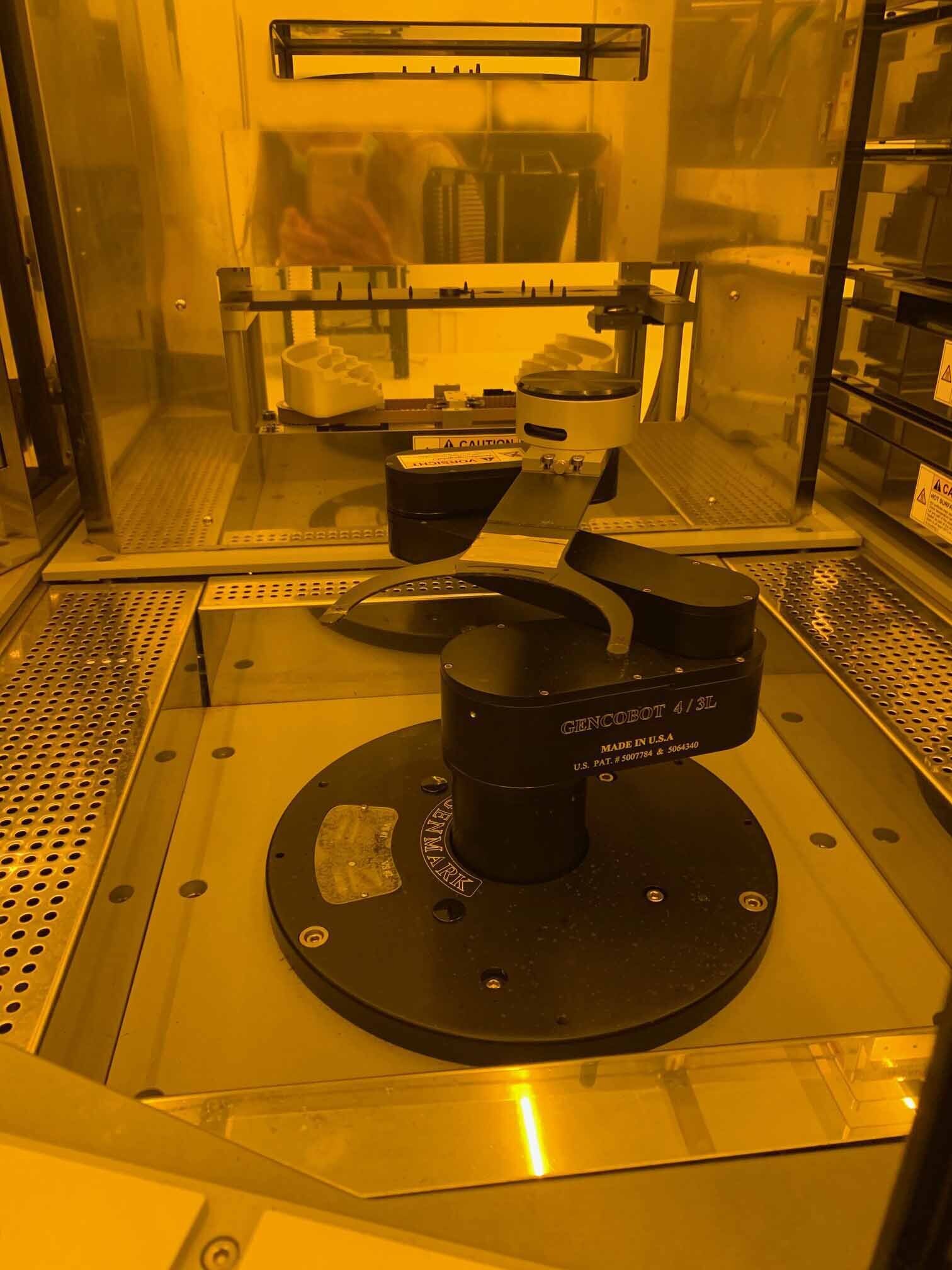

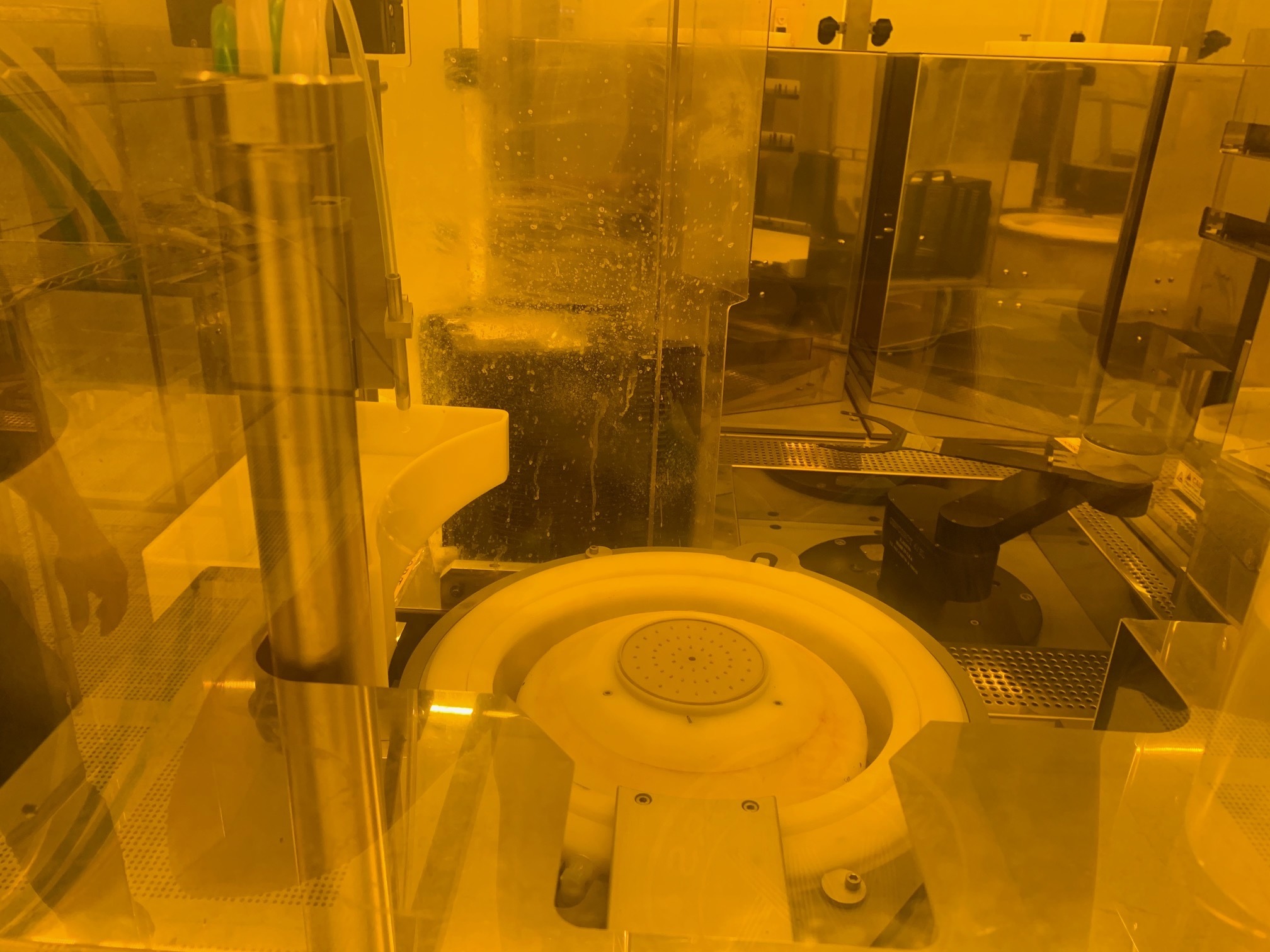

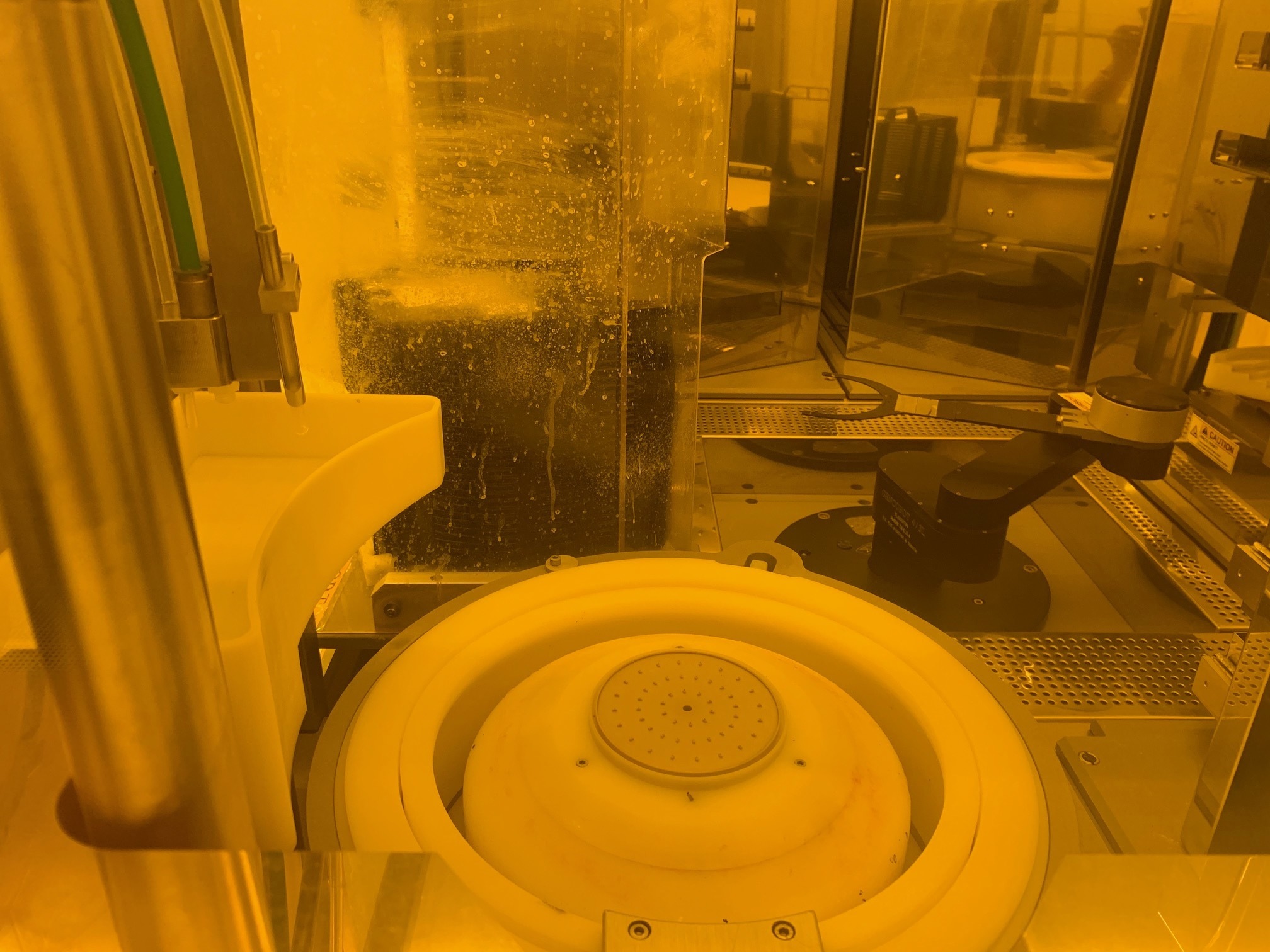

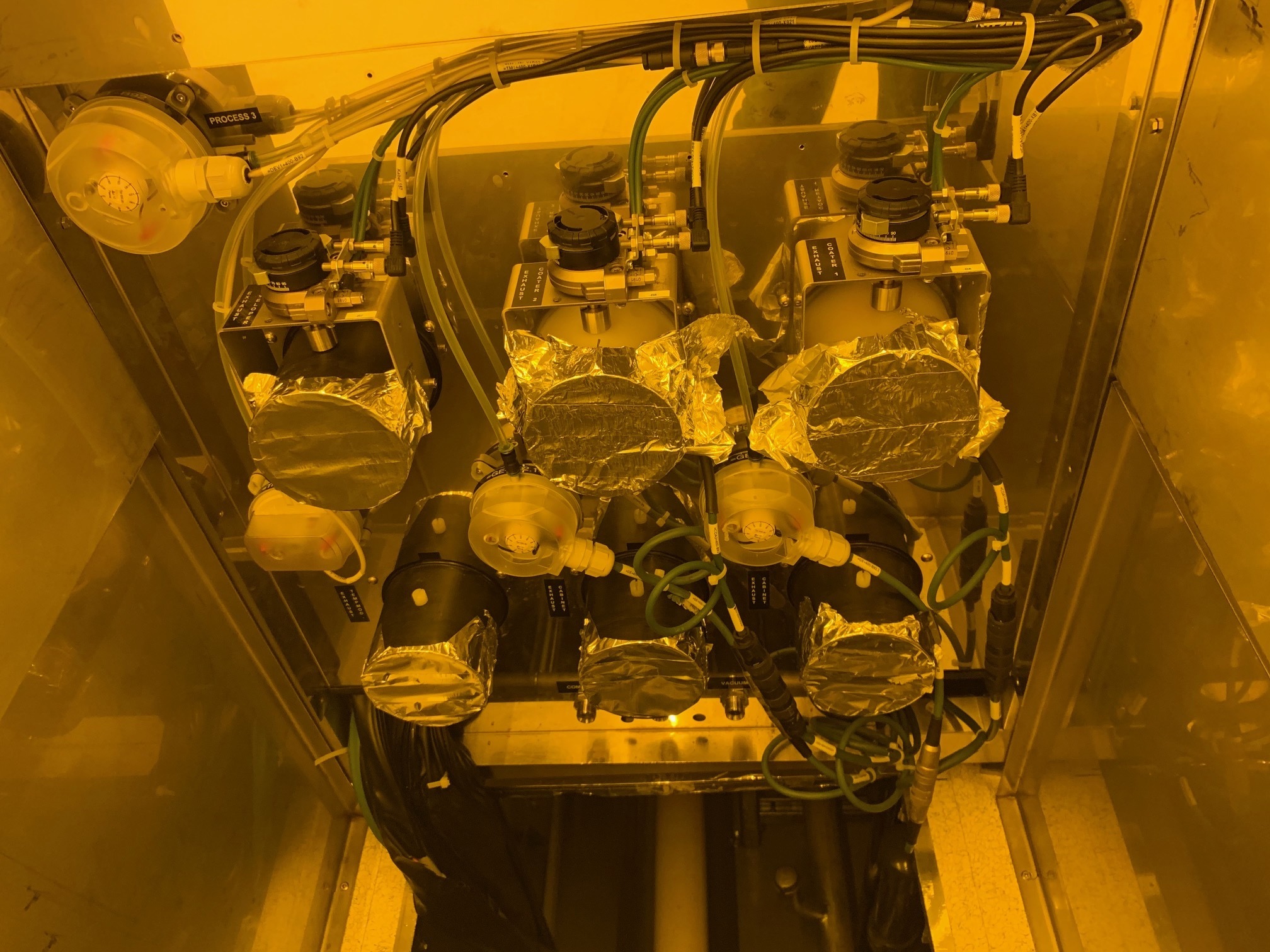

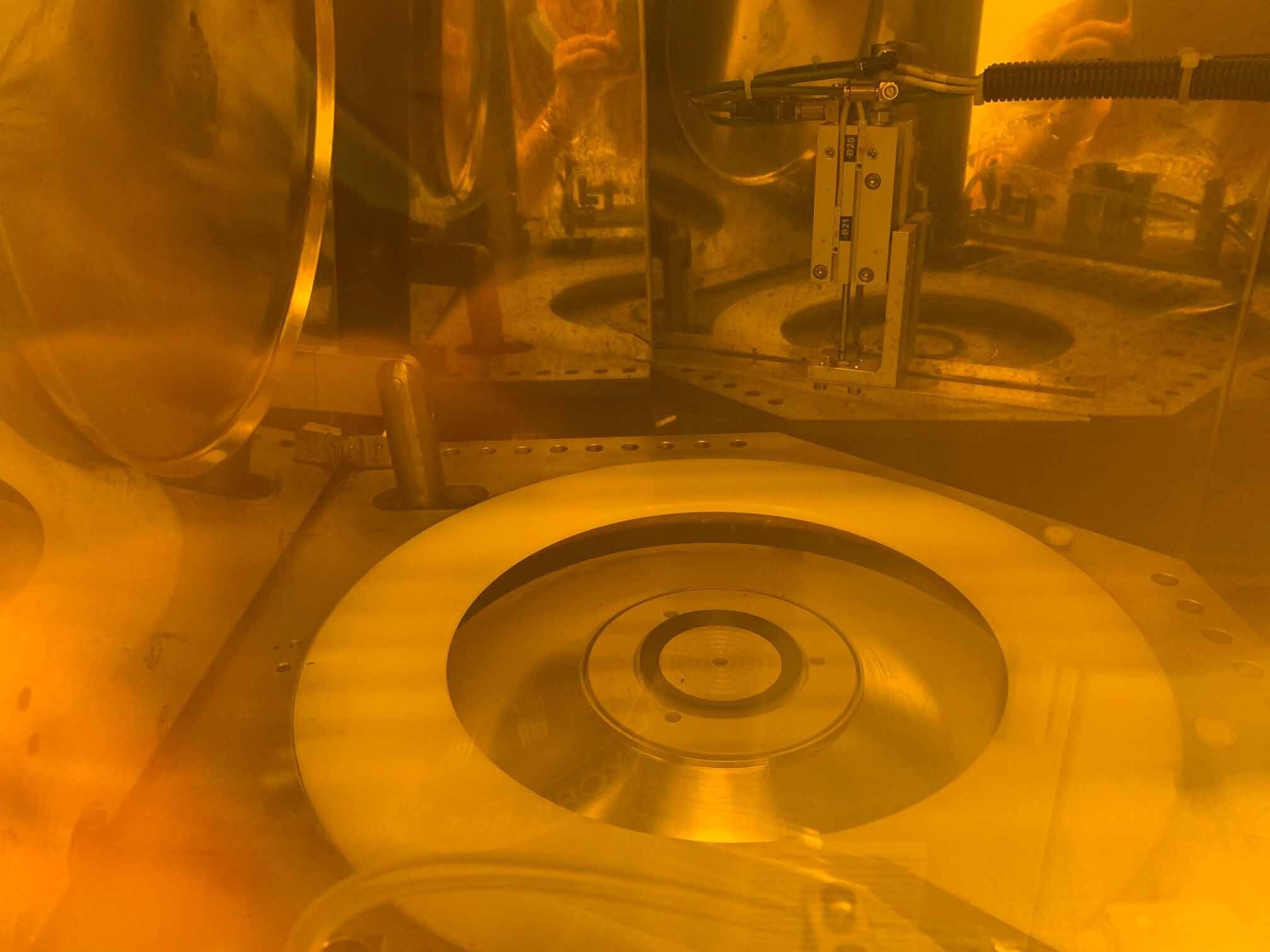

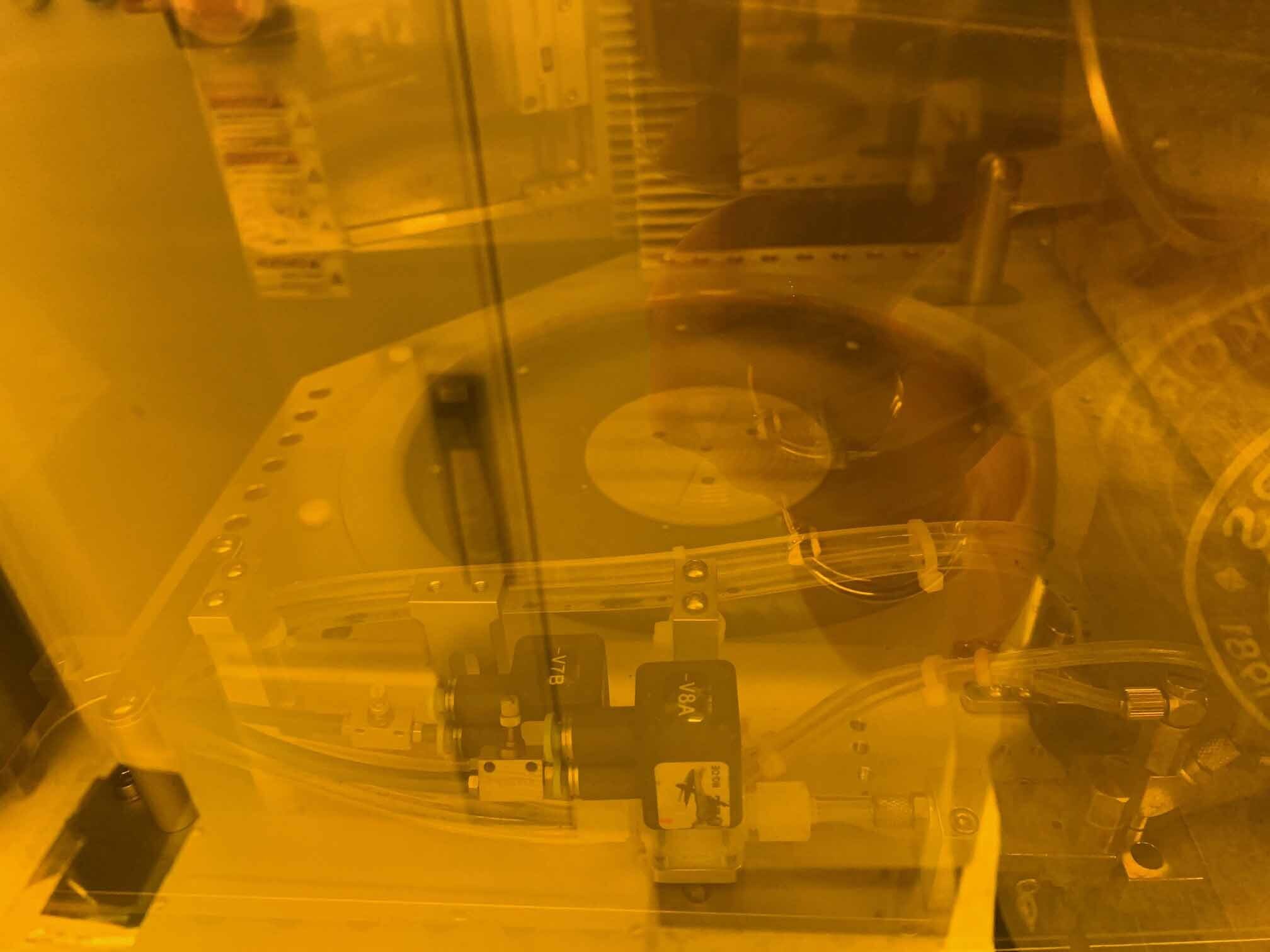

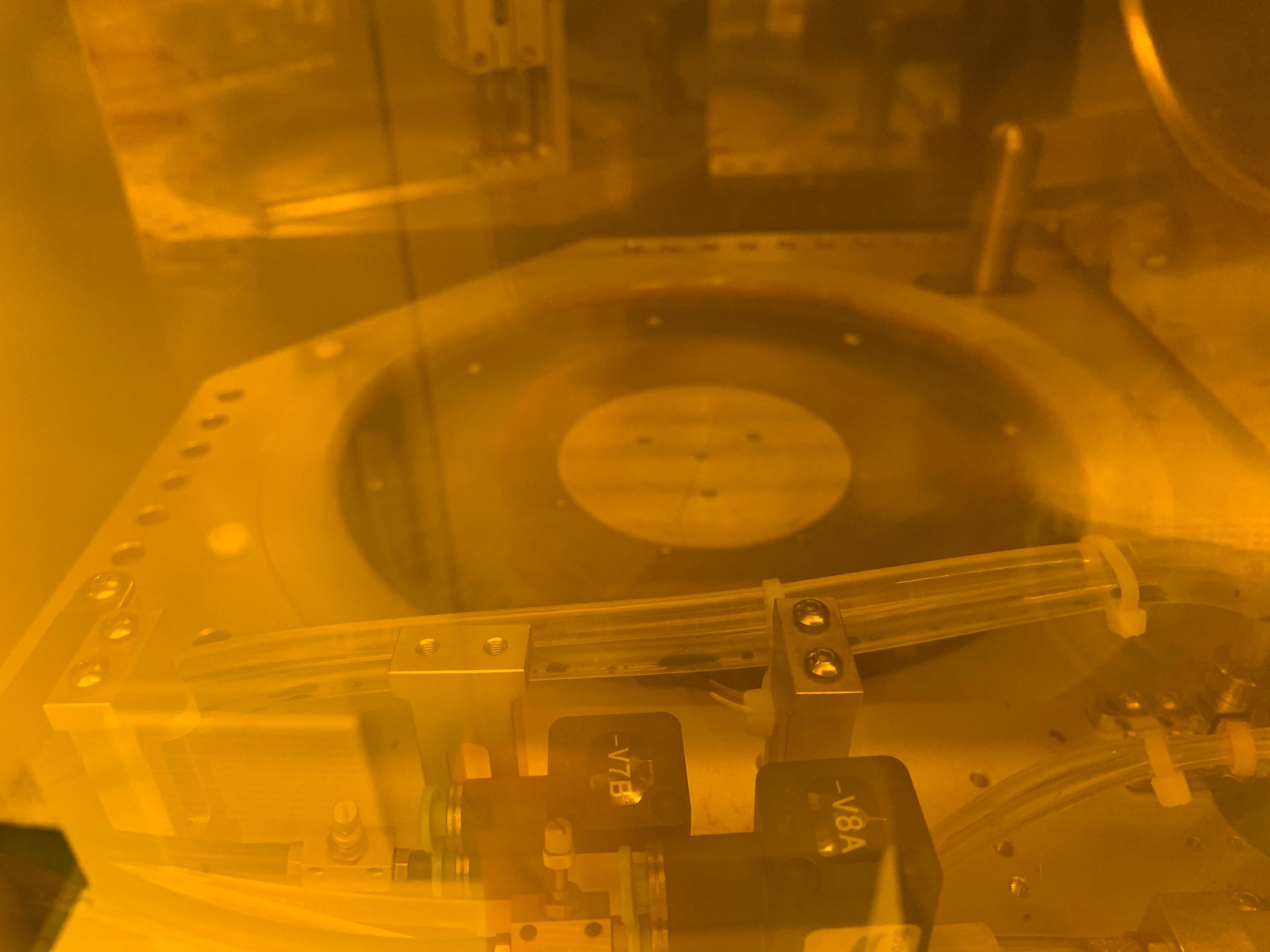

KARL SUSS / MICROTEC Gamma is a photoresist equipment designed for processing of substrates with up to 250mm diameter. The system consists of a photomask aligner and a track. The aligner is designed for high resolution alignment and exposure of mask and substrates up to 250mm in size. The track contains a liquid handler and an oven, for photoresist coating and baking, respectively. The unit has a stepper motor and a camera, which enables automatic control of the aligner's operation and registration of the alignment accuracy, respectively. MICROTEC Gamma machine is a dry lithography process, which is further divided into two stages; masking and imaging, and photoresist coating. The masking and imaging stage involves the use of a light source which is directed onto the substrate, through a mask. This results in the patterned exposed substrate. The photoresist coating stage involves the use of a liquid handler to coat the substrate with photoresist. The liquid handler dispenses photoresist onto the substrate, by means of a nozzle. Subsequently the oven is used to thermally process the coated substrate, in order to activate the photoresist solution. KARL SUSS Gamma tool is further equipped with a vacuum chuck which enables vacuum contact of the mask onto the surface of the substrate. This allows precise alignment of the mask onto the substrate surface, and also creates a uniform contact between the mask and the substrate. Furthermore, Gamma asset offers a stepper motor control and a motor look-up table that increases the model performance. The stepper motor enables a precise control of the exposure area, while the motor look-up table gives the opportunity to control the alignment accuracy with regard to the exposure area. KARL SUSS / MICROTEC Gamma equipment further features a chart recorder for quick and accurate charting of the overall lithography results. Overall, MICROTEC Gamma is highly effective photoresist system that is designed to meet the needs of the modern photolithography process. The unit incorporates advanced features such as a stepper motor, a vacuum chuck, and a motor look-up table, which enable reliable and precise alignment of the mask onto the surface of the substrate. This ensures uniform contact between the mask and the substrate, allowing for accurate lithography results. Additionally, the machine offers a chart recorder, which makes it easy to chart the lithography results, allowing for a quick and accurate process documentation.

There are no reviews yet