Used MICROBAR WM5 #159885 for sale

URL successfully copied!

Tap to zoom

ID: 159885

Chemical delivery system

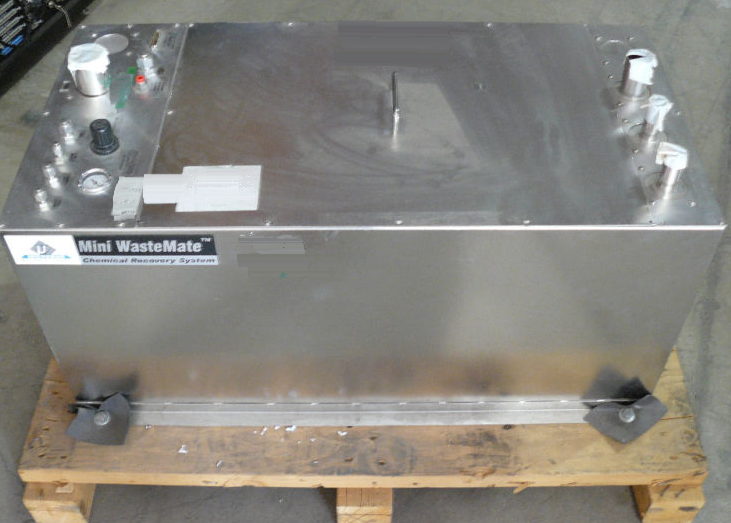

MICROBAR Mini Wastemate chemical recovery system, model # MWM

Single phase, 115 V, 15 amp.

MICROBAR WM5 is a photoresist equipment developed by Industrial Components Inc. It is used for the accurate deposition of coatings onto complex shapes and components. WM5 system uses a highly efficient, automated coating techniques based on the use of a photosensitive resist as the photoactive material. The unit is designed to produce electrohardened surfaces and provide an effective barrier to the environment, such as corrosion and oxidation. The photoresist is applied in a continuous, uniform film over the entire surface. An electron beam is then used to crosslink the resist, creating an electrohardened surface with excellent properties. The machine utilizes a unique combination of advanced process control and computer software that simplifies and automates the deposition of photoresist. The software includes advanced error-detection and correction algorithms to ensure precise deposition and uniformity. The tool is also capable of detecting and correcting for surface defects, eliminating the need for rework. It is precise enough to deposit multiple layers of photoresist onto a single substrate, greatly increasing the number of components that can be processed simultaneously. The asset is specially designed to handle a wide range of shapes, sizes and materials, making it suitable for applications in various industries. MICROBAR WM5 model is capable of deposition speeds up to three times faster than manual methods, and is capable of producing very precise and uniform coating thicknesses. The equipment is also designed to reduce labor costs while improving results. Other benefits of the system include increased safety, convenience and reduced cost of ownership. Overall, WM5 unit is an extremely precise and efficient tool for photoresist deposition. It enables production of components with excellent corrosion resistance and electrohardened surfaces, at speeds much higher than manual methods. The application of the machine is dependable and repeatable, making it suitable for a variety of industrial applications. The automated process ensures uniformity and accuracy, reducing labor costs and allowing for higher throughput and greater efficiency.

There are no reviews yet