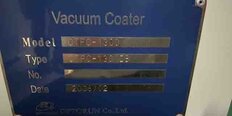

Used OPTORUN OTFC-1300DBI #9398672 for sale

URL successfully copied!

Tap to zoom

ID: 9398672

Vintage: 2008

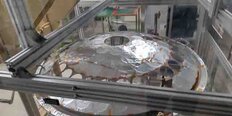

Optical thin film coater

SUS304 Vacuum chamber: D 1300 mm x H 1610 mm

Substrate dome size: D1130 mm

Pump:

Mechanical pump: 4000L /min

Mechanical booster pump

(2) Diffusion pumps, 22"

Optical film thickness control system:

OPTORUN HOM2-R-VIS350A

Wavelength range: 350 nm - 1100 nm

Shutters:

(2) EB Sources

ION Source

Cold trap: POLYCOLD PFC670HC Meissner trap coil

INFICON VGC023 Vacuum gage

EB Source:

Left: Loop hearth

Right: 24 Points hearth

JEOL 270 Degrees deflection system

(2) JEBG EBG-203LFO

JST-10F Power supply

Substrate fixture: 10-50 RPM Variable speed dome

INFICON XTC-2 Crystal film thickness monitor

6-Points rotary crystal sensor

INFICON VCC500 Process gasses controller

INFICON VDM005-X Controlled valve

PLC Control

PC Included

2008 vintage.

The OPTO-RUN OPTORUN OTFC-1300DBI photoresist equipment is a versatile photochemistry system designed for applications such as etching, sputtering, and layer deposition. It enables precise, simultaneous exposure of up to four masks without sacrificing throughput. Featuring a flexible light engine and numerous process options, this photoresist unit provides accurate photoresist exposure with uniformity and repeatability. The OPTO-RUN OTFC-1300DBI photoresist machine consists of an exposure chamber, a light engine, and a controller. The exposure chamber employs a multicavity tool that can house up to four masks simultaneously. The light engine is constructed from a ring of fluorescent lamps arranged around the masks, delivering high intensity UV light on demand. This engineered light source is adjustable, allowing for dose, exposure time, and exposure power to be adjusted independently for each mask. In addition to the exposure chamber and light engine, the OPTO-RUN OPTORUN OTFC-1300DBI photoresist asset also incorporates a precise digital display controller. This enables the user to customize the exposure settings of the model, and allows for precise control of the exposure parameters. Moreover, the controller has a powerful opto-electronic interface that allows the user to control the entire equipment from an external computer. The OPTO-RUN OTFC-1300DBI photoresist system is ideal for many different types of microelectronics production, including integrated circuits (ICs), flat-panel displays, and printed circuit boards. Its precise exposure capabilities make it especially suitable for advanced semiconductor applications, such as the fabrication of heterogeneous flip chip packages and MEMS devices. The unit's flexibility and easy-to-use interface make it an attractive choice for quality control and general clean room operations. In sum, the OPTO-RUN OPTORUN OTFC-1300DBI photoresist machine offers a highly efficient solution for precise photoresist exposure in microelectronics production. It is a versatile solution that can be easily adapted to any production environment, and its precise digital control makes it an invaluable tool for both quality control and specialty applications.

There are no reviews yet